When choosing an adhesive for foam plastic, many factors are taken into account: in addition to the mandatory absence of acetone, toluene and other organic solvents, it is required to ensure high-quality and long-term adhesion of smooth products to the work surface. For fixation, specialized brands are used that have a corresponding note about their purpose in the instructions and on the packaging. Depending on the base material and the method of application, choose dry mixtures (gypsum or cement with additives of polymers), polyurethane or rubber in the form of polyurethane foam, liquid nails or homogeneous suspensions.

Types of adhesives for outdoor use

In this case, only moisture and frost-resistant grades with high adhesion are used, which make it possible to glue the insulation on the vertical walls of the facades. Dry mixes Ceresit, Knauf, T-Avangard-K, Berg and polyurethane types have proven themselves well. A prerequisite for installation is to strengthen the fastening with dowels with disc heads. In this case, the speed of work depends on the curing time of the glue.

1. Titan Styro 753.

Professional polyurethane compound for the installation of foam plates in wet facade systems and gluing them together. It is appreciated for its high adhesion to any building materials, insulating properties and ease of application. The shape of the balloon allows you to quickly glue the sheets to the walls, it is allowed to start the external department after 2 hours. Tytan Styro 753 is not used in winter, the manufacturer's recommended temperature at the time of installation is from +10 to 30 ° C. Allowed correction time is 15 minutes.

2. Ceresite CT 83.

Dry glue for fixing to external walls when insulating facades on a mineral and polymer basis. It is used at a positive temperature. Can be used as a leveling material. Consumption depends on the curvature of the walls and the method of gluing; slabs that are smeared along the edges with simultaneous sculpting inside the sheet are best kept. This method is recommended by the manufacturer, it allows you to glue foam to uneven surfaces with maximum reliability.

3. Ceresite CT 84.

Highly adhesion polyurethane adhesive in cylinders with a homogeneous structure, without the addition of freons. It is characterized by a high speed of hardening (additional fixation with dowels and subsequent finishing is carried out after 2 hours), resistance to moisture and temperature extremes, volume stability. This is one of the few varieties that is not afraid of high humidity and cold weather (but not below -10 ° C), you can glue polystyrene foam even in winter.

4. BERGhome MK 35.

Professional winter glue, used at temperatures from -15 to +30 ° C. Frost resistance of the mixture reaches 75 cycles, pot life - 3 hours (initial mobility is 40-50 minutes). These characteristics allow the boards to be glued to the prepared walls in winter, the only condition is mixing the mortar with warm water (about 40 ° C). For high-quality hardening, it is recommended to apply the glue in a thin layer: within 2-5 mm. This type is used both for fixing and for reinforcing foam plastic before finishing plaster.

Adhesive requirements

In the selection process, first of all, buyers pay attention to the price of foam glue. Experienced installers give advice on selection. They argue that the presented tool must have a number of special qualities.

The glue should ensure perfect adhesion of the expanded polystyrene boards to the base. In this case, the composition should not react to temperature changes, precipitation and other adverse environmental influences. The glue should not be toxic, so as not to harm the health of the master and the people living in the house. It is also important that the composition is applied to surfaces simply and evenly.

Not all manufacturers meet these requirements. Only proven well-known brands, constantly improving and controlling the properties of their products, can boast of similar characteristics of the glue.

Basic rules for gluing

After choosing the adhesive, prepare the surfaces. They must be cleaned so that grease, dust and other contaminants do not impair the adhesive's tenacity. If you are only working with Styrofoam, then it is enough to wipe both sides thoroughly with a dry cloth. When glueing the styrofoam to untreated wood or very uneven material, sand it down with sandpaper. It is also necessary when dealing with large pieces of material. This will increase the adhesion level and the foam will stick easily.

The next step is to apply glue. If you require a strong and durable hold, then spread it over the entire bonded area in a thin and even layer. If you don't need to glue that tightly, apply a few drops or strips of glue to the foam surface. In the event that you have to work with a large layer, pour the glue into a glass or plastic container and spread it with a brush with artificial bristles. Some types of adhesives can run out of seams and even foam. In this case, wipe off the excess material as quickly as possible with a dry cloth. Remember that glue is difficult to wash off your hands, so rubber gloves are the best to work with.

Then place the surfaces to be glued together and press firmly. Depending on the type of glue, you have about a minute to change the position of the pieces, after which the substance will begin to set. To enhance hold, apply a thin layer of glue to the border of the two surfaces where they touch. In the next step, you just need to wait for the glue to dry.

See also: How to glue glass: detailed instructions

Rules for gluing plastic at home

How to store persimmons at home?

Varieties

Foam adhesive for indoor and outdoor use may differ in a number of characteristics. Various compositions are used for facades. They can be supplied dry or ready-made. Such products should not contain active solvents (for example, gasoline, acetone). Otherwise, they will burn through the insulation. Holes will appear in the expanded polystyrene.

Builders often use foam glue for such a finish. If you need to make installation in one go, you can purchase a ready-made composition. All proportions are observed in it. Such a remedy hardens relatively quickly. Therefore, it is only enough for a one-time installation. If the procedure must be performed several times, dry mixes should be preferred. They can be kneaded several times as needed. This variety is used if the base is characterized by significant irregularities.

Most often, glue with an aerosol or polyurethane base is used for mounting plates from the presented material.

Tips: how you can glue the foam together

Styrofoam can be glued using a wide variety of methods and materials. Many of these can be purchased at regular stationery stores, which can be used to process and join simple designs.

But if you need a serious fixation for a long time, your road lies in special construction stores, where you will need to carefully analyze the entire product range and choose the glue that suits your intentions.

The most common and simple way to create a full-fledged fixation is precisely glue of various strengths and purposes, although people sometimes use other means, such as polyurethane foam.

Foam bonding can be done using the following tools:

- Ordinary PVA glue - for simple structures and crafts, with a characteristic short-lived operation.

- Special adhesive for Styrofoam for gluing together. You can find one in specialty hardware stores at a fairly low cost under the Styroglue configuration, but it is quite rare on the shelves, which is the difficulty in acquiring it.

- When insulating beam structures, it is quite possible to use polyurethane foam, however, all the individual characteristics of operation must be taken into account.

- Hot glue. It must be used with extreme caution and exclusively with a special glue gun.

- Spray glue, which can be used to glue different materials to each other, as well as foam elements.

Of course, this is not the whole list of possible means for gluing, because in the trade line you can often find special adhesives for gluing foam plastic to other surfaces - wood, metal, and so on. But for the purpose of gluing together, they are absolutely not suitable.

Bituminous composition

When choosing the best outdoor adhesive for expanded polystyrene, there are several options to consider. One of them is a bitumen-based composition. It contains a light solvent. It is not dangerous for building materials that are used in the insulation process.

Bituminous glue is sold ready-made. It is easy to apply to the base. When using this solution, the walls must be perfectly flat. Before applying the composition, they must be rubbed and thoroughly dried. You will also need to apply a coat of primer. If there are traces of dirt, rust or dust on the walls, the presented remedy will not be effective. Therefore, when it is applied, increased requirements are put forward for the surface quality.

A layer of bituminous glue is applied with a ribbed trowel directly to the wall. It shouldn't be too thick. Next, the plates are mounted on the glue. It will take about 20 minutes for the polystyrene foam to adhere to the base. Plates must be fixed with special props.

Preparation for gluing foam

Even when using high-quality and suitable glue for a certain surface, you may encounter not the best result. This happens in cases where the need to prepare the surface for work is not taken into account. The substrate must be clean, all stains, paint residues, combustible materials, bitumen must be removed. If mold or mildew is found, work with a brush, in addition, the use of fungicides is mandatory. The foam itself does not absorb moisture, but when glued to a moisture-absorbing base, it should be primed. It is necessary to take into account the weather conditions: dry and warm weather will be ideal for outdoor foam insulation.

Cement glue

Outdoor adhesive for expanded polystyrene can be made on a cement basis. It is used for both exterior and interior decoration. This solution option will be ideal when insulating walls made of cinder blocks, brick or concrete. With proper installation, the plates will firmly adhere to the surface. In this case, the service life of the insulation will be long.

Most often, these formulations are sold as a dry mix. It is diluted with cold water.The advantage of this glue is its relatively low cost. However, in the process of work, a certain time will be required to prepare the solution. This is a disadvantage of dry cement mixes.

The glue contains special cement and polymers. This increases the plasticity of the adhesive, making it quick and easy to apply to the substrate. After the mixture has dried, the finish will be resistant to high humidity and temperature changes. It is a long-lasting compound.

Types of compositions and their description

We will analyze the following options:

- Cement-based adhesive;

- Special polyurethane adhesive;

- Polyurethane foam;

- Liquid Nails.

All of them are suitable for gluing foam, but they have their pros and cons. Let's deal with each composition separately.

Cement-based adhesive

This option has the following features:

- Sold in bags... The package weight is usually 20-25 kg. The dry mixture is diluted with water, stirred, after which it can be used as directed;

Cement-based adhesives are sold as dry mix

- Suitable for facades... With this glue, foam slabs can be fixed to brick, concrete and aerated concrete substrates. Moreover, the mixture is suitable for both external and internal use;

- Possesses high strength... The foam is fixed very securely. If the surface was prepared correctly, then the composition can withstand from 30 to 50 years of operation;

- Suitable for outdoor decoration... With this composition, you can not only glue insulation, but also plaster the surface. It turns out a very durable layer that is able to withstand even strong enough blows;

Cement adhesive is also suitable for plastering the outer surface of foam

- Reasonable cost... For a bag weighing 25 kg, you will pay 300-500 rubles. At a consumption of 4-6 kg per square meter, the packaging is enough for an average of 5 squares. That is, gluing one square meter costs 60-100 rubles.

- Weather dependent... You can work with the composition at temperatures above +5 degrees. I advise you to glue the foam at a temperature of +15 to ensure the best quality of fastening.

Work instructions:

| Illustration | Stage description |

| The surface is primed... This is necessary to strengthen the base, reduce its absorbency and increase the adhesion of the adhesive composition. The primer is applied with a brush or roller. |

| The starting base profile is attached... Its width should be equal to the thickness of the foam you are using. Installation is carried out using quick fixing plugs. To work, you need a hammer drill with a drill, the diameter and length of which correspond to the dowels. |

| An adhesive composition is being prepared... To do this, water is poured into the bucket, and then the required amount of dry glue is poured. The instructions on the packaging will tell you all the proportions of the components. It is best to carry out the work with a drill or a hammer drill with a mixer attachment. In this case, the quality of the glue will be higher than with manual stirring. |

| The glue is applied to the foam. If the surface of the wall is even, then it is possible to distribute the composition with a notched trowel with a tooth height of 8-10 mm. But if the base is uneven, then the distribution of the adhesive mixture is carried out as shown in the photo. Apply adhesive around the perimeter and in several places in the middle using a narrow trowel. |

| The sheet is glued to the surface... First, the bottom row is exposed. The elements fit tightly into the starting profile and are pressed against the wall. In the same way, work continues on the rest of the surface. |

| Holes are drilled for dowels for thermal insulation... Fasteners are also called fungi, and they are needed in order to ensure complete reliability of fixation. |

| A layer of glue is applied on top of the foam... It can be spread with a trowel or spatula. |

| The mesh is pressed onto the surface... Press it down so that it adheres to the layer of glue.Thanks to this reinforcement, the composition will not crack under the influence of temperature extremes. |

| Another layer of glue is applied on top of the mesh... It is distributed so as to completely cover the reinforcing material. |

| Finish is applied to the surface... It can be a bark beetle or other decorative plaster. Or you can simply paint the wall, the main thing before that is to treat it well with soil. |

When purchasing glue, pay special attention to the timing of its production. The composition retains its properties for 12 months, subject to storage conditions. But I recommend choosing mixes made no more than 3-4 months ago.

Special adhesive in cylinders

Adhesive foam for expanded polystyrene appeared relatively recently. But the convenience and quality of the composition was appreciated by both professionals and those who sometimes do the work with their own hands. The main features of this option are as follows:

Glue in cylinders is easy to transport and apply to foam

- Convenience... The composition is available in the same containers as professional foam. A mounting gun is used, which allows you not to spend extra money on a special tool;

- Versatility... The composition allows you to attach foam to any surface - from brick and concrete to wood, metal and even plastic. The glue can be used for both indoor and outdoor use;

The adhesive is suitable for attaching foam to metal structures

- Low cost... This is the most cost effective solution of all. The price of the balloon is from 200 to 500 rubles. One package is enough for 10-12 square meters. That is, the meter costs you from 20 to 50 rubles;

- Ease of use.

The work is carried out as follows:

| Illustration | Stage description |

| The surface is prepared:

Work continues only after the surface is completely dry. |

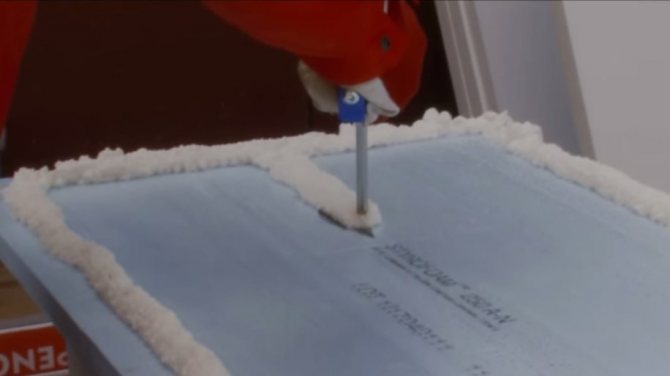

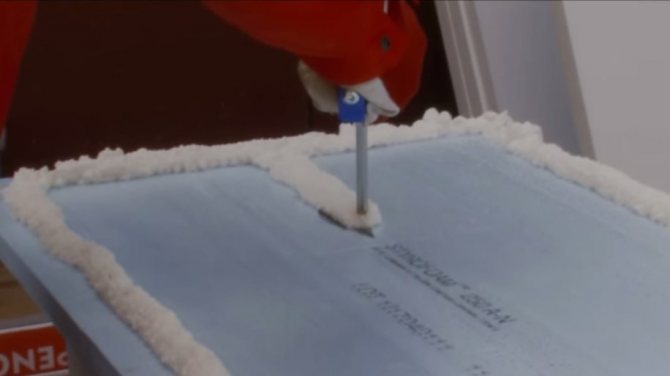

| Adhesive is applied... It is distributed around the perimeter with an indentation of 3-4 cm from the edge and in the middle in several places. It is not difficult to distribute the glue with a pistol. |

| Pre-drying. After application, the sheet is left on for 5-10 minutes. This is necessary in order for the composition to set, and you do not have to hold the elements on the surface for several minutes. |

| Installation. The sheets are gently pressed against the surface. They need to be held for 20-30 seconds. After gluing, it is necessary to additionally fix the sheets with dowels. |

| The gaps are sealed with adhesive... If there are voids at the corners or at the joints, then they can be filled with polyurethane glue. After the composition has dried (and this takes from several hours to a day), you can start finishing the surface. |

Polyurethane foam

Polyurethane foam is a glue that can hold foam well, although this composition is not intended for these purposes. Let's analyze the features of this option:

- Availability... Polyurethane foam is sold in all hardware stores and is much easier to find than special polyurethane glue. The main thing is not to take the winter version, since it contains formaldehyde, which corrodes foam;

Polyurethane foam is well suited for fixing foam

- Good fastening quality... The foam fixes the foam very securely on different substrates. The main thing is to let the composition dry before continuing to work;

- Ease of application... There are options for applying from a pistol, and there is the so-called household foam, which comes with a tube for applying the composition. But it is undesirable to use household cylinders with large volumes due to the high consumption of the composition.

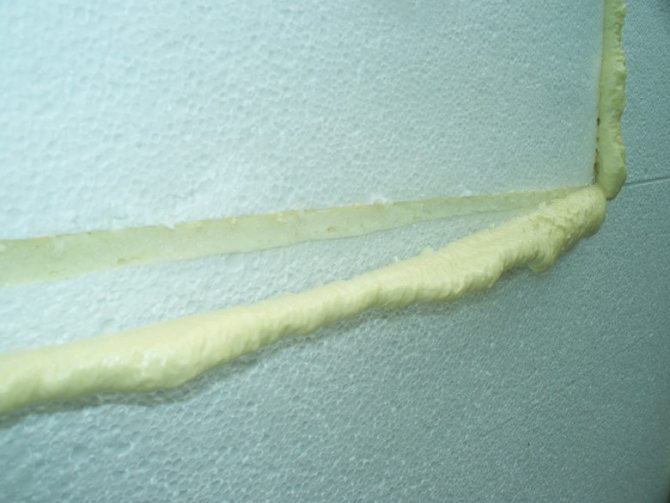

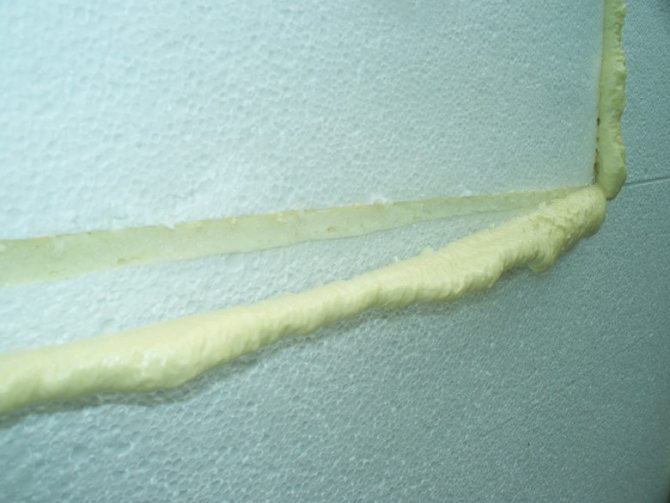

With the similarity of the composition with polyurethane glue, there is one important difference - the foam consumption is much higher than that of the glue, since it needs to be applied much more for high-quality gluing.

Foam is applied to the foam in thick lines to ensure strong adhesion to the substrate

The working process is carried out in the same way as when using polyurethane glue, so there is no point in disassembling it again. The only difference is that the foam does not need to be kept for 10 minutes, but can be glued immediately after application. Just press the sheet to the surface and hold for 30 seconds.

It is best to fill the joints and seams with foam, and after it hardens, cut off the excess with a construction knife. You will get a continuous layer of thermal insulation.

The foam cuts off very easily after curing. The main thing is to have a knife with a sharp blade on hand.

Is the foam suitable for Penoplex and other extruded materials? Yes, it can be used for all solid insulation materials, high adhesion allows for reliable fastening even for products with a smooth surface.

Using liquid nails

This type of composition has the following features:

- High fastening reliability... Liquid nails have excellent adhesion to any material - from concrete and blocks to glass and plastic. Therefore, they can be used on difficult substrates, where other compounds will not provide high strength;

It is best to use a universal or heavy-duty compound, these are best suited for foam

- Demanding to the foundation... If the level drops on your surface are more than 5 mm, then liquid nails will not work. They can be used only on flat surfaces, since a small layer is applied, and it will not be possible to compensate for significant flaws;

- Ease of application... For work, a special gun is used, which is suitable for standard 310 ml tubes. It costs little and is sold in all hardware stores.

A simple gun allows you to quickly and efficiently apply liquid nails

The workflow goes like this:

| Illustration | Stage description |

| Preparing the surface... It is necessary to thoroughly clean the base and remove the remnants of old coatings. If necessary, a primer is applied. Naturally, different formulations are used for different materials. |

| A tube is inserted into the pistol... This is done simply: the stem is pulled back all the way, then the cylinder is put in and secured. The tip is cut off, here it is important to do it correctly so that the composition is distributed in a strip of the required thickness. Be sure to use liquid nails, the foam sealant cannot be used as it does not provide the required strength. |

| The composition is distributed along the perimeter and in the middle... Simply apply liquid nails so that the sheet is evenly coated and there are no large empty areas. |

| Sheets are glued to the surface... The element is firmly pressed against the surface and held for 10 seconds. If the work is done outside, then it is better to use dowels. If inside, then you can only do with liquid nails. |

Foam glue

Outdoor adhesive for expanded polystyrene can be made in the form of foam. It is created on a polyurethane base. Such a composition is sold in cylinders. Glue in this category has many advantages.

The polyurethane compound is easy to apply to polystyrene foam sheets. It dries quickly, thus avoiding the use of special props. The expense of funds is the most economical. He is not afraid of adverse environmental influences. The mass does not spread on the surface.

The quality of installation when using glue-foam increases significantly. The composition gains full strength within 2 hours. Other types of installers take up to 6 hours to dry completely. One can of foam equals 25 kg of dry cement mortar.

What glue to glue the foam together

So, let's define a specific list of the most suitable adhesives for processing and bonding foam.Of course, they will be specialized substances for such a specific material as polystyrene, or its closest relatives - extruded polystyrene foam, which is also quite common in household use.

The main qualities and features of special glue Styroglue for working with foam:

- It is made taking into account all the features of the non-standard constitution of the foam - its porosity and foam-like behavior.

- The best option would be to use a spray adhesive, because it penetrates even better into the complex structure of the foam and forms a kind of sticky film. But here we can highlight a feature - the obligatory use of gloves, because it easily gets on everything that is nearby and it is not easy to wash it.

- It is more durable and dries faster than many other adhesives when used as intended.

It is quite appropriate to use glue sprays or guns, but when using them, there are several features that are extremely important to consider so as not to harm the structure of the foam (in more detail - below).

Manufacturers

Today there are many companies that produce quality compounds for the installation of expanded polystyrene. These are world-renowned companies that have proven their reliability over the years of flawless work. It is strongly discouraged to give preference to little-known manufacturers.

The best solutions are created for expanded polystyrene for outdoor use "Ceresit", "Knauf", "Bergof", "Bolars", etc. These manufacturers use only high-quality raw materials in the manufacture of their products. In the process of developing formulas, new scientific developments are applied. Quality control is carried out by the represented companies at all stages of production.

The composition of the presented mixtures includes a balanced set of ingredients. This makes it easy to apply glue to the base, as well as significantly extend the life of the insulation. The presented companies produce products of various categories.

Consumption

Today, the most economical are polyurethane-based foam and glue-putty for polystyrene foam for painting for outdoor use. The last of the mixtures listed is used as an assembly tool and finishing plaster. This is a universal tool that is also in demand in the construction business today.

To calculate the required amount of glue that will be required during the installation process, you need to know the average consumption of funds. This indicator depends on the composition and production technology.

Dry mixes have an average consumption of 500 g / m² of expanded polystyrene. Bituminous mixture will require from 800 to 1000 g / m². Polyurethane adhesive is the most economical. One cylinder is enough for 8-10 m². That is why cement mortars or glue-foam are most often used in the process of creating external insulation.

Solutions: how to glue the foam

Before you ask yourself what is the best way to glue your foam, you first need to understand the main criteria for your choice. Yes, foam, as a universal and specific material, can be glued with the simplest and most popular stabilizers, but the quality and durability of this method depends on the subsequent use. So, for example, if you are doing a complex and large craft using foam, or you are insulating an attic floor, temperature, humidity and other factors will play an important role, which can easily neutralize all your efforts and abilities of the means with which you glued.

Points to consider when choosing an adhesive:

- Your goals for the subsequent use of the bonded foam and its features, such as durability;

- The loads that the foam will be subjected to;

- The temperature that it will undergo;

- Room humidity.

In most cases, it is optimal to use ordinary PVA glue, but if it comes not to a simple structure, which is entrusted with serious construction or decorative purposes, it may not justify itself.

The cost

The price of glue for expanded polystyrene for outdoor use is acceptable for different categories of buyers. This indicator is influenced by the type of base of the product, the manufacturer and the quality of the composition. The cost can vary from 150 to 1500 rubles.

The cheapest are dry cement mortars. They are in high demand. It is better to give preference to trusted, well-known manufacturers. The composition of such funds includes a sufficient amount of polymer additives.

The price of foam glue is about 400-700 rubles. for the balloon. When using it, you will need to additionally purchase a gun for applying the solution. It costs about 400-2000 rubles.

Bituminous and other ready-made solutions are more expensive. It is for this reason that they are purchased much less frequently than dry mixes.

Application method

The styrofoam outdoor adhesive requires proper application. Bituminous, cement mortar is applied in a permanent layer to the base of the slab. In this case, the wall must be properly prepared. It is cleaned of debris, cleaned and primed with high quality.

When using glue-foam, it is necessary to apply the product around the perimeter and in the center in a zigzag line. Next, the plate is installed on the prepared base. After the product has solidified, the excess is cut off. If the composition hardens for a long time, use special supports for the plates.

Having considered the features and types of adhesives for expanded polystyrene, everyone will be able to choose the best option for easy installation.