To protect heat-insulating materials from moisture, a layer of vapor barrier is laid, which should become an insurmountable barrier for condensation formed due to different temperatures in the room and outside, especially in winter.

After all, if the heat insulator gets wet, then it will cease to effectively retain heat and the room will become much colder, and in addition, the accumulation of moisture, even in small quantities, negatively affects the durability of most materials and structures.

However, not many, independently undertaking such work, understand the intricacies of this procedure and know exactly, for example, which side to lay the vapor barrier film on the insulation. This article will help you understand this.

Which side to lay

It is necessary to lay the vapor barrier material from the side of the room on top of the insulation with the side that is specially designed for this by the construction of a specific type of insulating material.

- Polyethylene film. Polyethylene film is one of the vapor barrier materials that provide complete isolation from water vapor contained in the air and is one of the cheapest and simplest vapor barriers. It has only one layer, with the same characteristics of the sides, which allows you to stack it as you like.

- Steam condensate film. The steam-condensate film is created using a two-layer technology with a smooth inner layer and a rough outer layer, along which drops do not flow down, forming puddles down and, lingering on its irregularities, evaporate. It spreads with the inner smooth side on the insulation material, and its rough side, respectively, looks into the room.

- Diffusion membranes. Diffuse membranes belong to the insulators with limited vapor permeability and consist of a polymer-based film and non-woven polypropylene. Unlike ordinary films, they let a certain amount of water vapor pass through themselves, which does not harm the insulation, as it evaporates very quickly. Such an insulator is fixed according to the same principle as its steam condensate counterpart, that is, the smooth side is on the insulation, and the rough side is outward.

- Energy saving vapor barrier materials. Energy-saving vapor barrier materials are mounted with a foil coating inside the room, because it has the property of reflecting heat back into the room in the form of infrared radiation. This type of insulation is represented by films with a heat-reflecting coating. The energy-saving effect in them arises due to the presence of an outer metallized layer that is resistant to high temperatures and reflects a significant proportion of energy in the form of radiation in the infrared range.

Materials for the installation of the vapor barrier layer of the roofing cake

Answering the question of how the vapor barrier is laid (which side), you should pay attention to the fact that it directly depends on the chosen vapor barrier material. To date, there are quite a lot of similar products on the building materials market.

Until recently, glassine was the most common thermal insulation material. It is still used today, but not as often. The fact is that it does not meet modern vapor barrier standards, because it has a relatively small margin of safety.

Currently, the most popular material for the installation of roof vapor barrier is polyethylene film, which has several layers and a special structure. It is highly resistant to temperature changes and does not allow moisture to pass through. It is about which side to put the film on the insulation that inexperienced craftsmen are most often interested in, who decided to independently equip a vapor barrier.

How to correctly and on which side to lay the vapor barrier on the ceiling

This vapor barrier material has an elastic structure and is therefore resistant to mechanical stress. It is very convenient to work with it, the installation of a vapor barrier layer from a film will not cause difficulties even for inexperienced craftsmen.

The film can be attached to other elements of the roofing cake using self-tapping screws, staples or nails. From this, she not only will not tear, but will also lie tight. Among other things, polyethylene is not damaged when interacting with other constituent parts of the roof. This is due to its high elasticity. Thus, the film is able to withstand a mass, even a massive heat-insulating layer.

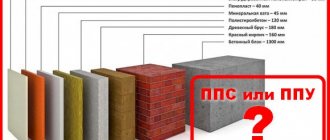

If there is a need to lay a vapor barrier, which is a film, then it is important to remember that there are two types of it:

- polyethylene, having a relatively small margin of safety, and therefore equipped with a reinforcing layer;

- polypropylene, consisting of a woven fabric covered with polypropylene. Such a vapor barrier is considered more reliable and durable, therefore, it is used by builders much more often.

Polyethylene and polypropylene films intended for the installation of vapor barrier are produced in rolls, so they are quite convenient to use when performing work. All that is needed to carry out the correct installation of the vapor barrier is to evenly unwind the roll so that the bobbin is at the bottom.

Determine the side

Often, when buying a roll of vapor barrier coating, an instruction is not attached to it, which could contain information about the marking of the inside and outside of the insulator. Sometimes such documents are simply lost and it is extremely difficult for a layman to determine the purpose of this or that layer just at a glance. But do not return to the store for instructions or call the seller, demanding clarification.

In such a situation, it is necessary to take into account the features of a particular material in each particular case, for example:

- in the case when the insulating coating is painted differently from different sides, as a rule, it lays down on the insulation with the light side;

- in the process of rolling the roll, the side facing the floor is almost always internal, that is, directly in contact with the insulation;

- a layer that has irregularities, corrugation or pile - during installation, it always looks inside the room, and a smooth one - faces the insulation.

Why is it needed?

Wood, like no other building material, is sensitive to unstable temperatures and fluctuations in indoor humidity. It begins to deform, collapse, the floor falls into disrepair along with insulation, which, without proper protection, absorbs steam and can no longer perform its functions.

In the premises of a wooden house, excess steam appears for the most common reasons, which cannot be dispensed with:

- cleaning;

- cooking food;

- wash;

- hygiene procedures.

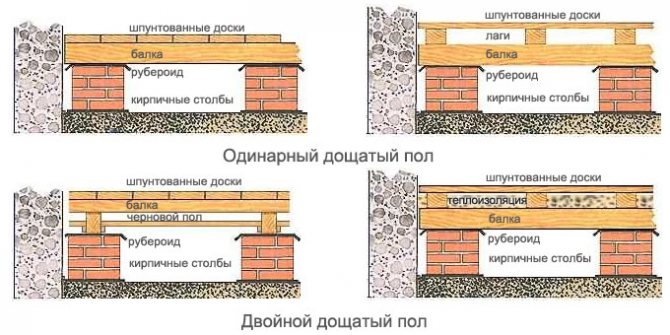

Having turned into condensation, the drops flow down to the floor, where they are absorbed by the wood. An additional reason for floor decay without vapor barrier is evaporation from the soil, since in most wooden buildings, logs that serve as support for finishing boards are laid directly on the ground.

In most cases, during construction, wood is treated with antiseptics and other protective materials, but their effect weakens after a while, and the structure is moved by the influence of moisture.

Installation features

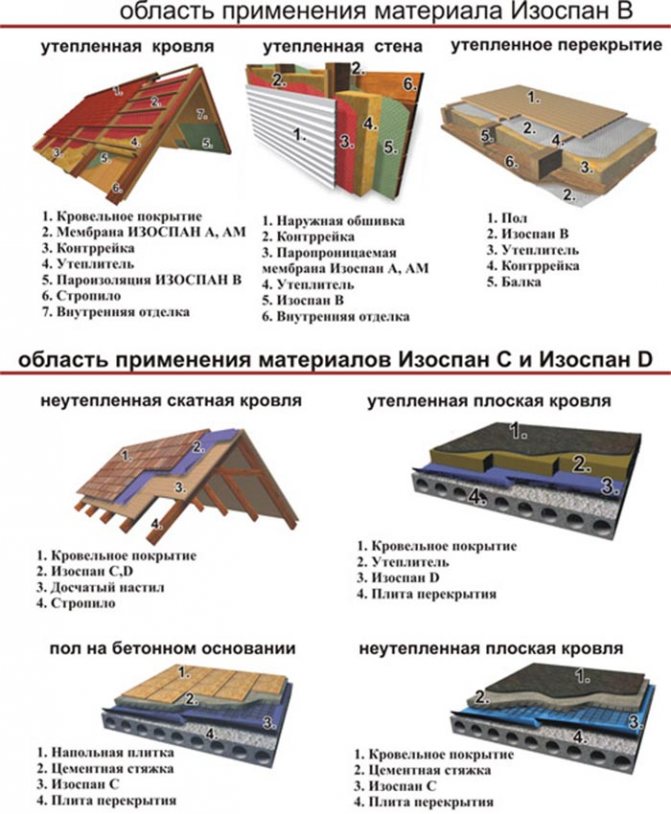

Mount from the outside or inside of the insulation

In the case of the floor, the vapor barrier material must be laid in two layers, that is, both from the outside of the insulation from below and from above to it.

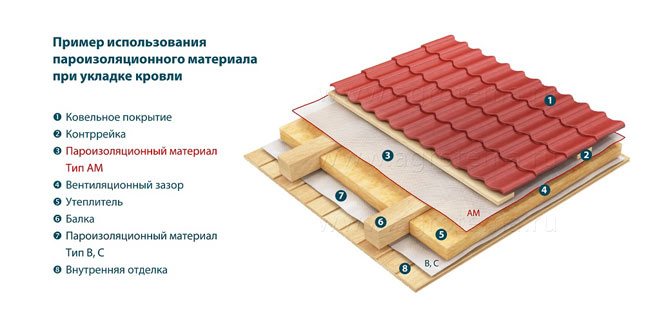

When organizing the vapor barrier of the roof of the building, the insulating layer is spread both on the outer surface of the roof and on its inner plane.

Vapor barrier of walls is realized according to standard technology, and like other options it can be inside and outside. The covering is fixed along the perimeter of the wall with a stapler, with a mandatory overlap and gluing the joints with tape. After that, a crate of thin slats is installed on top for the installation of thermal insulation.

Ventilation gaps: when needed

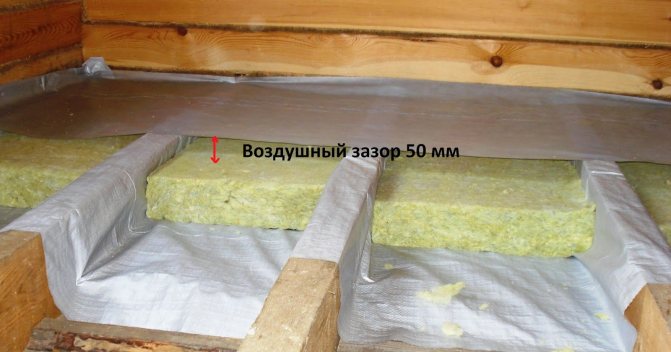

When laying deaf vapor barrier materials, it is necessary to organize ventilated gaps, especially with high air humidity, which, if they are absent, can cause a greenhouse effect.

In the event that the internal decorative facing is mounted without air gaps, in contact with the vapor barrier film, it will constantly be under the destructive effect of moisture condensed on it.

Thus, the free movement of air in the gap facilitates the unimpeded evaporation of condensate.

How to stack: overlap or not

Waterproofing canvases are laid with about 7 cm overlap each other, and the joints between them are sealed with special tape or covered

PVC or isospan film. This technology creates a single air and moisture impermeable barrier.

Material integrity

The integrity of the vapor control material is extremely important, because even if there is a small area that allows humid air to pass from the room, the entire vapor control layer loses its effectiveness.

Therefore, it is necessary to additionally glue with tape all places with damage and holes that have arisen during the installation process, as well as the area where the film is adjacent to door and window openings.

Methods for fastening a vapor barrier

The methods of fastening the vapor barrier differ depending on the type of material used: roll or sheet.

The roll-up vapor barrier is fixed along the entire perimeter of the surface to be coated with a construction staple and adhesive tape. In the event that further work does not provide for insulation, for the installation of the insulating material, you can use wooden or plastic slats screwed to the surface with self-tapping screws.

If it is necessary to lay a layer of heat insulator above the vapor barrier, its additional fixation is not required. Since both layers can be fixed at once on the same slats.

The vapor barrier, made in the form of sheets, is fastened with self-tapping screws on a profiled or rack-and-pinion frame made of metal or wood, respectively.

The vapor barrier is fixed with self-tapping screws, followed by gluing the joints with double-sided adhesive tape.

Vapor barrier installation process

Anyone can do the work on laying the vapor barrier material, even if he does not have special skills in construction and decoration. The process consists of several stages that must be taken into account when working:

- preparatory work;

Before laying the film or membrane, you need to inspect the condition of the floor in a wooden house. Do not forget about the processing of wooden elements of the subfloor with special antiseptic compounds that will reliably protect against the formation of rot, mold or mildew. It is important to proceed to the next stage of work only after the antiseptics on the wood surface have completely dried.

Also, the subfloor is thoroughly cleaned of dust and debris, leveled and removed existing cracks and chips on the surface.The vapor barrier film must be placed on a flat, defect-free surface.

- laying a layer of vapor barrier film;

The selected material is laid on the surface with slight sagging on the logs and carefully glued with construction tape at the joints. If the foil is laid without sagging, the foil will stretch even more during the installation of the topcoat and there will be a risk of breakage. All efforts will be nullified. It is also necessary to overlap the walls with dimensions of 10-15 cm.

It is important to carefully read the manufacturer's instructions on how to install the film. For ordinary plastic wrap, this is not important, but for foil wrap it is important to lay it with the foil side to the ceiling. In turn, the membranes are laid down with the side without company inscriptions.

- fixation of the material.

After laying the film, a crate is mounted on it, on which, in turn, a finishing plank floor will be attached. But first, a layer of insulation with a thickness of at least 50 mm is laid on the vapor barrier layer, and then the insulation is again covered with a layer of vapor barrier film.

On top of the log and the insulation cake, a finishing plank floor is mounted, which will either become an independent type of decoration, or a finishing floor covering will be laid on it.

Blitz Tips

- When using thermal insulation outside, it is mounted both before and after fixing the insulation, forming a three-layer insulation system.

- When mounting the film, it is necessary to maintain a balance between its excessive tension, which can lead to its rupture and its free hanging, which is also unacceptable, since it reduces the air gap between it and the finishing coating, leading to its direct contact with condensate on the film.

- When horizontally located insulation is adjacent to the walls, it is advisable to launch the material on their sheer planes around the entire perimeter of the room about 15 cm, this is enough to prevent it from getting wet from them.

- It is advisable to lay the vapor barrier on previously cleaned and absolutely dry surfaces, otherwise, a violation of technology and a deterioration in the quality of all work is likely.