Insulation vermiculite features and application

Vermiculite composition and processing

Vermiculite contains several components linked by one chemical formula. Most of all it contains silicon - about 35%, there is also 10% magnesium, iron, potassium, calcium, etc.

Natural vermiculite is a large, flaky crystal. From exposure to high temperature, they are transformed into twisted twisted filaments-columns, increasing in volume up to 10 times.

When the material is heated over 1000 degrees, expanded vermiculite is obtained - a light free-flowing material, brownish, golden in color.

Hygroscopicity

The main distinguishing feature of expanded vermiculite (hereinafter referred to as vermiculite) is its high hygroscopicity. 100 grams of material can absorb up to 500 ml of water. But vermiculite is just as easy with water and parting.

In fact, it is a natural hydraulic accumulator. Therefore, it is mainly used in plant growing, as an additive to the soil.

Thermal insulation

Another feature of the material is its high thermal insulation qualities. The thermal conductivity coefficient of bulk vermiculite is in the range of 0.05 - 0.07 W / (m * K), depending on the size of the fractions and the density of the rammer. That makes it possible to use the material as an effective insulation.

1 mm, 120 kg / cubic meter - 0.059

2 mm, 110 kg / cubic meter - 0.057

4 mm, 95 kg / cubic meter - 0.054

8 mm, 65 kg / cubic meter - 0.052

The use of vermiculite as insulation

It is effective to use vermiculite as a bulk insulation for thermal insulation of floors and ceilings. And also for filling various cavities in walls, partitions, pipe boxes ....

When used on attic floors, a reliable waterproofing is required on the roof side, as well as covering the material layer with a vapor-permeable membrane (paper layer). On the side of the room under the material there must be a vapor barrier-film

During installation, special attention is paid to ensuring continuity

Special use

Rigid slabs are made from vermiculite. They are more expensive, but they can be used instead of mineral wool, as they have similar characteristics.

Basic properties

Hydromica is not used in its natural form. The mineral serves as a raw material for the production of expanded vermiculite, which is widely used in many industries. The swelling process requires a temperature of 400–1000 ° C. Heating contributes to the separation of the mineral, which occurs due to the presence of water in the composition. Gradually turning into vapor, the liquid causes the mica to separate.

The volume of the material can increase 20 times. When exposed to high temperatures, cooling down, it retains a scaly structure. Then it is crushed to obtain a fraction of 5–20 mm.

Nomenclature

Expanded vermiculite is produced in accordance with TU 5712-091-00281915-2007 and is subdivided into grades depending on the bulk density and grain size of the main fraction.

VVF means Expanded Fractionated Vermiculite. Grade 100 means that the bulk density of vermiculite is not more than 100 kg / m³.

St. Petersburg Mica Factory offers expanded vermiculite:

Most heat insulators have one or more flaws - they are either fire hazardous, expensive, or not environmentally friendly. In search of the best option, developers are often interested in the idea of using vermiculite in this role - a layered mineral that changes its structure at high temperatures and acquires new properties that, at first glance, are quite suitable for insulating a building. How versatile is such a heater, does it have any drawbacks, and how to use it correctly?

Disadvantages of expanded vermiculite

The material has few drawbacks, these include its significant hygroscopicity, which requires the use of a diffuse membrane when laying insulation.Such a cloth provides protection from moisture and free steam escape.

The second drawback is the cost, among the bulk insulation, vermiculite stands out for its high price. The durability of operation and excellent characteristics fully justify the choice of this material from similar heaters.

Expanded clay properties

- high strength

- fireproof

- frost resistant

- does not contain harmful impurities;

- does not absorb water;

- durable

- does not lose its properties and does not collapse when frozen

- not subject to decay

Absolutely safe for humans and the environment.

Expanded clay is a product of fast firing of low-melting clays. From Greek, the word "expanded clay" is translated as "burnt clay", which is absolutely true. Despite the heat treatment, it not only does not lose the properties inherent in the clay itself, but also acquires additional, becoming porous.

Photo: Properties of expanded clay material. Application area

On their basis, kermzite-concrete blocks are made, the thermal insulation and mechanical properties of which make it possible to use them for the thermal insulation construction of floors, walls, ceilings, foundations and basements. Thanks to the expanded clay filler, these blocks also acquire its properties. They are lightweight, durable, fireproof, acid resistant, etc.

How to distinguish vermiculite

Geologists know this material as hydromica. Vermiculite got its name from the Latin "vermiculus" - "worm" (it contains worm-like silvery or golden scales, which are easy to detect when vermiculite is heated).

It is formed as a result of two processes: weathering and hydrolysis.

In appearance, these are golden brownish plates.

In gardening, the so-called agrovermiculite is more often used: it is the same mineral, but fired in the oven (this gives the material sorption properties, thanks to which it is so valued).

Its pluses

- It cakes less than perlite.

- When filling the pot, no voids are left.

- Vermiculite stones are not sharp, so they will not hurt even the most delicate roots.

- Holds water for a long time, so it will help out if you constantly forget about watering.

- When watering, it does not float (especially in soft and loose soil), unlike perlite.

- Due to its rich composition (more on that below), it is better suited for rooting cuttings.

Applications

Discovered relatively recently, a mineral such as vermiculite and its derivatives have found many different fields of application today:

- Ecology, oil and chemical industries. Few people will be able to answer when asked about vermiculite, that it is an excellent sorbent capable of binding alkalis and acids. This property allows it to be used to neutralize a variety of chemicals in production, as well as to limit oil spills.

- Nuclear industry and power engineering. It is used as an absorber for radioactive elements such as cobalt-58, strontium-90 and cesium-137, as well as a reflector of gamma radiation.

- Automotive and aviation industry. Various sound-absorbing and heat-insulating materials and products are made from vermiculite.

- In industrial and civil construction, vermiculite is used as follows:

insulation, as well as sound and heat insulator for roofs and floors;

- for filling as an insulating material into hollow panels;

- as an integral component of various plasters, lightweight concrete and dry building mixtures;

- in the manufacture of concrete and cement blocks, as well as heat-insulating mastics as a filler;

- in the production of fire retardant and heat-resistant plates, panels and other wall materials;

- when arranging self-leveling floors.

5. In industrial and private plant growing and horticulture. Let's take a closer look at how vermiculite is used for plants.

Scope of use

To the pluses of the material, you can add its versatility. It is used for different purposes in different ways.

For example:

- As a backfill insulation for frame structures and for well laying. In this case, you do not need to protect it from moisture.

- In the form of insulation backfill for the floor, attic, roof.

- The material is added to masonry mortars when the walls of the house are erected from aerated concrete blocks.

- Raw materials are added to plaster solutions to provide sound and thermal insulation of walls inside and outside, as well as partitions.

- The properties and internal structure of the insulation allows the use of material in the form of slabs and plaster to protect metal or other supporting structures from fire.

- By adding backfill to the floor screed solution.

- As a filler for decorative plaster.

- Agricultural use to improve soil, fertilize it and do mulching planting.

As for private housing construction, vermiculite is most often used for wall insulation.

Technologies for stacking vermiculite building materials

Work with mineral insulation is not difficult or harmful - according to the degree of impact on the human body, the vermiculite coating, according to GOST 12.1.007-76, belongs to class IV (low-hazard substances). To prevent dust from entering the eyes and respiratory system, before using vermiculite, the worker should protect them with glasses and a respirator. Provided that the building material is stored in dry, closed rooms, its shelf life is unlimited.

Thermal insulation of building envelopes with backfill vermiculite

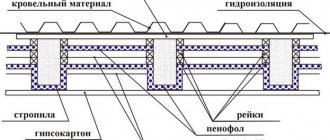

To protect the attic ceiling and the pitched roof surface from heat leaks, you must follow a simple algorithm:

- Cover the inner lining with an overlap with a vapor-tight film, which will prevent moisture from entering the vermiculite from the inside.

- Pour dry vermiculite into the formed cavities in the roof frame.

- On top of it, lay a windproof superdiffusion membrane, the task of which is to prevent the material from weathering and at the same time allow vapors to circulate freely.

- Install the counter-batten and lay the roofing.

The insulation scheme for attic floors is, in principle, the same:

- Reliable waterproofing is placed on the filing between the beams.

- A lag system is mounted, with a layer of 100–150 mm.

- A bulk insulation for the floor is introduced, which must be immediately covered with a vapor-permeable film.

- After installing the plank or plywood flooring, the floor is ready for finishing.

- To reduce material costs, vermiculite can be mixed with sawdust in a 1: 1 or 3: 2 ratio.

The layout of the insulation of frame wooden walls

Filling vermiculite into the walls is possible at the stage of their construction using frame or well technology, or in the process of external insulation. To do this, as the load-bearing wall and facing layer are being erected, the space between them is filled with vermiculite granules with light tamping. The approximate layer thickness is 100 mm (for Moscow). Additional vapor and waterproofing is not required, ventilation gaps in the outer wall are also not required.

Another way to create an insulated wall is to fill the cavities of the building blocks with vermiculite. The thermal insulation effect of such a structure increases dramatically, and the free steam exchange in the wall is not disturbed, and it remains light and breathable. If necessary, the outer wall can be further insulated if it is erected from concrete panels based on fast-setting cement with the addition of bulk insulation for the walls.

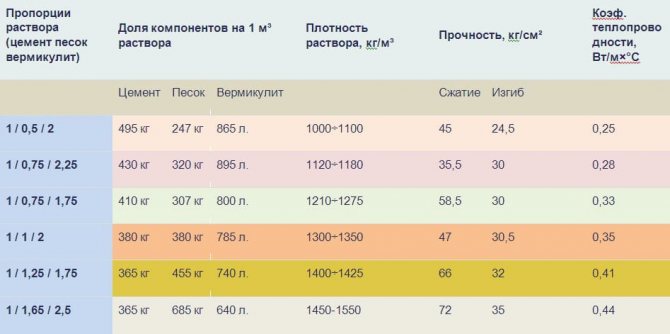

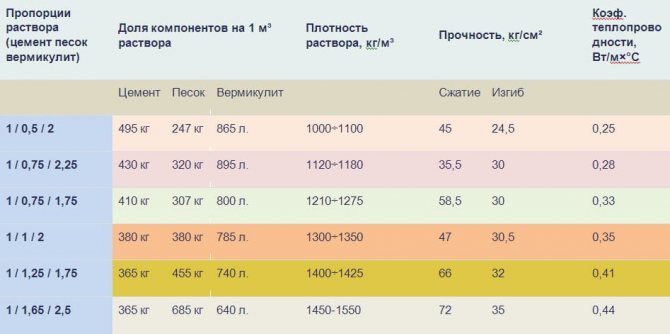

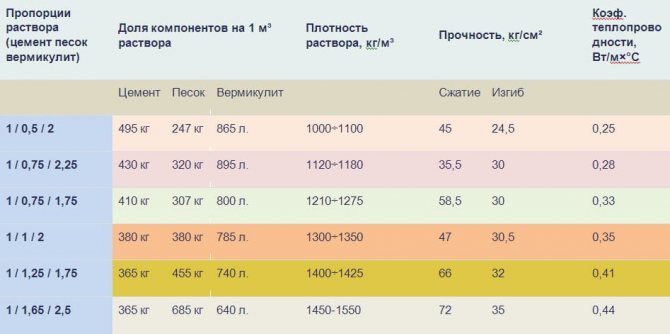

Proportions of mortars for screeds

Warming with dry vermiculite is a rather expensive solution, therefore in private construction they prefer to add this material to the composition of building and finishing mixtures.To prepare a solution for a thermally insulated screed, you need to stock up on standard M400 Portland cement, sand and fine or medium-fraction vermiculite. Due to its high water absorption, the solution must be consumed within 30 minutes after mixing.

For reliable insulation of the floor over an unheated space, 100 mm of the screed is usually enough, and for interfloor floors, 30 mm is enough. It must be remembered that the flooded ceiling, due to the small mass fraction of cement, does not have frost resistance, therefore, such screeds are recommended only for heated rooms.

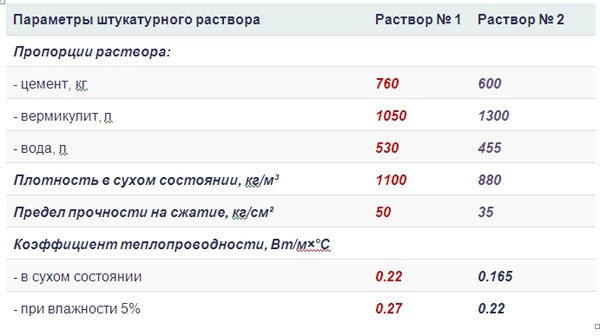

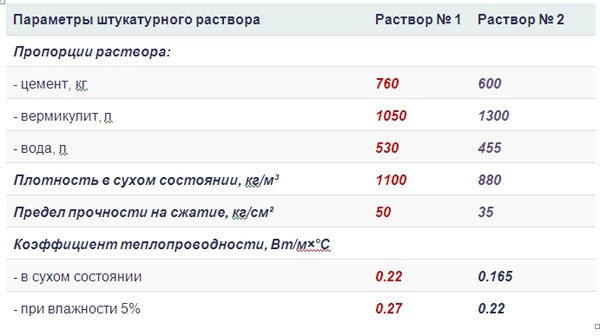

Recipe for plastering solutions for outdoor use

To plaster the walls from the inside, you can use the same composition, and for their external treatment, the proportions of the solution must be slightly changed. Both external and internal plasters have high vapor permeability, contributing to the normal self-regulation of the internal microclimate. Warm vermiculite-based plasters have a natural golden or silver sheen, but if desired, you can add pigment of the desired shade to their composition.

Interior plaster: C - cement, I - lime, G - clay, V - vermiculite

When laying walls, it is advisable to use modern thermal insulation materials (gas, foam blocks, vermiculite concrete), and the joints between them should be made of masonry mortar with a low thermal conductivity coefficient. You can knead it using the same vermiculite, having previously determined the optimal composition.

Thus, the demand for vermiculite in construction is obvious: excellent manufacturability and a unique combination of properties bring vermiculite backfills and slabs to the fore among fire-resistant insulation materials. The only significant obstacle to expanding the scope of their application is the high price, but the increase in production gives hope that it will soon be eliminated.

How are agroperlite and vermiculite similar and different from each other?

Agroperlite and vermiculite are similar and at the same time different from each other. - Vermiculite is specially processed mica, a sheet-structured mineral, and perlite is a foamed volcanic glass. - Vermiculite, unlike perlite, does not produce dust. But at the same time, many experienced gardeners advise rinsing it before use, but not for long, too long rinsing destroys the vermiculite plates. You can without rinsing, just sift the vermiculite through a flour sieve. - Perlite is inert from the point of view of plant nutrition (all substances in it are in a bound state, not assimilable by plants), but vermiculite contains potassium and magnesium in an accessible form. - The color of perlite is white, which determines the good reflectivity of the material, that is, the perlite in the upper layer of the substrate is able to easily reflect light on the lower surface of the leaves (as if further illuminating the plants from below). The color of vermiculite is silver or golden, its reflectivity is lower. - The presence of both components in the soil will not allow the substrate to overheat in hot weather, and in cold weather will protect against hypothermia. - Perlite, due to its inertness, is very popular for use in hydroponic culture. Here it is used both in pure form and in a mixture with vermiculite. - Both are widely used for rooting cuttings and germinating seeds.

- Both are not subject to decay and decay: their use reduces the risk of pests and the development of mold, which is especially important for seedlings. They can also be used for winter storage of bulbs and tubers. - Both are used as a drainage layer, large fractions are suitable for this. It is poured into the bottom with a height of 5 cm. Can be mixed with expanded clay.- As with perlite, the reaction of vermiculite is close to neutral, therefore their addition to the soil mixture can reduce its acidity (used in conjunction with peat). - Vermiculite and perlite can theoretically be reused (vermiculite after calcination, perlite after steaming), but practically unrealistic, since it is very difficult to separate them from the soil at home.

Why should perlite be used in conjunction with vermiculite?

Perlite with vermiculite complement each other perfectly: perlite conducts water well, but retains moisture poorly. On the contrary, vermiculite retains moisture, but becomes dense and makes it difficult for oxygen to access. Together, it is the ideal soil improvement compound. They are introduced into the soil by 15% of each of them, bringing the total presence in the substrate to 30%. It is common for flower growers to grow plants in a mixture of pure peat, perlite and vermiculite. In this case, the lack of nutrients helps to accurately calculate the required doses of fertilizers and the time of their application.

However, you should not add a lot of vermiculite to substrates intended for cacti and succulents; for these drought-resistant plants, it is better to use perlite as a loosening component.

Perlite for plants or vermiculite - the names of these substances are probably familiar to you, since they are often included in the list of ingredients of various earth mixtures, substrates. If you do not know what it is, then in this article I will talk about the properties of perlite and vermiculite, as well as how these materials are used by gardeners, gardeners, flower growers.

Vermiculite, perlite, photo:

Until recently, these components were not widely known to flower growers and gardeners. Today they are freely sold and are also widely used in crop production. They contain ready-made soil mixtures mixed with each other in different proportions. For rooting shoots, as well as for storing tubers, bulbs, pure compositions of this or that material are used.

Insulation properties vermiculite

Insulation vermiculite is a material that is widely used in construction and finishing works in the construction of new buildings, in carrying out major and current repairs of old buildings. It is used in the form of pressed plates, as a filler and as an additive to plaster mixes. It is used to insulate walls, floors, attics and ceilings. Vermiculite insulation is carried out during the construction of pipeline systems and highways for various purposes, which significantly extends their service life. This has a positive effect on the operation of the equipment and pipeline fittings installed for the smooth functioning of the entire system.

Technological features

Vermiculite in the form of slabs and in bulk.

Vermiculite is an environmentally friendly material created by nature. Refers to the minerals of the hydromica group. Has a crystalline form of golden brown, yellowish or bronze color. It was found that when the vermiculite plates are heated, they are transformed into threads or worm-like columns. Actually, this property made it possible to give the material such a name, tk. vermiculite translated from Latin means a worm. After examining its physicochemical properties obtained after heating, vermiculite insulation began to be used in various industries, agriculture and construction. Also read: "Choosing the best insulation for the roof."

The main advantages of the material include:

- fire resistance (1350 0 С);

- density (not higher than 150 kg / cubic meter);

- low thermal conductivity (no more than 0.12 W / m * K);

- resistance to aggressive media, bacteria and does not form mold on the surface;

- hygroscopicity;

- the ability to absorb sound (sound absorption coefficient up to 0.8);

- environmental friendliness;

- service life (60 years).

Before pouring antifreeze into the heating system of the house, you need to clean the pipes and batteries from all kinds of contaminants.

Here you can read what equipment is needed for pumping the heating system with antifreeze (non-freezing liquid).

Ways to insulate walls with vermiculite

View of a wall plastered with a solution with the addition of vermiculite.

Vermiculite insulation of walls is carried out in the process of erecting new buildings and objects of old buildings, erected from different materials. Bulk thermal insulation can serve as a filler in the manufacture of heat-resistant concrete and is used for plastering surfaces. It is produced in different fractions (from 0.5 to 12 mm) and is sold in the retail network in paper bags, most often weighing 25 kg.

Granular vermiculite can be poured into inter-wall cavities. The pressed plates are fixed with special fasteners; they can be cut before assembly. Slabs can serve as good insulation when cladding fireplaces, stoves, chimneys and pipes. Vermiculite for ceiling insulation additionally performs soundproofing functions in multi-storey buildings.

Vermiculite insulation, the properties of which remain unchanged regardless of its type, is also used for plastering vertical surfaces. To do this, in certain proportions, it is added to concrete mixtures. You can make them yourself or buy ready-made ones. Comprehensive insulation of the house with vermiculite (walls, floors, attic) will save on heating bills.

The method of how to install an electric heating boiler consists of two parts: an insert with a circuit and a connection to the network.

Insulation with vermiculite of the floor, attic

The technology of vermiculite insulation of the floor and the attic is the same. In this case, the thermal insulation is protected with special films. From the side of the warm room, vapor barrier should be installed, and from the side of the street or unheated attic - waterproofing.

When performing thermal insulation with vermiculite, the presence of waterproofing and vapor barrier is mandatory

In doing so, it is extremely important to correctly place these protective layers.

Insulation of a pitched roof

When insulating the floor, waterproofing is placed under the vermiculite.

With such insulation, it is important to choose the correct thickness of the poured vermiculite. It depends on temperature conditions and ranges from 10 to 20 cm

The technology for insulating a pitched roof is as follows:

- a vapor barrier film is laid on the rafters;

- granulated vermiculite is poured;

- covered with a layer of waterproofing and a counter-lattice is stuffed;

- the roof spreads;

- internal cladding is performed with any material.

Insulation vermiculite, the properties of which are well studied, is a modern material that has a wide range of applications.

Vermiculite as a building material

Vermiculite is a natural natural material of a multilayer structure based on lamellar crystals, containing in its composition a number of metals (iron, aluminum, silicon, magnesium) and their oxides in combination with water. In construction, expanded vermiculite is used, obtained in the process of heat treatment of raw materials, in the form of cubes of a porous layered structure of yellow-brown, golden or bronze color.

Expanded vermiculite

The main characteristics of vermiculite that determine the scope of its use are:

- thermal conductivity;

- hygroscopicity;

- sound absorption;

- heat resistance.

These characteristics differ depending on the fraction of the material in the following proportions:

Due to its physical properties, vermiculite is widely used in construction, these are:

- for protection against fire damage (fire protection) of building structures for various purposes and from various materials;

- for insulation of various elements (floor, walls, ceiling) of buildings and structures, as well as engineering networks (water supply, sewerage, etc.);

- as a filler in the manufacture of lightweight concrete;

- when installing self-leveling floors and heat-resistant partitions;

- when preparing plaster solutions;

- in the manufacture of building boards with increased fire retardant properties.

Pros and cons

In addition to the fact that vermiculite has good physical properties, it also has a number of advantages, such as:

- Environmental safety - during operation, there is no release of harmful substances for human health and the environment, in the entire temperature regime of use.

- Long service life, while the material is not subject to destruction, as well as compression and fall off under its own weight.

- When used as a heater, condensation does not form on its surface. Water is well absorbed into the structure of the material, and then evaporates easily.

- It has good fluidity (when used in the form of granules), which allows it to completely fill the space intended for insulation or fire protection.

- It is not affected by rodents, and also does not contribute to the formation of fungi and mold.

- Anti-allergenic and non-radioactive material.

The disadvantages of vermiculite are:

- The ability to absorb moisture in large quantities, 3 to 4 times its volume.

- The need for air gaps (ventilation) to remove moisture from the structure of the material, leads to an increase in the cost of construction and installation work with its use.

- Relatively high cost.

Types of vermiculite

When vermiculite is sold in the form of granules, it is classified according to their size, these are:

- Fine fraction - up to 0.6 mm;

- Average fraction - 0, 6 - 5.0 mm;

- Coarse fraction - more than 5.0 mm.

Vermiculite fractions

In bulk, the material is sold in bags of various sizes. For insulation, fine vermiculite is used, and depending on its density (kg / m3), it is classified as grade 100, grade 150 and grade 200, with a density of 100/150/200, respectively.

Vermiculite grade 100 corresponds to a thermal conductivity of 0.055 W / m * K. In the manufacture of vermiculite slabs, their dimensions are not regulated by standards, therefore, the industry produces products with a length of 0.6 to 1.2 meters, a width of 0.3 to 0.6 meters and a thickness of 0.02 to 0.1 meters. In the manufacture of vermiculite blocks, their dimensions can correspond to such values -300x300x120 mm or 600x600x120 mm.

Thermal and thermal insulation made of expanded vermiculite

Loose vermiculite, due to its physical properties and the ability to simultaneously serve as a thermal and heat insulator, is widely used at various stages of construction and installation work.

When insulating with bulk vermiculite, its 20.0 cm thick layer is comparable in terms of thermal insulation characteristics with concrete and brick walls 2.0 and 1.5 meters thick, respectively. Vermiculite is used for thermal insulation of walls, interfloor ceilings, floors and partitions.

The thermal protective properties of this substance allow it to be used in the manufacture of thermal insulation for chimneys and pipes of various equipment. Thermally safe enclosures of equipment operating normally at high temperatures, as well as during the construction of heat-resistant partitions. When vermiculite is used as a filler in the preparation of concretes, mortars and plaster mixtures, heat loss through joints and other surfaces covered with these compounds is reduced.

It is not recommended to use mortars and concretes made with vermiculite in the construction of underground parts of buildings, as well as the basement, which is due to the ability of the material to absorb a significant amount of moisture.

Vermiculite scope, pros and cons, installation features

Solving the urgent issue of thermal insulation of a home, one has to face the problem of choosing a thermal insulation material.

The range on the market is wide enough, but almost every option has significant drawbacks. In one case, flammability is discouraged, in the other - a high rate of hygroscopicity.

The article discusses the characteristics and benefits of vermiculite, which is the golden mean of price and quality.

Description and scope of vermiculite

Vermiculite is a natural crystalline mineral with a layered structure. Belongs to the hydromica group. It contains: silicon, iron, magnesium, calcium and other mineral components.

The main advantages due to which the material is used in construction are resistance to aggressive influences, high acidity, retains its integrity for a long time, does not decompose.

Many gardeners are familiar with vermiculite, it is often used as a mulching material, a component of a substrate, an aerator. In construction work, it is not used so often, although properties and physical indicators are of great interest for this field of activity. Among the mastered areas:

• production of paints and varnishes, soft roofing;

• when arranging a "warm floor" system;

• as a filler for heat-insulating and decorative plaster mixes;

• for insulation of individual zones in the house (chimney, floor, roof, etc.);

• as a component of a screed mixture.

Vermiculite has good insulating characteristics, so it is used in regions with a warm climate as a backfill in three-layer walls to prevent overheating of a house, and in northern regions - for thermal protection of housing.

The land in the regions of the middle zone and the Urals freezes over in winter, which often causes cracks in the concrete bowls of the pools. Vermiculite helps to correct the situation. It is poured into the bottom, as well as into the cavity between the bowl and the edge of the trench during construction.

Insulation is produced in the form of backfill, pressed plates, blocks, pipe segments, liners.

Pros and cons of vermiculite

To appreciate the material, you need to familiarize yourself with its advantages and disadvantages.

Among the main advantages of vermiculite:

• environmental friendliness, no toxic substances are emitted during operation when heated;

• low thermal conductivity (0.055–0.098 W / m • ° C);

• fire resistance (operating temperature range from minus 260 ° to plus 1200 °);

• does not shrink over time;

• has good vapor permeability, which excludes the formation of condensation in the room;

• resistance to microbiological processes, rodents and insects show no interest in the material;

Warming with vermiculite

The most common insulation method is the backfill method. Many parts of buildings are insulated with granular filler:

- pitched roofs;

- attic floors;

- walls;

- floor.

Pitched roof thermal insulation

The thickness of the layer used for thermal insulation of the roof depends on climatic conditions and is in the range of 10–20 cm. The work is carried out in the following sequence:

- the vapor barrier film is laid on the rafters;

- a crate is mounted on the vapor barrier;

- the crate is covered with a layer of waterproofing, which is fixed with a construction stapler;

- loose insulation is poured into the formed space;

- the roofing material is laid on top and fixed.

The inner side of the roof is clad with plywood, decorative panels, clapboard, etc.

Insulation of the attic floor and floor

Insulation of the floor and attic is carried out using the same technology.

The overlapping vapor barrier film is laid on the floor and placed on the joists. Adjacent rows must overlap each other by at least 10 cm. All seams are sealed with adhesive tape.

The insulator layer is filled up and leveled to a thickness of 10-15 cm. Then the second layer of vapor barrier is equipped. Such insulation is not afraid of rodents and is not susceptible to mold and mildew.

The edges of the diaper should be rolled up and glued. On top of it, you can lay two layers of plywood 10 mm thick. Docking of sheets should be carried out closely, providing a gap near the walls. Laying the second layer should be done in such a way that the middle of the sheet coincides with the seam of the lower row.

Warm walls

The insulator is backfilled during the construction phase. Walls with bulk material - a multi-layer system that includes a load-bearing base, a facing layer and insulation.

Laying is carried out in such a way that a space is formed between the cladding and the load-bearing wall, intended for filling the filler. To prevent shrinkage of the bulk substance, it is compacted during construction.

The work is carried out in a specific sequence. The first stage is the erection of the load-bearing wall and the installation of the cladding: should be carried out simultaneously to a height of 3-5 rows. The number of rows is determined by the height of the blocks used. Then vermiculite is backfilled, the insulation is rammed in height by 10-15%. Further work continues in the same sequence until the required height is obtained.

Walls filled with bulk insulator can "breathe", which eliminates the formation of condensation. To increase the thermal insulation performance, the wall surface can be plastered with warm mixtures based on vermiculite.

Application of expanded clay gravel

| Indicators | Fractions of expanded clay gravel, mm | ||

| 8/20 | 4/10 | 0/4 | |

| Pitched roof insulation | + | ||

| Thermal insulation and the creation of a slope of flat roofs, lawns on terraces | + | ||

| Production of ultra-lightweight concrete and lightweight ceramic-concrete blocks | + | + | + |

| Thermal insulation and sound insulation of floors and ceilings | + | + | |

| Thermal insulation and reduction of the depth of laying of foundations | + | + | |

| Thermal insulation of soil | + | + | |

| Thermal insulation and drainage in earth embankments of roads laid in water-saturated soils | + | + | |

| Hydroponics, creating an optimal microclimate for the root system of plants | + | + | |

| As a dry backfill for GVL floors in order to improve the heat and sound insulation capacity of the floor | + | ||

| Warm solution production | + | ||

| Production of facade and paving slabs | + |

Expanded clay will also be useful to those who lay heating networks near their homes. First, you will be sure that your pipes are heating you, and not the cold earth. Secondly, in the event of an accident, you will not have to dig long and tediously in search of a leak. Thirdly, after a successful repair, nothing prevents you from using the material again, while it will not lose its properties.

Expanded clay can be used not only in construction. With its help, the paths at the summer cottage are landscaped and even the yield of fruit trees is increased, creating a kind of drainage system for their roots. The same applies to indoor flowers and plants. For these purposes, expanded clay is used smaller in size.

The use of expanded clay when pouring the foundation as a concrete filler is not recommended. In this case, it is better to use any crushed stone, even crushed stone, even granite. Expanded clay is bad in this quality in that it has smooth rounded edges, and this does not prevent the occurrence of work on shear (shear-break) of the concrete mass. And the foundation should precisely exclude cracks (shifts) of the tape in the cross section.

Use of vermiculite for mixtures and solutions

Mixes for masonry and plaster are produced from fine-grained vermiculite. They are sold ready-made. Alternatively, make the raw materials yourself. You will need cement, sand and insulation. The ratios are as follows: 1: 0.5: 2 or 1: 1.25: 1.75. At the exit, the plaster will have a thermal conductivity coefficient of 0.24–0.4 W / m * K.

Reinforced concrete floors can be insulated with a screed with the addition of vermiculite. In addition to thermal insulation, the layer will protect the rooms from noise. At the same time, the screed formation technology does not change.

Nevertheless, since the insulation is hygroscopic, it is not recommended to use it for too humid rooms, basements, for the foundation.

Otherwise, vermiculite is a versatile, environmentally friendly and practical material used both in the process of building a house, as well as in a finished building. It is easy to work with it, and the long operational period will allow you not to think about changing the insulation for many years.

Scope of expanded clay

In addition, expanded clay is also used as an insulation, but it must be a highly porous material, and before using it as a backfill insulation, calculations that are not very complicated, but accessible only to specialists, should be made. Regarding its capabilities in the field of heat saving, we will only say that as a filling option, it loses to other heaters. The estimated thickness of the expanded clay backfill with a density of 600 kg / m3 is approximately 40 cm. This is not entirely effective.

At the same time, used in the manufacture of expanded clay concrete blocks, it significantly increases their heat-saving characteristics.

Expanded clay is actively used in the construction of a dry screed. Now this method is very popular, as it allows you to get a solid base for laminate, linoleum, cork in the shortest possible time, literally back.

Also, due to its unique properties, including resistance to moisture and frost, it is actively used for filling the foundation during the construction of various buildings and structures. This makes it possible to reduce the depth of the foundation by almost 2 times - from 1.5 m to 0.8 m, which leads not only to savings in building materials, but also to prevent freezing of the soil near the foundation of the building. The latter is fraught with distortion of the doors and window frames of the building.

What is vermiculite

It was 1824, Massachusetts. It was there and then that this layered mineral was discovered. But despite this, for 150 years no one imagined how it can be used and what is the use of the material. But in the course of many years of research, this problem was solved. Vermiculite can be found on all continents of the planet. However, the richest deposits of the mineral are located in Russia, especially in the Irkutsk and Chelyabinsk regions, as well as on the Kola Peninsula.

The mineral itself is a brown-golden stone with a layered structure, belongs to the group of hydromicas. Translated from the Latin vermiculite (vermiculus), translated as a worm or worm-like. It is named so for its appearance. After the mica is heated to a temperature of 900 or 1 thousand degrees, the water evaporates, and the form of the mineral changes. It increases from 6 to 15 times, during which columns or threads similar to worms appear.

Vermiculite consists of zeolite water, as well as various oxides: magnesium, potassium, chromium, aluminum, lithium, manganese, iron. After being mined at the enterprise, the raw materials are sorted and divided into fractions. And in the process of heating to the desired temperature, expanded vermiculite is obtained, which serves as a heater.

When fired, the stone does not change its chemical composition.

The material can be divided into 6 grades, differing in the size of the fraction:

- First grade - from 0 to 0.5 mm (Super Micron);

- The second is 0.5 mm (Micron);

- The third - 1 mm (Super fine);

- Fourth - 2 mm (Fine);

- Fifth - 4 mm (Midium);

- Sixth - 8 mm (Large).

Raw materials are produced in bulk, like paste and like slabs, with a thickness of 2 to 6 cm.

Material features and characteristics

The characteristics of vermiculite boards are represented by the following operating parameters:

- thermal conductivity;

- strength indicators;

- sound insulation properties;

- fire resistance and thermal stability;

- hygroscopicity.

Vermiculite is superior to basalt wool, expanded clay and polystyrene in terms of thermal conductivity

A feature of thermal insulation materials based on vermiculite is considered to be a high thermal conductivity, obtained due to the layered structure.There are voids between the thin plates in the slab mass, into which air can easily penetrate. This does not weaken the bonds between the structural elements of the material, due to which it has sufficient strength. In terms of thermal conductivity, a vermiculite plate is not inferior to workpieces made of mineral wool, and in terms of deformation stability it surpasses them.

Another feature of the insulation is good hygroscopicity - the ability to absorb moisture. But thanks to the layered structure, it also easily gives it away - it protects the elements of building structures from rotting and destruction. Good sound absorption is achieved due to the elasticity of the material and other characteristics. The maximum sound absorption is achieved by compressing the slab until its volume is reduced by 20%.

The thermal insulation material melts when the temperature reaches 1300 °, and does not form any harmful emissions during a fire.

Slab sizes

Vermiculite boards thickness from 15 to 60 mm

Vermiculite is produced in the form of discrete fractions, the size of which does not exceed 4 mm (in the form of backfill). On their basis, building boards of the PVO-500 type are made with a thickness of about 20-60 mm and dimensions of 600x600 mm (1200x600 mm). In the assortment of this material, the following five standard sizes of vermiculite products can be distinguished: 1200x600x20 mm, 900x600x20 mm, 600x600x20 mm, 600x300x20 mm and another atypical size 300x300x20 mm.

Vermiculite characteristics

The main characteristics of expanded vermiculite are presented in the table:

| Fraction, mm | Thermal conductivity, W / m * K | Volumetric weight, kg / m 3 | Humidity,% | Sound absorption coefficient, at a frequency of 1 kHz |

| 0.5 | 0.053 | 144 | 3 | 0,56-0,6 |

| 1 | 0.05 | 125 | 4 | 0,6-0,65 |

| 2 | 0.49 | 100 | 4 | 0,7-0,8 |

| 4 | 0.48 | 94 | 5 | Also |

| 8 | 0.045 | 87 | 3 | Also |

Main characteristics:

- The thermal conductivity of the coarse mineral is close to the values of mineral wool and extruded polystyrene foam, which makes its consumption in various insulating backfills economical. It should be borne in mind that the thermal insulation characteristics of plate vermiculite deteriorate due to the use of a large proportion of cement in them.

- Hygroscopicity - the ability to retain moisture, this quality makes the material in demand in agriculture and brings additional trouble to builders, since in order to preserve the heat-insulating properties, careful waterproofing of the insulation and ventilation are necessary to allow water vapor to escape.

- Sound absorption of vermiculite makes it possible to use slabs and plasters in sound insulating structures.

- Fire resistance - the melting point of the mineral is above 1300 degrees, which makes it suitable for insulating hot pipes, chimneys, stoves or fireplaces.

- Environmental friendliness - raw materials and expanded vermiculite do not emit gases harmful to humans, do not pollute nature, are not radioactive, do not cause allergies.

- It is unattractive to rodents, due to its hygroscopicity it absorbs marks and becomes unattractive to them.

- Resistant to aggressive media and bacteria.

- Durability of use up to 60 years.

Vermiculite insulation is a high-quality, harmless and affordable heat insulator for housing, public and industrial construction.

What is the difference between these drains

Perlite. It retains water poorly, absorbing it for a very short time, but it conducts it perfectly.

It is an “empty” substance, not enriched with any nutrients. Also, it does not participate in ion metabolism, is not subject to decay or mold.

This substance will help out if your flower is very picky about food. Its neutrality will not in any way affect the top dressing added to the soil. It is also a great solution for succulents.

Vermiculite. It retains liquid for a long time, but after being saturated with it, it completely does not allow oxygen to pass through, becoming dense. The mineral absorbs moisture (and strongly - it can draw in 400, or even 500 times more than it weighs), and eventually releases it.So if you add this substance to the soil, water the flowers less often than you are used to.

Vermiculite is quite rich in composition: it contains silicon, aluminum, iron, magnesium, potassium, and calcium. True, all substances here are in a so-called bound state: they are released very slowly, entering the soil in small portions. Therefore, it is possible to feed the flowers growing in it less often.

On a note! We believe that violets and saintpaulias should not be planted in pure perlite / vermiculite (a friend's plants died in pebbles, although the cuttings rooted in them perfectly), however, if you look at the vlogs of flower growers from the USA, you can find out that landless cultivation of these plants is widespread there. flower crops.

Florists use a mixture of vermiculite, perlite and peat. True, watering is used exclusively with wick watering. And of course, the plants are fed all the time.

Hazard class of substances: 4 (low hazard). The grade could be even lower, but there is dust in the bags with minerals.

Application of these pebbles

- Both minerals go into the pot as a drainage layer (in this case, the largest fraction of pebbles is used).

- Both large and small pebbles are good for germinating seeds and rooting cuttings. Minerals are poured into a glass, watered a little, and then a cutting is placed in it. Depending on the selected plant, perlite / vermiculite is used either in pure form, or mixed with sand, peat.

- A large fraction of minerals (and not only) can be used to decorate the top of the pot. Such "mulching", in addition to a purely decorative function, can also be of practical benefit - pebbles will retain moisture between waterings, the top of the soil will not allow an ugly crust to dry out, and will also protect your flowerpot from mold.

- If you dug flower bulbs from a flower bed, you can cover them with perlite / vermiculite, only dry for the winter! The pebbles have good thermal insulation properties, thanks to which the onion hidden in them will perfectly overwinter without suffering from cold, rot, as well as harmful insects or voracious rodents.

- Both substances are almost neutral in acidity. Due to this, it is recommended to mix them into the soil for flowers that prefer acidic soils (for example, for gardenia, azalea).

- Since the substances have slightly different "plumbing" qualities, they are often combined. This mixture has worked especially well in hydroponics.

- Both materials are environmentally friendly and free of heavy metals. These are practically sterile minerals that make the soil looser, softer and more airy.

This video will give you some practical practice. The blogger will show you how to plant an orchid in vermiculite. This method is especially indicated if the roots of the plant are damaged:

And here - about rooting cuttings. Where is it better to expose them - in plain water or in perlite? The blogger will show and tell about his experience using the example of a cut violet (Saintpaulia) leaf:

What other materials are "competitors" to perlite and vermiculite?

You can also fluff the soil or make good drainage with:

- expanded clay (porous ceramics, which also retains water well);

- sphagnum moss (it can serve for years, but remember - it slightly acidifies the soil);

- hydrogel balls (can be colorless or bright; in addition to water, they absorb, and later slowly release fertilizers dissolved in moisture).

Also, some gardeners add pine bark cut into small pieces, shards from broken ceramics or broken brick (the so-called brick chips), pieces of foam or charcoal to the soil. All this is used both singly and in different percentage combinations.

If you have your own garden, where you collect soil, but there is solid heavy black soil, for flowers you can dilute it with peat, deciduous or coniferous soil, sand.

If you do not buy all these substances, but collect them in nature, calcine the substrates in the oven: this way you will kill all unnecessary bacteria (and it is better to rinse the sand as well).

Thermal insulation of horizontal structures

Horizontal structures - floors, attic floors, roof slopes with a slight slope can also be insulated with vermiculite backfill. To keep the backfill in working order, a vapor barrier is required from the bottom and waterproofing on top of the insulation layer.

When performing overlapping on wooden logs, after installing the subfloor, a vapor barrier material is laid over the entire surface, fastening it at the joints with a special double-sided vapor barrier tape. The overlap of adjacent panels must be at least 15 cm.

On the vapor barrier, the insulation is covered with a layer that provides a standardized heat transfer resistance of 2.5 m2 * K / W (for central Russia, at least 17.5 cm). on top of the backfill, a waterproofing material is laid and running flooring is performed on the attic floor or a clean floor in the interfloor floor.

ATTENTION! In order to save money, it is possible to insulate the structure with a mixture of vermiculite and sawdust in a ratio of 1: 1, 3: 2. The mixture will not lose its qualities as a heat insulator, and sawdust can be purchased at a bargain price.