Categories of materials

Stone wool

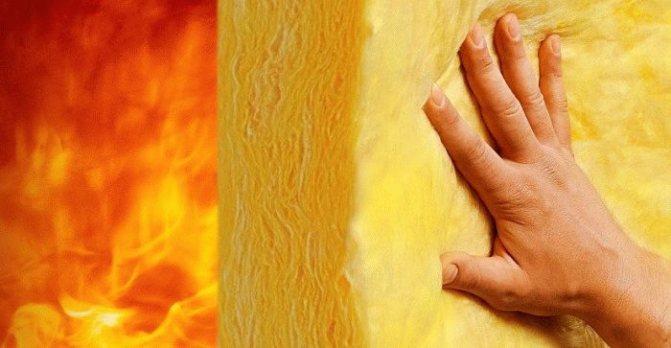

Heat and sound insulating stone wool slabs. Produced on the basis of basalt. Due to their low thermal conductivity, stone wool slabs retain heat in winter and cool indoors in summer. Completely safe for human and animal health. The service life of the materials is comparable to that of a building.

Areas of use

- attic;

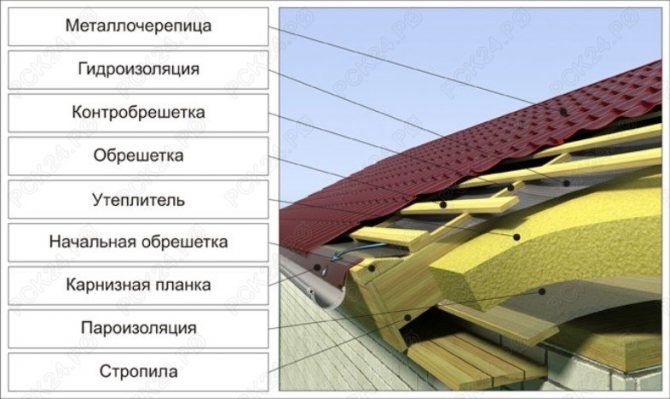

- pitched roof;

- cold attic;

- baths;

- floors on logs;

- frame walls;

- overlappings;

- partitions;

- facades for siding;

- ventilated and plaster facades;

- other structures where the material does not perceive external loads.

* based on the results of studies carried out according to the methodology of the standard DSTU B V.2.7-182-2009

A versatile and modern material from extruded polystyrene foam. Possesses high heat-saving and strength properties. Low-thickness XPS creates a reliable thermal insulation layer, reduces heat loss and saves more usable floor space. The material is resistant to moisture, mold and mildew

Areas of use

- floor, including underfloor heating technology;

- walls from the inside;

- balconies and loggias;

- blind area and basement;

- foundations.

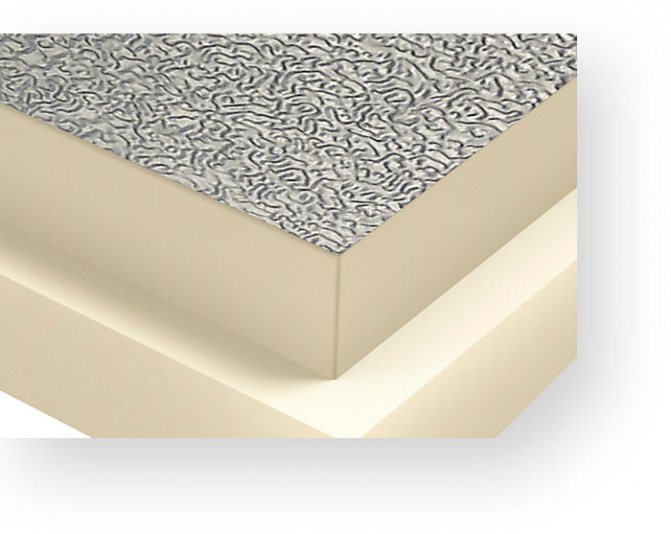

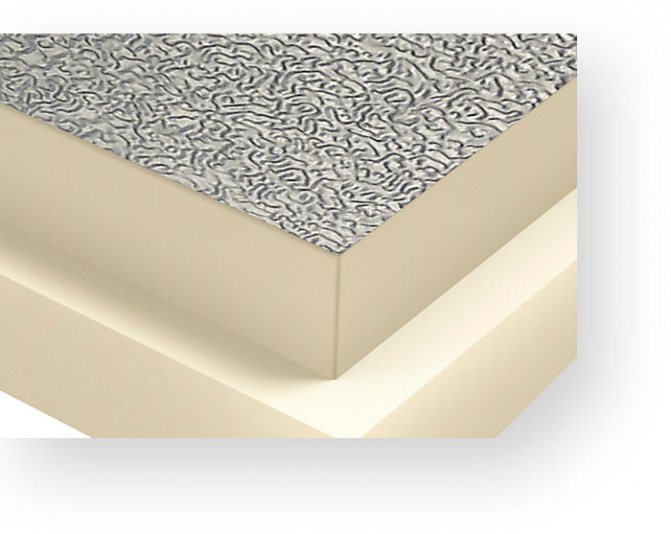

Innovative environmentally friendly rigid polyurethane foam insulation. Possesses high thermal insulation properties and mechanical strength at low thickness. Saves indoor space. Retains its characteristics for over 50 years. It is lightweight and easy to assemble. The double-sided foil coating additionally reflects heat and imparts water resistance.

Thermal insulation Technonikol

In the Russian market, Technonikol has long gained popularity with a wide selection and quality of heat-insulating materials. The range of manufactured stone wool produced on the basis of basalt rocks. Basalt fibers are mined by melting mineral rocks. As a result of production, a very dense and durable material with low thermal conductivity is obtained.

Currently, there are a huge number of different types of materials. Most insulating materials are not only intended as heat insulators. They also have sound insulation properties and help protect structures from destructive impacts. The company strives to produce the highest quality product lines.

Techno produces versatile types suitable for various working situations in the construction sector. These include Rocklight insulation.

What is stone wool?

Stone wool is made from volcanic rock. In its natural form, it is a solid material, so that it takes on a "cotton" shape, it is melted and separated into fibers. Depending on the manufacturer, one or another technology (centrifugal or spinneret drawing, blowing, swathing) can be used for this procedure. Basalt processed in this way becomes free-flowing, and so that it does not crumble, and so that a certain shape can be formed from it, the fibers are treated with a sticky substance.

Phenol-formaldehyde resin - this is the very adhesive, in any case, it is used more often than analogues. It glues the fibers together, making the layers of the required thickness. Then the stone wool is treated with a special oil to make it water-repellent. The last stages of production are the cutting and packaging of the insulation.

Photo insulation of the facade with stone wool

Introductory information

Insulation is an irreplaceable material in the construction and reconstruction of buildings. Mineral wool "Technonikol" is the most successful solution for thermal insulation.It is actively used in the territory of the CIS countries. It is widely known in some European countries.

The company focuses on the production of stone wool, which is made from rocks belonging to the basalt group. By introducing synthetic substances, the products are given a geometrically regular shape. Despite the content of artificial components, the products are safe for the human body.

Varieties of stone wool

Stone wool comes in different types. Basically, it is divided into types by density.

- Soft cotton wool, it is also a roll insulation. Its density ranges from 10-50 kg / m. cub. The thermal conductivity coefficient is 0.033 W / m * C. It is used to improve pipelines, frames, ceilings, partitions.

- A semi-rigid board can have a density of 60 to 80 kg / m3. cub. The thermal conductivity coefficient is 0.039 W / m * C. It is often used for facades, roofs, ceilings or sandwich panels.

- The rigid slab has a density of 90-175 kg / m. cub. The thermal conductivity coefficient is 0.046 W / m * C. This insulation is used for surfaces that are subject to significant mechanical stress. This can be the floor, roof, foundation, underground pipelines, etc.

Mineral wool is the most popular material among roof insulation

Minvata is subdivided into the following subspecies:

- Stone wool;

- Fiberglass;

- Slagged.

The last option from the list is not recommended for use in the decoration of residential premises. This type of insulation is produced from the waste of the metallurgical industry, therefore, they should be finished with buildings that are not intended for the permanent residence of a person.

For home insulation it is safer and better to use modern basalt insulation. It contains such types of resins as formaldehyde, but the percentage of this additive is insignificant. In addition, this chemical is present in the building material as a polymer. The composition of such a resin is chemically stable, and it is in a cured state that does not pose a danger to human health.

For finishing flat roofs it is necessary to use mineral wool slabs with high stiffness and density (140-160 kg / m³).

For thermal insulation of the roof of the pitched structure, softer plates are used, which are mounted between the rafters. It is easy to give the material the desired shape and size, simply by cutting the slabs according to the desired parameters. They are also laid between the lags. The top of the insulation is covered with a protective cover. Mineral wool is one of the most demanded materials used for roof insulation. The fact is that it has a special, "breathing" structure. Any wood structure requires good ventilation. If you use a heater made of polymer, then the "breathing" of this design loses its intensity. This can damage the rafters. Therefore, it is recommended to use mineral wool. In addition, it does not burn, the maximum can melt, but only at a very high temperature - from 1500 degrees and above.

This type of insulation also has its drawbacks. It is too hygroscopic, that is, it absorbs moisture well. On the roof, of course, this is useless. The thermal conductivity coefficient of this building material in a dry state is 0.036 W / m3 K, and if the mineral slab is wetted, it will become approximately 2 times higher. If any area is still exposed to moisture, it is better to replace it. Another disadvantage is the crumbling of mineral wool over time, with the formation of fine dust. It is worth ensuring the insulation of mineral wool with the help of special films, which at the same time will prevent the accumulation of water in the thickness of the insulation and its shedding.

URSA

This trade brand has been known on the market since 2002. It was formed by combining Spanish and German companies. The brand is widely known in Europe and is one of the best in the rating of cotton heat insulators.The manufacturer successfully produces roofing insulation made using staple fiberglass. The product is relatively affordable in cost, while it fully complies with world quality standards.

The main advantages of the product:

- excellent sound insulation;

- high rate of elasticity;

- the working temperature range of the material is in the range from -70 ° C to + 180 ° C;

- the density of the insulation is in the range of 10-32 kg / m3.

Such material is used both for arranging slopes and for flat roofs. Its strength characteristics are at a high level. Ideal for insulating roofs with a high level of noise, for example, from metal tiles. One of the few drawbacks can be considered the fact that when laying it, it is necessary to additionally perform waterproofing work. The average price is about 1100 rubles / unit.

Rockwool

This brand is originally from Denmark, where it has been produced for over a hundred years. The company initially operated gravel production in quarries. To date, she produces a material for thermal insulation, which is lightweight and is not afraid of moisture. These qualities allow him to perfectly cope with the function of roof insulation.

Properties and characteristics of stone wool

Stone wool is often compared to other types of similar material. Namely, with glass wool, slag and mineral wool. Below are comparative characteristics that allow you to navigate in one or another parameter of all types.

| Parameter | Stone wool | Mineral wool | Glass wool | Slag |

| Average fiber diameter (μm) | 5-15 | 4-12 | 4-12 | 4-12 |

| Fiber length | 20-50 | 16 | 15-50 | 16 |

| Thermal conductivity (W / m2 * k) | 0,033-0,046 | 0,077-0,12 | 0,038-0,046 | 0,46-0,48 |

| Usage temperature | -190 to + 700 ° C | -60 to + 600 ° C | from -60 to + 450 ° C | -60 to +250 |

Types of mineral slabs

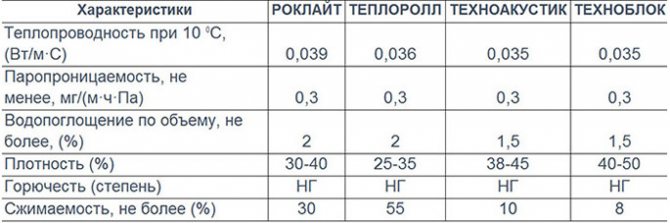

There are several basic types of basalt insulation. They differ in a number of properties. Popular materials such as "Teploroll", "Technoblock", "Technoacoustic" and "Rocklight".

Insulation "Teploroll" is a long mat, which is sold in a roll. The structure of "Rocklite" includes resin. A small content of phenol is determined in them. It is one of the best materials used for insulating private buildings.

"Technoblok" can also be used as thermal insulation in the arrangement of frame dwellings. The material has a low phenol content. "Teploacustic" differs not only in thermal insulation properties. He can withlower noise levelthat goes into the room from the outside environment. This is possible due to the special arrangement of the fibers.

Advantages and disadvantages

Experts note both the advantages and disadvantages of stone wool, so before buying it for insulation, it is necessary to weigh the pros and cons. What are the advantages of stone wool?

- The material is lightweight, which allows it to be easily carried and laid during the insulation of the room.

- This is a time-tested insulation.

- High insulating properties.

- Stone wool is not afraid of temperature extremes. Regardless of the weather, it does not expand or contract, it keeps its shape and retains its properties.

- The basic characteristics are the same regardless of the manufacturer. So, for example, insulation from Rockwool and Isobox have similar parameters and qualities, but differ in terms of price, additional raw materials used for production and other parts. Hence the price difference.

- The material is not flammable.

- Depending on the quality of the insulation, vapor permeability can range from 0.3 to 0.55 mg / m hPa. The higher the indicator, the better this property is expressed.

- Laying stone wool is pretty easy, even without practice.

Now about the disadvantages of stone wool.

- Contrary to misconceptions, it does not scare away rodents. Mice and rats are not afraid of it and can live peacefully in it.

- The environmental friendliness of stone wool is often questioned due to the fact that the fibers are held together with resins during production.Manufacturers rarely explain what these resins are, their exact composition and whether they are harmful, so the question remains open.

- During the laying of stone wool, dust appears, which is strongly recommended not to inhale. Therefore, you can only work with it in a respirator.

Photo of stone wool Technonikol and Rockwool

Characteristics of Rocklight insulation

The thermal insulation of this brand is made of mineral wool slabs, the fibers are bonded with non-toxic resins. Sheets may vary in size.

Among the advantages of Rocklite, the following properties should be noted:

- Vata is not afraid of fire;

- It is an environmentally friendly breathable material;

- Low water absorption;

- The insulation will not be gnawed by mice, insects will not settle there, it does not rot;

- The price is very affordable;

- Long lasting.

Thermal insulation is produced by Technonikol, which has long specialized in building materials and has a well-deserved reputation.

Cotton wool is not afraid of temperature changes and installation is not difficult. Installing stoves will help you seriously save on heating.

Where is stone wool used?

Since the 20th century, stone wool has become widespread. Due to the fact that it is 95% natural material, it is used for insulation of various types of buildings.

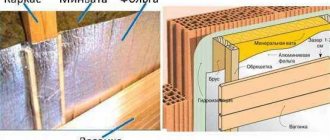

- Walls. As a facade insulation, this material is very popular. Thermal insulation properties help prevent heat loss in winter and keep cool in summer.

- The floors are often insulated with them. It allows you to make screeds, provides sound insulation.

- Roofs (flat and pitched) are partially insulated with this insulation. True, it is not recommended to use only stone wool, but it is suitable as part of protection.

- Partitions inside rooms are often made with the participation of this material. It provides additional sound insulation.

- Bearing beams and columns, reinforced concrete floors, transit air ducts, cable and pipe passages can be made using stone wool. This provides fire protection and additional safety for the occupants.

Product opinions

“I have come across glass wool before, so I have a negative attitude towards it. Penoplex, based on the specifics of the structure, also did not fit. I made a choice in favor of thermal insulation from TechnoNIKOL, and I have no regrets. I used it everywhere - for walls, roofs, floors on the 1st floor of the house. I carried out all the installation work myself, therefore, I can objectively assess all the advantages and disadvantages of the material. Therefore, I give a review about the Rocklite insulation company the best. An excellent option, if, of course, do not forget about the competent arrangement of the waterproofing layer. "

Andrey Artemiev, Omsk.

“To be honest, I have not seen any bad reviews about TechnoNIKOL products. Therefore, I opted for Rocklight. The material in use is universal, therefore, without any problems, it can be used for thermal insulation of all parts of the house. The only thing I want to warn about is density. In terms of operation, there are no complaints about this characteristic of Rocklight. But during transportation, there may be damage to the plates. Since it is sold in packaging, defects are sometimes invisible. Before buying a particular pack, I advise you to take a close look at the Rocklite edges. "

Vasily, Leningrad region.

“I've heard a lot of different opinions about the advisability of purchasing this TechnoNIKOL product. Based on my own experience, I will say that Rocklight is the right solution as a heater for the roof. Everyone knows - high-rise work from the category of increased complexity. The low weight of the slabs, dimensional accuracy, combined with some elasticity, allow the installation of thermal insulation in a relatively short time. I believe that all negative reviews about this basalt insulation are either far-fetched or given by incompetent people. If you correctly equip the waterproofing of the roof, then Rocklight is an excellent option for a private house. "

“I just recently finished finishing the house, so I dare say that Rocklight is quite convenient in terms of installation.The slabs are cut quickly, and there were no problems with their laying in the crate cells, given that, although they are dense, they are compressed.

The only thing that I did not take into account at the very beginning is the hygroscopicity of the material. I took off the packaging on one side and left some of the insulation outside the house. It rained at night, and in the morning I saw the products swell. I believe that moisture absorption is a significant disadvantage of Rocklite. For the rest, there are no complaints. We spent half of the winter in the house and in terms of thermal insulation everything is fine. "

“I went over the roof and made sure that the rafter system will still serve. In order not to load it too much and not to mount a continuous flooring, I decided to limit myself to a metal profile. I chose Rocklight, I did everything from start to finish on my own, so the final cost of the work was not high. Already 2 years have passed since the roof was repaired, so my conclusion is that I was not mistaken with thermal insulation. It is always dry, warm and cozy in the attic. "

Mansur Atynbaev, Pskov.

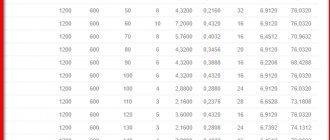

Prices are for the Moscow region, in rubles. It is advisable to cite various data. This will help the reader to better understand what thermal insulation will cost him using Rocklight.

1. Analysis of customer reviews shows that the price of insulation for 1 m2 (installation work) is about 58-60.

2. 1 "square" of Rocklite slab costs an average of 55.

3. The cost of 1 m3 - within 1220-1320, depending on the volume of the purchase.

4. For packing TechnoNIKOL insulation you will have to pay from 450 (6 pieces) or 950 (12 plates).

Author: Sergey Isaev

| can you specify from what address the bus leaves from Volzhsky? |

| Hello, Departure address: Volzhsky, 31 md. |

| Hello Sergey. We have checked the availability and functionality of the "Return" button. Everything works as usual. The "Return" button is located in your personal account (Select the order you want to return and click the "More" button, there you will see the full information on the order, as well as the "return" button). |

| Hello Alexey. Thanks for your feedback. The mobile application is already under development. |

The best stone wool manufacturers

Stone wool is produced by many manufacturers, but not all of them guarantee quality and durability. In order not to regret buying in the future, you should focus on leading manufacturers.

- TechnoNIKOL - a well-known manufacturer. Stone wool Technonikol comes out in series. For example, Rocklight - slabs cost from $ 12 per cubic meter. Teploroll - a roll, costing up to $ 23 per cubic meter. Technoacoustic - has excellent sound insulating properties. Price from $ 45.

- Isover Is a French manufacturer. Famous lines - Isover>

Photo of wall insulation with stone wool

Range of heaters and prices

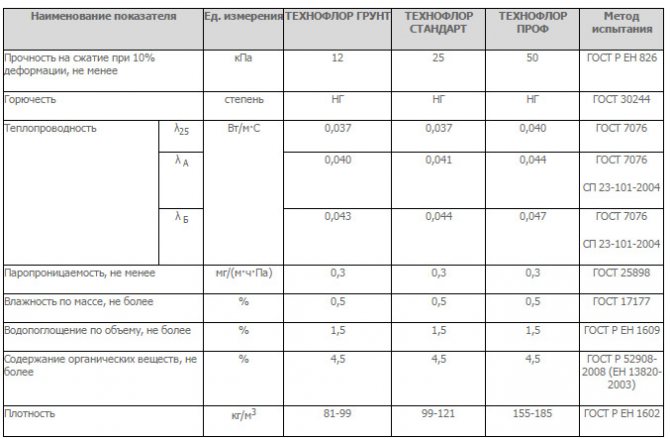

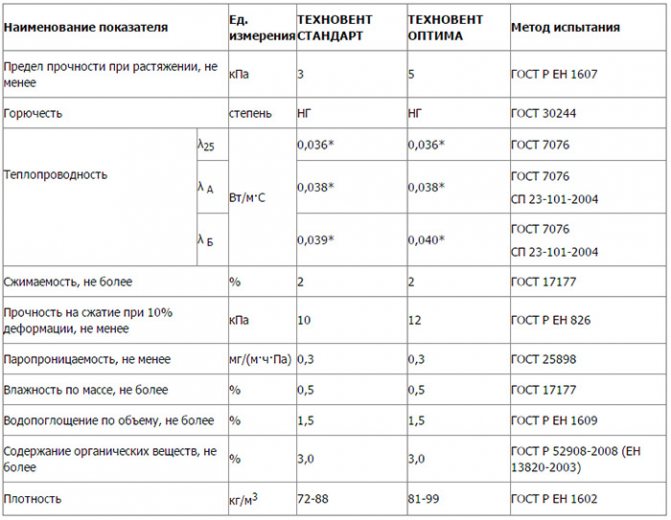

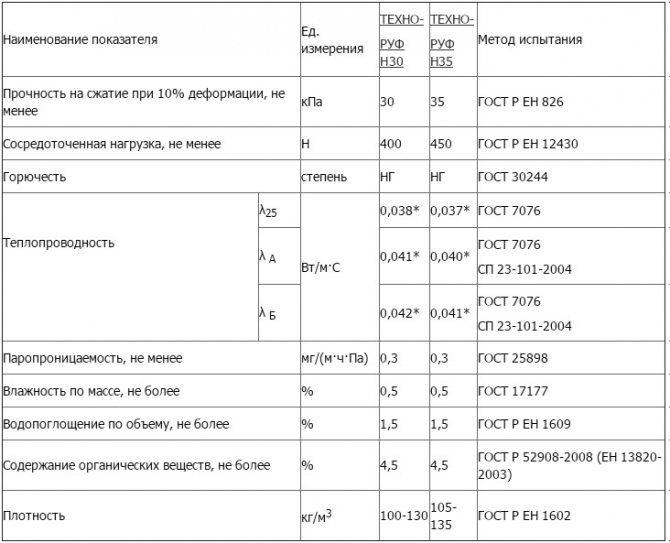

The company produces insulation with dimensions and technical characteristics for specific building structures. To make it easy for the consumer to navigate the variety of products presented, each such type is given its own name.

Basalt wool

The most widely represented is the line of basalt mats. The manufacturer offers plates and rolls:

- Rocklite;

- Technoruf;

- Technovent;

- Technolight;

- Technoflor;

- Technofas;

- "Technoblok";

- Technoroll.

Rocklite. Lightweight basalt fiber slabs (density 35 kg / m3) for external and internal thermal insulation of horizontal and vertical structures in private houses: mansard walls and frame buildings, floors, internal partitions; ceiling from the attic, pitched roofs.

Available in two sizes:

- 120x60x5 cm at a price of 170 rubles / m2;

- 120x60x10 cm costing about 250 rubles / m2.

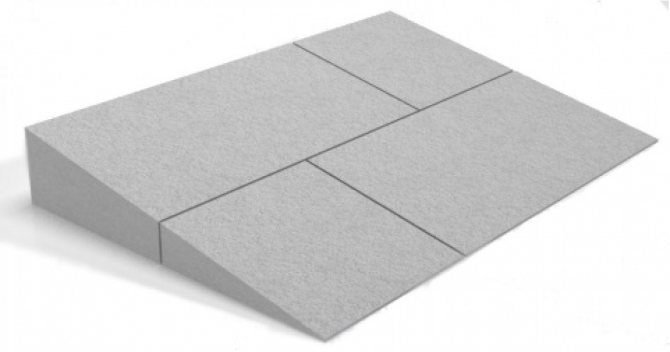

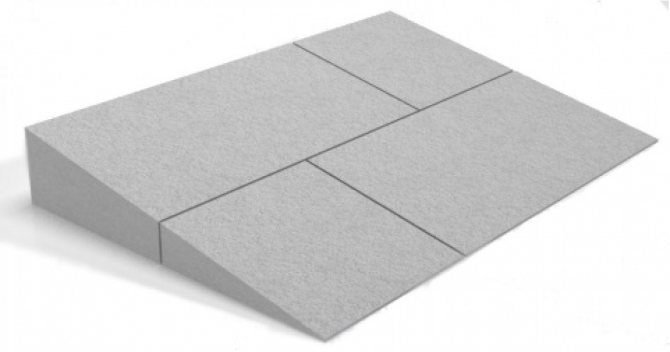

Technoruf. The main purpose is to insulate facades with a "wet" method for decorative plastering or painting and a flat roof under a screed. For this, the company produces Technoruf boards with a density of 140 kg / m3 and a high peel strength (at least 15 kPa). In addition, the production of wedge-shaped insulation ("Technoruf" n prof) has been mastered.

Dimensions in length and width are standard: 120x60 cm. The thickness can be any in the range of 20-100 mm. Slabs 120 mm thick can be made to order. The price is high, starting from 7,000 rubles / m3.

Technovent. Specialized insulation for walls with a ventilated facade. The manufacturer also allows the use as a middle layer in the "wet" method of insulation for painting and decorative plaster with a small thickness of the mortar. You can buy for 2.8-3.2 thousand rubles / m3.

Technolight. Technolight is another specialized type of basalt wool - insulation for pitched roofs. According to its characteristics, it can also be used for the internal insulation of balcony walls along the frame, the ceiling and walls from the inside of the apartment along the crate and the wooden floor along the logs - you can only fix the bullet.

But when used not for its intended purpose, you need to look at how much 1 m2 of this type of mats costs, because for profile heat insulators, it may be lower. The cost of 1 m3 is about 1800 rubles.

Technoflor. A heat insulator with high compressive strength, withstands up to 50 kPa and a density of about 170 kg / m3 is intended for warming floors with increased stress: sports facilities, warehouse and industrial premises. Therefore, it is practically not used in private construction (it is used for insulating a flat roof of residential buildings). It is expensive - 4,960 rubles / m3 or more.

Technofas. The entire line of this name of basalt mats belongs to the best facade insulation "TechnoNICOL". It is used for thermal insulation of buildings made of bricks and concrete, followed by finishing with building mixtures. The price ranges from 3,300 to 5,500 rubles / m3, which is a bit expensive for the middle class.

Technoblok. The material was created for wall insulation using the "well" method, when an insulation layer is placed between two walls: load-bearing and decorative. It has a high density, which allows it to withstand significant loads on the rib when the mats are supported on each other. But it does not always have the same flat compressive strength. Therefore, it is not used for horizontal insulation. The price fluctuates around 2 180-2 470 rubles / m3.

Technoroll. The only type of basalt insulation that is sold not in sheets in packs, but in rolls. The length of the mat is 4,000 mm, the width is 1,000 mm, the thickness is standard: 50 and 100 mm. Lightweight (density 30 kg / m3), and therefore its use is possible where there are no static loads on the surface of the heat insulator: when insulating floors along logs, attics and ceilings. Budget price.

For information: At the time of preparation of the material, the company temporarily suspended the release of roll material. Therefore, it is not possible to indicate a more precise price.

Extruded polystyrene foam

For private construction, according to technical indicators, the best option is considered to be extruded polystyrene foam, produced under the general name "Carbon". On sale you can find varieties of insulation:

- XPS CARBON ECO;

- XPS CARBON ECO DRAIN;

- XPS CARBON ECO FAS;

- CARBON ECO SP;

- CARBON PROF;

- CARBON PROF SLOPE;

- CARBON SOLID;

- XPS CARBON SAND;

- Ts-XPS CARBON.

XPS CARBON ECO. Boards of this series are basic in the Eco range. They are used in low-rise construction for insulation of foundations, floors, roofs and facades. They burn well, therefore they are not recommended for insulation of walls and ceilings from inside the room. A package of 8 plates measuring 1180x580x50 mm can be bought for 1230-1252 rubles.

XPS CARBON ECO DRAIN. They have a distinctive feature - drainage grooves, which allows performing the following functions when insulating the foundation and flat roof:

- drain rain and groundwater;

- organize micro-ventilation of the roof.

It costs 1 m3 of such a plate from 17,590 rubles.

XPS CARBON ECO FAS. Specialized facade insulation for plastering. Technical characteristics allow using for wall insulation by the "well" method, pitched roof, ceiling from the attic and floor under the screed.A distinctive feature - it has excellent adhesion to mortars and all kinds of adhesives based on cement and gypsum. Price from 215 rubles / m2.

CARBON ECO SP. Tough and very durable insulation is used for thermal insulation of shallow foundations like "insulated Swedish plate". It has no analogues of Russian origin. There is a package of 4 plates measuring 2360x580x100 - 2 670-2 780 rubles.

CARBON PROF. CARBON PROF boards are basic in the version of insulation for multi-storey buildings. The Prof line from Eco is distinguished by:

- reduced flammability class due to the addition of fire retardants;

- the presence of a special edge to speed up installation (some Eco series also have it);

- the ability to withstand significant loads during operation.

A plate is used to insulate foundations, flat roofs and floors on the ground and under the screed. Insulation costs from 4,090 rubles / m3.

CARBON PROF SLOPE. The original form of insulation, patented by the company, for a pitched roof. Consists of 5 wedges of different sizes. In the assembled state, a slope is created to remove water from the wet areas of the rafter system. It costs more than 6,000 rubles for 1 m3.

CARBON SOLID. EPPS CARBON SOLID is the ideal floor insulation. It can also be used when laying highways and railways - it does not deform under loads, does not swell in a humid environment. The price starts from 6 490 rubles / m3.

XPS CARBON SAND. Plates are produced for enterprises producing sandwich panels.

Ts-XPS CARBON. The main purpose is laying on top of a "dry" floor screed. It can be used for thermal insulation of other building structures during refurbishment. The cost of 1 m2 - from 865 rubles.

Stone wool reviews

It cannot be said that any stone wool is good for use and durable. There are both positive and negative customer reviews.

- Mikhail Pavlov: “Stone wool was required to insulate the house last year. The choice fell on Technonicol. This is a relatively inexpensive type, so in total you can say that it saved. Cotton wool was used quickly, without problems. Of the shortcomings, I can note that it is very loose, although I took it of medium density. So when choosing, you should be careful. As for the qualities, the house has become warmer, this was noted already in the first year after insulation. "

- Dmitry Zaitsev: “Rockwool is a well-known stone wool brand. And indeed the material is of high quality, very good. After insulation, the house is warm, comfortable, there are no drafts, and even the dampness has disappeared. However, anyone planning to buy this product should also purchase a pair of protective suits for work. This is a really dangerous insulation. On the skin it caused irritation, redness, itching, constant sneezing, shortness of breath. In general, nothing good - you can't work with him without protection! "

- Elena Alexandrova: “Isobox stone wool is our choice for home insulation. Throughout the summer, she was engaged in insulation of the house, both inside and outside. This insulation has both advantages and disadvantages. It insulates sound really well, retains heat, and the price is affordable. As for the problems, there is a lot of dust flying from the stoves, which causes irritation, so it is better to use a respirator. The downside is that the insulation has an uneven density over the entire surface. It crumbles a lot, breaks down and I am sure that this will affect the service life. "

| Sintering temperature | 700-1000 | 600 | 450-500 | 250-300 |

| Heat capacity | 500-800 | 1050 | 1050 | 1000 |

| Compressibility (%) | Up to 40 | 40 | 60 | 60 |

| Elasticity | 71 | 60 | 55 | 50 |

| Flammability class | NG - non-flammable | NG - non-flammable | NG - non-combustible | NG - non-flammable |

| Sound absorption | 0,87-0,95 | 0,75-0,95 | 0,8-0,92 | 0,75-0,82 |

| Vibration resistance | Not | Not | Not | Not |

| Binder (%) | 2.5 to 10 | 2.5 to 10 | 2.5 to 10 | 2.5 to 10 |

| Moisturizing per day (%) | 0,035 | 0,095 | 1,7 | 1,9 |

| Chemical resistance to water | 1,6 | 4,5 | 6,2 | 7,8 |

| Chem. alkaline resistance | 2,75 | 6,4 | 6 | 7 |

| Chem. acidic resistance | 22 | 24 | 38,9 | 68,7 |

| Release of harmful substances | Yes, if there are harmful binders | Yes | Yes | Yes |

| The need for binders | Yes | Yes | Yes | Yes |

| Taunt | Not | Not | Yes | Yes |

Consumer opinion (reviews)

Since the heat insulator TechnoNIKOL

It has been on the building materials market for a very long time, all the main positive qualities and shortcomings of the material have long been identified by customers and posted on the Internet as reviews, which are shown below.

- Excellent sound insulation and energy efficiency.

- The sheets are even with the same density and thickness.

- For the production of heat insulators TechnoNIKOL

only environmentally friendly materials are used. - The price is not expensive and there is a wide choice for certain tasks.

- The ability to keep high temperatures.

- With poorly made waterproofing, the material gets wet and loses its own properties by about 7-10%.

- Without a reinforced layer, it has poor contact with the base of the heat insulator.

- During work, you need to use respirators or petals.

- Decomposes when exposed to alkaline solutions.

- Different density of sheets in one package and crumble during installation.