The choice of insulation for a pitched roof

On the market of modern building materials, there is a huge amount of all kinds of thermal insulation materials of various origins, made using a variety of technologies.

To decide on a suitable insulation for a pitched roof, it is worth considering the following indicators:

- Low thermal conductivity, no more than 0.05 W / m × K.

- Minimum weight so as not to overload the roof. To determine the mass of an insulating material, it is enough to know its density. For insulation based on mineral wool, 45-50 kg / m3 is enough, and for fiberglass - 14 kg / m3.

- The material must be water-repellent. If it gets wet, it will lose up to 60% of its useful qualities.

- Resistance to sharp temperature fluctuations, including severe frosts and various natural influences, which seriously affects the durability of the material.

- Environmental cleanliness - namely, the release of harmful substances into the space during operation.

- Fire safety. It is very good if such a material does not burn and does not support combustion.

- The ability to maintain its shape for a long time, which affects the quality indicators of the heat-insulating layer.

- Durability. Modern thermal insulation materials are distinguished by enviable durability. Insulation for pitched roofs must have a service life of at least 50 years.

The following modern heaters satisfy similar requirements:

- Mineral wool produced on the basis of basalt rocks: PAROC, eXtra, ROCKWOOL Light BATTS, ROCKWOOL Light BATTS SCANDIC, ISOROC ISOLIGHT, TECHNOLIGHT Extra, TECHNO Rocklight.

- Mineral wool produced on the basis of fiberglass: URSA Pitched roof, ISOVER Pitched roof, ISOVER Roll frame - M40-TWIN-50, KNAUF Pitched roof Thermo Roll-037, KNAUF COTTAGE Thermo Roll-037, KNAUF COTTAGE Thermo Plate-037.

- Expanded polystyrene (polystyrene) is suitable for insulating non-residential attic spaces. It is laid on the floor, and then poured with a cement-sand screed. This is due to the fact that the material burns and emits a whole list of harmful substances.

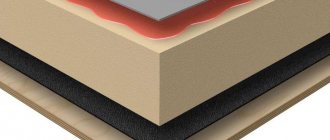

- Extruded polystyrene foam, like PENOPLEX, is also used in conditions where there is no contact with fire (presumably).

- Polyurethane foam - insulation in liquid form. It is applied by spraying or filling the free space.

It should be noted that almost all wool, of any origin, absorb humid air. In this regard, the installation of such heaters is accompanied by the installation of special waterproofing films. Plain polystyrene or extruded polystyrene foam is also used as insulation for pitched roofs, although many experts do not recommend this.

This list includes some of the most demanded heaters of our time. At the same time, one should not discount environmentally friendly insulation based on natural materials such as seaweed, roof insulation based on flax, straw, hemp, as well as cork. Almost all of them are flammable, although there is one plus - they do not emit toxic substances during combustion.

Therefore, it makes sense to consider the most famous and affordable ways of insulating pitched roofs based on modern insulation.

Basic materials for insulation

There are many materials for this type of work, so I will give a brief overview of heaters for pitched roofs that are most suitable for this:

1. Polystyrene - there are various varieties of this material, however, expanded polystyrene is a common use as insulation.

Its main properties are low weight, low thermal conductivity and long service life. But these are all his merits. There are a huge number of disadvantages: the material is extremely flammable, has the property of destruction from high temperatures (80-900) and with the help of it you cannot get rid of cold bridges. Better not to use it.

2. Cellulose is a fairly new material that is just beginning to gain popularity. Cellulose insulation has a number of positive features - low thermal conductivity, environmental friendliness, good air permeability, and also has good sound insulation. The material is not subject to combustion, resistant to external temperatures, and during installation creates a monolithic insulation structure. The disadvantages include the overpriced cellulose insulation and minimal demand. Often, material is only delivered to order, which is inconvenient to wait.

3. Basalt wool - the most common and affordable material, which includes many positive qualities.

note

Distinctive features of basalt wool - almost complete absence of thermal conductivity, increased sound insulation, increased density and porosity of the material. Basalt wool is not subject to combustion, which increases the safety of the building. The service life of such insulation is on average 25 years, which makes it possible to simply forget about the problems associated with roof insulation for a quarter of a century.

Our team uses this material most often, and my own recommendations for insulating pitched roofs are always associated with basalt wool.

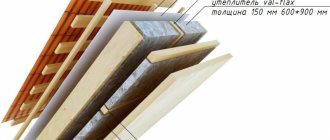

Roof insulation based on "Ursa - pitched roof"

Thermal insulation for pitched roofs, produced by a German company using URSA Spannfilz technology, is widely used in the construction of all kinds of construction, both residential and non-residential buildings.

Insulation URSAGlasswool Pitched roof

The advantages of this insulation:

- the elasticity of this insulation allows it to be held in the spaces between the beams without sagging and the formation of cracks;

- lightness of insulation;

- the presence of soundproofing characteristics;

- low thermal conductivity - 0.036 W / m × K;

- excellent flexibility of insulation, which allows you to fill difficult spaces;

- there is no need for additional fastening elements, it is held in the openings by itself;

- under the packaging, the insulation is compressed 5 times, and after unpacking it quickly returns its volume;

- the material practically does not burn.

Prices for URSA Pitched Roof insulation depend on the size of the mats and start at $ 50. for 1 cubic meter. The thickness of the material is 150 and 200 mm, but mats with a thickness of 150 mm are considered the most demanded. As a rule, this thickness is always sufficient for insulating pitched roofs in most cases. When calculating the thickness of the insulation for a specific climatic zone, you will have to use the SNiP 11-3-79 manual. The material is produced with a width of 1200 mm, with a length from 3900 to 4200 mm. It fits seamlessly between the roof rafter system without joints and gaps.

Roof insulation with polyurethane foam

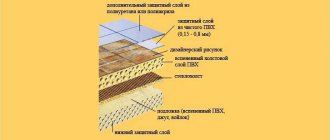

Note that this insulation material is a foam that is applied to the roof truss system. Under the influence of air, the foam concentrate polymerizes and becomes strong. In fact, a seamless layer is formed on the insulated surfaces, somewhat similar to polyurethane foam. In principle, this is it, just a different modification with different technical characteristics.

Polyurethane foam is a two-component material. For mixing the ingredients, special equipment and a compressor are used, which ejects the finished mixture under pressure. Note that the foam has high adhesion properties, so it easily sticks to any building materials.

Insulation specifications:

- thermal conductivity 0.019-0.028 W / m K;

- density from 30 to 150 kg / m³;

- operating temperature from -160C to + 150C;

- closed form of bubbles;

- water absorption 2%;

- flame retardant material (G1);

- does not decay, is resistant to solvents and chemicals;

- service life - up to 30 years.

Roof insulation technology "Ursoy"

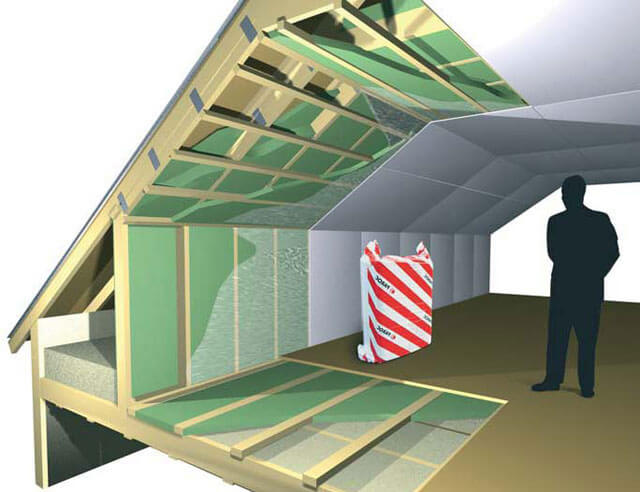

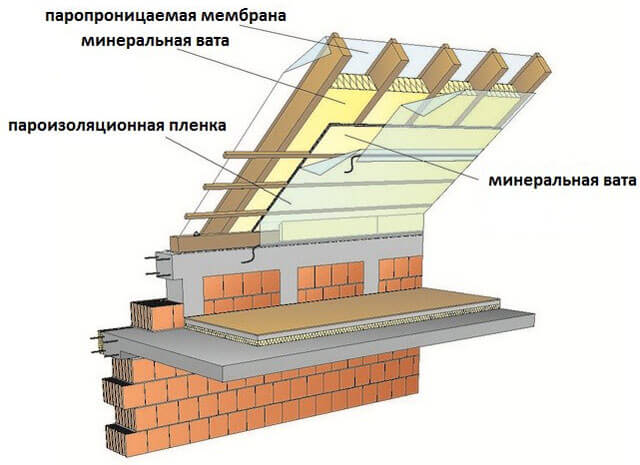

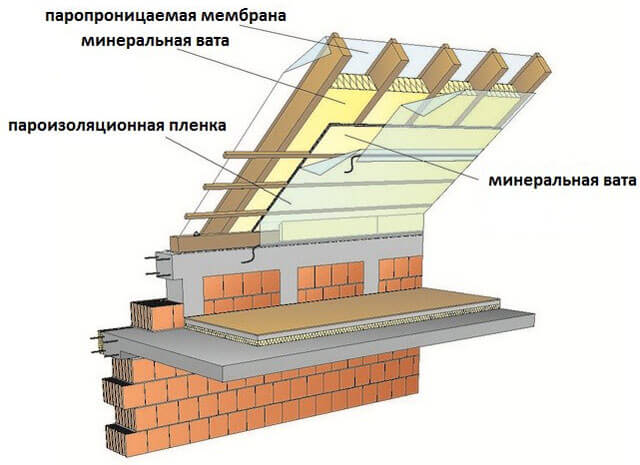

Thermal insulation for a pitched roof requires a special laying technology due to the possibility of condensate penetration into the material, as well as steam rising from the room. Basically, such insulation is used in conditions when it is necessary to insulate the roof in order to create a part of the room under the roof for living.

To carry out the operation to insulate the roof slope with Ursa "Pitched roof", you will have to take some steps.

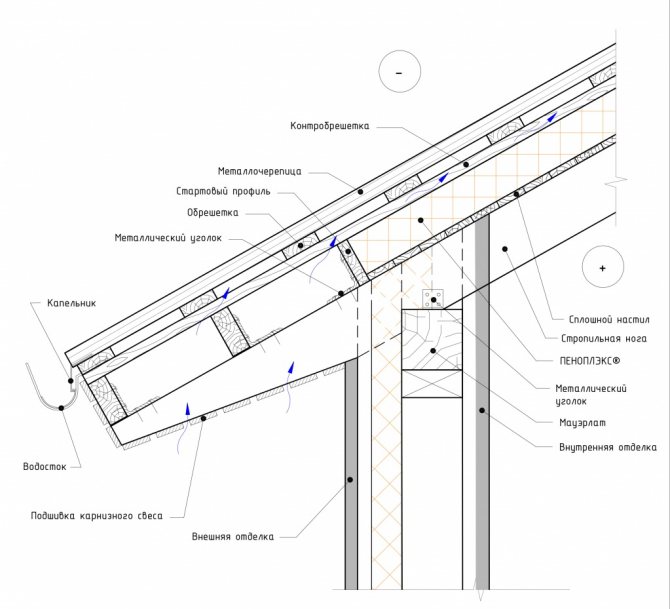

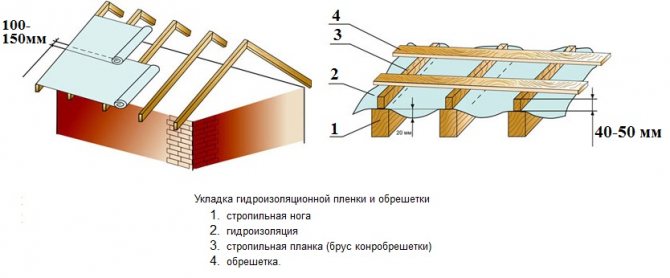

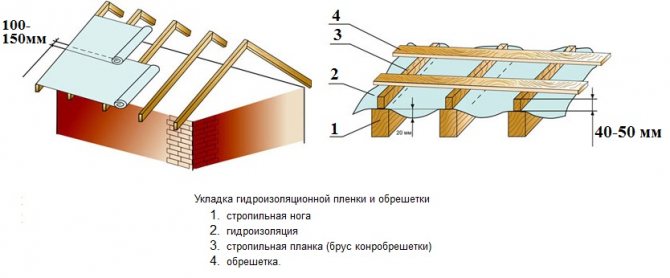

Before starting the installation of the roof itself, a waterproofing film is laid on top of the rafters. The type of film depends on many factors, such as the characteristics of the insulation, the material of the roof and the film itself. The film is laid across the rafter system with an overlap of 100 mm. The joints of the film are connected using special tape. The material is fixed to the rafter system with a stapler or nails with a wide head.

It should be noted that the waterproofing material should never be tightened. There must be a sag, but no more than 2 cm per 1 meter. This is due to the fact that in the presence of subzero temperatures, the film will stretch even more and may break.

On top of the film, a lathing made of bars with a section of 25x25 mm is mounted, although there may be more, depending on the calculated data. The thickness should be sufficient for the under-roof space to be ventilated very actively. It turns out 2 ventilation gaps between the insulation and the film, as well as between the film and the roof, which prevents condensation from appearing. This means that the crate is also mounted on the other side of the waterproofing film.

Before insulating the pitched roof, roofing material is laid. It is attached either directly to the lathing, or on chipboard or OSB sheets, which are previously mounted on the lathing.

After that, you can start laying Ursa Pitched Roof. To begin with, the material is unpacked and left in this state for 20 minutes so that it straightens out and takes on a working state. After that, the insulation for the roof is cut into separate sheets of the required size, adding 2-3 cm to the width. In this case, the material will fit tightly into the space between the rafters. To straighten the edges, press lightly on the canvas.

Good to know! In order not to cut the insulation and not waste precious time on this, the distance between the rafters is made slightly less than the width of the insulation by 2-3 cm.

A vapor barrier film is spread on top of the insulation (from inside the attic), which is attached directly to the rafters. After that, the attic space is finished (if necessary). Before finishing, another lathing of wooden blocks or a classic metal frame for a plasterboard system is mounted.

If the attic space is not supposed to be used as a living space, then such an insulation scheme is not entirely suitable, since in this case it is necessary to isolate the attic space by laying the insulation on the attic floor.

In the case of buying a ready-made house, where the attic insulation is not performed, you can resort to some work. Since there is a ready-made pitched roof, the waterproofing film is laid on top of the rafter system, and so that it repeats the relief of the structure. After that, the insulation is mounted in the gaps between the rafters. It turns out that the wooden structure is not protected from leaks, and the insulation is protected.

There is one more method, similar to the first one, but of a higher quality. The space between the rafters is not filled with insulation, but a waterproofing film is filled.Suspension elements used in plasterboard systems are attached to the rafters. The insulation is wound up behind the hangers and attached. After that, the insulation is closed with a vapor barrier film.

A similar method of insulating pitched roofs is applicable for any type of mineral or glass wool insulation.

Laying the waterproofing layer

The greatest number of mistakes occurs due to the fault of the builders. I would like to quickly install the roof so that after that you can safely proceed to the interior decoration of the rooms. This is quite reasonable, since with a roof over your head you will feel protected from various weather conditions (snow, rain). If you start interior decoration without a roof over your head, you can get caught in heavy rain and the same plaster will simply start to crumble, and huge puddles of water and mud will appear on the floor.

First of all, do not forget about waterproofing under the roofing material. Functions of waterproofing material:

- leakage protection;

- preventing the formation of condensation.

Layout of waterproofing film and lathing.

Thus, a film or roofing material, laid under the roofing material, protects wooden rafters from moisture, prevents their rapid destruction and decay. Of course, there is also the protection of the house. Indeed, when leaking, water accumulation and destruction of the ceiling in the room is possible. It is not always advisable to use waterproofing. If the installation of the roofing material is done correctly, and the attic is ventilated perfectly, then there will be no leaks or condensation. In other words, you can do without laying waterproofing material. But if you decide to carry out the installation of such a coating, then you should pay your attention to the following nuances for high-quality work:

- consider the strength indicator;

- take into account the vapor permeability of the material.

Do not try to save money, choose quality materials for installation. Usually the manufacturer indicates these indicators on the packaging of the material. But this does not always happen, so you have to work a little yourself to do some rough calculations. The calculation boils down to comparing two figures showing the resistance to vapor permeation of vapor barrier and waterproofing. The latter should have a lower value. This will eliminate the formation of condensation and its accumulation on the waterproofing material.

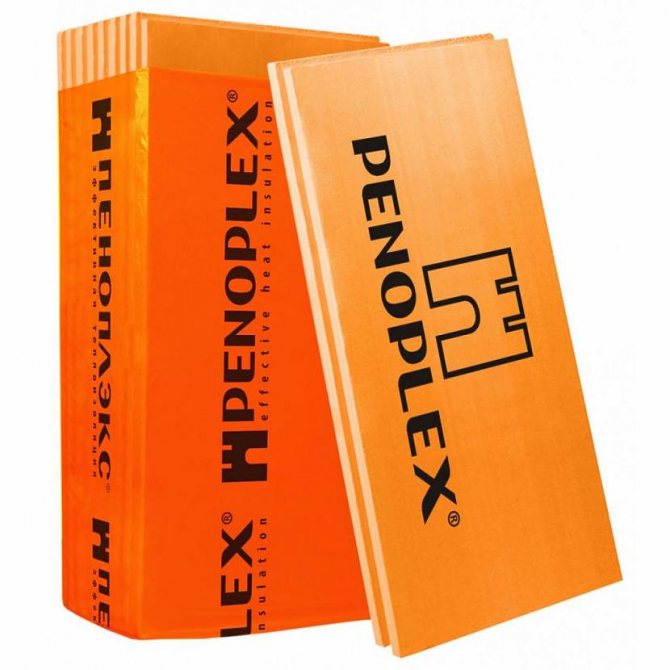

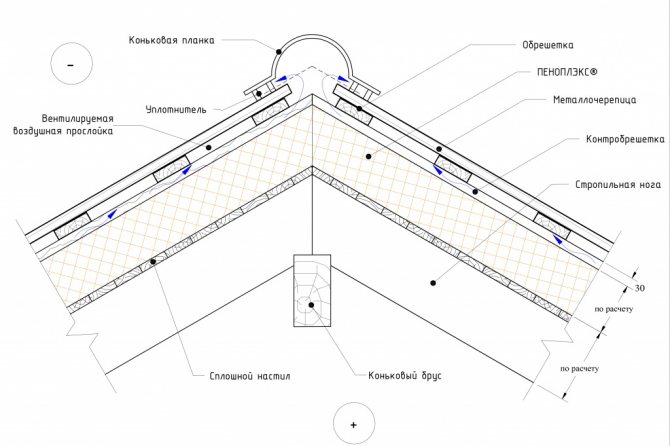

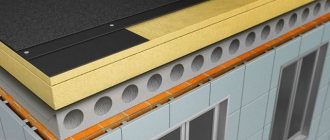

Installation of Penoplex boards on top of the rafters

As a rule, it is used in cases where it is not possible to use another insulation. This is possible if a residential building is being built from scratch. Penoplex boards can have a thickness of 60 to 120 mm.

Stages of work:

- After installing the rafters, a rail is attached from below, the width is the thickness of the insulation. This will prevent the plates from sliding down.

- Then the insulation is laid out in a checkerboard pattern.

- A vapor-permeable waterproofing film is laid on top.

- A lathing made of wooden blocks, with a section of 40 × 40 mm, is mounted to ensure an air gap. The bars are fastened with self-tapping screws, but before fastening, you should drill holes in the "penoplex".

- Roofing material is mounted on top of the lathing.

Penoplex does not require additional protection.

Thermal insulation of a pitched roof with ecowool

This insulation is nothing more than recycled cellulose. Its insulation is 81%. The rest is additives: flame retardant and antiseptic. In appearance, this material is a loose mass, which is filled with places that are subject to insulation. To increase the speed of thermal insulation work and increase the efficiency of laying material for thermal insulation of roofs, special equipment is used. In it, ecowool is moistened and supplied under pressure through a hose.

What is ecowool Source saw-wood.com

Specifications:

- thermal conductivity 0.032-0.041 W / m K;

- density 30-73 kg / m³;

- flammability class - G2 (moderately flammable);

- vapor permeability - 0.3;

- ecowool easily absorbs moisture and also gives it away easily, while its qualities do not change;

- it is a good sound insulator, it reduces the sound pressure by 65 dB with a layer thickness of only 5 cm;

- insects and rodents do not like ecowool, the reason is the presence of borax in its structure;

- applied in a seamless way, does not require additional fasteners;

- service life - up to 80 years.

Insulation for pitched roofs in the form of expanded polystyrene

Since this material is cheap compared to other types of insulation, it is used quite often.

When working with him, you should take into account the following nuances:

- the foam is poorly cut, so it is not very convenient to work with it;

- it burns and emits harmful substances when it burns.

Naturally, the technology of its installation is the same as the installation of "Penoplex", with the only difference that after the styrofoam is laid, many cracks are formed, which then have to be foamed, for example. It is desirable to protect the foam from direct sunlight.

In conclusion, it should be noted that the insulation of a pitched roof is a serious process that takes a lot of effort and money. Before starting work, it is better to consult which of the materials is better or more economical.

Insulation of a pitched roof with an unheated attic

When building a house with pitched roofs and an unheated attic, the thermal insulation layer can be formed from two types of materials:

- bulk thermal insulation materials - expanded clay, crushed slag, as well as granules pressed from various types of heat insulators, such as polystyrene, cork material, wool, shale chips;

- roll insulation materials - mineral wool, felt, etc.

Bulk materials are placed on a special screed, and wooden boards are additionally laid on top. The thickness of the layer of bulk heat-insulating materials depends on the material itself, since each one can have a different weight, and is approximately calculated based on the fact that it is necessary to make a layer weighing 100 kg for each 1 m2 of the surface to be insulated.

Common mistakes when installing roof insulation

Some homeowners begin thermal insulation work with absolutely no idea how to insulate the roof on their own, making typical mistakes. The most important mistake: the wrong choice of heat insulator and its dimensions - especially the width.

The process of internal insulation of the roof of the house

If the width of the building material for creating the thermal insulation layer is less than necessary, this will lead to the formation of cracks, and the thermal insulation made in this way will not fulfill its main function and, naturally, the roof insulation from the inside will be ineffective.

To avoid such an unpleasant situation, the correct selection of a heat insulator must be carried out at the stage of creating a roof project.

Important: the thermal insulation installed on the roof must be strictly dry. Otherwise, the rafters and other parts of the rafter system will rot.

The main mistakes in the construction of the heat-insulating layer, which negatively affect the condition of the entire roof, are as follows:

- A waterproofing layer is not laid on top of the insulation on the roof.

- The waterproofing is installed, but it was not securely fixed, as a result, the heat insulator is displaced with the formation of cracks into which cold air enters.

- The ventilation gap is not provided for by the project. As a result, there is the formation of condensation, which accumulates on the wooden parts of the rafter structure and on the insulation itself.

- Lack of vapor barrier.

This is also important to know: Insulation of the attic - how to turn the under-roof space into a living space