Considerable attention is paid to insulation in construction. It is not an easy task to build a stable, durable and comfortable house for housing, a bathhouse, a storage room, but there will be no use in them if the issue of insulation is approached with carelessness and frivolity. After all, there is one situation when a person occasionally looks into such premises, but it is completely different when a person lives in them and spends a large amount of his time. This is especially true for frosty winter periods when insulation plays a fundamental role. Today we will figure out how best to approach the issue of warming the attic floor using wooden beams in a residential building, what material to use, and how to calculate everything correctly.

The process of warming the attic floor

When it comes to insulating a residential building, builders often neglect many of the most important criteria and points. So, for example, when insulating houses, the main attention is paid to insulating the floor and walls, which is correct, but after that many forget about the high-quality covering of the floor from above.

This is a gross mistake, because if we turn to the basic laws of physics, we will remember that warm air is always higher than cold air.

Obviously, with improper insulation, it will simply be ventilated into the attic, in fact, not fulfilling its main role. It follows from this that insulating the attic floor unit (in fact, the ceiling) is as important as other surfaces of the living space. The task is to insulate a wooden attic floor. You need to start with theory, namely, with the definition of the main criteria and features of a particular room, its characteristics and parameters.

What you should pay attention to when insulating the floor:

- On the specific features of the used floor material. If wooden beams are considered, then it is necessary to fully understand and sensibly evaluate its strength, durability and ability to withstand loads.

- On the ability to noise and moisture permeability of the material.

- Floor construction.

When planning the insulation of the attic, it is not only the hollow space in the beam floor itself that matters, but also the size of the beams themselves. So, on average, they are up to 40 cm in height, up to 15 m in length and up to 18-20 cm in width.

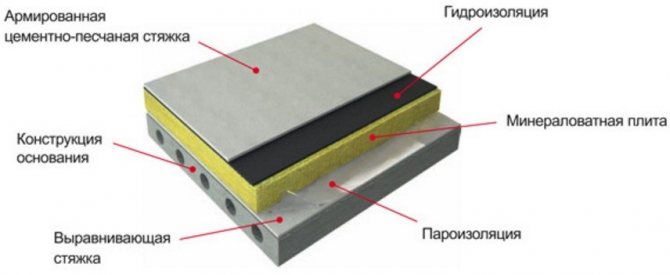

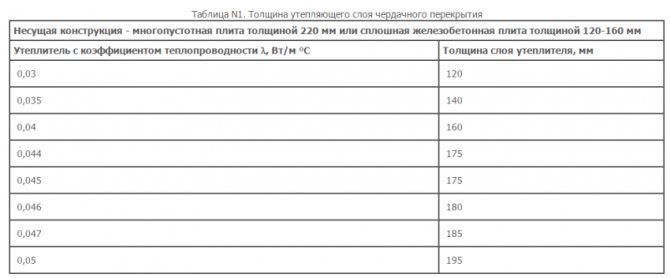

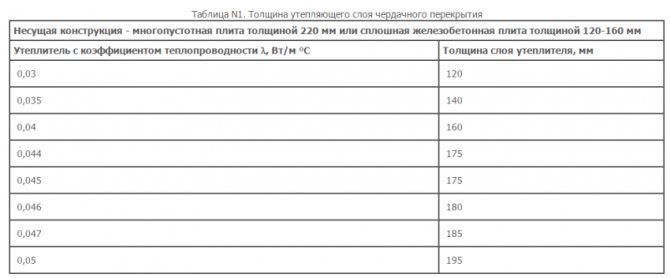

Norms for insulation of attic reinforced concrete slabs

To produce high-quality insulation of the attic floor and extend the service life of the roofing and rafters, you need to use a vapor barrier. It is worth knowing how to lay the vapor barrier correctly. The vapor barrier is laid on the slab, and on top there is already thermal insulation. This will prevent moisture build-up on the wood and metal parts of the attic space. In case of violation of the vapor barrier layer, as a result, the thermal insulation properties of the insulation deteriorate.

The thickness of the insulating layer of the attic floor

The choice of insulation for overlapping the attic

One of the main questions that arise for everyone who takes on the burden of insulating their attic is the question of which insulation to choose. After all, it is on this choice that the subsequent actions of a person, as well as the final result, will depend.

Among the most used and receiving positive reviews of materials, the following can be distinguished:

- Mineral wool. It has sufficient thermal insulation characteristics, but when choosing, be careful with the views.Mineral slag (slag wool) has the characteristics of steam accumulation, therefore, if we are talking about high-humidity rooms, check its properties when purchasing.

- One of the most common options is polystyrene. It is quite suitable for insulation, since it is practically incapable of accumulating moisture, and also copes well with sound insulation. However, some species are sensitive to severe temperatures and during frosty winter times, the duration of its operation can be reduced.

- Penoplex insulation. The best option for most cases, since in all respects it fully corresponds to the desired result. High density does not allow water to be absorbed, retains heat, is durable and has a long service life. It is also unfavorable for the reproduction of microorganisms and is resistant to biodegradation.

There is a method of spraying PPU (polyurethane foam). However, here it is worth considering all the features of this material. Thermal insulation depends on the number of layers applied, and sound insulation also correlates with the characteristics of its application and the type.

Each selected insulation has its own characteristics and properties that should be taken into account.

However, it is more resistant to chemical and biological influences, almost does not absorb moisture. There is insulation with expanded clay, a layer of basalt and other materials for an individual case.

Insulation materials

For thermal insulation, four groups of heaters are used:

- Bulk. This group includes: ecowool, sawdust, expanded clay.

- Roll. Presented with mineral wool or Isover-type insulation.

- Sprayable. Penoizol belongs to this group.

- Plated. Foam or compacted mineral wool sheets.

In addition to the direct function of thermal insulation, they have sound insulation properties. In summer, they protect the house from high ambient temperatures. Among the main properties of heat-insulating agents that are important for insulating the ceiling are:

- Thermal conductivity. It will be better if this parameter is less.

- Moisture resistance. For any construction, high resistance to moisture is important.

- Flammability. The heat insulator is laid on wooden beams, so combustible insulation cannot be used.

The process of installing a thermal insulator on wooden ceiling beams - Lifetime. The property will allow the insulation to be used for a long time without replacement.

- Environmental friendliness. Purity, absence of harmful impurities.

Before making the final choice of thermal insulation, it is also important to analyze:

- Climatic conditions. The colder it is outside in winter, the thicker the insulation layer should be.

- Budget. Quite often, the choice depends only on the availability of money.

- Additional work. What else needs to be done to insulate the floor.

Laying mineral wool in the beams before lining the ceiling with clapboard

Perhaps this is the replacement of structural elements, finishing materials, the application of an additional layer of waterproofing or treatment with refractory preparations.

Sawdust

Sawdust can be used for thermal insulation of the floor. Affected by its low price, availability, low cost of work. The main disadvantage of sawdust is flammability, low moisture resistance. This leads to easy fire, decay, and the appearance of fungus. Therefore, before laying, the sawdust is processed.

The process of filling sawdust in the cavity between the beams under the flooring sheets

To reduce the moisture content and prevent the appearance of mold, sawdust is dried in a special chamber for a year. Later they are treated with antiseptic agents, fungicides.

Thermal insulation using sawdust is carried out in two ways. Sawdust is simply poured onto the prepared surface; this method is not required. Since the shrinkage of the material begins rather quickly, which requires regular replenishment.For the second method, sawdust is mixed with cement mortar.

Styrofoam

The plate is breathable, has a low price, does not accumulate moisture, does not rot. Mold, fungi, microorganisms do not grow on the foam. It has high thermal conductivity, high temperature resistance, good sound insulation. Conducts moisture well. Its light weight allows it to be laid on thin floors. Long lasting.

Installation of foam sheets to the ceiling

Main disadvantages:

- Flammability. This is the main drawback of the material. It is not installed where there is free air access. When used for floors, they must be treated with plaster or refractory preparations.

- Rodents. Mice are very fond of making their nests in Styrofoam.

To exclude the penetration of rodents, use a fine-mesh metal mesh.

Expanded clay

Bulk material is the second most popular insulation. It has high thermal insulation properties, is always on sale, it is easy to install it yourself. Disadvantages of expanded clay:

- Weight. A layer of expanded clay 20 cm has a significant weight. It is used on concrete floors. Its use is not recommended on thin wooden floors.

- Moisture resistance. Expanded clay is not moisture resistant. The first layer of thermal insulation is the vapor barrier of wooden structures.

- Thermal insulation. In areas with a temperate climate, a layer with a thickness of 20 mm is laid, with a cold one - 50.

Drawing with the dimensions of the device for the insulated floor in the building

For styling, large and small particles are mixed. This combination will fill the empty space. To protect against moisture, cement mortar is poured. Its thickness should be no more than 20 mm.

Mineral wool

It is produced in the form of a roll, rolled out on the surface, cut off. The material is inexpensive, has good thermal insulation, and fits quickly. Among its shortcomings are noted:

- Shrinkage. Vata shrinks by 15–20%.

- Moisture resistance. Cotton wool has a low moisture resistance, quickly absorbs water. Therefore, when installing it, waterproofing is first laid.

- Thermal barrier impermeability. This property depends on the air that is contained between the fibers of the cotton wool.

The thermal barrier decreases when the cotton is squeezed, therefore, it cannot be stepped on; flooring is made immediately after installation.

Heaters of this type are poured or sprayed on. This material cannot be laid by yourself, because its application requires special equipment, protective suits, professional skills.

Foam products fill all the slightest cracks and cracks. They do not attract insects, do not burn, and are safe for humans. The substance contains a large amount of air bubbles, which contribute to the insulation of a private house.

- High price.

- Fragility. The material does not regain its original shape after damage.

- Shrinkage. Penoizol has a slight shrinkage.

How to choose insulation for the attic floor

If sound insulation is not worried, but only the qualities of heat preservation are important, this is one option, and if everything in the complex is important and would like to do everything once and for all, forgetting about it for a long time, this is completely different.

What you need to take into account when choosing insulation for the floor:

- Directly the parameters of the material. The properties of some of them require additional attention and work, since they do not have all the necessary properties, or vice versa, they themselves create the need for them.

- Thermal insulation - its indicators.

- Soundproofing level.

- Water vapor permeability.

Also pay attention to the characteristics of the material.Most of them will require certain manipulations, such as, for example, an additional layer of vapor barrier underneath so that moisture does not linger and does not have a destructive effect on the wood.

Before buying a base for insulation, it is advisable to know the dimensions of the depressions in the overlap in order to accurately fall within the necessary framework.

In order to understand exactly what the requests are, you can refer to the source of SNiP (Building Norms and Rules). Also, on top of the material itself, you will need to lay the level of the fastening base, or a thin screed, including for the purpose of additional heat and vapor barrier.

THE MAIN

Warming the attic of a house (it would even be more correct to say the attic floor) - the operation, in principle, is not difficult, for example, in comparison with the same insulation of a residential attic. But even here, due to lack of knowledge, mistakes can be made. Now we will consider this issue in more detail.

So, first of all, we need to decide on the type of insulation that we will use and calculate the thickness of its layer. How to make the calculation was described in the previous article - “How to insulate the roof. Calculation of the thickness of the insulation ". What can you say about the choice of insulation? First of all, there is plenty to choose from. These are various mineral wool insulation, polystyrene foam, conventional and extruded polystyrene foam, all kinds of backfills (expanded clay, shungizite, crushed slag ...), etc. etc.

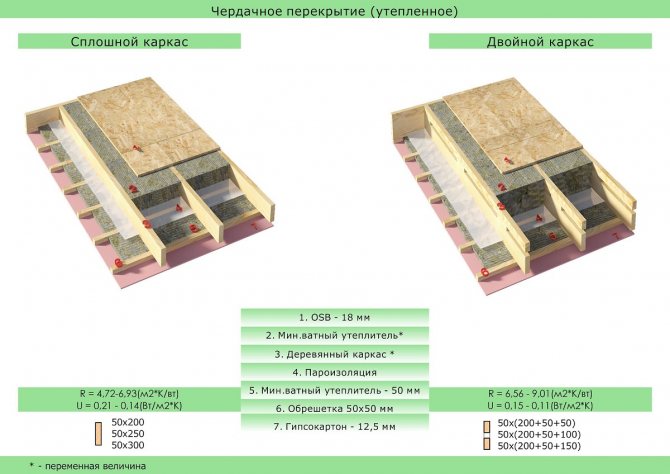

There are no increased requirements for the thermal conductivity of heaters used on attic floors, as, for example, when insulating an attic, when it is necessary to make the layer as thin as possible. Those. When equipping a residential attic, it is recommended to use lightweight insulation with a thermal conductivity coefficient of no more than 0.04 W / m ºС, otherwise we will get a layer too thick to be placed between the rafters. And when insulating an attic, the thickness of the layer does not really matter. Therefore, you can choose less heat-efficient materials, but cheaper ones.

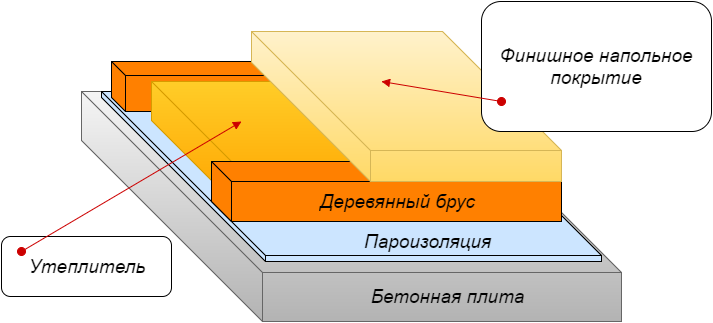

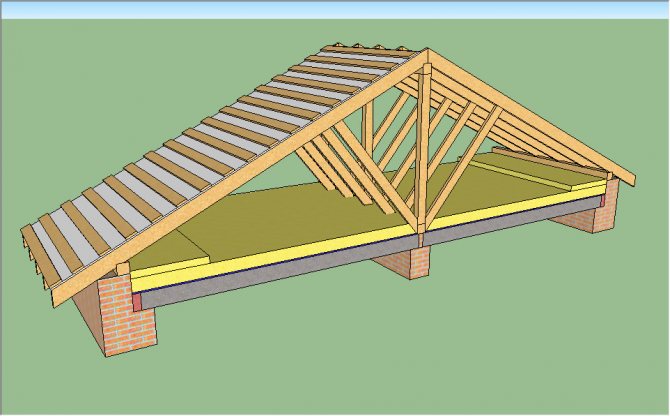

In modern cottage construction, attic floors are most often made either reinforced concrete or on wooden beams.

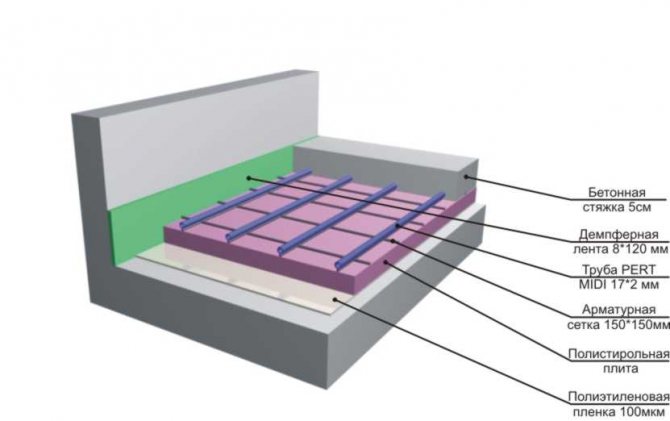

Reinforced concrete floors are either monolithic or prefabricated (from ready-made floor slabs). There are no restrictions on the choice of insulation for them. In addition to lightweight materials, here you can easily use various backfills, which, due to their large mass, for example, are rarely used today in ceilings on wooden beams.

A little about the technology of work. It is necessary to prepare the upper floor surface only in cases when it is not even, and you are going to insulate with materials with a stable shape (polystyrene, expanded polystyrene, EPS, etc.). It is not uncommon for floor slabs to have such a surface, especially if used ones are used. I saw on some sites a recommendation in this case to make a small leveling screed. This is certainly possible, but is it worth it to strain and make such additional expenses. It is much easier to make a small leveling layer of some kind of backfill, for example, ordinary sand.

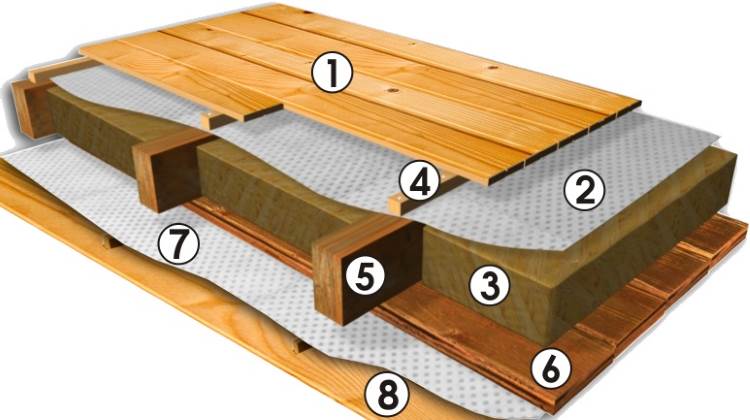

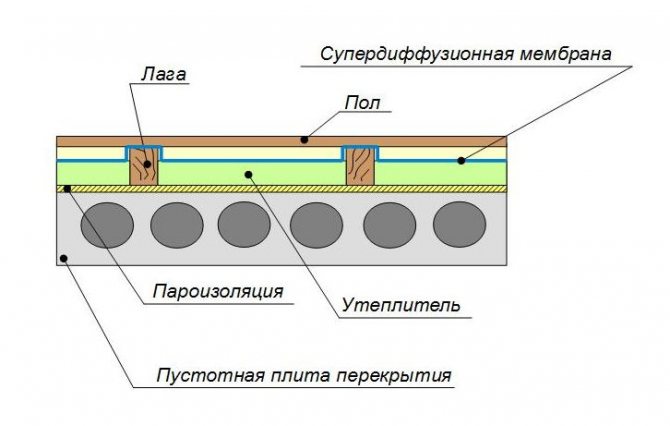

Consider the figure below:

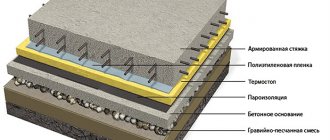

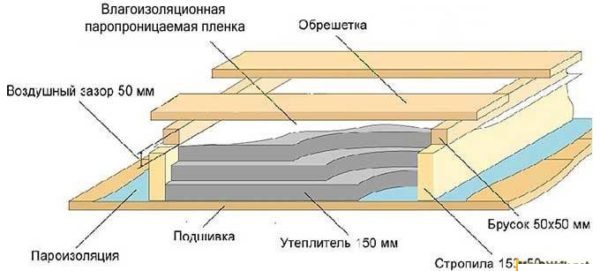

On the ceiling under a layer of insulation, it is necessary to spread a vapor barrier material with a bend in the edges on the walls (a kind of trough is formed). In the most economical version, it is either plastic wrap or glassine. More often now, special under-roofing construction films for various purposes are used, in this case, vapor barrier. So, for example, the vapor permeability of a polyethylene film is 14-20 g / m2 per day, while a modern vapor barrier can be about 0.4 g / m2 per day. There will be a separate article about these materials, which will be released in the near future.

The exception here is the insulation of the attic with extruded polystyrene foam. It is not necessary to do a vapor barrier under it. As a safety net, it can only be done over wet areas, such as a bathroom.

The figure shows that an additional layer of insulation is placed along the perimeter of the outer walls. It is recommended to lay it about a meter wide, and its thickness is equal to half the thickness of the general layer (determined by calculation). This measure allows you to more reliably protect the ceiling corners in the house from freezing. For the same (pay attention to the figure), 5-10 cm of polystyrene foam is laid between the end of the floor slab and the brickwork.

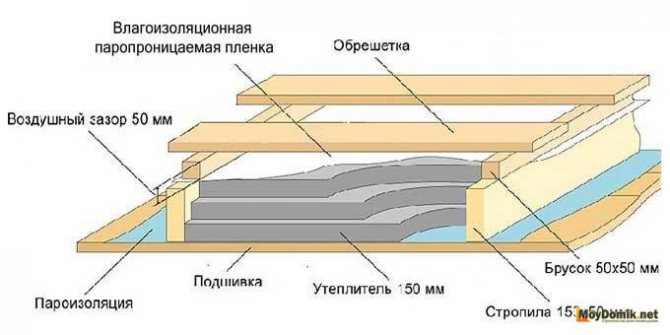

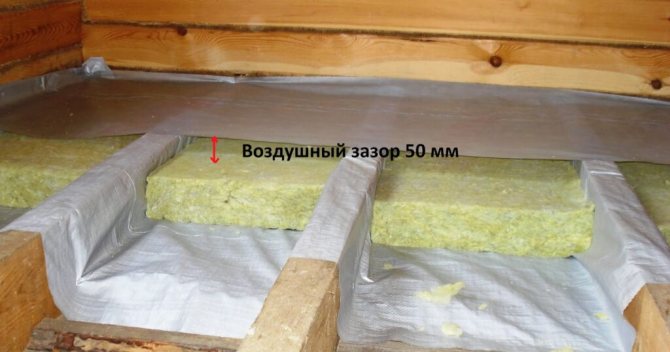

When insulating attic floors on wooden beams, a vapor barrier is also done first, then insulation is laid. Vapor barrier is done either by wrapping the beams from above, or attached to the beams from below, as shown in the first figure at the beginning of the article. I have always preferred the method when the vapor barrier is from the bottom and mineral wool as insulation. Since mineral wool has a high vapor permeability (unlike, for example, expanded polystyrene), wooden beams "breathe" perfectly.

It's another matter if we redo the attic insulation in a not new house, when the interior decoration is done and cannot be touched. This also happens, and here the vapor barrier is already done by wrapping the beams from above.

Nowadays, foam polyethylene with a heat-reflecting surface (foil) is often used as a vapor barrier. In this case, it must be taken into account that such materials retain their reflectivity only when an air gap of 4-5 cm is provided between it and the interior decoration. any finish should be mounted on a rack or aluminum frame, or stretch ceilings are made.

On top of the attic floor insulation, including mineral wool, it is not necessary to cover with any films. All water vapor that can leak out of the house through the vapor barrier layer freely leaves the insulation and is removed outside thanks to the attic ventilation device.

On roofs with roofs made of materials that do not represent a continuous carpet (metal tiles, corrugated board, slate, etc.), a waterproofing film is attached to the rafters before filling the lathing for additional protection of the attic from possible leaks. In principle, a counter grill is not needed here. The best choice in this case is an anti-condensation waterproofing film. It has a rough inner surface (facing the inside of the attic). This prevents possible condensation from accumulating in large drops and falling onto the insulation. It is not difficult to find information about this type of tape on the Internet.

Ventilation of the attic can be carried out through cornices, dormer windows, through a ridge, or through special ventilation elements of the roof. This topic will also be covered in a separate article. Follow the newsletter.

SEE OTHER ARTICLES ON THIS TOPIC:

- Construction of X-shaped (eight-pitched) roofs.

- Construction of a T-shaped roof of a house.

- Installation of an L-shaped roof with gables of various widths.

- L-shaped roof of the house with equal gables.

- Do-it-yourself hip roof of the house.

The best way to express gratitude to the author is to share the link to the article with your friends!

| Parasites live inside everyone! Doctor's advice - take 120 ml of boiling water and ... Read more |

Look, you can "slow down" your electricity meter by 2 times! ... Completely LEGAL! You need to take it to the one closest to the meter ... Read more

How to insulate the attic floor

So, having selected the optimal warm material and having acquired everything you need, it's time to take on a simple but painstaking job (in most cases). It should be noted that depending on the choice of the resource, the installation will become more complicated or simpler as it is done.

Insulation of the attic floor:

- Initially, you should calculate all the parameters (if you did not do it at the time of purchase) - the width, length and height of the floor.

- If the length and thickness are a matter of chance, then the height correlates with several factors, which is why many experts give different indications on this score. Optimally - 250 mm in height, so that the insulation rises slightly above the beams.

- Install an additional bottom layer of steam insulation (if necessary).

Depending on the material chosen, place it in the space between the timber beams and fit tightly. If you use spraying, do it to a solid structure of the formed plaque. Again, if you chose this option - make a surface coating, or start laying the screed.

Competent insulation of the attic floor on wooden beams (video)

Pay particular attention to the mineral wool, or rather to its swelling properties in contact with water. To eliminate such consequences, it is better to provide it with a moisture-insulating film. Approach the issue of construction with due attention and excluding frivolity. Do not forget about ceiling insulation.

Comments (1)

0 Daniel 27.01.2018 07:29 When I equipped the attic, I did not have such knowledge and I simply insulated the attic with foam plastic, without air gaps, it was my mistake, but as it is, if this information turned up to me at that time, I did everything would be as it should. Competent information.

Quote

Refresh comment list RSS feed of comments for this post