It often happens that cold weather comes unexpectedly and sunny days are replaced by chilly wind and rains. Therefore, you should take care of the weather in the house in advance and you need to start with the windows. If you make the right choice when deciding how to glue the windows for the winter, you can keep up to 2/3 of the heat in the room.

Contrary to popular belief that only wooden windows need to be insulated with their own hands, plastic structures also often need to improve their heat-saving qualities. This happens if the service life of plastic windows has ended or the structures were installed in violation of the technology.

Basic principles of insulation

To insulate windows for the winter with your own hands, you need to create the most airtight space between the frames, since the air in an enclosed space has excellent thermal insulation properties.

To get a comfortable room temperature, you need to eliminate the cracks through which cold air enters.

To insulate wooden frames, one (or both) of the traditional methods is usually used: gluing a sealing gum, sealing cracks with cotton wool, glue and paper strips, cloth or tape. An adsorbent can be placed between the frames - a substance that absorbs moisture, such as activated carbon, silica gel, soda or salt.

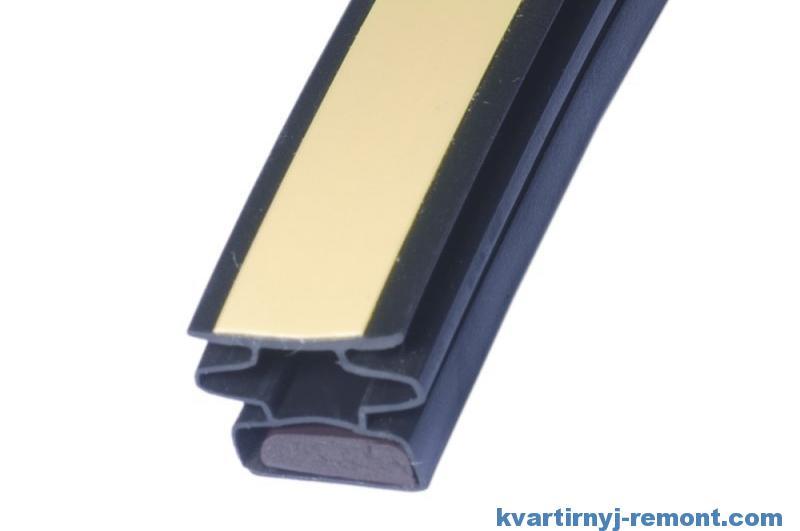

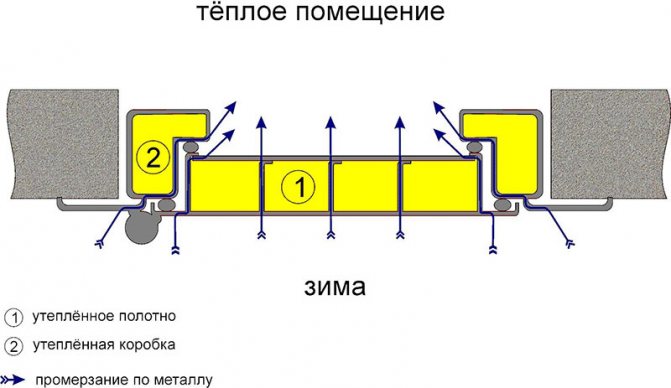

Seal for metal doors

The choice of the seal will directly depend on the size of the gap that needs to be eliminated. For example, if the gap with the door closed is from one to four millimeters, then you can purchase a rectangular seal, for example, made of polyethylene foam, PVC, foam rubber. But in most cases, rubber seals are used for metal doors. They can have different shapes, the section of which resembles the letters of the Latin alphabet:

- C - the profile is used for those slots that are up to three millimeters thick.

- K - the profile is similar to the first one.

- P and V - the profile is able to eliminate gaps with a thickness of three to five millimeters.

- О and D - the profile is mounted in those doors where the gap is up to seven millimeters thick.

The seals are available in different colors. This allows you to customize the color for your door. So, the aesthetics of the doors will not deteriorate in any way. The most common colors are white, black and brown.

Note!

According to some studies, the colorant can degrade the quality of the rubber. For this reason, it is best to sacrifice aesthetics and stick on a standard black seal!

The main requirement for all seals is door sealing. On this basis, the seal must meet high standards. The seal must be waterproof and airtight, must provide excellent shock absorption of the door leaf when it is closed and slammed. When closing the metal door, a light and soft click should be heard, and not rattling and noise. Among other things, the seal should not freeze and harden in the cold. Regardless of the conditions in which it is used, the seal must maintain its basic characteristics under all circumstances.

Preliminary preparation of wooden windows

Before starting work, wash and dry the windows, inspect the gaps between the frames and glass. Such cracks appear when the frames dry up, and the window putty in which the glass is installed crumbles.

Repair stages

- Check the condition of the glazing beads - the long wooden slats with which the glass is reinforced in the window frame.It is better to replace rotten and cracked elements with new ones immediately.

- Remove the problematic glazing beads and nails. Remove the glass and clean it from the remaining putty using an alkaline product, for example, soda ash diluted in water.

- Clean the frames from putty and paint in the places where glass is inserted, wipe dry and treat with transparent silicone sealant.

- When installing the glass, try not to pinch it. Secure the glazing beads with window nails.

- Coat the remaining gaps with the same sealant, let it dry for 2-4 hours and wipe the windows with a special detergent.

Installation on a metal door

If you have a branded door, then the manufacturer makes a profile in which there is already a specially designated place for laying the seal. From the point of view of tightness, such metal doors are the most reliable. Therefore, when buying them, pay attention to this detail.

In the event that you do not have funds for such a door, the seal should be purchased and installed on your own. Using self-adhesive tape, this is very easy to do. The most important thing is to choose the appropriate thickness. We talked about this above. Gluing the seal is easy enough. Wrap plasticine in polyethylene and put it between the door and the frame. After, close the door tightly and open it. As a result, you will have a finished cast of the required thickness. As for the seal sticker, do not rush to immediately remove the protective layer from the entire tape. As the film peels off, stick the seal to the frame. While doing this, press it firmly.

Note!

In the event that the seal comes off after a few days or weeks, then glue it with Moment glue.

How to insulate wooden frames

Window structures made of wood are usually insulated with the help of:

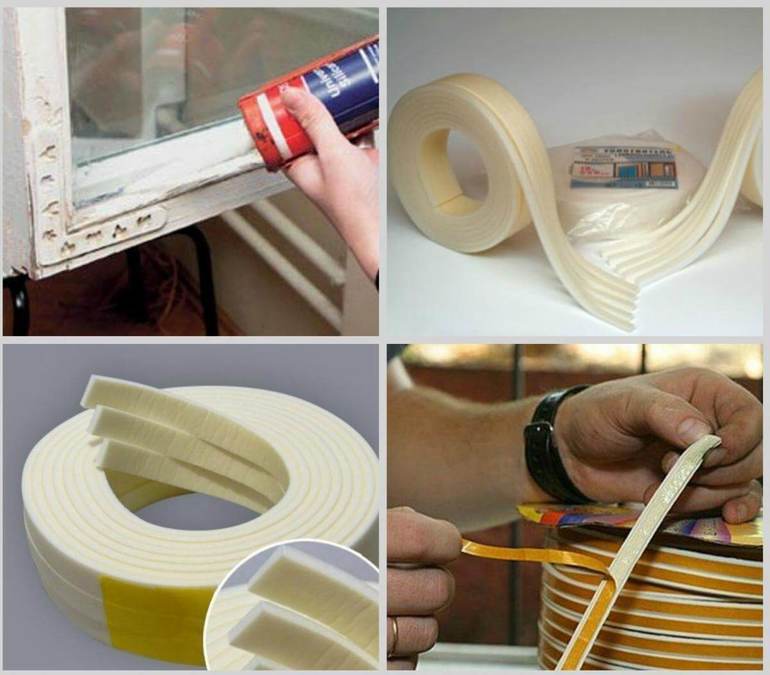

Modern profile gasket

Window seal profiles

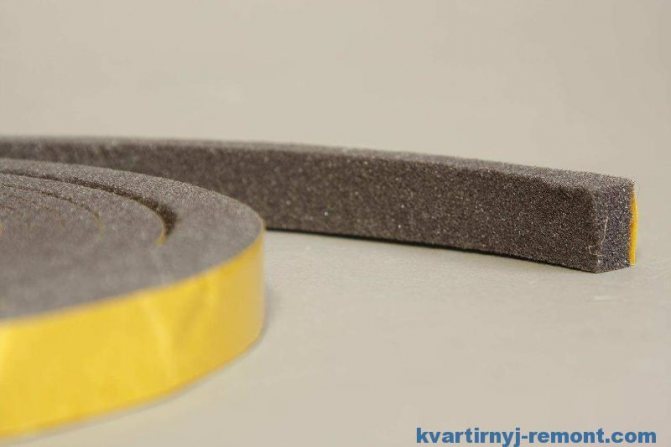

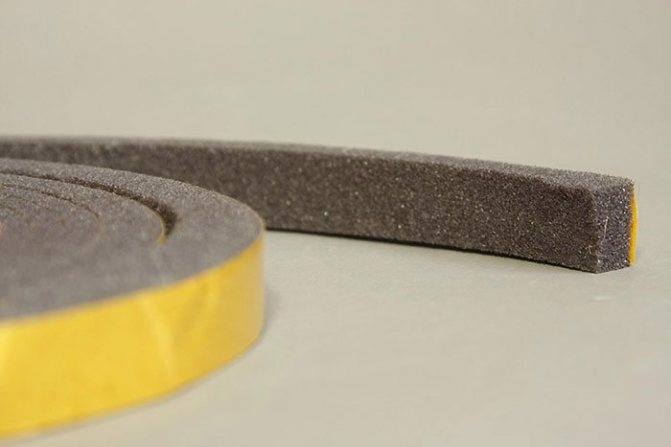

This material is sold at any hardware store and comes in tape, with or without adhesive. Such a seal is also called a tubular profile and is made from the following materials:

- foam rubber

- rubber

- polyvinyl chloride;

- polyethylene foam;

- polyurethane

Adhesive-based seals are more popular. But their disadvantage can be considered the fact that they cannot stick as securely as their self-adhesive counterparts.

The foam seal absorbs moisture, so it must be replaced annually. The polymer tape does not care about water, which significantly increases its service life.

The seal is easy to use: the tape is glued to the open sash around the perimeter, inside and outside. To eliminate particularly large gaps, you can additionally use masking tape.

A seal for a wooden window is attached to the perimeter of the frame

It is best to use a transparent silicone adhesive sealant to glue the seal without an adhesive base.

Improvised means

The method is suitable to insulate old wooden windows for the winter, as it is designed to eliminate too large gaps. They can be filled with cotton wool, rags, paper or foam rubber. A special putty for wood is also suitable.

Insulation stages:

- tamp cotton wool or other material tightly into the crevices using, for example, a wide screwdriver;

- glue strips of fabric or paper over the material.

Glue for these purposes can be made from a soap solution or two components - water and starch. The recipe is simple: pour a heaped tablespoon of starch with one glass of water 200 ml, bring to a boil, stirring constantly.

Sifted flour can be used instead of starch. After cooling the paste, proceed to the insulation.

Paraffin

Paraffin wax can be purchased at any hardware store

This method was widespread several decades ago among housewives, who know exactly how to insulate wooden windows for the winter, as it made it possible to close large gaps quickly and at no cost.

The paraffin candle must be melted in a water bath and the hot mixture is poured into a pre-heated syringe. With this device, you need to quickly process all the gaps.

Putties

Insulating windows for the winter with special mixtures or something similar with your own hands is an effective, but radical method. Removing such insulation often damages the paint, so this method is suitable for old windows that you plan to replace soon.

As a heater, glue putties, a 1: 1 solution of alabaster and chalk, and special sealants for window seams are suitable. The mixture is applied to the gaps, leveled with a spatula and left to dry completely.

Heat Saving Film

Heat-saving film is an effective way to avoid heat loss

This method is suitable for insulating wood and PVC windows.

In hardware stores, you can find a special protective film that has universal properties - in summer it protects the room from the sun's rays, and in winter it raises the temperature to 5 degrees.

The material of the required size is glued to the frame glazing beads using double-sided tape and blown with air from a hair dryer for leveling and transparency.

Additional cold bridges

Be sure to check lintels above the windows, as they often serve as a place for heat leakage. Lintels are insulated from the outside by alternately applying facade polystyrene foam, reinforcing mixture and plaster.

Also, cold conductors can be slopes... For thermal insulation, the side surfaces are sanded, then primed and PVC panels are installed. If voids have formed inside, it is necessary to fill them with tow or polyurethane foam.

Window sill, improperly processed with foam, is insulated by attaching a piece of PVC panel, adjusted to size, under it. The voids are filled with the same materials as for the slopes.

Selection and classification of the seal

Often, metal doors do not cope with their main role, namely, keeping the heat in the house. Although these doors are insulated, the result is often poor. You can pick up a special seal that can solve the problem of drafts and unpleasant odors coming from the entrance. There are a large number of seals that differ in type and method of application. For example, some are glued around the entire perimeter of the door. If the door has a double rebate, then the seal is glued to each of them. At the same time, it is recommended to choose insulation in each individual case individually. So, for example, if you buy a very thick seal, then it can cause obvious problems. Conversely, a very thin material will not give the desired result.

Seals for metal doors are classified according to several technical characteristics.

- Material type... It can be foam rubber, plastic, polyethylene foam, rubber, silicone.

- Design... The seal can be equipped with a clamping metal strip or made of one material.

- Attachment method and system... Seals are self-adhesive or self-tapping. As for the latter, special strips can only be installed on wooden doors.

If you wish, you can make the seal yourself. To do this, you can use foam rubber, after wrapping it in artificial leather or leatherette.

For metal doors, seals are sold in rolls. One roll can be up to six meters. If the door is standard, then one roll will be enough for sealing.Remember that it is best to buy a self-adhesive seal for metal doors.

How to insulate plastic windows yourself

To improve the thermal insulation qualities of plastic windows, it is imperative to use insulation. It can be traditional polyurethane foam or a suitable sealant for this purpose:

Sealant for sealing gaps

- Polyurethane sealant. Experts consider this material ideal for sealing deep cracks, since the mass after hardening increases its volume several times and penetrates far into the depth of the gap.

- Silicone sealant. This is the most popular and affordable way to get rid of unwanted sources of air entering the room. The sealant fills gaps tightly and has high elasticity, which makes it easy to use.

- Acrylic sealant. Differs in elasticity and ease of use - its excess during application can be easily removed, unlike silicone sealant. But this material has one drawback - in a short time of operation, the acrylic sealant changes color from white to gray. This is due to its ability to attract dust and dirt to itself.

When insulating plastic windows, follow the basic steps:

- Clean the cracks with a stick or brush from loose foam or debris.

- Go over the slopes, frames and windowsill thoroughly with a degreasing cleaner.

- Fill the gaps with polyurethane foam or sealant, depending on the material chosen.

Wood door seals are a fairly popular option.

To seal a wooden door, you can stick any of the profiled or solid rectangular (square) material specified in the previous chapter. Of course, of those that are intended for this installation (self-adhesive and installed using glue). For a good secure attachment, in addition, the sealing inserts can be screwed through the washers with self-drilling screws. The installation locations are the same as for a metal door.

And you can make the seal with the material of its manufacture - in other words, rollers. We wrap any material for insulation (foam rubber is often used) in dermantin or vinyl leather. This is the roller. You need to install it in the middle of the apartment (house). Installation is performed:

- On the box - along its inner surface on the left, on the right side and on top at a short distance from the door. It is necessary to achieve that the door, when closed, fits snugly against the rollers. The rollers are not installed on the threshold, due to the fact that they wear out in a short time.

- And on the door - to its lower edge.

The fastening of the rollers is done with decorative nails along the side opposite to the place where the dermantin is doubled around the foam rubber.

Manufacturers and prices

A running meter of profiled thermoplastic sealant brand Deventer (Germany), costing 200 rubles, long-term and durable material;

Self-adhesive tape seal Victor V702, Moscow, elastic and durable material with good thermal insulation properties. The cost of a bay of 3 running meters is 330 rubles.

Sealing tapes by door type

For each individual variety, its own seal has been developed.

Input

I want to see everything!

I want to see everything!

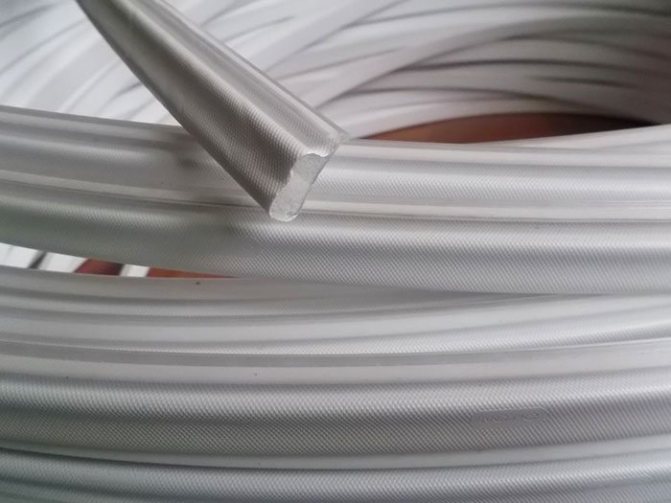

Most often, entrance doors are finished with a dense material in the form of a tube, inside of which there is a void.The considerable thickness and blistering of the material create a secure fit between the door and the frame. How to choose reliable and warm doors to the house, read this article.

Of particular interest is the internal structure of these rubber bands for door insulation. Due to the presence of internal pores, a multiple increase in the warming effect is achieved. Most often, the front door seal has a self-adhesive base, which makes it very quick to install.

On the other hand, over time, the glue loses its characteristics, and the stripes begin to lag around the perimeter. You can read about complex door insulation.

Interroom

The function of protecting the room from the outside cold is not assigned to the seal for interior doors, as in the previous case.

This allows you to make it more aesthetic by using more elastic and softer silicone instead of dense rubber. The installation method of these products may differ, which will be discussed below.

If during the repair process you decide to change the doors, then be sure to read this article.

Plastic

This group of materials is characterized by a high speed of laying and dismantling. On plastic doors, grooves are usually applied along the line of contact with the frame, therefore the seals are given a special shape that repeats the configuration of these grooves. Due to the presence of walls on the sides of the fixing point, the sealing strip receives additional protection from external aggressive influences. The seal for plastic doors is not afraid of moisture and temperature changes, so it can be used without much difference both in the street and in interior doors. It is important to keep in mind that this rubber seal was specially designed for plastic slotted doors, therefore it is not recommended to seal other types of doors with it. In addition, different manufacturers complete their plastic doors with an individual seal: this should also be clarified when choosing a suitable material.

How to adjust the front door and get rid of squeaks and drafts?

Learn about the pros and cons of plastic doors in the room.

Glass

In the manufacture of a seal for glass doors, silicone is used, equipped with a special profiled notch. During the installation of the strip, it is necessary to pre-moisten the area where it will be placed: this will make the connection as strong as possible. Since the design of glass doors can be very different, therefore, a separate seal is developed for each of them.

Energy-saving finishing of balconies and loggias

Insulation of plastic windows and doors consists in gluing a strip of rubber or foam rubber seal, which prevents the penetration of cold air into the apartment.

What is a self-adhesive seal

Installation of a sealing tape on a plastic base

This is a finishing option in the form of a tape, which is installed along the perimeter of the box and the door leaf or window opening. It can also be used for energy-saving cladding of structures made of metal or wood.

Insulation of the loggia can also be done by installing self-adhesive tape at the joints and cracks in the decorative finish. The seal is available in the form of a self-adhesive tape or as a rubber cut-in tape finishing energy-saving material.

Seals on an adhesive base have a form of release in the form of a roll of foam rubber and can have a different profile and an adhesive base, which is protected by a paper gasket.

You can use a special roller for high-quality installation of the sealing tape

Installation recommendations:

- To ensure high-quality thermal insulation, it is necessary to choose the correct width of the profile, which should completely cover the gap, but not interfere with the tight closing of the doors;

- The mortise seal is also made of foam rubber, but on the basis of durable and hard plastic. This ensures the strength of the fastening, but it is important that the canvas and the box have a special groove for mounting the seal;

- All modern models of plastic and metal structures are equipped with a special groove for mounting a seal, which can be replaced or installed by hand.

Advice. Before gluing the material to the surface, it must be cleaned of dust and residues of paint or other finishing, and degreased. This will provide better adhesion, the sealant layer will adhere firmly and will not come off during use.

Sliding doors

Similar designs are used in rooms where space is very limited, sealed interior partitions are used to divide the room into zones. Special rollers are attached to the ceiling, thanks to which the sashes move along a rail installed parallel to the wall.

Sliding doors are made from several types of material:

- wood;

- glass;

- composite.

Note that this design is considered the safest among all models. The movement of the sash along the guide completely eliminates injury to a person in the event of a sudden opening.

Brush seal for improved tightness

Purpose of door seals

It is quite simple to understand why seals are installed on the door. Suffice it to recall the refrigerator, which is in every home. What if there was no rubber strip on the door? The answer is obvious - it is tantamount to leaving the door open, the effect of cooling products would have to wait a very long time. Indoor cold air constantly mixed with warm air, as a result, the refrigerator would turn into an air conditioner that lowers the temperature in the kitchen. To localize the cooling zone, it is necessary to stop air circulation. This task is performed by the rubber seal.

Similar processes occur with the entrance and interior doors. The door leaf adjoins the frame with a technological gap of 3-4 mm, otherwise the door simply will not open. Through it, air can freely penetrate both in one direction and in the other. If this does not play a special role for internal doorways, then a stream of cold or hot, sultry air will move through the entrance doors all year round. In winter, cold drafts will begin to blow inside the hallway, freezing will increase. In summer, hot air from the street will appear in the house, and at the same time dust and noise.

Glass products

Modern interiors are now adorned with glass structures. Products of this type look original in a large multi-room apartment. They zone the room, visually expanding the space. To give the glass increased strength, they are made of special 8 mm shock-resistant glass.

Installation is carried out using special awnings. The door frame is also chosen strong and reliable, since the weight of the glass sheets is high. Sliding glass models are considered the most demanded in the household market today.

Zoning space with glass doors

Plastic Models

Polymeric materials are often used for the manufacture of canvases. At the same time, the pine frame with a sealing layer is faced with PVC panels. Additional bars add rigidity to the product. Further, it is decorated with decorative plastic plates.

The outer surface of polymer sheets imitates the texture of various types of wood. From above, it is covered with a thin film with the desired pattern.

Tightness of plastic models

The advantages of plastic models:

- are not afraid of moisture;

- durable;

- perfectly seal.

The elastic seal gives the structure increased tightness. Therefore, such models are installed in rooms with high humidity:

- bathroom;

- pool;

- bathroom;

- greenhouse.

Preparation for work

Do-it-yourself window insulation is a simple job, but you must first prepare for it. The most critical points need to be identified first. It should be understood where the cold comes from - from the windowsill or sash. Sometimes problems arise from worn seal or bad slopes.

To determine exactly where the cold air is blowing from, you can run your hand over the entire surface of the window or light a candle, lighter and bring them to the frame. The air stream will stir the fire, which is very sensitive to draft.

You can look at the windows in the rain. Moisture accumulated in a specific location will indicate tears and cracks. If it collects in the corner of a window or along one of its edges, there is a problem with the tightness of the joints. Moisture accumulating in the middle of the pane indicates cracks.

The wind blows through the window due to the loose closing of the frames. To check this, you need to take a sheet of paper and close the window with it. If the paper is easy to remove from the frames, this means that they do not fit well together.

Materials that can be used

We will analyze different options so that you figure out how to insulate plastic windows and how to insulate wooden frames. These are different types of structures, and how they work can be very different.

I will start with the simplest solutions, at the beginning of each section it will be indicated what type of windows the technology is used for so that you only learn what works for you.

Option 1 - cotton wool and paper

It is the cheapest insulating material for window frames that is used on wooden structures. The technology assumes that work is carried out indoors, since paper and cotton wool are not intended for outdoor use.

As for the recommendations for the work, they are as follows:

| Illustration | Description |

| Cotton wool... It can be bought at any pharmacy, the price is low, but the reliability is not the best. You need to change the insulation every year, even if you don't open the doors. Cotton wool absorbs moisture and begins to deteriorate over time. |

It is better to purchase the option, as in the photo - in the form of a roll, it is much easier to separate such cotton wool and push it into the cracks.

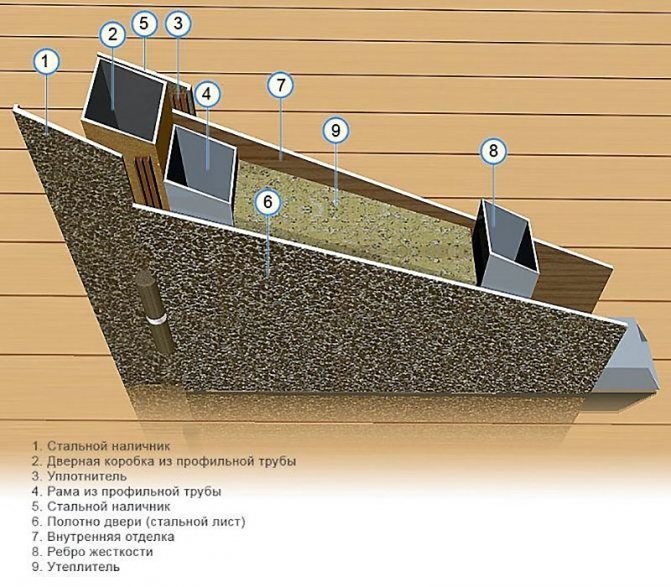

Materials for insulating a wooden door

To insulate wooden doors, you need to prepare the material.

Insulation for the door leaf:

- mineral wool (if the structure does not go directly to the street);

- foam rubber is an inexpensive material, but not very durable;

- Izolon is a modern insulation with excellent performance characteristics;

- foam sheets - a lightweight material that retains volume and shape well for a long time;

- expanded polystyrene - characterized by a long operating period and a low level of thermal conductivity.

Mounting foam is necessary to eliminate the draft through the joint between the door frame and the opening.

A gasket is required to insulate the door around the perimeter:

- Foam tape of various thicknesses on an adhesive basis. It is inexpensive, but it breaks down quickly.

- The silicone seal is environmentally friendly. At the end of the operational period, it begins to tear and becomes sticky.

- The rubber band is a versatile sealant with superior performance.

- The thermoplastic elastomer gasket is the strongest and most durable material. The disadvantage is the complicated installation process.

- The self-adhesive polyurethane sealant is easy to install and has good technical characteristics.

To decorate the door leaf and protect the insulation from street moisture and air, you will need upholstery material: leatherette, eco-leather, lining made of natural wood, laminated with MDF. Accompanying materials that are required for work are upholstery nails and wire.

Frequent mistakes in insulation

Warming metal doors is a fairly simple and straightforward process, so it is not necessary to involve professionals to carry out the work.

Having decided on an independent rework, it is important to adhere to the described algorithms. And in order to avoid unnecessary mistakes, take note of simple tips:

- When insulated, the door becomes thicker than it was originally. This fact must be taken into account when selecting fittings - locks, handles, peephole.

- It is not necessary to carry out insulation work while the door is in an upright position. This will not only complicate the process, but also lead to a displacement of the insulation.

- Using polyurethane foam to fill the joints, it is worth considering its ability to expand. When dry, its volume increases by 2-3 times, which can violate the integrity of the structure.

- When installing a new iron door, it will be useful to leave the old wooden one. Thus, the air space formed between the canvases will help to enhance the heat and sound insulation properties.

- If, after laying the insulation in the cells of the frame, gaps have formed, they can be eliminated using pieces of foam or polyurethane foam.

Following these tips will help you achieve good results and avoid annoying mistakes when insulating your home. Knowing how to insulate an iron door on your own, you do not have to seek the help of professionals.

Making old wooden windows warm

When you think about how to insulate old windows with your own hands, you can perform a procedure that will be similar to restoration. To implement the idea, you will need to purchase new wooden glazing beads - slats that hold the glass in the frame and silicone sealant around the perimeter. When you buy everything, you can start the procedure. All work must be done extremely carefully so as not to injure yourself or break the glass.

- With a thin screwdriver or a knife, carefully remove the glazing beads;

- Wearing gloves, pull out the glass;

- Thoroughly clean the inner surface of the frame - the place where the glass stood;

- Wait time for the wood to dry;

- Apply sealant to all seats;

- Place the glass directly on the sealant;

- Hammer in wooden glazing beads.

The whole procedure should be done with all windows.

Polyurethane foam as insulation

Polyurethane foam is used in case of large gaps between the frame and the window opening. Free spaces must be cleaned of dirt and dust. Shake the can with foam, and release a portion of the composition into the slot. The applied layer will expand, the sags that have come out can be cut off with a knife the next day. Insulate the foam surface from atmospheric precipitation.

It is not recommended to use foam insulation for old windows, as under the influence of the increased volume of the composition, the frame may crack.

How to install

Consider what to glue the car door seal on, how to do the work correctly. It is important to choose the right type, the thickness of the part, if it is necessary to increase the tightness, the thickness is increased. Moreover, the thicker the elastic band, the more difficult it will be to open and close the doors.

Old parts are removed. Find the ends of the tapes, pull them until they jump off the door or body. If there is no end, the gum is cut anywhere with a knife, the resulting end is pulled in the direction opposite to the body.

Install the seal carefully. Its shape is tailored to the configuration of the doorway, other schemes are unacceptable.The rubber is soft, prevents the seal from acquiring the correct shape. First, the elastic is applied to the opening, it is advisable to enlist the help of a partner, then the approximate part is carefully put on. When the part begins to fit into place, it will be possible to lay out the seal on the opening completely. Haste is inappropriate. If the ends of the product do not match, the installation must be done again.

Problems with putting on an elastic band arise after an accident as a result of a change in geometry.

The easiest way is to glue the part with special glue. They use BF-88, Moment, other construction adhesives, less often liquid nails. The surface is preliminarily prepared - cleaned and degreased. After applying the glue, you need to press the gum for 20 minutes and wait until the surfaces seize.

Sealant

The next option than to glue the seal to the car door is a sealant. Ask your hardware store or auto store for a high temperature, heat resistant gasket former. The tool does not present any difficulties in use, it is applied to degreased surfaces.

Sooner or later, doors made of natural materials begin to dry out, forming an air gap or gap. Iron structures close very loudly or do not fit tightly. Window frames lose their tightness and allow the cold to pass through. Self-adhesive door seal is able to relieve these problems. Its service life is 5 years or more, it all depends on the quality of the material.