The choice of insulation

When choosing a heater for an attic floor, it is important to take into account its heat-shielding properties, strength, as well as resistance to external factors. The type of flooring will also play a role: concrete and wooden floors have their own characteristics. So, how to insulate the attic floor?

Popular insulation for the attic floor

Types of heaters:

- Basalt mineral wool.

- Expanded clay.

- Styrofoam.

- Sawdust.

Mineral wool

Most often, the insulation of the attic floor is carried out with the help of mineral wool. What are its features and why is this insulation so popular?

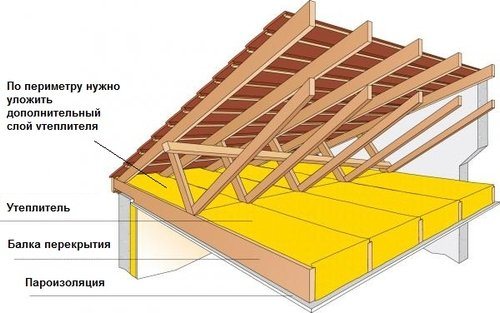

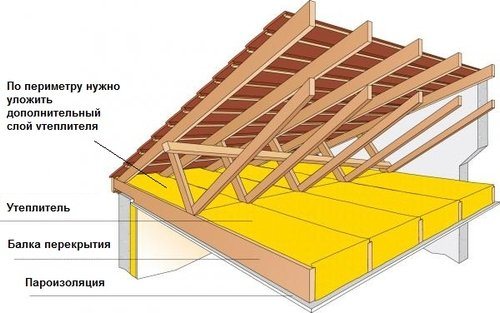

Minvata is laid between the wooden beams of the attic floor

Benefits of mineral wool:

- High thermal insulation. For example, in order to insulate an attic floor with mineral wool, a layer thickness of 3.5 times less than when using expanded clay is needed.

- Ease of material installation. This insulation is not difficult to work with, even for those who are engaged in insulation for the first time.

- Fire safety. Mineral wool is not easily flammable, therefore, when a fire occurs, it does not serve as a fast carrier of fire, which, for example, cannot be said about expanded polystyrene.

- Long operational period. If you properly cover the mineral wool, it will not roll and create cold bridges.

- Affordable price.

It is thanks to all these advantages that mineral wool insulation of the attic floor is a widely used method of saving heat in a room.

However, this insulation also has disadvantages. In particular, due to its ability to absorb moisture, the mineral wool insulation layer may no longer provide the same thermal insulation as before. Also, when insulating the attic floor with mineral wool, it is important to observe safety precautions. Mineral wool fibers, when in contact with the skin, can cause irritation, so you should work with it in tight clothing, glasses, a respirator and, of course, gloves.

Another material for insulating the attic floor is expanded clay. Although this insulation is rarely used, it still has a number of advantages.

Expanded clay - very popular in the earlier heat insulator

Advantages of expanded clay:

- The cost of insulation.

- Good thermal insulation performance. However, in order to achieve a really good result, the thickness of the expanded clay layer should be about 35-40 centimeters.

- Fire safety.

However, expanded clay as insulation also has significant disadvantages:

- Greater weight compared to other insulation materials. Thermal insulation of a wooden attic floor creates a load on the beams, therefore, when choosing expanded clay, this moment should be taken into account.

- Inconvenience when styling. It can take a lot of effort to lift a huge amount of expanded clay into the attic.

Polyfoam is one of the best materials for wall insulation, so some people decide to use it for thermal insulation of the attic floor. Although foam has advantages, it is not recommended to use it.

Attic roof insulated with foam plastic from below

Benefits of Styrofoam:

- Moisture resistance. This is a plus compared to the widely used mineral wool.

- Affordable price.

- Easy to install. It is not difficult to lift the foam sheets and lay them on the attic floor.

Despite these advantages, foam as insulation has a number of significant disadvantages.

Disadvantages of Styrofoam:

- High flammability. If the fire reaches the insulation, it will hardly be possible to extinguish the fire.

- Intolerance to high temperatures.At a temperature of + 60 ° C, the material deforms, at + 80 ° C it begins to melt, which is why toxic substances are released, and at + 210 ° C the foam ignites.

- Fragility. Polyfoam is capable of crumbling, which reduces its thermal insulation properties.

In view of these shortcomings, especially the insecurity in the event of a fire, it is better not to use polystyrene as insulation for a wooden attic floor. After all, the combination of polystyrene with wooden beams is very dangerous. However, this insulation can be used to insulate a concrete floor.

This method of insulation was very popular earlier, before the advent of modern thermal insulation materials. It is not devoid of its advantages, although they are very insignificant in comparison with other heaters.

Insulation of the attic floor with sawdust

Sawdust benefits:

- The absence of toxic substances, as well as the natural origin of the insulation.

- Relatively affordable price.

If we talk about the shortcomings of sawdust, then we can note:

- The need to prepare a solution consisting of sawdust, cement, lime and water. All other insulation materials are purchased ready-made.

- Heavy weight, which creates additional load on the floor.

- Large thickness of the insulation layer.

Important! After analyzing all the advantages and disadvantages of different heaters, many come to the conclusion that mineral wool is an ideal option, because it has high thermal insulation properties, is fireproof, easy to install, and also has an affordable price. As for its disadvantages, hygroscopicity can be compensated for by installing vapor barrier and waterproofing, and the inconvenience when laying mineral wool can be compensated for by observing safety rules.

How to insulate a cold roof?

Oftentimes, setting up a cold attic is just an intermediate step. Most cold roofs are insulated over time in order to increase the living space of the house. This is easy because there is no need to redo the cold roof pie - it is, in fact, the top of the insulated roof pie.

In order to make an attic out of a cold attic, you just need to add a layer of insulation and finishing. If, as we recommended, you used a waterproofing vapor-permeable membrane and not a micro-perforated film as waterproofing, then the material for thermal insulation is placed close to the rafters. Then an internal lathing is made with bars of the required thickness, between which a second layer of insulation is mounted. They can also be used to fix the finish - wood planks or drywall.

When insulating a cold attic, a vapor barrier is not needed, since water vapor from inside the room will pass through the insulation and exit the roofing cake through the waterproofing membrane into the under-roof space. Therefore, before insulating a cold roof, do not forget to treat all internal wooden structures with compounds that prevent decay.

In addition to this method, the insulation of the cold attic of the roof can be performed using polyurethane foam spraying. This is one of the fastest and easiest options, and besides, this insulation is considered one of the best on the market. It is fireproof, has excellent thermal insulation properties, is durable, resistant to acids and alkalis, and does not rot.

In addition, the insulation of a cold roof made of corrugated board with the help of polyurethane foam allows you to create a continuous layer of thermal insulation, in which not only there will be no cracks, but the rafters will also be closed. The only drawback to this method is the cost. Also, you will not be able to do this work yourself, as it requires expensive equipment.

Helpful article? Save it on social networks so as not to lose the link!

The site uses modern web technologies and your browser (web browser) does not support them. To work with the site, please update your browser or install any of the recommended ones:

Installation process

Having decided on the material for thermal insulation, the question arises: how to properly insulate the attic floor? If we talk about mineral wool, what density should it have and what layer of insulation will be the best?

The choice of layer and density of mineral wool

Mineral wool insulation is best done in two layers

In short, the larger the layer of mineral wool, the better. However, it must be remembered that mineral wool has its own coefficient of specific thermal conductivity. The smaller this coefficient, the higher the thermal insulation properties, and, therefore, you can lay a smaller layer of cotton wool or have a higher insulation efficiency. Often, mineral wool with a thickness of 15-20 centimeters is used, however, to provide increased thermal insulation, a 30-centimeter layer of insulation can also be used. It is also worth noting that with an equal thickness of insulation, two layers of mineral wool are always better than one.

You also need to pay attention to the density of mineral wool, because it can be different: from 30 kg / m3 to 220 kg / m3. Thermal insulation properties practically do not depend on density. A denser insulation is used for facades and screed floors. Mineral wool with a density of 35 kg / m3 is also suitable for the attic floor, because the insulation will be on a horizontal unloaded surface.

Vapor barrier

Since mineral wool has the ability to absorb moisture, you need to start insulation with the installation of a vapor barrier material.

Vapor barrier - the first layer of insulation

Important! It is best to lay a layer of vapor barrier under wooden beams, otherwise they will be very susceptible to decay. Nevertheless, if it is impossible to put a vapor barrier film under the beams, they must be impregnated with solutions that protect against decay and mold.

The best option is to lay a continuous layer of vapor barrier, but due to the size of the attic this is not always possible, so all joints must be glued with special tape to ensure tightness. The edges of the vapor barrier must be raised above the level of the future insulation and glued with the same tape.

Thermal insulation

You need to work with heat-insulating materials in overalls

This is followed by the installation of insulation. It must be laid in such a way as to completely fill all the space between the timber beams. When it comes to mineral wool, then it does not need to be pressed or squeezed. It must completely cover the space between the beams, leaving no gaps or gaps. The floor beams themselves will also not be superfluous to cover with heat-insulating material, because they can serve as a kind of cold bridges.

When laying mineral wool, it is very important to protect yourself, and especially your respiratory tract, from the ingress of insulation fibers. Therefore, you need to use a respirator, as well as gloves, goggles and long-sleeved clothing.

Waterproofing

We complete the insulation of the attic floor with waterproofing and a sub-floor

Due to the properties of mineral wool to absorb moisture, waterproofing should be laid on top of a layer of mineral wool. It is also necessary if a concrete screed will be poured over the insulation.

If the attic is constantly in use, a sub-floor can be made on top of this insulating “pie”. It can be a concrete screed or OSB slabs. If the attic is practically not used, then you can simply lay the boards on top of the already existing beams. Then, if necessary, go up to the attic, moving around it will not create difficulties.

As you can see, insulating an attic floor is an affordable task, even for those who have never done it. It is necessary to decide on the material for thermal insulation, although most often it is mineral wool that serves as it. When assembling the heat-insulating "pie" it is important to remember the need for vapor barrier and waterproofing. This will allow you to achieve high results in warming the attic floor.

What is an attic

The attic space is limited by the roof slopes and the ceiling of the residential floor. This place is often used for arranging additional living space.

The attic of private households is of two types:

- Residential. It is called the attic. It can be used to equip a living room, study, bedroom, library, etc. The height of the room in this case should be at least 220 centimeters. In addition, it is necessary to provide ventilation, natural lighting, and insulate the slopes in it.

- Non-residential. Such an attic space is usually used for placing technical equipment, storing old or unnecessary things. In this case, a 2-meter height will be enough, and it is not necessary to equip natural lighting. Instead of warming the slopes, they make thermal insulation of the attic floor.

When deciding on the repair or rebuilding of the house, you need to decide in advance for what purposes the attic will be used in order to make the calculation and the design of the floor. The list of required materials and the gap between the beams depends on this. They must provide the required strength and bearing capacity.

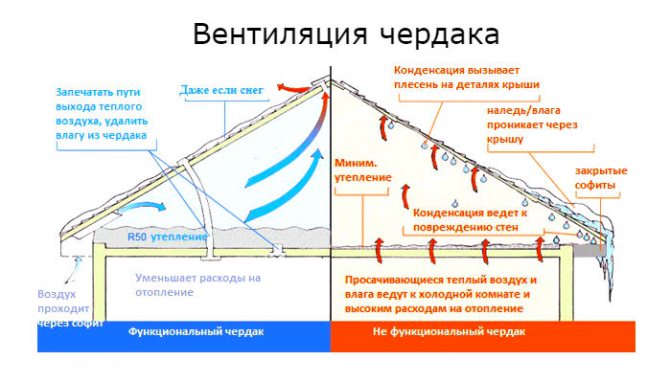

Cold attic ventilation

The last issue in arranging a cold roof is the ventilation of the attic. It should be adjustable so that in the summer heat at the level of the attic floor the temperature is close to the air temperature, and in the event of a sharp cold snap there is no abundant condensation. In winter, the ventilation is shut off, which makes it possible to exclude intensive blowing of the insulation and save as much heat as possible.

As a rule, in a private house, an entrance door to the attic and one openable window in the upper part of the gable on the opposite side are sufficient. If the roof is hip, you need to make a small ledge under the window.

For roofs with an area over 300 m 2, it is recommended to arrange additional vents. They cut into the top of the ramp and help remove air entering the attic in the Mauerlat area. To ensure full air circulation, perforated panels must be inserted every 70–80 cm when soffits are sewn up. You can avoid installing air vents when covering the roof with material with a wavy profile. On the line of convergence of the slopes, you need to leave a gap of about 100-140 mm, which is covered with a wide ridge.

Functional purpose of floors

The design of the attic floor depends on the parameters of the structure and the purposes for which it is planned to use the under-roof space. The attic has the function of a kind of air gap that separates the cold roof from the heated floors.

The attic floor has a number of tasks:

- carrier. The overlap, located between the upper residential floor and the attic space, has a load-bearing function, therefore it is made reliable and durable, since people will move along it, it is planned to place equipment on it and equip storage places;

- insulating. In a cold attic room, the temperature is not much different from that outside the house. In this case, the floors in the attic have a thermal insulating function, thereby preventing air cooling on residential floors. To keep warm, thermal insulation of the attic floor is required. It is advisable to entrust such work to professionals.

Features of the device and construction of floors

Since the overlapping of attics performs two functions - load-bearing and insulating, they have a multi-layer structure.Each of the elements of the "pie" complements each other, which provides the created structure with a long service life, strength and the ability to withstand heavy loads.

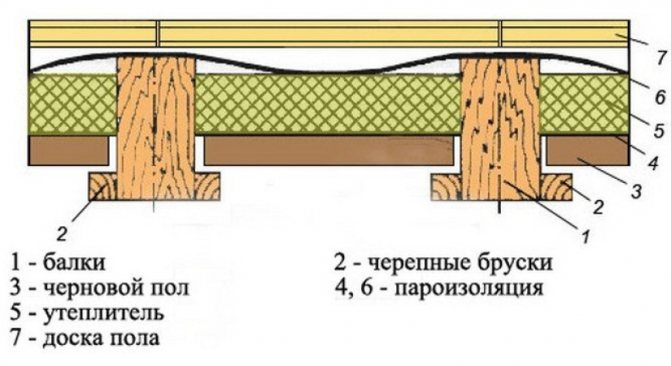

The device of the floor in the attic assumes the presence of the following layers:

- Finishing floor. This name is given to the floor covering, which is laid on a rough base. If this is an attic, then when arranging a final floor, linoleum, laminate, parquet, etc. are laid. In non-residential premises, the finishing flooring may not be available.

- Rough base. It is a boardwalk that is mounted on logs. The subfloor is lined from edged boards with a thickness of 4-5 centimeters or, in order to save money, from unedged boards.

- Lags. These are solid, even wooden elements that are laid perpendicular to the floor joists to create a floor covering. When the arrangement of the attic floor on wooden beams is carried out, a heater is placed between the logs, which is protected from below with a layer of vapor barrier, and covered with waterproofing material on top. If you do not use insulating layers, then repairs will be required after a few years.

- Beams. The floor frame is built from thick and durable beams, which are either mounted on the protrusions of the walls, or embedded in them. They must support the entire weight of the structure. A flat roof can also be made over wooden beams, which is quite practical.

- Ceiling paneling. From the side of the rooms, the floors are decorated with finishing materials, for example, natural wood or drywall.

Types of attic floors

For the device for overlapping a cold attic, materials are used that differ in weight, durability, cost and bearing capacity.

There are several types of floors, depending on what they are made of:

- Wooden elements. For their manufacture, you can use beams with a cross section of 150x150 or 200x200 millimeters. The advantage of this option is that wood is a fairly strong and at the same time relatively light material, so wooden elements do not put additional stress on the foundation of the house. In addition, their great advantage is their low price and availability. But such an attic floor is used when the size of the building does not exceed 6-10 meters, since this is the maximum length of lumber.

- Metal products. Metal I-beams are durable, able to withstand heavy weight without deformation. But they weigh decently, so they are rarely used in wooden houses, but for brick and aerated concrete buildings they are the best option.

- Reinforced concrete products. Molded floor beams made from reinforced heavy-duty concrete are used for multi-storey buildings, since they are of greater weight and the same length.

Of all the above types of floors in private low-rise housing construction, in most cases, wooden beams are preferred. They have an optimal balance between price and quality. With competently performed calculations and adherence to technology, overlap repairs will not be required in the coming years. Ventilation is also required in the attic of a private house, for the arrangement of which additional knowledge will be needed.

In what cases is the waterproofing of the ceiling used?

The main purpose of the waterproofing layer in the floor:

- Waterproofing the ceiling from top leaks is important in apartment buildings. It is done in the bathroom and toilet. Its purpose is not only to protect the premises from flooding and damage to furniture, but also to prevent the appearance of mold on the ceiling.

- The coating increases the service life of finishing materials and protects building structures from water damage.

- Ceiling waterproofing in a private house is designed to protect electrical wiring from getting wet and short circuits.

Ceiling surface waterproofing is performed in rooms with high humidity (bathrooms, kitchens, lavatories), in basements, on balconies and loggias, basements. In a private house, this layer will protect living quarters with a leaking roof.

Waterproofing materials and applications

In apartment buildings, the ceiling is often waterproofed from the inside. For these purposes, materials that are different in composition, principle of application and action are suitable. Each of them is designed for a specific type of surface and has its own pros and cons. The largest selection among products designed to protect concrete surfaces from moisture.

Related article: The Central Bank considered what the World Cup will bring to the Russian economy and its citizens

Gluing materials

This insulator is divided into two types:

Recommended reading: Where are the most expensive new buildings in the Moscow region?

- Polymer products are made on the basis of atactic polypropylene and modified copolymers. This includes polyethylene and vinyl plastic.

- Non-polymer waterproofers - roofing felt, roofing felt, fiberglass.

Installation of this waterproofing on the ceiling is quite laborious, therefore it is impractical to use these materials. There are glued insulators with a self-adhesive base and materials that are fused onto the surface with a gas burner. The only place where this option for moisture protection is appropriate is a loggia and a glazed balcony.

Penetrating insulation

Ceiling penetrating waterproofing is the most effective method of protecting the ceiling surface from moisture. The resulting coating is durable. The mixture is applied to a damp ceiling, which causes the active ingredients to convert into insoluble crystals. They tightly fill all the pores and cracks on the ceiling surface. Suitable for use on concrete ceilings only. These products have been proven to increase structural strength by 15-20 percent.

Important! The main advantage of penetrating waterproofing is its harmlessness and the fact that it does not interfere with the air exchange of the treated surface.

Coating waterproofing

These formulations are divided into several types:

- bitumen-rubber (elastic);

- bitumen-polymer (elastic);

- cement-polymer (inelastic).

They are easy to apply and cost effective. However, above this waterproofing layer, plaster must be applied. The insulator is laid in several layers and is used to treat cracks, seams, floors, walls, ceilings in bathrooms, bathrooms, on a balcony or loggia.

Worth knowing! According to their composition, the coating products are two- and one-component. The latter are immediately ready for use, while the two-component ones require preliminary preparation.

Waterproofing by plastering

In addition to cement and sand, such plasters include special additives and waterproof polymers. After hardening, they form a surface that protects against moisture penetration even under significant pressure. Waterproof plasters are suitable for brick and concrete surfaces. They are applied only on a dry surface, without cracks.

Powder insulation

It is a mixture of resins, plasticizers and cement. A solution of plaster consistency is prepared by dilution with water. After that, the mixture is simply applied to the ceiling surface. This material is rarely used due to its low resistance to mechanical stress.

Paint compositions

This includes special paints, varnishes, emulsions based on rubber, bitumen, latex and other waterproof components. These mixtures are distinguished by ease of application, environmental friendliness, and economical consumption. Their main disadvantage is a short service life. Suitable for various surfaces, including wood.

Requirements for the device of the pie

Since the safety of staying in the house depends on the quality of installation and repair of attic floors, a number of requirements are imposed on their arrangement.

In order to know the value of the maximum permissible load that the structure can withstand, it is necessary to perform the appropriate calculations, and then, based on their results, they begin to develop a project, from which it will be clear how to properly insulate the attic floor in the house.

Requirements concern:

- Carrying capacity. It directly depends on the material of manufacture of the beams and on the gap between them.

- Distances between structural elements. The maximum allowable value for this parameter in accordance with building codes is 4 meters.

- Resistance to temperature extremes. It is necessary that the beams can withstand such changes without problems. The fact is that the difference between the air temperature in residential floors and in the attic always exceeds 4 degrees.

- Insulation. The pie of the attic floor of a cold attic should protect the premises of the household from the penetration of cold and moisture from the under-roof space.

In the design process, the requirements for the beams used to equip the ceiling in the attic should be taken into account so that the result is reliable and durable. The distance between them must be calculated based on the loads exerted on them.

The technology of creating an attic floor on wooden beams

If you have experience in performing construction work, you can mount the ceiling of the cold attic on wooden beams with your own hands. This process is carried out at the final stage of the roofing work.

The sequence of actions will be as follows:

- Installation of load-bearing beams. For a small private house, wooden floors made of a bar with a cross section of 150x150 or 200x200 millimeters are suitable. They are laid on concrete or masonry walls.

- Installing lag. They are placed on the edge perpendicular to the beams in 60 centimeters increments. Lags are made from boards with a section of 150x50 millimeters.

- Thermal insulation laying. Insulation is placed between the logs - it will protect against cold penetration from the attic.

- Installation of rough and final floor.

- Sheathing of load-bearing beams from the side of the room in order to decorate the ceiling surface.

When insulating the attic floor, one should not forget about the arrangement of hydro and vapor barrier.

Attic construction with overlap

The construction of an attic, which undoubtedly expands the living space, is much more expensive, requires certain knowledge, time and labor. The device of a cold attic floor is several times cheaper and easier.

The device of the attic floor on wooden beams is a puff pie:

- boardwalk or roll;

- vapor barrier;

- ventilation gap;

- insulation;

- ventilation gap;

- vapor barrier;

- floor.

Ventilation is carried out through gables or roof slopes. Dormers are also made, placing them on opposite slopes so that air penetrates into all corners of the room.

Dormer windows are a difficult element to install, but useful. They can have different shapes, triangular, oval, they are placed at a height of 1 meter from the floor, equipped with grilles, blinds. Through them it is convenient to go to the roof for its inspection, maintenance, checking the chimney, antenna and other things.

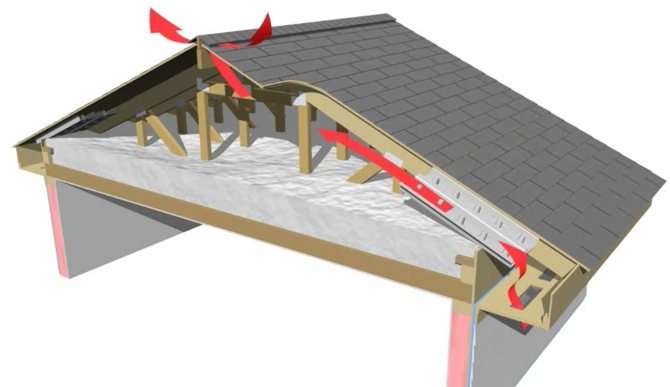

Cold roof waterproofing and ventilation

If you are laying a micro-perforated product, then such a layer will block the access of moisture from the outside, but at the same time water vapor can pass this area without problems. We can say that the installation of vapor barrier products on the roof slopes is optional in this case. After steam penetrates inside, it is between the waterproofing material and the metal cover, from where it is removed by natural ventilation.

With increased air humidity, condensation processes begin, so moisture accumulates on the back of the film and penetrates into all roofing materials. Due to this fact, it is not recommended to use materials such as polyethylene and polypropylene, roofing felt, and glassine for the construction of a cold roof.

The ventilation system for cold roofs is fairly straightforward. To create it, gaps are left, which, as a rule, are along the eaves. Air masses pass through them, collect all humidified air and remove it through the cold triangle located in the ridge of the roof.

The counter grill is a design to provide additional ventilation.

Most often it can be found on complex roofing systems, where products with a high degree of waterproofing are used as a coating, for example, metal, shingles and others. The gap that is created by installing a counter batten allows fresh air to dry the roofing cake from both sides, so structures with such a cake last much longer than others.

Attic beams

The overlapping of the attic is done on wooden beams after the installation of the supporting elements is completed. This is the easiest and most optimal way for the competent arrangement of the technical area.

The construction of the attic floor is usually made of wooden beams. These support elements have a number of advantages:

- maximum coverage 4.5 m between supports;

- light weight, load on the building, savings on the foundation;

- ease of installation, without the use of lifting equipment, crane;

- availability of wood as an inexpensive material;

- speed in work, the ability to install an attic floor in a day or two;

- the ability to use any soundproof materials.

For the manufacture of beams, conifers are used that are resistant to moisture, decay, and fungus. The cross-section of the beams for the attic floor must correspond to the load, climatic conditions, the thickness of the insulating material should be taken into account. The dimensions of the beams are 150x200 mm, if a serious load on the attic floor is expected. For example, it is planned to install a water tank, a transformer. With a minimum load, beams are used 100x150 mm.

The desire to save money and install 50x100 mm beams does not cause approval. Too significant element of the house is the attic floor, which provides thermal insulation, sound insulation and the reliability of the ceiling. The quality of the overlap guarantees savings in heat and heating costs.

You can calculate the number of wooden beams of the attic floor like this. Divide the length of the room by 60-100cm (the distance between the beams), add 2 pieces to the resulting value, which will fit on the walls. Beams should be laid on load-bearing and external walls.

The device of the attic floor is carried out in several stages, each of which determines the quality and reliability of the structure. The work algorithm looks like this:

1. Preparation. The required length is cut off, the wood is treated with a special compound that protects against rotting, swelling and other troubles, the edges of the beam are wrapped in roofing material, then the finished element rises up.

2. Laying in two ways:

- without protrusion beyond the outer walls;

- with release behind the outer walls.

It is necessary to lay along the length at the right distance in relation to other structural elements, with any method of laying it is taken into account:

- the maximum span width should not exceed 4.5 meters;

- the timber is laid on the ends of the walls, in some cases a Mauerlat is used - this is a thick timber fixed with thick nails or steel studs into the walls along the perimeter;

- roofing material is laid under each beam layer to ensure waterproofing;

- the pitch of the wooden beams is selected from the dimensions of the heat-insulating material.

3. The attic floor on wooden beams is carried out taking into account the arrangement of the roll, which is a covering of boards, slabs. Waterproofing, vapor barrier, insulation are placed between the upper and lower rolls. The lower flooring is made on supports to which the boards are attached, but it is better to use slabs, plywood sheets with a thickness of 15-20mm. Fastenings are carried out with self-tapping screws with a pitch of 10-15mm, so that the heat-insulating materials are securely held.

In order to mount the most durable structure, you need to fill 50x50mm wooden bars on the bottom of each beam, they form a ledge on which boards or sheets are placed. You need to fix the roll to the bars also with self-tapping screws. The advantages of such a design are exceptional reliability, the disadvantages will appear in the decoration of the ceilings, on which these bars will have to be repaired, hidden. Such a structure should be mounted if the active use of the attic is planned.

Related videos:

4. The final stage of the installation of the attic floor on wooden beams is the installation of the floor, for which boards are sewn on top, acting as a subfloor. For the finished floor, a tightly laid tongue-and-groove board is used.

The subfloor is mounted on all the same bars, from above. But before proceeding to the last stage, you should do:

- laying a membrane-type vapor barrier;

- thermal insulation;

- another layer of membrane fabric.

The finished structure is an important element for covering the roof and the entire structure.

The value of vapor barrier and methods of its installation

The vapor barrier of the attic floor ensures the safety of the wooden floor. It extends the life of the roof, contributes to the creation of an optimal microclimate in residential premises, taking away excess moisture, and prevents heat loss. The choice of material for vapor barrier should be carefully, without intent to save money.

The vapor barrier material has a different side structure. On one side there is a rough surface that absorbs moisture, the other side with a film prevents moisture from penetrating into the heat-insulating layer.

The vapor barrier is laid, as already clear, between the ceiling and the insulation in the attic floors. Materials used:

- polyethylene;

- polypropylene.

The canvases reinforced with a special mesh can be perforated. You can also use non-perforated film, leaving gaps during installation. The reinforced film has a metallized surface. The film spreads down a metallized surface to reflect heat loss.

The fiber layer absorbs moisture and then naturally evaporates. The materials are durable and resistant to ultraviolet rays.

There are also other vapor barrier materials that can be used to equip an attic overlap with wooden beams with vapor barrier. These are varnishes and mastics, asphalt, bituminous, bitumen-kukersolny. Today, such materials are rarely used, preferring nonwoven fabrics of synthetic origin. These are the so-called "breathing membranes", capable of passing moisture, air, multi-layer, single-layer, equipped with aluminum foil.

The material is laid with an overlap on the wall by 20 cm, fixed with a stapler, rough side down.

Related videos:

Installation of a cold roof from corrugated board in a residential building

Cold roof construction is very simple. On the slopes, neither insulation, nor vapor barrier, nor, moreover, finishing is needed. Naturally, the savings in this case are very significant, given that the price of insulation and finishing is 50-60% of the cost of the entire roof. In addition, due to the simplicity of the design, a cold roof made of corrugated board with your own hands fits without any problems.

Cold roof cake consists of the following elements:

- rafters;

- waterproofing film or membrane;

- counter lattice;

- lathing;

- professional flooring.

Cold roof waterproofing: is it necessary?

Cold roof waterproofing will protect the room from possible leaks and condensation that forms on the inside of the metal roofing. Since condensation is released on metal surfaces during temperature changes, there is a common misconception that it will not happen when an insulated roof made of corrugated board is installed.

Naturally, such an opinion does not correspond to reality, since, despite the fact that the under-roof room is not insulated or heated, the temperature inside will still differ from the outside temperature, and often quite significantly. Therefore, the answer to the question: "Will there be condensation on the corrugated board if the roof is cold?" - unambiguous: "Yes, it will."

In this regard, it becomes obvious whether waterproofing is needed under the cold roof sheeting. The consequence of its absence will be that condensation will fall on the ceiling, increasing the humidity in the attic. This will lead, at best, to accelerated damage to wooden structures, and at worst - also to a catastrophic decrease in the thermal insulation properties of the insulation, if it is unprotected.

The waterproofing membrane of the cold roof is laid on the rafters and fixed with a counter-lattice, after which the lathing is already mounted for installing the corrugated board.

If you are not going to insulate a cold roof in the future, then a micro-perforated film can be used as waterproofing, which is much cheaper than special membranes. However, it must be mounted with a mandatory sagging of 20-30 mm so that moisture flows into the space between the rafters, and does not moisten them, seeping through due to the capillary effect.

Vapor barrier and cold roof ventilation

Since micro-perforated films prevent the penetration of moisture from the outside, but do not interfere with the passage of water vapor, vapor barrier of the cold attic on the roof slopes is not required. Water vapor, passing through the film, finds itself between the waterproofing layer and the corrugated board, from where it is removed by the air flow.

If a waterproofing film for a cold roof traps water vapor, this will lead to excessive moisture in the room and, as a result, dampness. In addition, with increasing humidity, steam will condense already on the film from the inside. Therefore, ordinary polyethylene and polypropylene films, as well as outdated materials such as roofing material or glassine, are not suitable for waterproofing a cold roof.

Insulation of the attic floor

Thermal insulation of the attic floor, taking into account the wooden beams, is an important stage, both in terms of the choice of material and in terms of installation. The correct choice of material for thermal insulation should take into account the following factors:

- cost;

- availability;

- ease of installation;

- climatic conditions;

- environmental friendliness;

- fire safety.

Do not forget about the weight of the insulation, so as not to create unnecessary stress for the entire structure of the building.

There are many offers on the modern building materials market. Here are some of the most popular types of insulation:

- Expanded clay, bulk material, light weight, with high heat-saving characteristics, low cost;

- Vermiculite, natural bulk insulation with similar performance;

- Perlite, a free-flowing insulation of natural origin, which has approximately the same thermal conductivity;

- Mineral wool, produced in rolls and slabs, insulation with low thermal conductivity, high environmental performance. Read more in the article the technology of attic insulation with mineral wool;

- Glass wool, an analogue of mineral wool, of artificial origin, has a higher chemical resistance compared to mineral wool;

- Expanded polystyrene, produced in the form of plates, is afraid of rodents, has rather low thermal insulation properties and low cost;

- Extruded polystyrene foam, non-flammable, has a higher heat saving capacity than ordinary polystyrene foam;

- Polyurethane foam, produced in slabs, has excellent heat resistance, when sprayed creates a continuous protective film for heat and waterproofing.

- Peat slabs made of moss of natural origin are moisture resistant, lightweight and have excellent thermal protection;

- Reed, the most practical and cheapest material, with excellent characteristics, which can be made by hand.

If the thickness of the insulation is higher than the beams, you need to do additional laying of the battens so that an air gap appears. Bulk insulation is distributed evenly between the beams, the slabs are stacked end-to-end, without gaps.

Ventilation depending on the roof

In the event that the roof is covered with ondulin or slate without filing and a vapor barrier film, the owner of the house should not worry about creating ventilation. This is due to the fact that the air will move freely from the bottom of the attic to the ridge and go outside, while passing between the waves of the roof. Metal tiles have almost the same properties, but a lot of condensation forms under it, which requires laying the film.

If a gable roof is planned, then ventilation holes should be located in future gables. The simplest and most effective option would be a loosely laid gable lining and overhangs made of wood. The uniform gaps created will contribute to good ventilation of the entire attic space. Although it is worth remembering that when creating cracks, you should not be very zealous, so as not to create conditions for the free walking of the wind.

When creating stone gables or tightly fitting stitching, you will need to make holes in the wall. But here, too, it must be remembered that they must necessarily be located on opposite gables. You will also need to make several holes so that no stagnant zones form. As for the holes themselves, their total area should be within 0.2% of the entire floor area.

The holes made can be closed with ordinary ventilation grilles. The first should be installed from the outer part of the pediment, while its holes should be turned downward, thereby creating a barrier to rain penetration. The second, adjustable, will be installed from the inside. In addition, VTK ventilation valves can be installed instead of grilles. In addition, mosquito nets should be secured to prevent wasps, beetles and other insects from entering. To make the required hole sizes, you will need a drill, jigsaw, hacksaw, chisel and hammer, as well as a perforator (for stone gables).

Another option for arranging ventilation is suitable for an attic located under a hip roof, but it can also be used for a gable roof, in which it is difficult to make holes. To supply air to the room, you will need to make a hole in the wind lining, and to exit it - to the ridge. When arranging the filing with boards, you should leave a gap between them. And if you plan to use plastic, then it must have perforations, that is, have small holes.

There are times when the binder has been collected quite tightly. In this case, you can use small ventilation grilles with a diameter of 5 cm. They will need to be placed in the wind sheathing every 80 cm. As for the outlet of the incoming air, holes will have to be made in the roof itself.So, for example, an ordinary ventilated skate can be used for shingles, euro-slate and slate. But for ceramic tiles, it is best to install a special roof valve.

Attic waterproofing

After the interfloor cake is ready, the floor is mounted, you should think about waterproofing the cold attic room. Some advise to completely abandon it, but still, it will not hurt to lay a layer of waterproofing material under the roof. To avoid leaks, condensate should be installed with diffusion membranes. There will be no ingress of snow, rain, which significantly reduce the thermal insulation properties of the attic. Waterproofing is especially needed if corrugated board is used as a roofing material.

Recent articles:

- Diagonal floor tiles

Laying tiles on the floor diagonally Even among professionals, laying wall or floor tiles under ... - Living room in the attic Attic floor design: 100+ photos and solutions Thanks to popular American TV series and films, many dreamed of ...

- Brush Brushes for paint and painting: their types and sizes Many people do not even suspect that ...

- Chalet style fireplace Chalet style is synonymous with warmth, comfort and hospitality. Why do people love the huts of the mountaineers? Primarily,…

Steam and thermal insulation of a cold attic

For a roof with a cold attic space, it is most important to minimize heat loss through the attic floor as much as possible.

... For both wooden and reinforced concrete floors, a vapor barrier is mandatory. It fits on the floor itself and protects the insulation from vapors that can condense in the heat insulator, passing through the ceiling of the living room. Plate and bulk materials can be used as insulation. The ceiling cake consists of a vapor barrier, floor beams and insulation.

The following types of heat insulators are often used in the ceiling ceiling

:

- expanded polystyrene and foam boards;

- mineral wool boards or mats;

- expanded clay granules;

- fuel or granular slag;

- sawdust with lime or clay;

- pumice.

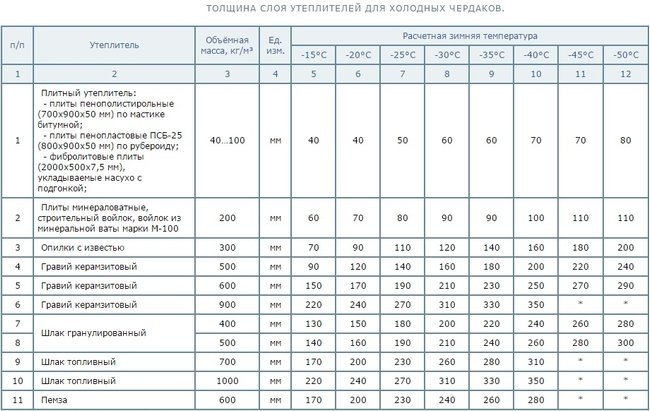

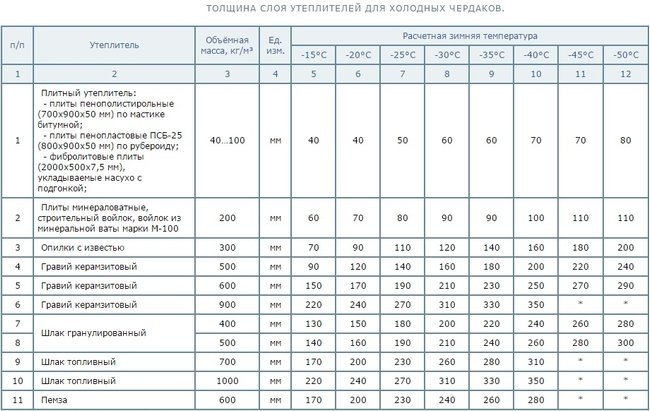

The thickness of the required insulation layer is selected depending on the estimated winter temperature using the table below.

Winter temperature is calculated according to SNiP 2.01.01-82 (construction climatology and geophysics) or selected by regions of the Russian Federation from the corresponding climatic maps.

Insulation is laid between the lags or beams of the ceiling, and a boardwalk for attic passages is made on top. The logs are usually 50 mm thick and the floorboards are 25-35 mm thick.

For ventilated attic spaces, soft or semi-solid heat-insulating materials are considered the most optimal.

Attic waterproofing device

Waterproofing roofs with a cold attic, according to many experts, is a controversial issue. Some say that waterproofing must be present under the roofing material, and someone strongly recommends abandoning it. Much depends on the type of roofing material and the angle of inclination of the roof slopes.

Metal roofs are most susceptible to corrosion due to possible small leaks or condensation

.

Therefore, we once again draw your attention to the fact that ventilation plays one of the main roles in the fight against the formed condensate.

.

For shallow metal roofs, experts recommend installing superdiffusion membranes. It will prevent moisture from entering the outside of the roof when blowing snow or rain. No matter how well the roof is laid, there is always the possibility of minimal leaks. That is why, by overpaying a little, you will receive additional protection against moisture ingress on the insulation in the ceiling of the cold attic.

Possible leaks or condensation when entering hydrophobic heaters significantly reduce their thermal insulation properties.

If, for example, slate is used as a roofing material, then waterproofing can be abandoned. There is also a corrugated board with an anti-condensation coating on the market, which can hold up to 1 liter of water per 1 m 2. For our part, we recommend that you always use waterproofing membranes, because this is the cheapest and easiest additional way to protect your roof from possible leaks.

.

When installing waterproofing membranes, a counter lattice is used. It performs the function of a fixing rail and, due to its height, provides the necessary clearance for ventilation of the under-roof space. The device for the lathing of the cold attic is no different from the insulated roofs. The dimensions of the lathing and its pitch determine the type of roofing to be installed.

Temperature range of the cold attic

To prevent ice and icicles from forming on the roof, it is necessary to maintain the correct temperature and humidity regime in the attic. If the thickness of the insulating material is insufficient, significant heat losses occur through the floor. Warm air, heating the roofing, causes snow melting and ice formation. By choosing the right insulation layer, this can be avoided.