What it is

Let's start with the definitions.

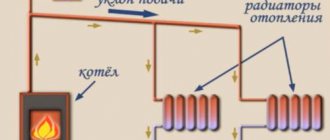

- One-pipe heating system is a simple ring between the supply and return shut-off valves in the elevator unit or between the outlet and inlet of the boiler. One pipe, parallel to which (or opening it, which is fundamentally wrong, but practiced) heating devices are embedded.

A multi-storey building may have several such rings, one on each floor or even in each apartment. More often, however, single-storey cottages are heated in this way.

- A 2-pipe heating system implies the presence of two pipelines along the entire heated perimeter of the premises. The heaters cut between them, creating hydraulic bridges and extinguishing the pressure drop.

This poses a number of problems; however, with a properly configured heating system, even with a very large area of the house and a huge number of heating devices, their temperature can be approximately the same. That is why we see this pattern most often in apartment buildings.

One-pipe and two-pipe heating systems differ the complexity of the wiring and material consumption

... It is clear that two pipes will cost more.

With natural and forced circulation

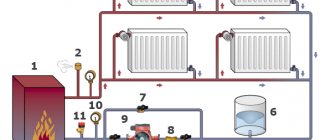

In the general case, for circulation in an apartment building, either the pressure difference between the lines of the heating main is used, or the operation of one or more circulation pumps.

A two-pipe heating system with natural circulation in the case of a house with one to three floors is possible, but it requires the fulfillment of two conditions:

- Top filling.

The feed is in the attic. - Supply and return pipelines

have a remote control not less than 32 mm. More is better.

First requirement

due to the fact that at the top filling we get a ready-made booster collector: the water heated by the boiler with a lower density rushes upward and from there it descends by gravity through the radiators or convectors, giving them heat.

Second

- with hydraulic resistance of the pipeline. The walls create a certain resistance to the flow of water, and it is the greater, the smaller the pipe diameter. And the difference that sets the water in motion, with natural circulation, is very small.

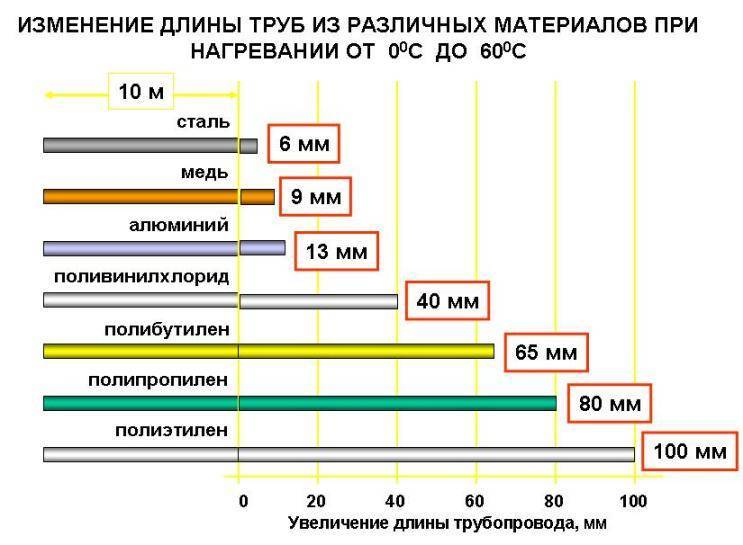

Advice: if you are going to install a two-pipe heating of a private house using natural circulation with your own hands, you should opt for polymer or metal-polymer pipes. They have a minimum so-called roughness coefficient and, with the same difference as steel, will provide a faster circulation of the coolant.

Polypropylene is good. But the underestimated diameter of the bottom filling is an obvious mistake.

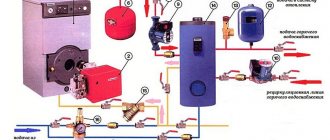

Pressure regulator

The operation of the batteries and the pump is disrupted due to high or low pressure levels. Correct control in the heating system will help to avoid this negative factor. The pressure in the system plays a significant role in ensuring that water enters the pipes and radiators. Heat loss will be reduced if the pressure is standardized and maintained. This is where water pressure regulators come to the rescue. Their mission is, first of all, to protect the system from too much pressure. The principle of operation of this device is based on the fact that the valve of the heating system, located in the regulator, acts as an equalizer of efforts. From the type of pressure, regulators are classified into: statistical, dynamic. The choice of pressure regulator should be based on the capacity. This is the ability to pass the required volume of the coolant, in the presence of the required constant pressure drop.

A little about hydraulics

With the choice of the diameter of the pipes, the wiring diagram and the power of the circulation pump, such a concept as the hydraulic calculation of a horizontal two-pipe heating system is inextricably linked. It is performed with the aim of either calculating the head drop in a given section, or calculating the required pipeline diameter.

We deliberately will not give a complete description of the methods and formulas by which the hydraulic calculation of a two-pipe horizontal heating system can be performed: take my word for it, they are VERY complicated and give rather large errors.

We will only mention the main factors influencing the calculations.

- Roughness of the pipe surface. It is the highest for asbestos cement and steel pipe after a long period of service due to the large amount of rust and deposits.

The least roughness has, as already mentioned, polymer and metal-polymer pipes. What is especially pleasing is that the resistance of polypropylene and cross-linked polyethylene to water movement does not change over time.

- Increasing and decreasing the section.

- Bends, radial bends. Each pipe bend increases its hydraulic resistance by several degrees.

- Differential pressure between supply and return pipelines.

- Section and shape of channels in heating devices.

- The number of heating devices.

- Shut-off valves - type and quantity.

The optimal speed of movement of the coolant is in the range 0.3 - 0.7 meters per second.

At lower values, we get periodic airing of the heating system; in addition, one-pipe and two-pipe heating systems with a slowly moving heat carrier will give too much temperature spread on the heating devices.

At a higher speed, the heating will become too noisy. What is at least equally unpleasant, the erosion of the pipe walls will accelerate many times over by inevitable abrasive particles - sand and slag.

If you still want to do the calculations, the pipe roughness coefficients can be taken here.

Finally - a few simple practical tips, one way or another related to the operation of one- and two-pipe heating systems.

- In a one-story house, you should not complicate your life by using complex schemes. It is better to use a simple one-pipe system with a circulation pump and the possibility of natural circulation.

- A simple solution to the problem of airing risers during bottom filling is not to reset the heating system for the summer. Actually, this is prescribed by the norms for the operation of housing: filled with water, steel pipes are more slowly destroyed by corrosion.

- If all the heating devices are connected to one of the risers connected on the upper floor, put a valve on the second riser instead of a plug. It will be possible to overload it and expel the airlock from the basement.

- For a cottage with a floor area of up to 150 m2 and forced circulation, pipes DN25 mm are used. Radiators cut into them with a smaller diameter pipe.

Attention: do not confuse DU

(inner section of the pipe) and its outer diameter.

- In houses of a small area in a two-pipe system, balancing of heating devices with throttles is mandatory. The closest ones are pressed against the boiler so that the water flow through them does not extinguish the difference on the distant ones.

- In apartment buildings, balancing is achieved in a different way: by the difference in passability between the filling and the risers. If the filling has a cross-section of 80 millimeters, and the risers are 20, the ones closest to the elevator unit will not extinguish the difference on the far ones.

Pressure rate

Efficient transfer and uniform distribution of the heat carrier, for the performance of the entire system with minimal heat loss, are possible at normal operating pressure in the pipelines.

The coolant pressure in the system is subdivided according to the mode of action into types:

- Static. The force of action of a stationary coolant per unit area.

- Dynamic. Force of action when moving.

- Ultimate head. Corresponds to the optimal value of the fluid pressure in the pipes and capable of maintaining the operation of all heating devices at a normal level.

According to SNiP, the optimal indicator is 8-9.5 atm, pressure drop to 5-5.5 atm. often leads to interruptions in heating.

For each particular house, the indicator of normal pressure is individual. Its value is influenced by factors:

- power of the pumping system supplying the coolant;

- pipeline diameter;

- remoteness of the premises from the boiler equipment;

- wear of parts;

- pressure.

Pressure can be controlled by pressure gauges mounted directly into the pipeline.

Briefly about the return and supply in the heating system

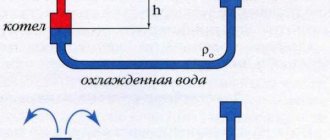

The hot water heating system, using the supply from the boiler, supplies the heated coolant to the batteries that are located inside the building. This makes it possible to distribute heat throughout the house. Then the coolant, that is, water or antifreeze, having passed through all the available radiators, loses its temperature and is fed back for heating.

The most straightforward heating structure is a heater, two lines, an expansion tank and a set of radiators. The water conduit through which the heated water from the heater moves to the batteries is called supply. And the water conduit, which is located at the bottom of the radiators, where the water loses its original temperature, returns back, and will be called the return. Since water expands as it warms up, the system provides for a special tank. It solves two problems: water supply to saturate the system; takes in excess water that is obtained during expansion. Water, as a heat carrier, is directed from the boiler to the radiators and back. Its flow is provided by a pump, or natural circulation.

Supply and return are present in one and two pipe heating systems. But in the first, there is no clear distribution into the supply and return pipes, and the entire pipe line is conventionally divided in half. The column that leaves the boiler is called the feed, and the column leaving the last radiator is called the return.

In a single-pipe line, heated water from the boiler flows sequentially from one battery to another, losing its temperature. Therefore, at the very end, the batteries will be the coldest. This is the main and, probably, the only disadvantage of such a system.

But the single-pipe version will gain more advantages: lower costs are required for the acquisition of materials in comparison with the 2-pipe version; the diagram is more attractive. The pipe is easier to hide, and it is also possible to lay pipes under doorways. The two-pipe system is more efficient - in parallel, two fittings are installed in the system (supply and return).

Such a system is considered by specialists to be more optimal. After all, her work stagnates on the supply of hot water through one pipe, and the chilled water is diverted in the opposite direction through another pipe. In this case, the radiators are connected in parallel, which ensures uniform heating. Which of them sets the approach should be individual, taking into account many different parameters.

There are only a few general tips to follow:

- The entire line must be completely filled with water, air is an obstacle, if the pipes are airy, the quality of heating is poor.

- A sufficiently high liquid circulation rate must be maintained.

- The temperature difference between supply and return should be about 30 degrees.

What is the difference between heating supply and return

And so, to summarize, what is the difference between supply and return in heating:

- The supply is a coolant that goes through water pipes from a heat source. This can be an individual boiler or central heating of a house.

- The return is water that, after passing through all the heating batteries, goes back to the heat source. Therefore, at the inlet of the system - supply, at the outlet - return.

- It also differs in temperature. The feed is hotter than the return.

- Installation method. The water conduit that is attached to the top of the battery is the supply; the one that connects to the bottom is the return flow.

Most of the heating systems of apartment buildings and private houses are built according to this scheme. What are its advantages and are there any disadvantages?

Can a do-it-yourself two-pipe heating system be installed?

Safety valves

Any boiler equipment is a source of danger. The boilers are considered explosive because they have a water jacket, i.e. pressure vessel. One of the most reliable and common safety devices that minimizes danger is the heating system safety valve. The installation of this device is due to the protection of heating systems from overpressure. Often, this pressure occurs as a result of boiling water in the boiler. The safety valve is installed on the supply line, as close as possible to the boiler. The valve has a fairly simple design. The body is made of good quality brass. The main working element of the valve is the spring. The spring, in turn, acts on the membrane, which closes the passage to the outside. The diaphragm is made of polymer materials, the spring is made of steel. When choosing a safety valve, it should be borne in mind that full opening occurs when the pressure in the heating system rises above the value by 10%, and full closure when the pressure drops below the response by 20%. Due to these characteristics, it is necessary to select a valve with a response pressure higher than 20-30% of the actual one.

The difference between a two-pipe heating system and a one-pipe

Let's first define what kind of animal it is - a two-pipe heating system. That she uses exactly two pipes is easy to guess from the name; but where do they lead and why are they needed?

The fact is that in order to heat a heating device with any coolant, its circulation is needed. It can be achieved in one of two ways:

- One-pipe scheme (so-called barrack type)

- Two-pipe heating.

In the first case, the entire heating system is one big ring. It can be opened by heating devices, or, which is much more reasonable, they can be placed parallel to the pipe; the main thing is that no separate supply and return pipelines pass through the heated room.

Rather, in this case, these functions are combined by the same pipe.

What in this case do we gain and what do we lose?

- Advantage: minimal material costs.

- Disadvantage: a large spread in the temperature of the coolant between the radiators at the beginning and at the end of the ring.

The second scheme - two-pipe heating - is a little more complicated and costly. Through the entire room (in the case of a multi-storey building - at least on one of its floors or in the basement) there are two pipelines - supply and return.

According to the first, hot coolant (most often ordinary industrial water) is directed to the heating devices in order to give them heat, according to the second, it returns.

Each heater (or a riser with several heaters) is placed in a gap between the supply and return.

There are two main consequences of such a connection scheme:

- Disadvantage: much more pipe consumption for two pipelines instead of one.

- Advantage: the ability to supply a coolant of approximately the same temperature to ALL heating devices.

Advice: for each heater in the case of a large room, it is imperative to install a regulating throttle.

This will allow you to even out the temperature more accurately, making it so that the water flow from the supply to the return on the nearest radiators will not "sink" those more distant from the boiler or elevator.

Features of two-pipe heating systems in apartment buildings

In the case of apartment buildings, of course, no one puts throttles on separate risers and does not constantly regulate the water flow; equalization of the coolant temperature at different distances from the elevator is achieved in a different way: the supply and return pipelines running through the basement (the so-called heating bed) have a much larger diameter than heating risers.

Alas, in new houses built after the collapse of the Soviet Union and the disappearance of strict state control over construction organizations, the use of pipes of approximately the same diameter on risers and stanchions, as well as thin-walled pipes installed for welding valves and other cute signs of a new social system, began to be practiced.

The consequence of such savings is cold radiators in apartments located at the maximum distance from the elevator unit; by a funny coincidence, these apartments are usually corner and share a wall with the street. A pretty cold wall.

However, we have deviated from the topic. The two-pipe heating system in an apartment building has another feature: for its normal functioning, water must circulate through the risers, rising and falling up and down. If something interferes with her, the riser with all the batteries remains cold.

What to do if the home heating system is running, but the radiators are at room temperature?

- Make sure the valves on the riser are open.

- If all the flags and lambs are in the "open" position, close one of the paired risers (we, of course, are talking about the house with, where both beds are in the basement) and open the vent located next to it. If the water flows with normal pressure, there are no obstacles to the normal circulation of the riser, except for air at its upper points. Tip: Drain more water until after prolonged snorting of the air-water mixture, a powerful and stable jet of hot water comes out. Perhaps, in this case, you will not need to go up to the upper floor and bleed air there - circulation will be restored after starting.

- If the water does not flow, try to bypass the riser in the opposite direction: perhaps a piece of scale or slag is stuck somewhere. It can be taken out by countercurrent.

- If all attempts have failed and the riser does not go to discharge, most likely a search for a room in which repairs were made and heating devices changed. Here you can expect any trick: a removed and damped radiator without a jumper, a completely cut riser with plugs at both ends, a choke blocked for general reasons - again, in the absence of a jumper ... Human stupidity really gives an idea of infinity.

Features of the top filling system

Another way in which the installation of a two-pipe heating system is carried out is the so-called top filling. What is the difference? Only in the fact that the supply pipeline migrates to the attic or the upper floor. A vertical pipe connects the inlet to the elevator.

Circulation from top to bottom; the path of water from the supply to the return at the same building height is twice as short; all the air does not end up in the risers in the apartments, but in a special expansion tank in the upper part of the supply pipeline.

Starting such a heating system is immeasurably simpler: after all, for the full operation of all heating risers, you do not need to get into every room on the top floor and bleed air there.

It is more problematic to turn off the risers when repairs are needed: after all, you need to go down to the basement and go up to the attic. Shut-off valves are located both there and there.

However, the above two-pipe heating systems are still characteristic to a greater extent for apartment buildings. What about private traders?

It is worth starting with the fact that in private houses the used 2-pipe heating system can be radial and sequential in the type of connection of heating devices.

- Radiation: from the collector to each heating device there is its own supply and its own return.

- Sequential: all heating devices are powered from a common pair of pipelines.

The advantages of the first connection scheme are mainly reduced to the fact that with such a connection, balancing of the two-pipe heating system is not required - there is no need to adjust the flow of throttles for radiators located closer to the boiler. The temperature will be the same everywhere (of course, with at least approximately the same length of the rays).

Its main disadvantage is the highest pipe consumption among all possible schemes. In addition, it will be simply unrealistic to stretch the piping to most of the radiators along the walls, while maintaining a somewhat decent appearance: they will have to be hidden under the screed during construction.

You can, of course, drag it through the basement, but remember: in private houses, basements of sufficient height with free access there are often simply not there. In addition, the beam scheme is somehow convenient to use only when building a one-story house.

What do we have in the second case?

Of course, we have left the main disadvantage of one-pipe heating. The temperature of the coolant in all heating devices can theoretically be the same. The key word is theoretically.

Setting the heating system

In order for everything to work exactly the way we want it, we need to set up a two-pipe heating system.

The setup procedure itself is extremely simple: you need to turn the throttles on the radiators, starting with those closest to the boiler, reducing the flow of water through them. The goal is to make sure that a decrease in the flow of water through nearby heating devices increases the flow of water at distant ones.

The algorithm is simple: we slightly tighten the valve and measure the temperature on the distant heater. With a thermometer or by touch - in this case it's all the same: the human hand perfectly feels the difference of five degrees, and we don't need more accuracy.

Alas, it is impossible to give a more accurate recipe, except for "squeezing and measuring": calculating the exact permeability for each choke at each coolant temperature, and then also adjusting it to achieve the desired figures is an unrealistic task.

Two points to consider when adjusting a two-pipe heating system:

- It takes a long time simply because after each change in the dynamics of the coolant, the temperature distribution stabilizes for a long time.

- Heating regulation of a two-pipe system should be carried out BEFORE the onset of cold weather. This will prevent you from defrosting your home heating system if you miss the setting.

Advice: with a small amount of coolant, you can use antifreeze coolants - the same antifreeze or oil. It is more expensive, but you can leave the house without heating in winter, without fear of pipes and radiators.

What should be the temperature of hot water in the tap?

Hot water temperature standard:

According to SanPiN 2.1.4.2496-09 Hygienic requirements for ensuring the safety of hot water supply systems:

The temperature of hot water at the points of water intake (washbasins, sinks, showers), regardless of the heat supply system used (from the central heating station or from heat exchangers in the ITP), must be at least 60 ° С and not higher than 75 ° С.

Important: Do not allow hot water temperature below 60 ° C. If you deviate from this temperature, there is a risk of contamination of hot water with highly contagious infectious pathogens of viral and bacterial origin, which can multiply at temperatures below 60 degrees, including Legionella Pneumophila.