The first mention of expanded clay dates back to the 19th century. Even then, the question arose as to what the material was named after. It is clear that the Greek keramos, as we understand, is associated with clay and the ceramics produced from it. What does zit mean, there are discussions.

In the photo, expanded clay building material

A similar word was found only in the Czech language. There the concept is translated as "live". The relationship with clay is unclear. Therefore, probably, Americans and Europeans call the hero of the article haidit, from the surname of the scientist who patented the technology for the production of expanded clay. He claimed his rights in the 1920s.

What is expanded clay

Externally, expanded clay is brownish granules of different sizes, round in shape. Particle contours are irregular, asymmetric. The surface of the granules is porous and rough. The material is warm and firm to the touch.

Expanded clay is produced from low-melting clay grades. The quartz content in these is less than 30%. The material acquires porosity in the course of reaction with diesel fuel, fuel oil or iron oxide. They are the ones who expand the baking clay. Without baking, expanded clay would not be hard.

In terms of application, expanded clay - a versatile material. He, for example, is poured into the bottom of flower pots. There, the hero of the article performs a drainage function. The porosity of the material allows it to absorb excess water, preventing root rot. When the soil is dried up, expanded clay, on the contrary, gives off moisture, allowing the plant to "get drunk".

Thermal insulation of the floor with expanded clay

The process of floor insulation includes the following stages:

- The soil under the coating is tamped properly. Then sand, which is mixed with gravel, is poured into a thickness of up to 15 cm.

- After that, the laying of waterproofing made of polyethylene is done in such a way that the entire space is filled. The seams of the strips are glued with construction tape, the edges of the waterproofing should go to the walls.

- Rough bars are laid on the waterproofing, used as the basis for the logs. Boards are laid between the beams to create sections for expanded clay backfill.

- The base is covered with insulation (granules up to 80 mm), the height of the layer is 15 cm. The logs are mounted on top.

- A moisture-proof membrane is laid on top of them, then the topcoat is installed.

The main principle of wall insulation is the filling of dry expanded clay into the voids. Insulation technology:

- The surface is dismantled and cleaned from dirt.

- Waterproofing is being installed. The film is mounted with an overlap, the joints are glued with special tape.

- Heat insulation is filled up.

- The leveling screed is poured.

Various structures can be insulated with expanded clay, including the floor. A fairly common technology is the addition of expanded clay to the cement mortar. Among other advantages of this method is the improvement of the thermal insulation properties of the floor. It is important to remember that the heat-saving properties of different grades of material differ from each other.

The ratio of the cement-sand mixture to the filler should be approximately 2 to 1. The consistency should be a structure that resembles a thick dough. Even experienced builders do not dare to name the exact proportions, because in the process of work, different brands of cement and expanded clay granules can be used. A sign of the correct ratio is the enveloping of the filler with a solution.

We offer you to familiarize yourself with: Fire safety of baths and saunas

Beacons are installed on the floor with the help of plaster, after which the solution is applied with a trowel and leveled with a rule. If the top coating is a concrete floor, then a solution of plain concrete should be laid on top of the expanded clay screed.The floors dry out after two days, but the floor covering can only be laid after a month.

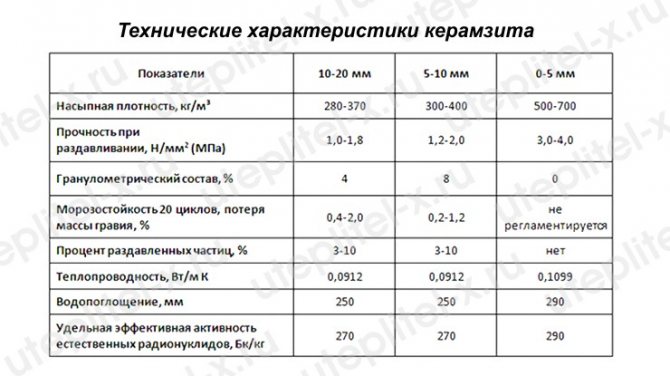

Properties and characteristics of expanded clay

As drainage fractions of expanded clay used for filling roads. It is important to "plant" them on a clay mound when the soil is saturated with groundwater. Expanded clay becomes an obstacle on their way to the road, the destruction of its canvas.

Foamed and baked clay granules are also called expanded clay gravel. The pores in it are easily filled not only with water, but also with air. The latter does not conduct heat and cold well. Therefore, dry granules serve as insulation in floors.

Expanded clay screed

In a dry screed, only expanded clay is used. It is evenly poured under wooden logs, on which sheets of plywood or boards are laid. Here, the hero of the article not only retains heat, but also eliminates the creaking of the floor. Screed with expanded clay limits the possibility of movement of boards prone to drying out and change in shape, and the support for plywood sheets turns out to be solid.

Floor with expanded clay in a dry screed it is as warm as possible, because the air is locked "not only in the pores of the clay, but also between the granules from it. If a wet screed with expanded clay is made, the gravel is inside a concrete slab instead of rubble.

The latter will not give heat, it will only strengthen the layer like reinforcement and reduce the cost of filling. According to the price tag, quarry is comparable to expanded clay, only the latter gives the floors the necessary warmth and soundlessness.

A building block is made from expanded clay

The air, like the temperature, is reluctant to transmit noises. Therefore, the expanded clay screed protects households from outside sounds, and neighbors from the details of the life of the apartment owners. In a private house, you can exclude audibility between the basement and first floors, between the first and attic.

Heat-conducting networks, foundations, walls are insulated with expanded clay. In the "fight" with competitors, the hero of the article wins due to environmental friendliness and antiseptic properties. The bacteria prefer to stay away from the clay granules.

The fire also keeps away. Clay belongs to rocks, composed of particles of quartz, aluminum oxide, sometimes, particles of carbonate rocks. All these are stones, and all are non-flammable. Where synthetic insulation like expanded polypropylene flares up, expanded clay will remain unapproachable, moreover, it will not emit harmful substances when heated.

Expanded clay is used in the construction of houses for insulation

Time thermal insulation with expanded clay possibly due to the filling of gravel with air, which means that the material is light. The exact weight depends on the species. Granules are of different sizes, but they differ slightly within the same brand.

There is, for example, expanded clay sand, fraction from 5 to 10 millimeters in diameter, from 10 to 20. In total, there are 11 species. There are 0.2 grams per cubic centimeter of the 250th. Expanded clay weight brand "M-300" is equal to 0.3 grams for the same area. 0.05 grams is added to the "M-350". Respectively, expanded clay cube weighs about 300 pounds.

Considering the lightness of the hero of the article and its heat-saving properties, granules are added to concrete building blocks. The result is strong and warm slabs that reduce the load on the foundation.

Plus, lightweight blocks are easier to work with. Like aerated concrete, blocks with expanded clay can be folded into a one-story house by a couple of people. One stands on the wall and fixes the "bricks", and the second feeds them from below.

Description of expanded clay

Expanded clay is a porous lightweight material that has a low weight and can also be produced by firing clay shale. Expanded clay gravel has an oval shape. As for expanded clay crushed stone, it has one difference, which is that the grains have a cubic shape with sharp corners and edges.

Expanded clay is a material that is also made in the form of sand.Depending on the technology used to process shale or clay, it is possible to obtain the final material with a certain bulk density, which is also called bulk density and varies from 350 to 600 kg / m³. However, this value can be higher.

Production and use of expanded clay

Initially, expanded clay was obtained by burning a mixture of clay with dust or sawdust. A kind of cakes were formed in the furnace, which were broken after firing. Such expanded clay in bags sold in the 19th century.

Modern production of expanded clay begins with crushing the rock with rollers. They are also suitable for the production of shungizite, which many confuse with the hero of the article. However, shungizite is made from shale chips, not clay.

The material is more resistant to aggressive environments and less moisture-consuming. However, in terms of thermal conductivity, shungizite is inferior to expanded clay and externally differs from it. Quartz granules are darker.

The clay crushed on the rollers is sent to the kiln drum. Its diameter reaches 5 meters. The unit can be as long as 70. The high temperature inside the drum is maintained by the nozzle. The heat dries up the clay.

If you need the most warm and almost non-water-absorbing material, the rock is melted. The dense crust protects the granules from water. At the same time, cavities with air are formed inside the expanded clay. The process is spurred on by additives such as iron oxide that are sent to the drum.

To the ground, the expanded clay drying drum is inclined. The formed granules are poured into the receptacle by gravity. Further, the products are packed in polypropylene bags or sold in bulk.

Decorative expanded clay

They hone the nuances of the production of the hero of the article and come up with new approaches at the Research Institute "Keramzit". This is the only research institute in Russia where clay granules are being specifically studied and experimented with.

The research institute is located in Samara. Rare black clay is also mined there. The rock is extracted from a 7-meter depth. Expanded clay turns out to be dark, like shungizite, and has something in common with its properties. Black clay is less porous and more durable than red and white varieties.

In the use of expanded clay, its strength is important. A screening test is done. The granules are poured onto the asphalt and pressed with your foot. If the "beads" are crumbled, but expanded clay price for 1 m3 high, requests are unreasonable.

Expanded clay is produced in various fractions

It is worth overpaying for the granules that remain intact. However, in some areas, the strength of the hero of the article is secondary. In the floor screed, for example, the granules will strengthen the concrete, and the dry backfill will cover and protect the final coating. The main thing here is the heat capacity of expanded clay.

Within the walls of the laboratories, you can also check the radioactivity of the hero of the article. This was done, for example, in Chuvashia. The expanded clay concrete produced here was sent to the center of hygiene and epidemiology.

They checked it according to the method certified at the Mendeleev Research Institute. The radioactivity of the blocks is several times lower than the norm permissible for building materials. Since radioactive nuclides are contained in the earth's crust, they also end up in human-made products.

Expanded clay is used in landscape design

It is important that the radiation from it is not overly active. As for expanded clay, the background in some samples is completely absent. So, the material can be easily used by people with a phobia of radioactivity and all those who wish to protect themselves and their families as much as possible.

There are no phenol, formaldehydes and other non-radioactive, but harmful and volatile components in clay granules either. However, this is a moot point. Working with low-quality clay, its properties are improved with the help of synthetic additives. They can be identified, again, only by an examination in the "Center for Standardization", "Rospotrebnadzor".

Equipment for the production of expanded clay

Necessary equipment

A large number of equipment is involved in the production of expanded clay, each of which contributes to obtaining a high-quality mixture. The main devices include:

- different rippers;

- drilled rollers;

- clay mixers;

- kilns for roasting;

- drums for drying and sorting;

- conveyors;

- conveyors;

- trays, etc.

Industrial production includes many devices that help you quickly handle large volumes of material.

Since almost any method of shaping involves primary processing, crushing devices, consisting of solid blades that move towards each other, will definitely be needed. In this case, all materials falling between them are cut and shredded. If it is envisaged to add special mixtures to improve the swelling, the mixing plant must be prepared.

Firing kilns are different, but most often they work on the same principle, evenly heating all substances that get inside.

Pros and cons of expanded clay

Let's start with the flaws. Purchase for construction works expanded clay m3... There is a lot of dust in cubic meters of material. No matter how strong the granules are, the clay microparticles still detach from them. Therefore, it is better to work with expanded clay in a mask. The process is dusty in the truest sense of the word.

If expanded clay is used as a heater, the granules must be waterproofed. Though slowly, the hero of the article absorbs moisture. By filling the pores in the clay, it squeezes out the air. Expanded clay loses its ability to retain not only heat, but also noise.

Insulation of the ceiling with expanded clay

Liquid mixtures based on bitumen or roll materials are used as waterproofing. The latter include, for example, hydroisol. However, plain polyethylene is also suitable for floor stitching. It is often taken as a vapor barrier underlay.

High-quality thermal insulation with expanded clay is achieved only when the granules are backfilled with a thick layer. 40 centimeters is the minimum. Not every building has the ability to "throw out" so much usable area. It is acceptable in a private house on the ground floor, but rarely in an apartment. It is also problematic to insulate the roof with a 40-cm layer of expanded clay.

Moving on to the pluses of the hero of the article, here are the numbers. The service life of a wooden screed with expanded clay reaches 50 years versus 25-35. The hero of the article itself does not collapse even longer. Retaining properties for centuries. Expanded clay is not called gravel for nothing. We are dealing with a stone. It is formed artificially, but carries the "baggage" of the natural.

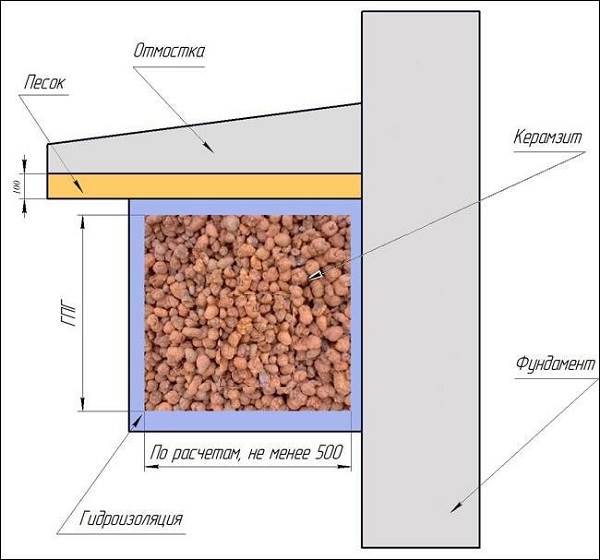

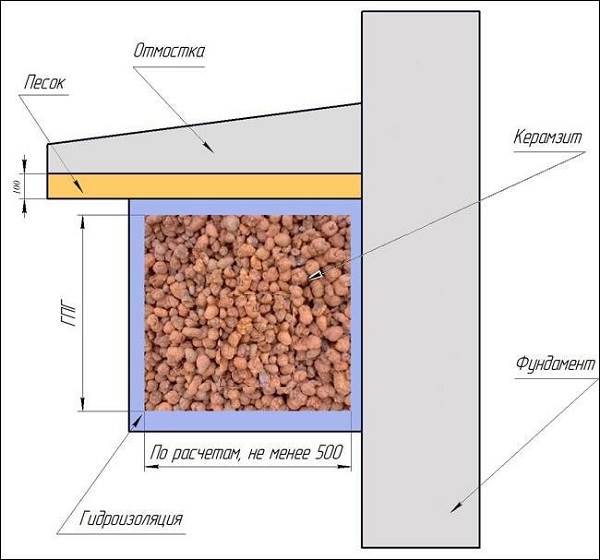

Warming the foundation with expanded clay

It takes no more than an hour to make the hero of the article. Usually, it is 45 minutes. The speed of the process indicates its simplicity. This means there are no extra costs. Hence the low price of granules "follows". This is another plus of the material. Let's talk about specific numbers.

Scope of use of expanded clay

At first it may seem that the area of application of construction expanded clay is small, but this is not so. Granules are characterized by excellent thermal conductivity, and a warm home will be cozy. It is this property of the material that allows it to be used for thermal insulation of floors, ceilings, for insulation of the attic. At the same time, thermal insulation is not the last useful property of granules.

The advantages of expanded clay include sound insulation and "underlying" properties. Such characteristics indicate that the granules can be used as a base when creating a concrete screed. Also, granules can be used for filling the foundation during construction work. Thanks to the use of expanded clay, it is possible to reduce the depth of laying the foundation by almost half, which not only saves building materials, but also speaks of the possibility of preventing freezing of the ground near the foundation.

This material is often used during the construction of baths - it is necessary for high-quality insulation of the floor and walls. And all thanks to the fact that with the help of granules you can achieve a suitable temperature and maintain it for a long time. If you are thinking about laying pipes, you can consider buying expanded clay. First of all, you will be sure that the pipes will warm the house, not the ground.

And if an accident occurs, there will be no need to waste time digging through the entire earth. The third advantage is that after the repair, you can reuse expanded clay, which will not lose its properties. In addition, this building material is suitable for the improvement of garden paths in the garden or the creation of a drainage system on the site, which will lead to an increase in yield. The main thing is to buy small granules.

Expanded clay price

Expanded clay is packed in bags, as a rule, at 0.04 cubic meters. Together with the packaging, it costs 120-600 rubles. The exact price tag depends on the fraction, the type of clay used and the need for delivery of raw materials. In regions with rock deposits, expanded clay, as a rule, is produced and immediately sold. In other areas, the goods are transported, which adds to the price.

In Russia, expanded clay has been in price since Soviet times. Then the hero of the article helped the country to step over to the stage of industrial construction. Socialist attitudes demanded that all citizens be provided with housing.

It was necessary to build quickly, from light and affordable materials. We developed standard projects of box houses and added expanded clay to concrete slabs for apartment blocks. It turned out faster and warmer than conventional blocks.

The citizens of the USSR also appreciated the silence in the apartments. Houses with them stand to this day. After the overhaul, Khrushchev's new buildings will last for decades. Keeping this in mind, expanded clay continues to be purchased for construction needs.

How to determine the required volume of expanded clay

If there is a need to carry out thermal insulation inside or outside the room, then the question arises of how much to buy building material. In this case, we are talking about expanded clay. If you, too, are among those who are wondering how many cubes of expanded clay are needed, it is important to calculate how much material is in one cube.

The weight of expanded clay will depend on the grade and density of the internal structure, as well as the moisture content and size of the fraction. As practice shows, 1 cube of expanded clay weighs from 200 to 400 kg. For a visual representation, it can be noted that one cube of expanded clay is 20 bags of 50 kg, 25 bags of 40 kg or 40 bags of 25 kg.

Application

The scope of expanded clay is very wide. Products of this type are used for the following purposes:

- Production of expanded clay blocks;

- Sound insulation and insulation of such elements of buildings and structures as roofs, walls, foundations, floors;

- Structures of dams, bridges, roads and other structures;

- Making "warm" mortars for masonry work;

- Arrangement of drainage elements for growing plants;

- Insulation of pipelines;

- Water purification from various impurities (filtration).

Depending on the type of work and the nature of the tasks that need to be solved by using expanded clay, the material of the most suitable fraction is selected. Thus, expanded clay sand, the granule diameter of which does not exceed 3 millimeters, is widely used for the preparation of “warm” masonry mortars. This is due to the fact that it is the seams in terms of thermal resistance that are considered the weakest link. And if the “cold” solution of cement and sand has a high level of thermal conductivity, then replacing it with expanded clay reduces the heat transfer coefficient by almost 3.5 times.

Material of fraction 0-5 millimeters is mainly used when making screeds. The use of expanded clay for this purpose makes it possible to make the floor that retains heat much more efficiently.The material of this fraction is also used as a filler in the production of concrete products for various purposes, in the arrangement of hydroponic and drainage systems in crop production.

Expanded clay gravel, the granule diameter of which is 5-10 millimeters, is one of the most demanded. It is used as a backfill for gypsum fiber sheets in the process of arranging "warm" floors, manufactured according to German technology, as well as for insulating building facades. In the latter case, expanded clay gravel is mixed with the required amount of cement, after which the resulting composition is poured into the space between the cladding layer and the surface of the bearing wall. This insulation is called capsimet. Expanded clay of 5-10 millimeter fractions is widely used for the manufacture of various concrete products, for example, at the output, material is obtained in the form of building blocks, which have all the advantages of this natural material.

Gravel of fraction 10-20 millimeters is an excellent insulation for walls with well masonry, for wooden floors, roofs. It is also used in the arrangement of sewerage systems, water pipes and other communications.

A distinctive feature of expanded clay with a granule diameter of 20 to 40 millimeters is its low bulk density in comparison with gravel of other fractions. In this regard, it is often used as a heater for filling attic rooms, cellars, foundations, since in such cases there is a need to obtain a large heat-insulating layer. Expanded clay of this fraction is also considered the optimal choice for arranging drainage systems, when planting rather large shrubs and trees.

Advantages and disadvantages of expanded clay

Many people who use expanded clay to insulate their homes are satisfied because this building material has high thermal insulation qualities and is also not expensive at all.

Strengths:

- Excellent thermal conductivity;

- Light weight (convenient for transportation, as well as for stacking);

- Ecological cleanliness;

- Low cost compared to similar heaters;

- Based on these advantages, expanded clay can undoubtedly be estimated at 5 points.

- The disadvantages are:

- The need to use a thick layer of expanded clay, otherwise it will not be enough for proper heat and sound insulation;

- It is highly susceptible to moisture, therefore it is necessary to either use a plastic or waterproofing film.

Table of used expanded clay fractions and their features for the construction of various structures

| Design | Fraction, mm | Water content,% mass | Thermal conductivity, W / mK |

| Roof | 10-20 | 0,5 | 0,09 |

| Interfloor overlaps | 4-10 | 0,5 | 0,11 |

| Ground contact floors | 10-20 | 6 | 0,12 |

| Geotechnical | 10-20 | 30 | 0,19 |

The disadvantages of expanded clay are quite insignificant and are fully covered by its advantages.

Due to the fact that expanded clay has an excellent pricing policy, it is very convenient and practical to use. The appearance is extremely attractive and is widely used in decoration. The material is environmentally friendly and harmless, in addition, expanded clay has a fairly simple production process. Based on this, it is possible to give this building material an assessment of 4.5 points.