Many in their lives have faced construction and the search for information about a particular product. This article will focus on the review and comparison of the world famous Rockwool products.

After reading this article, you will find out:

- What is ROCKWOOL

- You can watch the video: The history of the manufacturer ROCKWOOL

- Find out what types of ROCKWOOL insulation are available and where they can be used

- You can familiarize yourself with the summary table of technical characteristics and the price of Rockwool products

- Decide on the choice of insulation to insulate the surface you need.

For those who do not know what ROCKWOOL is

ROCKWOOL Is a group of companies that is a leader in the production of stone wool insulation under the world famous brand "ROCKWOOL", not only in Russia, but also in Europe, Asia and other continents of the world. Since 1909, it has constantly developed and improved its technologies, thanks to which the manufacturer has launched on the market a diverse line of stone wool heaters, which are designed for insulation, sound insulation and fire protection of residential, office, industrial and engineering buildings and structures.

To dateIn addition to stone wool insulation, the ROCKWOOL brand also produces acoustic suspended ceilings, road noise barriers, decorative façade panels and soil substrates for the horticultural industry.

Calculate your home's insulation

A cozy home is, of course, a warm home. The level of heat loss depends on the correctly calculated thermal insulation. To reduce it, it is necessary to correctly calculate the required amount of material for wall insulation and, in fact, calculate the optimal thickness of wool for insulation. Calculation of rockwool insulation for a facade can be determined in three ways:

- by contacting special construction organizations;

- on your own;

- using an online calculator.

Of course, the easiest way is to choose the first option and save a lot of time by getting just a number. But in this case, you will have to pay a considerable amount for such services, and this, as you know, is an extra expense during construction or repair, because you can calculate the amount of insulation yourself. It will certainly take some time, but the result will be just as accurate.

The calculation of the insulation (Scandic, Light Butts or any other) occurs according to a certain formula, and there is nothing complicated about it. It can be produced for absolutely any kind of material. But first, let's look at it with a specific example.

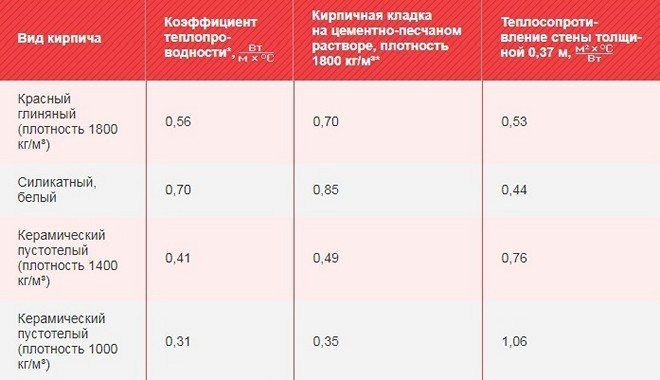

For example, we have a house made of bricks, the wall thickness is one and a half bricks. The work is planned to be done with the help of "Light Butts" or "Scandic". In order for thermal insulation to be effective and heat to be retained in the cold season, the wall must have a thermal resistance equal to at least 3.5 m2 * K / W. To determine the optimal thermal insulation, it is necessary to make certain calculations:

- To begin with, we determine the current thermal resistance of the existing wall. Its thickness is 37 cm, and the coefficient of thermal conductivity is 0.56. This applies to red clay bricks. So, for different types of material, thermal conductivity is usually different.

- We calculate the current thermal resistance. To do this, the wall thickness in meters must be divided by the thermal conductivity coefficient. As a result, we get: 0.37 / 0.56 = 0.66 m2 * K / W.

- We do not have enough up to the optimal value of 3.5 m2 * K / W: 3.5-0.66 = 2.84 m2 * K / W.

- Further, it became possible to calculate the required thickness of the stone wool layer: 2.84 * 0.045, where the second value is the coefficient of thermal conductivity of the insulation itself. Thus, we get the value in meters - 0.127.We find the value in millimeters - 127 mm. This is the required layer thickness for thermal insulation with Rockwool Light Butts and Scandic stone wool.

If you are still afraid of making a mistake in the calculations, you can use the online calculator, which are offered by many construction sites.

ROCKWOOL range of insulation

Thanks to modern equipment and the latest production technologies, in the range of ROCKWOOL insulation there are a dozen types of insulation that the manufacturer produces in different thicknesses, which allows you to insulate almost various objects and surfaces.

Among them are:

LIGHT BATTS

LIGHT BATTS SCANDIC XL 100mm

ACOUSTIC BATTS

FLOR BATTS

FIRE BATTS

SAUNA BATTS

ROCK FACADE (BATTS FACADE)

WIRED MAT

TECH BATTS

RUF BATTS

LIGHT BATTS is the best basalt insulation for private housing construction, which is produced in the form of plates 1000x600x50mm and 1000x600x100mm in size.

They insulate them: attics, balconies, loggias, frame walls, partitions, floors, roofing and ceilings between floors.

LIGHT BATTS SCANDIC XL 100mm is a new, most popular and convenient insulation for private housing construction, with an increased size of slabs. The size of one slab is 1200x600x100mm.

They insulate them: attics, balconies, loggias, partitions, floors, ceilings between floors and walls.

ACOUSTIC BATTS is a specially developed technology for the production of stone slabs, in which the fibers of stone wool are arranged in a random order, which maximizes the effect of sound insulation and helps to provide a sound barrier against ambient noise and very loud human speech.

They insulate them: middle layers inside the room (partitions in living quarters, overlaps along the lags).

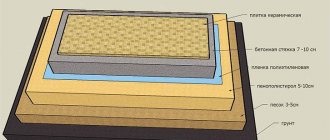

FLOR BATTS are rigid slabs specially designed for thermal insulation of floors, with a load of up to 3 kPa.

They insulate them: ceilings between floors, as well as for laying under a cement screed, underfloor heating and a screed made of gypsum fiber board and particle board.

FIRE BATTS are high temperature stone slabs that are covered with aluminum foil to create a reflective heat effect and avoid heating up adjacent structures.

They insulate them: fireplaces and stoves in private houses, as well as piping systems.

SAUNA BATTS are light heat-resistant plates with foil, on the one hand, which are produced specifically for rooms with high humidity and temperature, where it is important to reduce electricity costs, as well as keep the room warm.

They insulate them: walls in steam rooms, saunas and baths. Can be used without vapor barrier.

ROCK FACADE (BATTS FACADE) are moderately rigid heat-insulating plates that are resistant to deformation and perfectly retain heat.

They insulate them: building facades, for subsequent plastering and finishing with siding panels.

WIRED MAT is a technical insulation with stainless wire, which is produced in rolls with or without foil.

They insulate them: air ducts, high temperature equipment and piping for heat preservation and fire protection.

TECH BATTS is a line of flat heaters produced by the manufacturer with different densities for insulating flat surfaces.

They insulate them: technological equipment, vertical and horizontal surfaces, stoves, fireplaces and other flat surfaces.

RUF BATTS are basalt slabs with increased rigidity, which are resistant to mechanical stress and are available in the following stiffness options:

- RUF BATTS - 160 kg / m3.

- RUF BATTS V - 190 kg / m3.

- Roof Butts N - 115 kg / m3.

- Roof Butts S - 135 kg / m3.

- Roof Butts EXTRA - the layers differ in density and are glued together: the outer layer is 210 kg / m3, the inner layer is 135 kg / m3. There are markings on each side of the mat.

- Ruff Butts OPTIMA - the layers differ in density and are glued together: the outer layer is 200 kg / m3, the inner layer is 115 kg / m3. There are markings on each side of the mat.

They insulate them: roofs, when arranging attic floors.

Dimensions (edit)

Light Butts Extra is a unique heat-insulating material that restores shape and structure. The packaging will take up 70% less space than when the boards were unpacked. This is due to the fact that the material is in a vacuum, the air is completely removed. As a result, thermal insulation is easy to move, even in small cars. For the comfort of movement, the material is made in 2 sizes:

- standard;

- XL.

In 1 case, miniplates have the following parameters:

- length - 0.8 m;

- width - 0.6 m;

- thickness - 0.05 or 0.1 m.

XL insulation in large sizes:

- length - 1.2 m;

- width - 0.6 m;

- thickness - 0.1 or 0.15 m.

1 package contains 5, 6, 12 pcs.

Frame walls (inclined, vertical), attics, ceilings, partitions are insulated with mineral wool slabs. Their density is 30 kg per cubic meter. m, the thermal conductivity coefficient is 0.035-0.040 W per mK. Unlike ordinary mine slabs, in Rockwool the fibers are arranged horizontally and vertically. That is why they have such an elastic structure. Recommended temperature indicators for use - up to +250 degrees. When heated more, the binder evaporates. As a result, the terms of use of the material are reduced.

Dimensions Rockwool Light Butts

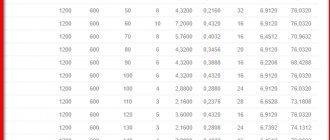

Table of technical characteristics and prices for Rockwool insulation (prices are valid as of 01.02.16)

| LIGHT BATTS SCANDIC * | LIGHT BATTS * | ACOUSTIC BATTS * | FLOR BATTS * | FIRE BATTS * | SAUNA BATTS * | FACADE BATTS * | WIRED MAT * | TECH BATTS * | RUF BATTS * | |

| Density (types, separated by commas), kg / m3 | 30 | 35-37 | 45 | 125 | 100 | 40 | 145 | 50, 80, 105 | 90, 110 | 115, 135, 160, 190 |

| Thermal conductivity, W / (m K), λ10 | 0,036 | |||||||||

| Thermal conductivity, W / (m K), λA | 0,042 | |||||||||

| Thermal conductivity, W / (m K), λB | 0,045 | |||||||||

| Peel strength of layers, KPa | from 4 to 15 depending on the type of insulation * | |||||||||

| Compressive strength at 10% deformation, KPa | from 20 to 65 depending on the type of insulation * | |||||||||

| Water vapor permeability, mg / m h Pa | 0,3 | |||||||||

| Water absorption, no more than kg / m² | 1 | |||||||||

| Service life, more than 50 years | Yes | |||||||||

| Flammability | NG | |||||||||

| Insulate construction types: | ||||||||||

| attic | + | + | ||||||||

| balconies | + | + | ||||||||

| loggias | + | + | ||||||||

| frame walls | + | + | ||||||||

| partitions | + | + | + | |||||||

| floors | + | + | ||||||||

| roof | + | + | ||||||||

| floors between floors | + | + | ||||||||

| overlap on lags | + | |||||||||

| floors between floors, under a cement screed | + | |||||||||

| fireplaces, stoves, high temperature equipment | + | + | + | |||||||

| piping systems, air ducts | + | + | ||||||||

| walls in steam rooms, saunas, baths | + | |||||||||

| building facades | + | |||||||||

| vertical and horizontal surfaces | + | |||||||||

| roof | + | |||||||||

| Price per package, rub (thickness 50 mm) | 475 | 598 | 733 | 761 | 2781 (30mm) | 682 | 796 | 1230 | 925 | 955 |

* — you can always find out detailed information and current prices in Rockwool product catalog.

Features of mineral wool boards

Mineral wool is a material that is made from molten volcanic rock, blast furnace slag, or glass (passed through a centrifuge to pulp and mix with phenol-formaldehyde resins).

Important! Due to the technical characteristics of Light Butts Rockwool mineral wool slabs and ease of use, slabs hold leading positions in the market of building materials used to insulate roofs and facades.

The advantages of using mineral wool slabs include the following:

- duration of operation (terms of use will be 50 years);

- good parameters of heat and noise protection;

- high vapor permeability;

- adequate price;

- comfort of marking, cutting, installation;

- small specific weight, which allows you to remove the load on the structure;

- high density, strength;

- bio-, fire resistance;

- unattractiveness for attacks by rodents and other pests.

The disadvantage of mineral wool will be that the material is vapor-permeable, water vapor will pass between the fibers. Therefore, it is important during installation to allow the vapors to provide an outlet to the outside so that they do not accumulate in the slabs: the wet mineral wool will not dry out, it will have a high thermal conductivity.For example, polystyrene or polystyrene is almost completely vapor-tight.

The device of the miniplates

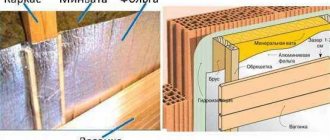

How to mount the slabs correctly: the example of the attic

It is necessary to work with the Light Butts insulation in compliance with safety rules, be sure to use protective equipment: a respirator, gloves and goggles. Simple precautions will help you avoid contact with the smallest particles of material during operation.

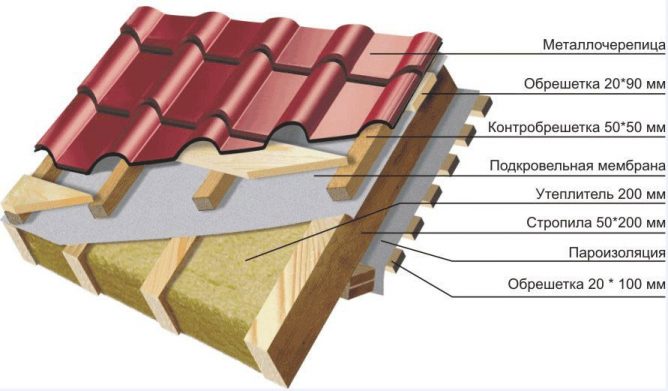

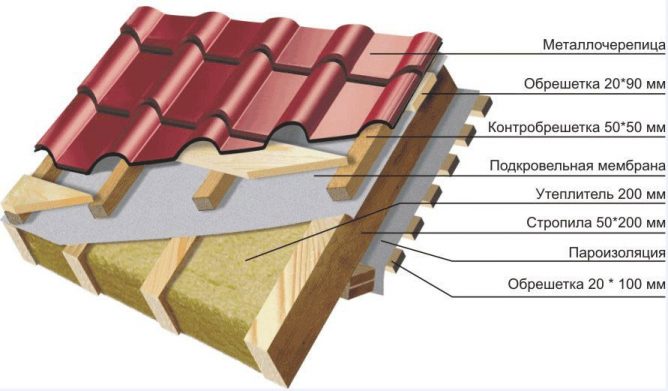

When insulating the attic, the first priority is to lay a moisture-windproof membrane. It is necessary to protect Rockwool insulation from condensation. Performing the main function, the membrane does not deprive the structure of the ability to "breathe", allowing the steam to be removed in a timely manner until a dangerous amount of moisture accumulates. Fasten the film with a construction stapler to the rafters.

On the surface of the membrane, lathing slats are attached for the ventilation gap device. Its length depends on the length of the roof slope. The longer the slope length, the larger the ventilation gap should be.

The direction of the Light Butts insulation slabs will depend on the pitch of the rafters. Given the feature of the products that simplifies installation, it will be most convenient to insert them between the rafters in increments of 600 mm. Plates are fastened in two layers and always with a gap that does not allow cold bridges to form.