Classification of rolled roofing TechnoNIKOL

Soft roof TechnoNIKOL for an Economy class roof is designed for waterproofing a variety of building buildings and utility rooms. Despite its low cost, such a roof perfectly protects in conditions of temperature extremes and lasts up to 20 years. Euroruberoid and Bikrost are representatives of the economy class of a soft build-up coating. These materials are characterized by ease of installation. Euroruberoid has less carcinogenicity and low toxicity in comparison with ordinary roofing material.

Bikroelast and Biopol belong to the Standard class. The TechnoNIKOL coating of this class perfectly copes with the protective function, it is convenient to install, it has increased resistance to external factors and mechanical influences, and has a long service life. It should be noted that this type of product has an acceptable price-quality ratio. Biopol is most often used for waterproofing foundations, additional carpet on roofs. Marking will help determine for which particular work it is worth using this or that material. Biopol P is used for lower roofing carpet and water protection of foundations. Biopol K - for the outer layer of the roof. Bikroelast has similar characteristics and markings.

Roof covering with soft roof Bikroelast Source stroypay.ru

On our website you can find contacts of construction companies that offer the service of roofing works of any complexity. You can communicate directly with representatives by visiting the Low-Rise Country exhibition of houses.

The representative of the roll-up soft roofing of the Business class is Uniflex. It is widely used in construction in various climatic zones. The marking will help determine the type of dressing and the scope of this material. Uniflex K - used for the top layer of the coating. It has a coarse grain coating. And Uniflex P - with fine dusting is used for waterproofing structures. This coating is based on polyester, fiberglass or fiberglass.

Premium roll roofing has earned an excellent reputation in all countries. Technoelast is a representative of this class of coatings. Technoelast has improved waterproofing properties, the greatest strength and durability. It is used in different climatic zones for roofing buildings and for protecting structures and foundations in places with increased groundwater pressure and high subzero temperatures.

Another representative of the advantage class is TechnoelastMost - a coating that is used for waterproofing the structure of bridges and floor slabs. The base made of artificial rubber will reliably perform its functions in conditions of increased loads.

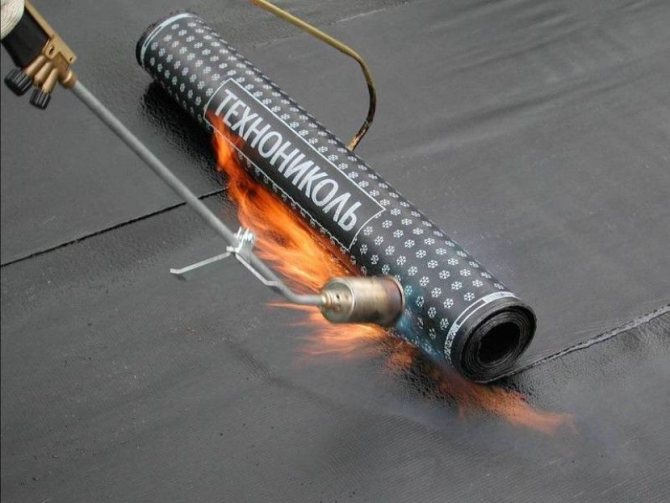

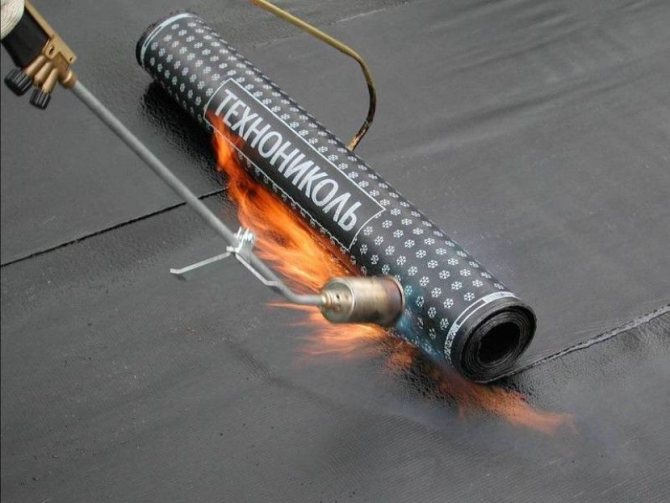

During installation, the lower part of the roof heats up, which allows it to stick to the surface Source hi.decorexpro.com

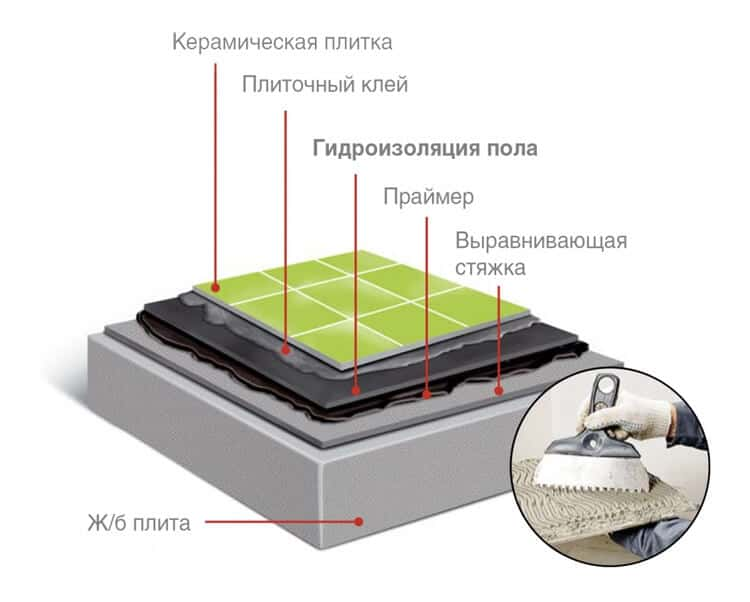

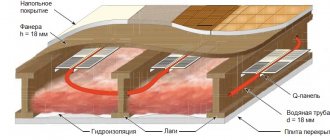

Varieties of waterproofing materials for the floor

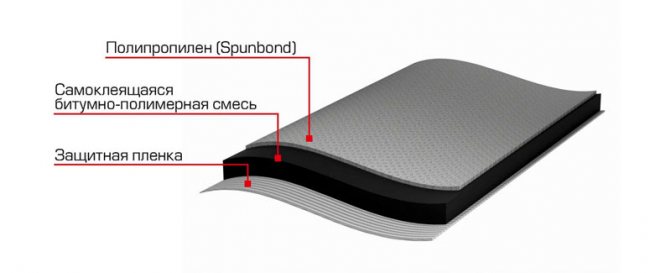

Roll waterproofing produced by modern manufacturers differs in the way it is attached to the base and in the type of base material. According to the method of fastening, it is customary to distinguish between adhesive, welded and mechanically fixed waterproofing materials.

Weldable Insulation is usually based on fiberglass, fiberglass or polyester, which have become substitutes for traditional cardboard.

The binding component of roll waterproofing is bituminous mastics and their bitumen-polymer grades (often with the addition of atactic polypropylene (APP), which is also called artificial plastic or styrene-butadiene-styrene (SBS), also called artificial rubber).

Roll surfacing waterproofing is one of the most popular materials due to its performance, easy installation and affordability.With the correct (in compliance with the required technology) laying, such waterproofing forms a single whole without cracks and joints, which significantly increases its waterproofing qualities.

Mechanically fastened roll waterproofing differs from the deposited version in that the bottom layer in it is not a polyethylene film, but fine-grained sand. The prototype of this kind of roll waterproofing with a mechanical method of attaching it to the surface is the well-known roofing felt.

Modern roll-up waterproofing is attached to the surface by means of self-tapping screws or overhead strips. The disadvantage of using this material is the laboriousness of its installation and low efficiency in protecting the surface from moisture.

Okleechnaya waterproofing, or, in other words, adhesive waterproofing, like a welded one, has a base consisting of polyvinyl chloride or fiberglass with a bitumen-polymer component and mineral chips applied to it. The adhesive waterproofing is laid using mastic or epoxy-based glue. Reliable moisture protection is achieved by creating 2-5 layers of waterproofing material.

Soft roofing technology

For the long-term operation of the roofing material, it is extremely important to observe the Technonikol soft roofing technology. Almost all roll coatings on the market today are weldable. For high-quality and long-term service, it is worth considering a number of features and styling rules. For all Technonikol products, preparatory work should be carried out before installation.

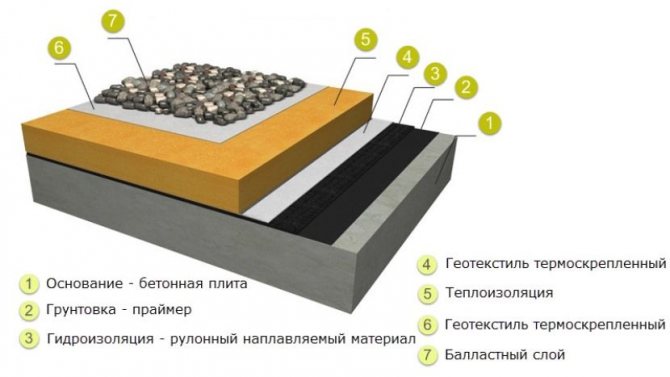

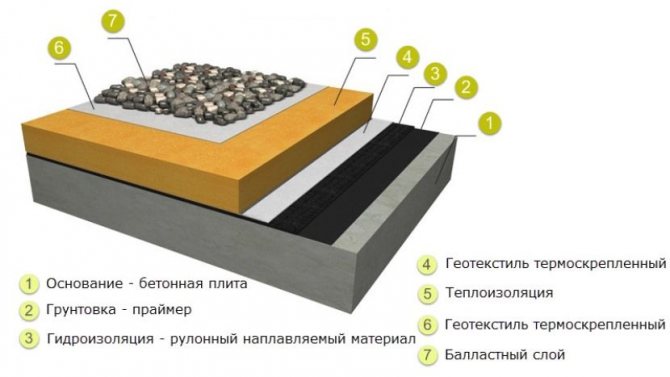

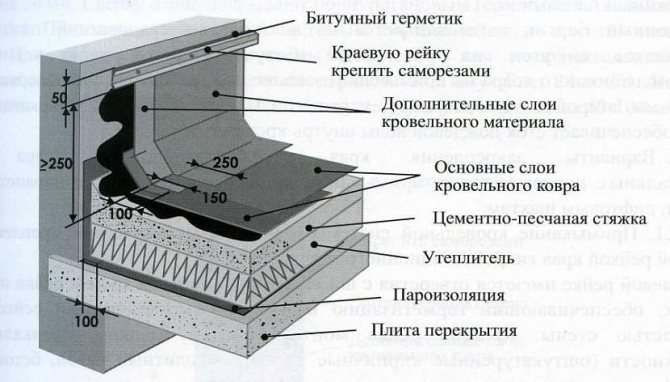

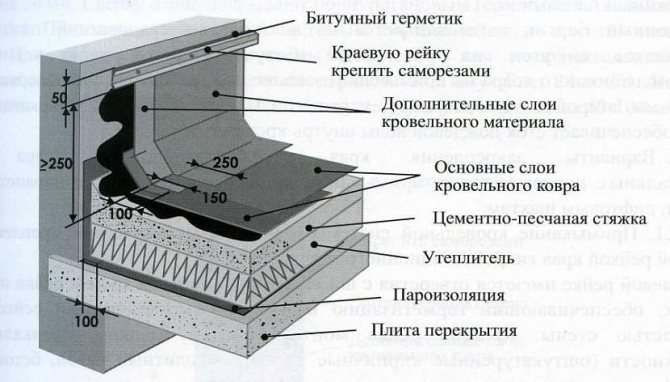

"Pie" for a warm and non-leaking flat roof Source stroypay.ru

TechnoNIKOL coating is most often used for the top layer of flat roofs. Thanks to this, the installation of such a coating is minimized. There is no need to build a rafter system, and the issue of wind protection is not relevant - since the windage of such a roof is minimal.

Installation of a flat roof begins with laying the base. Best of all, under the base of such a roof will be metal or concrete. The next layer is expanded clay or crushed stone. Next, a vapor barrier and insulation are lined. If the insulation material is not rigid enough, then a screed layer is applied on top. The finishing layer of the roof is TechnoNIKOL coating.

Particular attention should be paid to the flow of water. In small buildings, external gutters are used for this purpose. At the lowest point of the roof, drain funnels must be installed.

This might be interesting!

In the article at the following link, read about the passage of the chimney through the roof.

Stages of laying a soft roof

- The surface of the base should be carefully clear

from dirt and sand. If it is necessary to repair the roof, then the old material must be removed.

- The base of the roof must be flat

... If there are cracks or chips, they should be repaired. To do this, you need a cement-sand mixture.

- At the junction of the base to the vertical structure, it is necessary to create sides

- fillets at an angle of 45 °. For this, a cement-sand mixture will be used. The material is laid so that it completely overlaps the side and adheres well to each other.

Corner overlap of the roof of the soft roof Source stroypay.ru

- All protruding elements plaster

... Parapets are plastered to the height of the covering material.

- Before laying the material, the surface is carefully wipe and dry

... It is advisable to check the humidity with a moisture meter.

- Necessarily need a foundation prime

... A bituminous primer is suitable for this.

- The roofing material is laid in one direction

... When the angle of inclination of the roof is less than 15 °, the material is rolled out perpendicular to the water flow, starting from the lowest point of the roof. In the event that the slope of the roof is more than 15 °, the roll is rolled from the top point to the bottom.And a flat roof is covered from its edge.

- At the beginning of work, TechnoNIKOL coating needs try on

on the roof surface, make sure that it goes over the protruding roof sections.

- When trying on the material and in order for it not to move, the edge of the cover must be fix

... A few days before the installation work, the rolls are put on the edge so that they take the correct shape.

- The overlaying roof is laid by “to myself

". So it is more convenient for the master to monitor the level of heating of the bitumen layer. It is immediately clear whether the material has warmed up well enough. It is extremely important to make all movements smooth and uniform, without jerks. Places where the material is laid with an overlap must be additionally heated.

Laying of a soft roof is done "on oneself", in this case it is clear how much the material has warmed up Source realsroier.ru

This might be interesting!

In the article at the following link, read about the repair of a soft roof.

- If the canvas slides to the side during installation, you can try it move

but do not peel off. If it is not possible to fix it, then the panel is cut off and glued further with an overlap.

- Glue the material with a torch by fusion

... Due to this, the material is tightly glued to the base and to each other, which provides excellent waterproofing properties. The sheets are overlapped. Each next strip should overlap the previous one by at least 100 mm. The end joints between the panels are laid at a distance of 500 mm. When laying the roll perpendicular to the ridge, the canvas is transferred by 200 mm to another slope.

- The burner is held so that it warms up all coating layers evenly

... If you do not follow the rules for heating the material, then a bituminous roller appears during installation.

- It is imperative to warm up the material evenly

to prevent overheated and cold areas. If swelling appears during styling, they are cut through.

Advantages of floor waterproofing in rolls:

- universality, i.e. suitable for waterproofing floors under screeds or ceramic tiles;

- the ability to work on a wooden or reinforced concrete base;

- laying is done in one layer;

- installation does not require special skills and equipment, one person can handle the installation;

- the laying process from the preparation of the base to the installation of the floor covering is carried out in one cycle, there is no need to wait for the screed to dry (for example, the waterproofing of the bathroom will take only 1 day);

- no open flame during installation;

- roll area (7.5 m2) is best suited for waterproofing the floor of small rooms, such as a bathroom and a toilet;

- service life 45 years.

Rolled roof repair work

When the temperature rises significantly in summer, the roof gets very hot. And at high humidity, the carpet material peels off, air and water bags appear, and mechanical damage to the material occurs. To extend the service life of the overlaid roofing TechnoNIKOL, it is important to regularly inspect the integrity of the coating and eliminate defects in a timely manner.

If defects appear, urgent repair is required - the slightest crack can cause the gradual destruction of the entire coating.

If cracks or tears of the roofing material appear, they must be cleaned, covered with mastic and sealed with a new layer of material, but at least 200 mm wider. Pieces of decayed material are cut out with a margin, then the hole is smeared with mastic and sealed with new material right next to the old one. Put another layer on top, but already overlapping the joints by 150 mm.

Insulating composition of roll waterproofing materials

The main ingredient for such materials can be bituminous compositions, bitumen-polymer compositions and membrane waterproofing.

Bituminous the waterproofing composition is bituminous resin mixed with crushed basalt-shale crumb. This combination is used in the production of roofing felt, roofing roofing and glass roofing material.

The bitumen-polymer composition is obtained by adding special additives to the bitumen, designed to increase its elasticity and heat resistance. Plastic modifiers in such compositions are artificial rubber (or plastic). Such modifying additives are needed to increase the resistance of the bitumen component to temperature extremes and ultraviolet radiation, which makes it possible to use this type of coating in areas with hot climates.

Membrane insulation belongs to a new generation of high-tech materials. It is made of high or low density polyethylene, PVC or polyofepine and is a thin film with a thickness of 0.2 - 2 mm. For some grades of membrane waterproofing, a layer of corrugation is applied to better adhere to the mortar.

The advantages of waterproofing membranes are their mechanical strength, resistance to damage, long service life (up to 50 years), environmental friendliness, resistance to decay and decomposition, as well as a wide temperature range from -40 to +50 degrees Celsius.

Roll waterproofing of the brand is one of the main leaders among waterproofing construction materials in this segment of the international market. The reasons for such a high popularity of this type of TechnoNICOL product are:

- a high level of their reliability and effectiveness of protection against moisture penetration and the formation of condensate accumulations;

- biological and chemical resistance;

- the ability to maintain flexibility and elasticity at low temperatures;

- the ability to withstand significant tensile loads;

- long-term (about 35 years) service life;

- profitability;

- ease of styling.

All these qualities of TechnoNICOL waterproofing products are due to the use in them of a multilayer composition having a polyester base, two layers of bitumen-polymer filler and a protective film. The production of all types of brand coatings is carried out in accordance with state standards and applicable technological building codes.

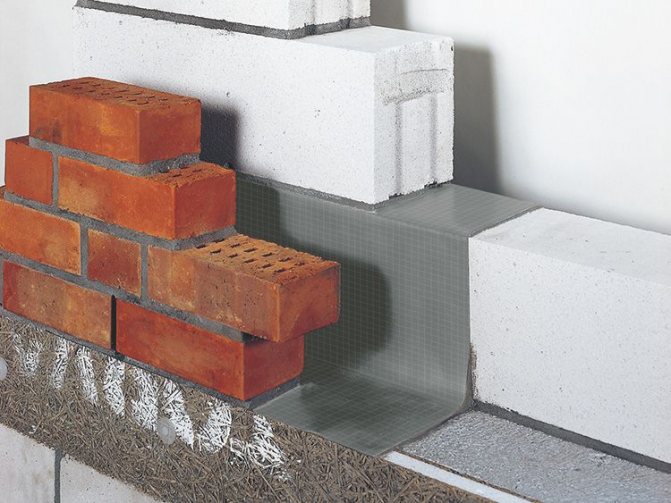

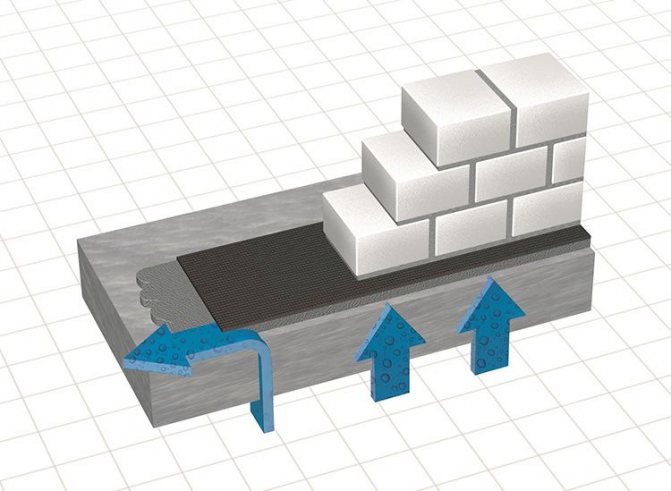

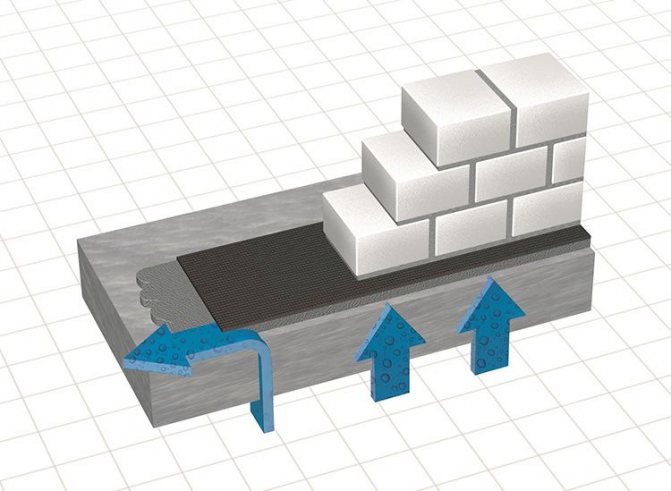

The principle of operation of shut-off waterproofing, depending on the type

Waterproofing materials offered to manufacturers can have a different principle of action. To understand how the TechnoNikol 400 shut-off waterproofing for a foundation works, you need to know its characteristics and installation method. We offer you to understand the main types and their distinctive features.

The principle of operation depends on the type of hydro-barrier

Horizontal shut-off waterproofing: distinctive features

The device for shut-off roll waterproofing is performed using materials that have polymer-bitumen and bitumen bases. Manufacturers offer rolls of various widths, which allows you to choose the best option depending on the protected area. The most widely used material is 400 and 600 mm wide.

Cut-off waterproofing "TechnoNicol 200" - the best option for narrow bases

Attention! Due to their high performance characteristics, TechnoNikol 600 and TechnoNikol 400 cut-off waterproofing is able to prevent moisture penetration into the wall with a strip thickness of only 1 mm.

The thickness of the strips to be laid is small

Horizontal shut-off waterproofing is installed during the construction of a house:

Impregnating cut-off waterproofing

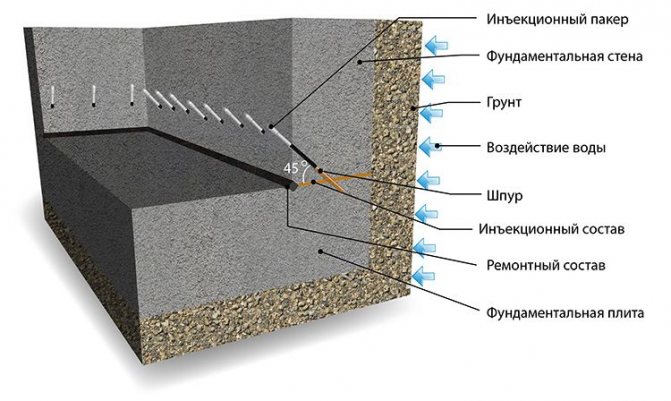

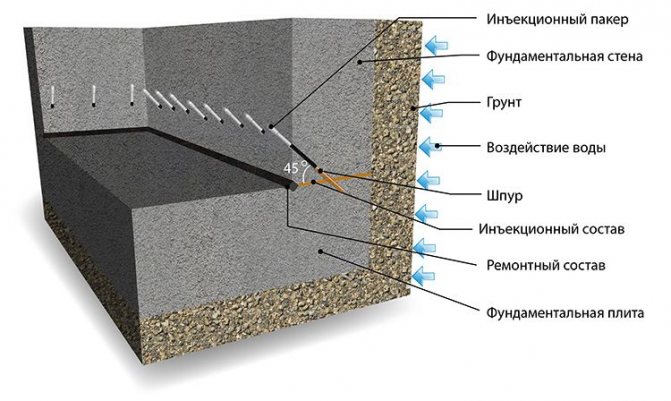

The base / plinth shut-off waterproofing can be done using penetrating materials. They are pumped into pre-drilled holes, forming a reliable and strong hydro-barrier for the entire protected surface.

Quality materials are used to form the protection Comment

Mikhail Starostin

Repair and construction team leader

Ask a Question

«

The composition for the hydro-barrier device is selected taking into account the material used for the manufacture of the protected surface.

«

For a brick, concrete or stone base, siloxane silicone mixtures are required to form moisture-proof films inside the cavities. If lime is present in the base, a silicate alkaline solution is required.

The thickness of the formed hydro-barrier must be sufficient

Attention! Penetrating compounds can be used to treat the walls of not only a house under construction, but also a long-built one.

Improvement of the operational characteristics of new and renovated buildings is possible

How to properly lay TechnoNIKOL

TechnoNIKOL soft roll roofing is laid on flat roofs of industrial and administrative buildings. The deposited products are produced on a synthetic basis, they have a five-layer structure.

During the production process, a bituminous coating is applied to both sides of a reinforced substrate such as fiberglass. From above, the material is protected with mineral dressing with colored granules, and on the reverse side the self-adhesive layer is covered with plastic wrap.

The advantage of this roofing product is its absolute waterproofing, resistance to subzero temperatures and the presence of soundproofing qualities.

Another positive point: the TechnoNIKOL soft roofing technology does not provide for the use of sophisticated equipment. Since the deposited material can easily take the shape of roofs of various configurations, including domed ones, it is often used by designers in order to translate their original ideas.

A wide range of soft roofing, especially flexible shingles, which are made in a variety of colors, allows you to diversify the appearance of private households.