Photos from the site: 1poteply.ru

Recently, there has been a steady tendency towards the origins, towards something primordial and real, such that our ancestors respected very much. Today, it is no longer possible to surprise anyone with a jacuzzi or a rain shower in your own bathroom, but you will not be able to get much pleasure, and even more benefit, except for personal hygiene. A completely different matter is the Russian bathhouse, with the help of which you can even cure a number of diseases, with which even skeptical doctors have long agreed. However, if you think that it is enough to put a log house and that's it, then you are deeply mistaken, an important factor is also the insulation of the steam room of the bath, in which the whole main process of healing takes place, as well as obtaining positive emotions. How to properly insulate a steam room in a wooden bath will be discussed in our article.

What material for thermal insulation to choose

View gallery

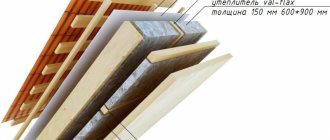

You can insulate the steam room with one of the many modern materials. For example, basalt wool, made in the form of rigid slabs or rolls, based on molten fibers of basalt rocks, is perfect. The thickness of this material can vary from 20 to 100 mm. It is used for thermal insulation of walls and ceilings, as well as for the chimney, in the area where it passes the ceiling.

Among the advantages of basalt wool, compliance with environmental requirements should be highlighted, so it can be used in a steam room without restrictions. But cotton wool also has its drawbacks, which are that slabs and rolls have a fibrous structure, which indicates insufficient rigidity. Under load, cotton wool can crumple, so it is most often used to insulate the ceiling and walls, but not the floor.

Thermal insulation of the steam room can also be carried out with foil-clad mineral wool, which has almost the same technical characteristics as the material described above. The only difference is the presence of a thin foil layer on one or both sides. This mineral wool is used for the same purposes.

Among the advantages, the presence of a glossy layer should be highlighted, which is designed to reflect the infrared spectrum of thermal radiation. In this regard, the material is able to retain heat for a longer time. In addition, the metal foil acts as a barrier to water vapor and moisture. This prevents condensation from accumulating inside the insulation. But such mineral wool has one significant drawback, which is its higher cost.

View gallery

Step-by-step instructions: how to insulate a bath from the inside

The main problem is that the thermal insulation from the inside of the steam room has to be approached individually, taking into account three main factors:

- Construction of walls and floors in the bath;

- Bath wall material, its vapor permeability and thermal conductivity coefficient;

- A type of insulation for a steam room.

You can, of course, not try to collect possible schemes of "warm pie" for walls and ceilings, but make the steam room insulation from the inside with a margin of thickness of thermal insulation of all layers. Perhaps such a bath will turn out to be very warm, with a minimum consumption of firewood for heating, but there is one circumstance - even the excessively powerful and thick thermal insulation of the steam room of the bath does not guarantee reliable protection against condensation.

Thermal insulation from the inside of the bath is always a fight against heat loss, without reflective insulation from the steam room “up to 30% of the heat escapes

It would seem that the simplest solution is to arrange thermal insulation along the outer surface of the walls. Moreover, it would be easier and safer to put insulation for the steam room outside, but this method is recommended for brick and block buildings. It is customary to lay the main array of steam room insulation in a wooden bath from the inside.

What does the internal insulation of the steam room give:

- The walls are insulated from high temperatures and hot water vapor;

- The dew point is located in the thickness of the wall, and not inside the more vulnerable insulation;

- The steam room box with internal insulation is better ventilated and dried from moisture.

Most of the steam remains cut off by thermal insulation from the inside of the room, and good airflow on the outer surface of the walls helps to get rid of condensation, even if the bathhouse uses an additional insulation scheme with a ventilated facade.

In order to decide how to insulate in a steam room in a bath, you need to remember three fundamental things. First, the thermal insulation of the steam room should not lose its qualities, regardless of external and internal conditions. The material should not degrade under the influence of heat, be damaged by rodents and microflora, while being safe in all respects, especially in a situation with a possible fire.

Secondly, the insulation for the steam room from the inside must pass air well and partially water vapor in a hot state. Cold or over-condensed water vapor must be cut off and returned either to the outside, if it came with rain moisture, or to the inside of the steam room, in the process of cooling the bath.

Thirdly, the very design of the insulation for the steam room of the bath should provide for air vents to remove water vapor. It is clear that absolutely impermeable materials do not exist, therefore, a system for removing leaked condensate drops should be provided from inside the walls of the steam room.

Thermal insulation of a bath with foam is not the best option

In addition, reflective surfaces based on aluminum foil are used in the construction of a heat-insulating layer from the inside of the steam room according to modern techniques. This somewhat impairs the removal of hot steam, as part of the radiant energy from the stove or sauna heater is reflected into the steam room. The layer of thermal insulation turns out to be somewhat colder, the dew point shifts from the outer surface of the walls inward, into the thickness of the insulation.

First of all, you cannot use the same scheme for laying insulation for a steam bath if the box is built from different materials. Simply put, you cannot stupidly copy the scheme for a frame steam room, transfer it to a brick or block bath box. There are certain differences that need to be elaborated on.

Below is the correct scheme for warming a frame steam room.

The main difference is that the thermal insulation layer of the steam room is actually split into two separate layers, which are laid with overlapping seams. This makes it possible to block the possible occurrence of cold bridges. In addition, a ventilation gap must be installed in the thermal insulation of the frame steam room and a superdiffusion membrane is installed. It passes condensed water vapor in one direction, from inside the room to the outside.

For block and log baths, you can use a simpler option. For example, for a steam room made of profiled timber, lay the insulation directly on the wall. Do not be confused by the lack of a special ventilation duct. Due to the mezhventsovy seams, hot water vapor will relatively easily leave the space between the insulation and the timber wall of the steam room. Such schemes are actively used for baths attached or built into the premises of a private house.

In this design, aluminum foil or a polyethylene foam heat insulator with a reflective layer is already actively used.Since the walls of the steam room are warm enough, it makes no sense to spend internal heat to remove the dew point as far as possible to the outer surface of the bar and block.

It is clear that for log and timber steam rooms, you have to pay attention to the sealing and capping of the interconnection joints, otherwise a large amount of moisture and humid air will get into the bath through the cracks and cracks.

In a similar way, you can build insulation in a steam room made of cinder block. In this case, the supporting beam of the lathing can be laid horizontally. But this option is considered even more preferable, since there is no risk of rupture of the insulation layers during the shrinkage of the walls, as in the case of the crowns of a log or timber frame.

The choice of the most suitable material for insulating a room from the inside also depends on the size of the steam room and the heating method. It is believed that from modern materials stone wool of the "Rocklight" type, foil-clad polyethylene and the traditional insulation of walls and floors - extruded polystyrene foam - are best suited for the steam room.

For large-sized steam rooms, you can use PP, the larger the volume of the steam room, the lower the thermal load, which means that when the stove is more than 2 m away from the wall, it is quite acceptable to carry out insulation with sheets of foam or even high-density foam. True, in this case, it is recommended to sew up the insulation layer from the inside with OSB-3 sheets.

If the dimensions of the steam room are small, then it is best to use stone wool, it is believed that in this case the radiant and convection heat load on the walls is very high, so it is best to use heat-resistant stone fiber.

Sometimes, instead of traditional mats, rolls with glued aluminum foil are used

The use of an additional surrounding coating is always fully justified, but you should be as careful as possible when applying it:

- If the steam room is heated by an electric heater, and there is no powerful air suction through the subfloor from the stove installed in the dressing room, then aluminum foil will be the best addition to the main insulation;

- For options where the steam room is heated with a wood-burning stove with air intake from the inside and outward, it is best to use polyethylene foam with glued metallized coating.

Aluminum foil, despite the fact that it is closed from the inside by the lining of the lining, is easily damaged and often breaks down due to gusts of wind during the drying process. Polyethylene turns out to be more resistant, although with a strong heat load due to infrared radiation from the body or chimney of the furnace, it can easily melt almost to the point of holes.

The very process of laying thermal insulation on the walls and ceiling of the steam room is not particularly difficult. Before starting work, the walls, floor and ceiling of the steam room from the inside must be subjected to antibacterial treatment and thoroughly dried. If moisture remains, then the laid insulation of the bath will preserve it from the inside.

Materials such as rock wool, superdiffusion membrane, aluminum foil are usually stored somewhere in the dressing room, but not inside the steam room. As they are used, the materials are brought in and laid on the walls from the inside; it is not worth storing them inside the steam room. Not only is it extremely harmful to breathe dust from mineral fibers, the microparticles themselves often stick to the lining and decoration details of the bath room. All this will then have to be thoroughly washed and removed before the steam room is put into operation.

We offer you to familiarize yourself with the Stove for a bath with a firebox from the dressing room - Everything for the comfort of your home

To install mineral fiber insulation, you only need a jigsaw, a screwdriver and a stapler with staples, a building level. To secure the membrane and aluminum foil, you will need tape, and for metal, adhesive tape with a metal coating.

In addition, perforated hangers are needed, which are used in the assembly of suspended ceilings, fastening material - self-tapping screws of different lengths. It is clear that the thermal insulation will need to be mounted on the lathing and counter-lattice, so you will need to stock up on a 40x60 mm bar and a 20x20 mm wooden counter-batten.

Thermal insulation with parallel sealing of the counter-lattice with a film

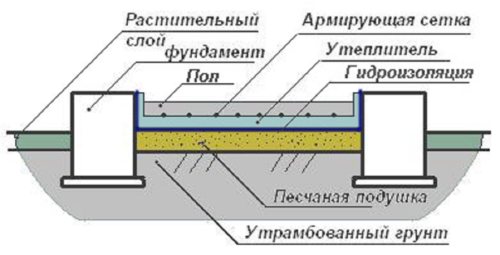

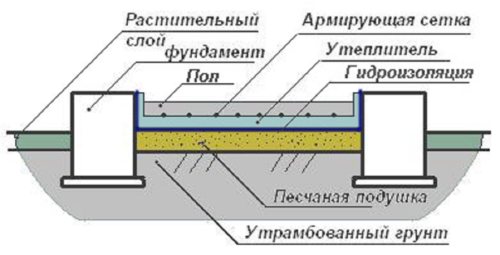

There are two main schemes for insulating the floor from the inside. If the bath is located directly on the ground, then the floor in the steam room has to be insulated with two layers of thermal insulation:

- The lower tier is poured over the waterproofing sequentially with sand, crushed stone, gravel screening and a thick layer of expanded clay. A vapor barrier and waterproofing is laid on top of the granules, after which you can install insulation from expanded polystyrene or polystyrene with a thickness of at least 150 mm. The finishing layer is made of a cement-sand mixture;

- In the event that the basement of the bath is raised above the ground level, the floor can be insulated with both expanded polystyrene and mineral wool, laid between the rafters on a lining made of a vapor-waterproofing super membrane.

Floor insulation with screed

In the first case, the warm floor in the steam room is laid with tiles, sealed at the entrance and along the perimeter of the room with heat-resistant silicone sealant. On top of the tiles, wooden lattices or a raised floor - payoli are usually laid. In general, the effectiveness of such insulation is sufficient to reliably isolate heat and prevent moisture from leaking from the inside.

Log bath

Why choose expanded clay

Warming of steam rooms is quite often carried out also with expanded clay, which looks like brown pellets. Products have a porous inner structure and a dense outer surface. The shape is round and the particles have a diameter of 5 to 30 mm. Pellets act as a free-flowing insulation material for thermal insulation of attic floors and floors. In the case of expanded clay, a number of advantages can be distinguished, namely:

- low specific gravity;

- fire safety;

- low cost;

- low degree of water absorption;

- ease of use when filling voids.

Expanded clay can be used to hide cavities. However, it also has its drawbacks, for example, an increase in weight when wet, as well as a low coefficient of thermal conductivity.

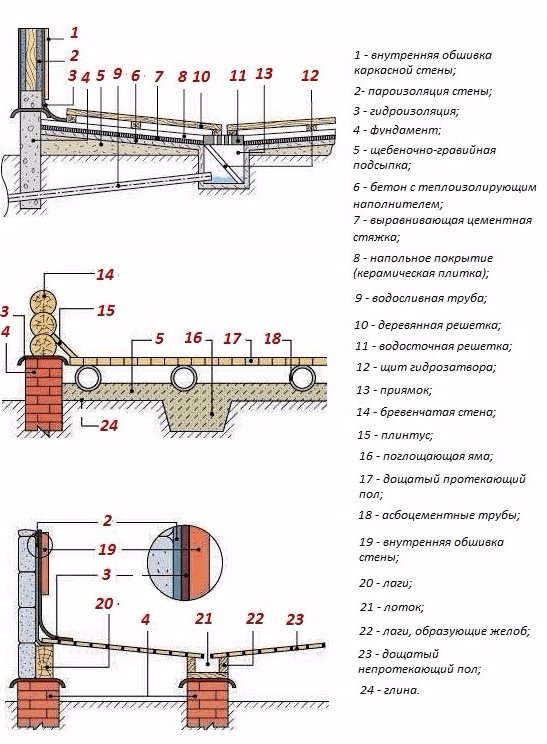

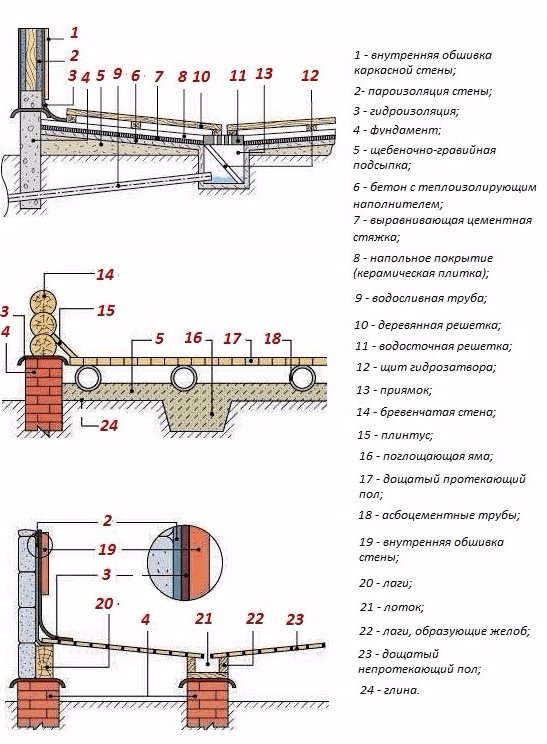

Step-by-step guide: insulating a concrete floor

Warming of a concrete floor occurs according to different rules:

- Step 1. Concrete slabs lying on the foundation must be covered with a layer of waterproofing. As a rule, this is a mastic made from a combination of bitumen and rubber. It is applied by dense coating. You can use roll material or a combination of wash and roll coating.

- Step 2. A layer of thermal insulation is laid: mineral wool, expanded polystyrene, perlite solution or expanded clay. The layer height depends on the properties of the selected material and technical characteristics.

- Step 4. A reinforcing mesh is placed on the layer of insulation with the help of supports and the top screed up to 3 cm thick is poured.

- Step 5. After fixing the rough screed, further coating depends on the individual decisions of the owners: either a final screed with subsequent finishing, or a wooden finishing floor, or ceramic tiles.

Foam insulation

Thermal insulation of the steam room in the bathhouse in the floor area is quite often carried out also with polystyrene foam, which is made from expanded polystyrene granules. The material is realized in the form of sheets, the thickness of which reaches 150 mm. Sheets can be used for floor insulation. Among the advantages, it is necessary to highlight:

- low cost;

- small specific gravity;

- low heat transfer coefficient;

- lack of ability to pass water and absorb moisture.

View gallery

However, the foam does not allow water vapor and air to pass through, burns and melts, during which it emits suffocating smoke, and also allows use at temperatures no higher than 70˚.

Do I have to do this

Bath floors are constantly exposed to unfavorable conditions: high humidity due to water ingress and temperature, especially in the steam room. This negatively affects the strength of the floor material. This environment is ideal for the development of fungus, mold and disease-causing bacteria. All this does not contribute to healing and relaxation, although bath procedures are intended for this. But the selection of the right raw materials and high-quality installation will help to avoid these troubles.

Bath flooring depends on the flooring used

The combination of a high room temperature and a cold floor can make a person sick. And the heat will disappear much faster. This means that much more fuel will be needed to maintain the desired temperature. And this does not save the budget in any way.

Therefore, the floor covering in the bath must be insulated. And this will have to be done in all rooms: a steam room, a changing room, a rest room, a washing room.

Only "dry" wooden and concrete floors are insulated, that is, the bases of which do not leak. The drains in them merge due to a 10-degree slope to the side where the gutter or special hole is located. There is a drainage tank through which it all flows into the sewer or ditch. If this system is done correctly, the insulation will last a long time.

Is it worth using EPS

Insulation of the steam room from the inside is sometimes also carried out with extruded polystyrene foam. It is a slab of molten mass. The thickness of the products can be up to 100 mm. Among the advantages, it is necessary to highlight the positive aspects of foam. The density here, however, is higher, therefore, the extruded polystyrene foam is able to undergo heavy loads. For this reason, it is more preferable to use it for floor insulation. Such canvases cost almost twice as much as polystyrene, and also have a slightly higher coefficient of thermal conductivity.

Using foil-clad polyethylene

Do-it-yourself steam room insulation can also be carried out with foil-clad polyethylene, which is sold under the trade name "Penofol". It is based on a polyethylene film, the thickness of which reaches 12 mm. It is covered with aluminum foil on one or both sides. Among the advantages, it is necessary to highlight low cost, lack of the ability to transmit and absorb moisture, good thermal insulation properties and the ability to reflect infrared heat. However, this material also has its drawbacks, consisting in the release of corrosive smoke during melting, as well as destruction at temperatures above 120 ˚С. This insulation does not have breathable properties.

Why is it so important to insulate the floor in the bath

Old bathhouses with leaking floors are still actively used by summer residents and residents of the southern regions. For those who happened to be born in the middle and northern regions, it is better to think about floor insulation. Despite the fact that warm air naturally rises upward, a considerable part of it is lost when it comes into contact with a cold floor.

A large temperature difference between the upper layers of the steam room and the cold floor in a room intended for taking periodic bath procedures can adversely affect human health. To eliminate heat losses, as well as to speed up the heating of the bath room and create an obstacle to the cold from the outside, it is required to put high-quality insulation for the floor in the bath.

Floor insulation

View gallery

It is recommended to start insulation work from the floor. If we are talking about a soil surface, then sprinkle it with a sand pillow. Unevenness in the ground must be leveled before starting manipulations. Substrates are cleaned of debris, plant roots and large stones. The soil must be moistened and compacted with a vibrating plate or a manual rammer.A sand cushion is poured over the area of the room, the thickness of which can reach 150 mm. The sand should be leveled and moistened again so that it can be easily compacted.

Step-by-step instructions for insulating the steam room from the inside at the next stage provides for the installation of waterproofing. It will act as a barrier for moisture that could penetrate inside from the ground. To do this, roofing material or a thick plastic film is laid on the surface of the sand cushion. You can use roll-up waterproofing, which has a self-adhesive edge.

How to insulate a wooden or concrete floor with your own hands

The main work on thermal insulation must be performed during the construction period, otherwise it will not be possible to avoid dismantling not only the old coating, but also the wall decoration. Features of the use of various materials and installation work depend on the type of floor.

If there is a concrete floor in the bath, work begins by placing heat-insulating material on floor slabs with reliable waterproofing. A reinforcing mesh is placed on the insulation, and a cement-sand screed is placed on it. The option of two stages of pouring concrete is possible, between the layers of which a heat-insulating layer is made.

The main materials for the insulation of the concrete floor:

- styrofoam, styrofoam, expanded polystyrene;

- perlite;

- mineral and glass wool;

- expanded clay;

- foam concrete.

The wooden floor has low thermal conductivity, but in the bath its properties are enhanced with an additional layer of insulation. To do this, first, a cranial beam is placed on the lower floor beams as a subfloor and a vapor barrier layer. Then the insulation is installed and covered with a waterproofing material.

The main materials for the insulation of a wooden floor:

- styrofoam, styrofoam, expanded polystyrene;

- perlite;

- mineral or glass wool;

- construction felt impregnated with bitumen;

- foam concrete.

Methods of work

Laying the film is carried out in such a way that from each side it goes 200 mm onto the walls. The joints of the film are glued with wide tape. If you decide to use roofing material, then each subsequent canvas should overlap the previous one by 100 mm. The joints of the sheets are welded with a gas burner.

Insulation of the floor in the steam room of a bath at the next stage provides for backfilling of insulation. If these are expanded clay pellets, then they are poured over the waterproofing, and then distributed over the surface. For this, you can use guide profiles or a metal rule. For normal thermal insulation, an expanded clay layer thickness of at least 200 mm is required. Then you can start laying the reinforcing mesh. The subfloor will look like a concrete screed.

Insulation from the inside of a brick bath

Brick is not the most suitable material for building a bath, but if there is a brick factory somewhere nearby, then brick baths begin to grow like mushrooms. Due to the high thermal conductivity of bricks, such a bath needs to be insulated without fail. Warming is carried out only from the inside, and to make the bath look cool from the outside, decorative jointing is done.

Typically, the cake of the insulated wall of a brick bath looks like this:

- brickwork;

- waterproofing,

- insulation;

- vapor barrier;

- sheathing.

Waterproofing between the brickwork and the insulation is optional: if the walls are built correctly and waterproofed from the foundation, they will not dampen. If there is no confidence in the walls, then waterproofing is better done.

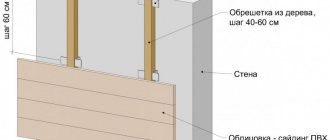

Insulation on the brick walls of the bath is attached to the frame.

We build a frame on the wall from a bar of 100 × 40 with a step in the width of the insulation, lay it in with insulation, lay the vapor barrier, sew on 20mm slats and sheathe it with clapboard.

The bathhouse of our user S4sha is laid out in half a brick, but it steams perfectly even at -30. Its walls are insulated like this:

- mineral wool;

- vapor barrier (in the steam room - foil);

- ventilation gap;

- lining.

Insulation thickness - 50 mm.

Floor insulation

View gallery

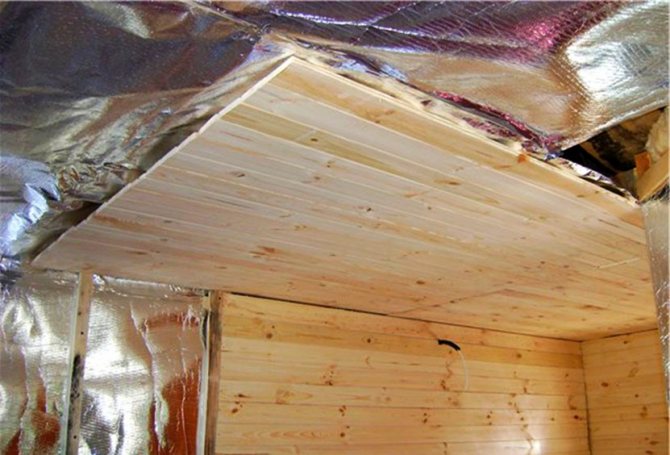

In the construction of rural saunas, false ceilings are often installed. The structure is based on horizontal load-bearing beams supported by external walls. Rough ceiling boards are sewn to the beams. Insulation in this case is carried out from 2 sides. From the inside, a vapor barrier, a heat-reflecting screen and decoration are laid.

As for the attic, it is necessary to lay a vapor-permeable membrane and a layer of insulation there. Insulation of the ceiling in the steam room from the inside involves fastening the waterproofing to the boards. The joints are glued with aluminum tape. It is necessary to fix the counter-lattice slats to the boards. An internal finishing lining from the lining is mounted on the frame made of slats.

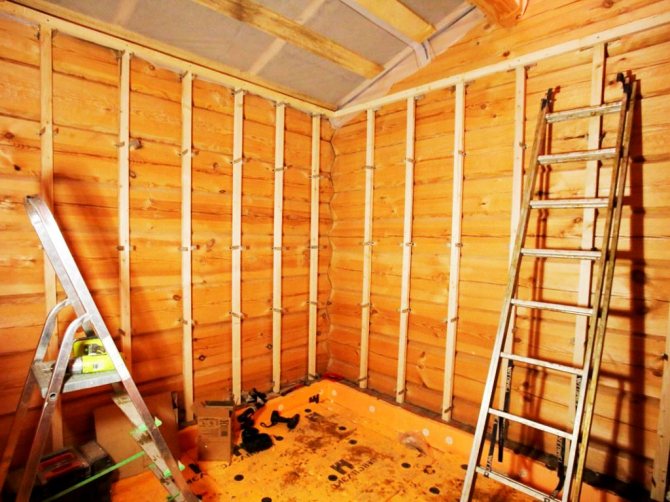

Insulation of the frame bath from the inside

For insulating a frame bath, roll mineral insulation is most often used.

To insulate the walls of a frame bath from the inside:

- Insulation is placed in the interbeam space of the structure;

- The next layer is vapor barrier (foil);

- Ventzazor;

- Sheathing.

The photos below show how Nomadniki insulated his frame bath. Insulation - basalt wool.

Do-it-yourself bath insulation from the inside: step-by-step instructions.

The foil acts as a vapor barrier, so it is important that even the slightest holes and damage are absent in it, and all joints are well glued with high-quality tape. The tape is always sold with foil, and its quality must be checked in the store (glue the tape to the foil and try to tear it off).

Work on wall insulation

View gallery

To create a layer of thermal insulation of the walls in the steam room, it is necessary to fill vertical wooden blocks. The step between them should be equal to the width of the roll of thermal insulation material. Insulation material is laid between the bars. Any modern solution will do.

It is important to exclude the formation of cracks, otherwise it will not be possible to insulate the steam room with high quality. A layer of waterproofing is covered on top and nailed with wooden blocks. There should be no gaps between the insulation and the waterproofing so that moisture does not penetrate the insulation. At the final stage of warming the walls of the steam room from the inside, it is necessary to perform cladding.

Thermal insulation of a bath from blocks from the inside

For the construction of a bath, durable and moisture-resistant blocks of expanded clay concrete are preferred. Insulation of such a bath is thought over at the stage of its construction. The most important thing here is to remove the ice block of concrete from the heating circuit. There is a technology promoted by our user ZYBY, which allows you to solve this problem by constructing a frame-wall made of boards indented from the walls of the bath. It is suitable for insulating all stone-walled baths.

To ventilate and dry the space between the frame and the walls, several air vents are made in the walls of the bath, above and below the outside. The vents are closed while people are steaming in the bath, the rest of the time they are open to dry.

Insulation cake for the steam room and washing room using this technology:

- concrete wall with air vents;

- insulation on the frame-wall (with a block from the concrete wall);

- frame-wall;

- foil;

- finishing with a 50th unedged board (aspen, linden or cedar) to get solid wood into the steam room.

With this approach, you will not have to heat the ice walls. And the insulation will dry out between vapors.

But many owners of a bathhouse made of blocks traditionally insulate it from the inside:

- concrete wall;

- insulation (attached to the frame);

- foil;

- ventilation gap;

- lining.

Such a bath needs insulation outside too.

Additional recommendations for wall insulation

The way we carry out insulation work will depend on what lies at the heart of the walls of the steam room. If you have erected a log house, then it will not need thermal insulation, because the thickness of the logs is sufficient. Whereas if you have an old chopped sauna, then it may require caulking and sealing the cracks between the logs. Such work can be carried out using felt or mezhventsovy heaters.The same insulation procedure is carried out in the case of buildings made of glued or profiled timber. And then, if cracks appeared during operation.

The insulation of the walls in the steam room of the bath is carried out in parallel with the installation of the protection of the vapor barrier foil layer. In this case, we are not talking about foamed polyethylene foam insulation. For this purpose, clean foil must be used, which is located between the wood trim and the inner surface of the wall. The technology here is quite simple: the foil must be nailed to the surface with lathing strips. The joints of the material should be made with an overlap of 10 cm. Additionally, they are glued with aluminum tape, which ensures tightness.

At the next stage, interior trim elements are attached to the battens of the lathing. The same scheme is used to insulate baths made of bricks, foam blocks and gas silicate products, since it is recommended to protect such materials from contact with moisture. A foil vapor barrier is laid from the inside, while the main “cake” of insulation must be made from the outside.

Thermal insulation of the ceiling of the bath from the inside

The bath is insulated from the inside in the following order: ceiling - walls - floor. Most of the heat in the bath goes through the ceiling, therefore

This is how the authoritative FORUMHOUSE participant with the nickname Nomadic, who is authoritative in matters of banning, recommends to insulate the ceiling.

We suspend insulation at least 10 cm under the black ceiling. Better basalt wool, glass wool and polystyrene in the steam room. The insulation can be hung on the lacing. Then the foil, the gap along the slats and the lining.

https://www.youtube.com/watch?v=nH8EUT14t0Q

Regardless of the material of the walls of the bath, the ceiling is insulated in the same way.

Thermal insulation of the ceiling in a bath without an attic is performed from the inside, if there is an attic, you can insulate both inside and outside the room. Do not forget to insulate the chimney as well. If it is made of a sandwich pipe, inside which an insulation layer is provided, such thermal insulation will be quite sufficient.

If the chimney is made of one pipe, it must be wrapped with basalt insulation, and a pipe of a larger diameter must be put on top.

Insulation of the ceiling structure can be done in three ways.

False ceiling

Thermal insulation of such a ceiling is very similar to wall insulation. The attic floor beams act as a frame for the hemming flow.

- From the side of the attic, a layer of waterproofing is laid on the beams, and then the boards are laid.

- Insulation plates are tightly placed between the beams from the inside of the bath room.

- The insulation is covered with a vapor barrier film or foil material, which is attached to the beams themselves.

- Sheathed the ceiling with clapboard.

Panel ceiling

Such a ceiling consists of special panels, on the inside of which there is already a layer of insulation and vapor barrier. Usually 10 cm thick mineral wool is used.

Ceiling shields are collected at the bottom, and then, in finished form, rise up. However, the panels are quite heavy, and it is quite difficult to lift such a structure yourself. Therefore, they are usually lifted in parts and mounted at a height.

After installing and fixing the panels, spacers of insulation material are laid between them and the main ceiling.

Deck ceiling

This ceiling is characterized by the absence of floor beams. It consists of boards with a thickness of 50 mm, which are placed directly on the walls of the bath or on bars nailed along the perimeter of the room at a distance of 10-12 cm below the ceiling.

Thermal insulation in this way is suitable for small rooms no wider than 2.5 m. In this case, only thin insulation with a thickness of no more than 5 mm can be used.

The following insulation scheme is used:

- The boards are covered with a vapor barrier foil.

- Insulation is placed on top.

- Then comes a layer of waterproofing.

- Everything is covered with plywood sheets or boards.

Using the instructions for the internal insulation of the bath, you can independently insulate not only new, but also old buildings. But before insulating the old building, it is necessary to carefully prepare the walls, close up cracks and cracks, treat the wood with an antiseptic and only after that proceed to thermal insulation.

If you decide to remake a change house or a trailer for a bath, then their insulation can also be carried out according to the given scheme.

For many years, he has been professionally making decoration and thermal insulation of wooden houses in Moscow and the region. If you want your bathhouse to delight you with warmth and comfort, your duty will serve you, the optimal temperature regime was maintained in the steam room, we are ready to help you with this.

You can find our coordinates in the "Contacts" section.

Calculate the cost of painting and insulating your home right now