General rules for thermal insulation

To properly insulate a wooden outbuilding, certain rules are followed.

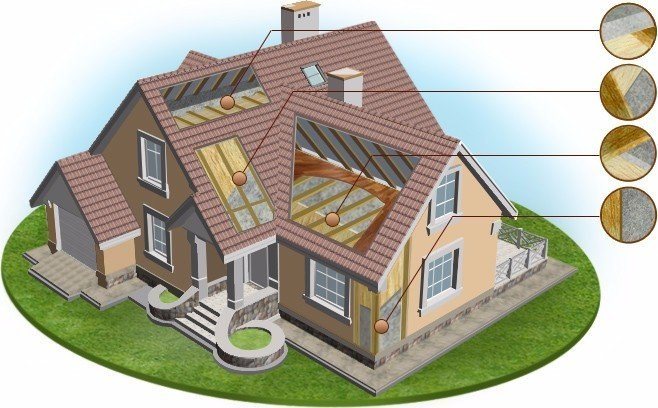

- First, we prevent heat loss through the roof - we cover the structure with a special film. Only then can the roof be laid in the form of corrugated board or ondulin.

- To increase heat resistance, MDF panels are used, installed on special profiles. Fill the free space with a heat insulator of your choice.

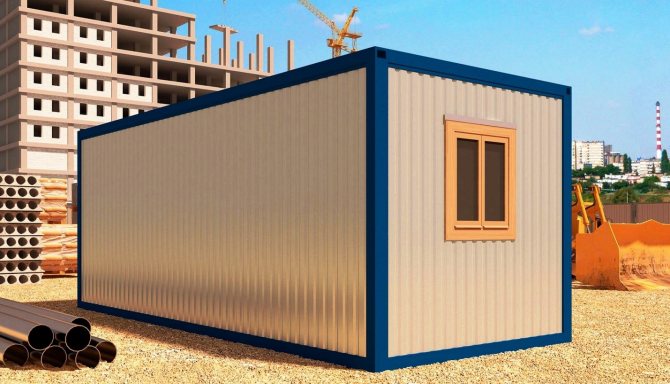

Change houses made of metal are highly resistant to mechanical and other influences. The metal frame is completely protected from moisture by a special flooring. But the roof of a farm building is often subject to corrosive processes. To prevent corrosion, it should be treated with a polymer-based coating or paints and varnishes.

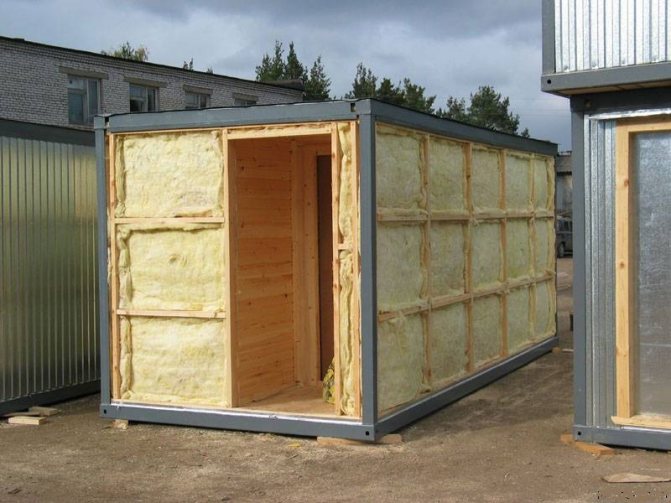

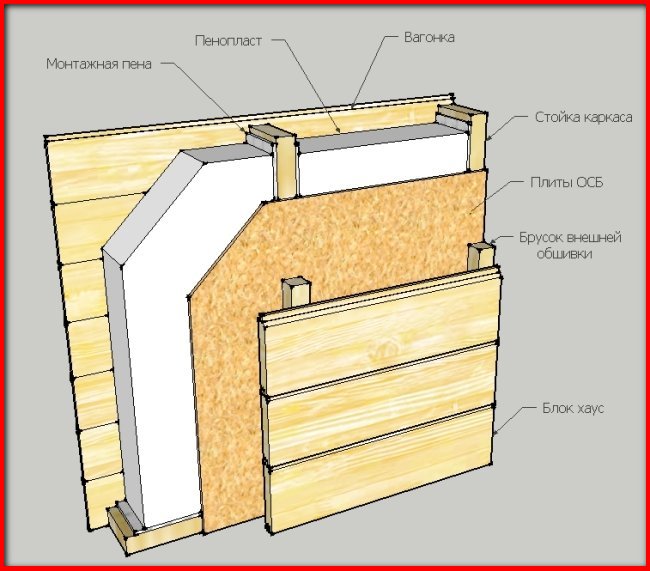

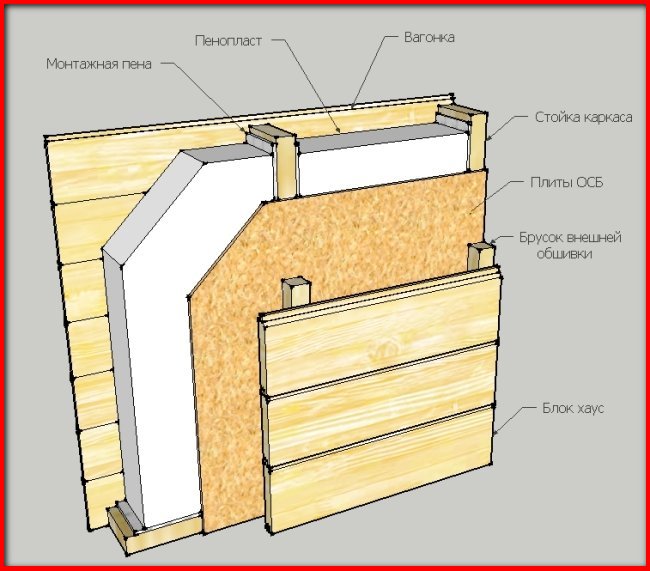

Wall structures are sheathed with clapboard, block house or plastic panels. Heat insulators are mineral wool or polyurethane foam. To prevent heat loss, slots and joints are sealed with a tongue-and-groove board. Combined outbuildings are insulated in the same way.

Where to start insulating a change house

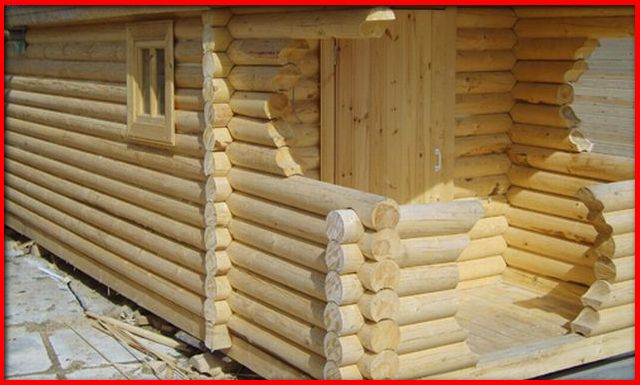

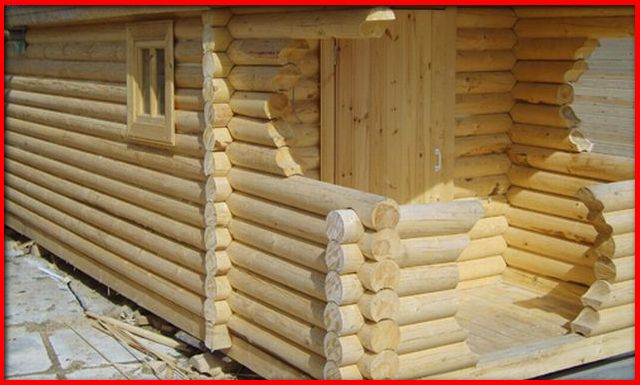

If you are just going to purchase a change house for winter living, then first of all you need to pay attention to the material from which the structure is made. There are three main types of cabins: metal, wooden and combined.

- The metal structure is a frame sheathed with profiled galvanized iron. The design is resistant to moisture penetration and therefore exhibits better heat retention properties.

- The wooden shed is very vulnerable to the penetration of cold and moisture into the room, therefore, it requires more thorough thermal insulation.

- The combined change house is a structure made of several materials. It is necessary to make insulation taking into account the material of the change house in its individual areas.

Do-it-yourself change house insulation

The owners sometimes carry out the thermal insulation of the change house on their own. Uncomplicated insulation technology allows even an inexperienced person to properly fix the heat-insulating material, the main thing is to observe the main points and consult with an expert in advance.

Thermal insulation of the change house outside

In order for the wall insulation to be successful and without additional costs, the owners carefully monitor the sequence of the work carried out. Thermal insulation of the outer side of the outbuilding begins with the installation of a layer of vapor barrier material. For this, materials such as polyethylene film, foil and others are used.

The main task of the vapor barrier layer is to ensure maximum ventilation of the facade of the building. If the mounting surface is too smooth, fasten the rails vertically, with their help the vapor barrier material will be held.

Now they are starting to install the thermal insulation. Experts recommend using mineral wool or fiberglass products. For optimal protection of the building, two layers with a thickness of 10 centimeters each are enough, although when insulating a change house for living in winter, an additional layer is fixed. Mineral wool does not need special attachment to the main surface: due to the rigidity of the slabs, they fit tightly to the vertical slats. Gaps and solid joints are not allowed between them.

A special film is mounted on the heat insulator to ensure waterproofing, which will prevent moisture from entering. The waterproofing material is attached with a furniture stapler.The film is overlapped by 10 centimeters for maximum protection, the joints are sealed with special tape.

Internal thermal insulation

The next stage is the insulation of the internal premises of the change house. Each owner of the farm building chooses the methods of insulation independently. Among insulators for internal thermal insulation of household structures, cotton insulation is common. It is environmentally friendly and safe. Such material is difficult to cut, so the work will take a lot of time. Some owners use thermal insulation materials similar to products for external insulation.

When installing insulation, it is important to remember about the arrangement of air vents to quickly remove the resulting condensate. The holes are located at the top and bottom of the wall. To strengthen the thermal insulation, the insulation is covered with a special material - penofol. Its surface creates a "thermos effect".

Thermal insulation with penofol

To carry out high-quality insulation, penofol is fixed in solid parts, which significantly reduces the number of joints between the pieces. All formed seams are carefully sealed with special tape to ensure maximum tightness.

To ensure maximum heat saving, experts advise to insulate the floor and ceiling. The whole process is similar to the thermal insulation described earlier. After completing the work on internal insulation, they think over the aesthetic design. Plasterboard sheets are attached to the insulation, which level the surface and improve the quality of sound insulation. The fasteners are self-tapping screws and dowels. Instead of gypsum board, fiberboard is sometimes used. The last stage is finishing the change house according to the owner's preferences.

For giving you can visit the official website. The quality of the product is guaranteed!

A change house is a versatile design that can be used as a summer house, warehouse or living room in winter. In order for the temperature in the building in the winter to be comfortable, you need to take care of the insulation of the change house from all sides in advance.

This can be done with the help of various heaters, ordering a service from professional workers or doing everything with your own hands. Self-insulation will save on payment for the work of specialists, which is important for people with a modest family budget.

Where to start insulating a change house

If you are just going to purchase a change house for winter living, then first of all you need to pay attention to the material from which the structure is made. There are three main types of cabins: metal, wooden and combined.

- The metal structure is a frame sheathed with profiled galvanized iron. The design is resistant to moisture penetration and therefore exhibits better heat retention properties.

- The wooden shed is very vulnerable to the penetration of cold and moisture into the room, therefore, it requires more thorough thermal insulation.

- The combined change house is a structure made of several materials. It is necessary to make insulation taking into account the material of the change house in its individual areas.

How to insulate, review of materials

You need to choose a material for insulation based on the building in which you need to perform the work.

- We choose thermal conductivity, the lower this value, the less heat loss will be in this building.

- Sustainability of the material is an important aspect, especially when it comes to residential buildings.

- The price of the material is relevant for people with limited budgets.

- Ease of use is important when you need to do the job as quickly as possible or you plan to carry out the insulation yourself.

- Insulation quality.A relevant parameter, since there is a huge selection of materials on the market today, but not all of them meet the desired quality requirements.

In the manufacture of ours, we use only environmentally friendly materials from trusted manufacturers. The thickness of the insulation is 100 mm.

Styrofoam (expanded polystyrene).

One of the most popular and inexpensive materials for insulation. It consists of 10% expanded polystyrene foam, 90% air filling the cells between it. Sold in sheets of 0.5, 1 and 2 square meters. Thermal conductivity

0,043W / m 0 C

.

Pros: cheap material, easy to use, moisture resistant, durable.

Basalt wool.

A fibrous material made by blowing rocks at high temperatures. It is sold both in rolls of 5-10 meters long and in slabs of various thicknesses. Thermal conductivity

0,047W / m 0 C

.

Pros: does not burn, eco-friendly, durable.

Cons: requires additional waterproofing, may lose density over time.

What are the cabins

To install a wooden change house, a foundation is not needed.

Change houses, insulated for a summer residence, differ both in the material of manufacture and in their design. They are united by one feature - the lack of a foundation. In some cases, contractors offer to install a change house on a pile foundation, but often they are placed on low pads. The main thing is that there are no distortions, everything must be done according to the water level.

Wooden cabins insulated for summer cottages are:

- shield;

- frame;

- from a bar;

- from a log.

Cabins for summer cottages made of metal are either a container or a trailer; there are even cabins from old buses. Sometimes the possibilities are limited only by imagination. Such mini-rooms are needed for storing inventory, in order to change clothes and keep warm. Change houses are often equipped with heating. In this capacity, electric heaters, stoves and stoves, gas or liquid fuel heaters are suitable.

The change house, insulated, with a stove, can be operated without problems in winter.

It is an integral part of any construction site. In it, workers not only change clothes and have lunch while on business trips, they live there. Of course, the lack of water, sewerage and a bathroom cannot but create inconveniences, but in the absence of an alternative, the winter insulated change house is quite suitable for temporary residence. If the size allows it, it can be divided into several rooms, in which it is quite possible to create minimal conveniences.

How much will the insulated change house cost?

The cost of such a construction with insulation may be different in the domestic market. It all depends on the size of the structure used to insulate the material, the presence of a stove, and so on. The average price for an insulated container in the Russian Federation can be about 100 000 rubles. In this case, the buyer can choose designs of different shapes.

A change house is a country house:

- Wireframe.

- Shield.

- From logs.

- From a bar and others.

Insulation materials

A change house without insulation will not fulfill all the functions and tasks for which it is intended. Therefore, you should carefully consider and select the insulation technology, as well as choose a suitable insulator.

The modern market provides a variety of thermal insulation materials. Let's consider the most common in detail.

Styrofoam

Such a heat insulator is mainly used to insulate the walls of outbuildings. Foam insulation is beneficial when decorating cabins made of wood. The material is resistant to moisture, simple and easy to install. Foam insulation has disadvantages: a short service life and a large volume for good insulation, and with low-quality products, significant heat loss.Several layers of foam will reduce the area of the room, and improper operation of the structure will lead to a fire.

Mineral wool and fiberglass

The advantages of materials are considered fire safety and excellent thermal insulation characteristics, while observing all the requirements of the technological process. If you mount several layers of heat insulator, then the acoustic properties of the rooms will increase. Disadvantages - the constituent components are harmful to health.

Basalt slabs

Such fibers are made by careful processing of basalt rocks. On the construction market, slabs are a common form of material, which can be easily cut to size and laid. The heat insulator is completely resistant to fire and does not lend itself to deformation for a long time. The easy-to-use material will not take up a lot of free space, so the area of the cabins will remain almost the same. The disadvantage is called the many seams that remain after the installation of thermal insulation.

Cotton thermal insulator

This substance is the safest for today. It is of high quality and environmentally friendly. It can be used to insulate the walls inside the trailer and does not require special skill during installation. It is often used for thermal insulation of change houses in which it is planned to live. The downside is that the product is hard to cut.

Polyurethane foam

This heat-insulating material is the most widespread and effective for the insulation of utility structures. There are 2 types: liquid and hard. Experts recommend using the second option to increase the heat capacity of the building's exterior finish. It is great for strengthening roofing systems and outside walls. With the help of the unique structure of polyurethane foam, it is possible to mask possible defects in the roofing system and increase the temperature in the structure.

Thermal insulation materials

In order to create sufficiently comfortable conditions inside the change house at any time of the year, it is necessary to create an effective thermal insulation system inside the walls. At the same time, its durability should be ensured, subject to the minimum level of financial costs. High-quality thermal insulation will reduce the cost of heating the premises in the winter season and create a cozy warm atmosphere in the change house during cold weather.

Of the whole variety of thermal insulation materials offered on the construction market, the most popular for thermal insulation of cabins are:

- mineral wool and basalt slabs;

- expanded polystyrene and polystyrene;

- polyurethane foam.

These heaters are easy to install, relatively inexpensive and have a low specific weight. In addition to good thermal insulation properties, they will provide increased sound absorption and are not subject to decay.

What you need to know about materials

There are several important parameters that must be considered when choosing a heater, below is a table with these characteristics.

| Thermal conductivity, Watt Kelvin | Density, kg.m3 | Waterproofing | |

| Expanded polystyrene | 0,019 – 0,028 | 40 – 80 | low, 1% mass |

| Extruded polystyrene foam | 0,03 – 0,035 | 35 – 52 | low, 0.4% mass |

| Mineral wool | 0,037 – 0,042 | no more than 130 | high, 16-20% of the mass |

| Basalt wool | 0,03 – 0,052 | no more than 350 | average |

| Polyurethane foam (sprayed) | 0,02 – 0,032 | 20 – 200 | low, 1-2% of the mass |

Thermal conductivity is the amount of thermal energy that a material passes through itself. The lower this indicator, the better the material retains heat and the less layer is needed.

Mats made of fluffed mineral materials, basalt wool

Mineral wool. Roll material, width of which is 1m -1.2m, length up to 10m.

Mineral wool insulation is a traditional material for insulating cabins. The recommended thickness of the mats is 100 mm. To improve the quality of installation of the heat-insulating layer, you can lay the material in two layers of 50 mm each.In this case, the overlap of the joints between adjacent slabs and the absence of possible cold bridges will be ensured. Benefits:

- low price,

- ease of use,

- low level of heat loss,

- fire safety.

To protect against moisture and the formation of condensation on the outer wall from the side of the shed, a wind barrier made of non-woven roll materials should be fixed. From the inside, provide for the presence of a vapor barrier that will exclude the penetration of moisture from a warm room. As a vapor-repellent layer, you can use rolled foam foam.

Foam boards

Polyfoam is sold in slabs of various thicknesses. From 0.5 to 2 m2. The lower the density of the material, the more efficiently it keeps heat.

Polyfoam and expanded polystyrene are easy to install, not subject to decay and moisture. These materials have a low coefficient of thermal conductivity and are very effective insulation. The foam grade for insulating cabins must be at least D40 (this is indicative of the relative density). It is best to use extruded polystyrene foam with overlapping locks on the end sides. Benefits:

- durability,

- moisture resistance,

- wind resistance.

Fixing with foam plastic on a metal wall is done using special glue. The inner surface can be covered with plywood, plastic or other sheet material. The flooring is done along the logs, between which the insulation is laid.

Polyurethane foam

This material is sprayed onto the surface. After solidification, a dense foam forms. Can be used both internally and externally.

This insulation is more expensive than finished foam and mineral wool boards. It is supplied in cylinders, completely ready for use, or in the form of two chemical reagents, which are mixed immediately before use. Expandability during hardening provides a high degree of sealing of crevices, joints and holes.

To fill the inner space of the wall and floor, two enclosing surfaces are required. The supply of insulation can be done in layers or through holes in the partitions.

How to insulate the floor

You can use a foil underlay as waterproofing sweat insulation. It will create an extra effect. It can be used not only on the floor but also on the walls.

Any materials with waterproofing properties are suitable for insulating the lower part of the change house, it can be: basalt slabs, polystyrene foam, polyurethane foam and even bulk materials such as expanded clay. Mineral wool should not be used as it will absorb moisture.

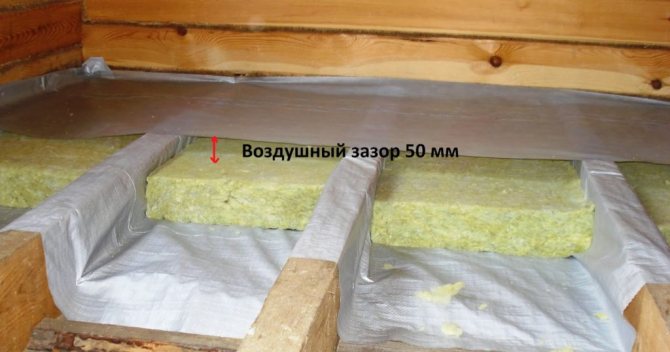

It is also necessary to use a hydro-barrier. The air gap between the layers will create space for air circulation, which will not allow dew to form.

We insulate the roof

This work can be done in two ways: insulate from the outside or from the inside. For external insulation, heat-insulating material is selected taking into account resistance to temperature drops and aggressive environmental influences. Such heaters include: foam, mineral or basalt wool. From the inside, you can use any of the materials described above.

Step-by-step instructions for insulating a change house

Work can be carried out both inside the trailer and outside. These methods have both positive and negative aspects. Insulation of the change house from the outside will allow you to keep the internal volume in it... It will also protect the walls of the building from external negative factors, which will extend the service life of the trailer. The disadvantage of insulating the change house from the outside is the fact that then it will have to be trimmed with decorative material so that it looks attractive.

For work inside, it is important to use non-toxic and environmentally friendly materials that do not burn. An excellent option would be to use mineral wool. The installation process consists of the following stages:

- Equipped with a frame on the wall.

- The space between the beams is filled with cotton wool.

- Laying a layer of waterproofing.

- Facing.

Preparation

You will need to prepare the following materials and tools:

- Steam insulator.

- Minvata.

- Bar.

- Mastic for wood processing.

- A hammer.

- Screws.

- Nails.

Floor insulation

How to insulate the base of a change house with your own hands? For such work, you can use:

- Expanded polystyrene.

- Minvatu.

- Styrofoam.

The instructions say that initially you need to lay a frame made of timber on the floor. Previously, the base will need to be cleaned of dirt. The tree must be treated with antiseptics so that it does not rot, and insects do not multiply there. The cells in it need to be made 50x50cm. Insulation is placed in them. A layer of waterproofing lays on top. Then the surface is covered with boards.

Roof

How to insulate a trailer for winter living from above? Such work is recommended to be carried out outside. To do this, you need to remove the roofing material (slate), lay waterproofing and insulation under it. Then attach the roofing material back.

If it is not possible to do such work from above, then it is necessary to thermally insulate from the inside. To do this, you need to attach beams to the ceiling. Thermal material is placed between them and chipboard is sewn up. It is worth remembering that this can reduce the height of the room.

Frame installation

The walls must first be treated with antiseptics so that they do not rot and rust. It will also help prevent the formation of fungus on the surface. Then slats made of wood are attached to them, to which a heat insulator is mounted with a stapler. The distance between the bars should be equal to the width of the heat insulator.

When carrying out work, it is worth leaving the air vents on the walls at the bottom so that steam does not collect and condensate does not form. You can also put penofol on top of the insulation, which will create the effect of a thermos in the building.

Window

The windows can be sealed with silicone. To do this, you will have to dismantle the glazing beads and apply a layer of sealant under them. Then the glazing beads are attached in place. This will help keep the room warm. You can, of course, put double-glazed windows.

Winter cabins for summer cottages

If the summer cottage is planned for operation throughout the year, then considerable attention should be paid to the degree of its insulation. In this case, it is worth purchasing ready-made winter cabins. Warm cabins can be made of wood or metal. Wooden country cabins are warmer and more comfortable for operation in the cold season, unlike metal ones. Winter shed made of a metal profile and insulation with an external brick finish If the purchased shed does not meet your requirements, you can insulate it yourself.

Back to the table of contents

Ways of insulating change houses

You need to know that there are three ways to insulate summer cottages with your own hands: due to interior decoration, due to exterior decoration, as well as wall insulation. The last method of insulation can be implemented only in frame structures of temporary huts, and its implementation is planned already at the construction stage.

After the summer cottage has already been assembled and put into operation, it will be very problematic to produce in-wall insulation.

In our case, we will consider the option of warming a summer cottage with our own hands in the case when the finished change house requires additional insulation. How to do it? It is best to insulate temporary housing outside.

This is due to the following factors:

- A layer of external insulation will not reduce the interior space of the room;

- External insulation will protect the main structures of the temporary house from freezing in the winter, which will increase their service life;

- Many heaters contain toxic substances that will adversely affect the state of the inner atmosphere of the change house;

- External thermal insulation for buildings will become an additional layer that will prevent the negative impact of aggressive environmental factors on the structural elements of the change house.

However, there is one drawback here: additional costs for wall cladding with siding, blockhouse, etc., since the insulation will need to be somehow isolated from the environment.

In the case of an internal version of insulation, you can do with foam or expanded polystyrene. It is economical, easy to install and does not require the installation of additional waterproofing and vapor barrier materials. Construction of a winter shed from a wooden frame filled with foam plastic However, such insulation is temporary and is not suitable for finishing capital sheds for a summer residence.

Back to the table of contents

Materials for insulating change houses and the technology of their laying

Ecowool, basalt fiber and polystyrene foam (or expanded polystyrene) are used as heaters for the garden shed. All these heaters have a number of advantages and disadvantages. Let us dwell on each of them in more detail.

Ecowool has a high percentage of not only thermal insulation, but also noise absorption. In this regard, the use of ecowool as a heater provides the change house with warmth and silence inside the room.

Basalt fiber differs in that it is absolutely non-combustible material, since it is made from the remains of basalt processing. In addition, even a thin layer of it provides good thermal insulation of the room. An example of insulating a change house with basalt fiber However, when insulating a change house with your own hands using basalt fiber, gaps are formed between the plates, which require additional sealing.

Insulation of the change house outside

Insulation of a structure from the outside can have both pros and cons. The advantage is the preservation of free space in the room, and the negative is the need to finish the outer part with siding or eurolining.

It can act as a heater Styrofoam

which has a porous structure, light weight and soundproof performance. It retains heat well and is highly resistant to decay. You can also use basalt slabs, slag wool, glass wool. To thoroughly seal the joints and cracks, polyurethane foam is used, which perfectly seals and retains heat in the room.

Heating shed

Organizations use trailers as mobile buildings. With frequent moves, it is impossible to use stoves, boilers for liquid, solid fuels. The premises use electric heaters. Private traders, on the other hand, buy inventory buildings for use in one place without transportation between sites. Therefore, metal cabins for summer cottages are often heated by a wood-burning stove, pellets, briquettes.

With the small dimensions of the building, air heating from the stove is sufficient. If the house is assembled on the SNT / ONT section of several trailers, it makes sense to install a boiler, stretch the water heating circuits.

Thus, the walls of the cabins are usually insulated from the outside using the ventilated facade technology. Thermal insulation in the floor, the ceiling is laid from the inside of the building. The heating option is developed individually, depending on the operational conditions of the building.

Back to the list

How to insulate a change house for winter living

Temporary often becomes synonymous with permanent, purchasing a change house for the country, you can assume that it will only be needed for the summer season, but in fact it will be needed in winter as well. However, not every house will be cozy during the cold season.That is why, how to insulate a change house for winter living is an important issue that requires consideration. In fact, the correct answer consists of two factors, without each other they will be useless. To live in a shed in the winter cold, you need not only to do insulation, but also to think about heating the structure.

Heating issues

Of course, it is difficult to organize a capital stove in a change house, however, there are several systems that will help make the house much more comfortable and provide a comfortable temperature in it. So:

- Electrical systems. First of all, it can be electric furnaces that have not only a suitable power, but also have good fire safety, as well as protection against possible burns. In addition, wall heaters, infrared heaters, electric heat guns are used in change houses;

- Gas systems. This type can work, for example, on liquefied gas from cylinders;

- Heat guns, multi-fuel, diesel, etc.

Having decided which room heating system to give preference to, you can do the second part of the process.

Insulation of an iron trailer

Before insulating the iron trailer, you need to fix the wooden crate.

Before insulating the iron trailer, the issue of finishing should be resolved. The design of the metal change house is quite simple - it is a frame made of profiled pipes, sheathed with corrugated board or other metal. Finishing needs to be fastened to something, you cannot do without a crate. To do this, you need to securely fasten wooden blocks to the frame made of profiled pipes. Styrofoam is placed between the crate, since it is the cheapest. The foam is attached to metal with adhesive foam, which has good adhesion to almost any surface.

The main methods and their features

There are only three options for insulating such a building - these are:

recommended articles:

- Izospan: versatile insulation material

- Thermal insulation Knauf: application and characteristics of insulation

- application of an internal heat insulator;

- installation of external insulation;

- and placing it in the space between the walls (this option is only possible for frame temporary huts!).

Installation of insulating materials inside the walls is possible only if the change house initially provides for this possibility. It is extremely difficult to change an already finished structure.

Internal insulation reduces the usable floor space. Therefore, this method is not suitable for small buildings. Also, the technical properties of the material do not always allow it to be fixed on the inner surface of the walls. For example, the selected insulation emits harmful substances or is a source of dust.

Insulated change house

External thermal insulation is the best choice for most cases. This method has a number of advantages, such as:

- significant saving of space inside the building;

- providing an additional protective layer outside (bad weather affects the integrity and safety of the entire structure less);

- reducing the likelihood of walls freezing in the cold season;

- environmental safety - no harmful chemical compounds will end up inside the change house.

A significant disadvantage is necessity. The finished layer of insulation must be carefully insulated from any external influences. This point is important to ensure the long-term operation of the material.

Thermal insulation of the building from the inside will be cheaper - here you can use expanded polystyrene or polystyrene (if no one lives in the change house!). The last insulation does not have a long service life and is not suitable for capital buildings that have been used for more than a decade in a row.

How to prepare a change house for winter

A summer cottage, when carrying out competent insulation and the presence of heating, may well be suitable for living in the winter.

How to prepare a change house for winter correctly:

- Floor insulation on sub-floors;

- Insulation of the ceiling base;

- External wall insulation;

- Replacement or improvement of the construction of windows.

As practice shows, the weakest link in the change house is the floor.

Therefore, even during construction, it is important to correctly determine the foundation (it is necessary, to put the change house on the ground - bad manners and the inability to warm it up normally).

To insulate the floor on rough floors, you will need a wooden beam with a cross section of 50x50 mm, mineral wool, a vapor barrier film, a floorboard and a solution against wood insect pests. Initially, the existing floor base is cleaned of dust and a protective emulsion is applied. Also, the entire wooden beam is processed in parallel with the solution. When the floor base dries well, a vapor barrier film is spread on it with the glossy side away from you. Further, stepping back from one of the walls of the change house 10-15 cm, parallel to the wall, the first beam is mounted on top of the film on the screws.

Having mounted the first beam, 100-120 cm recede from it and the second and all subsequent beams are mounted in the same way. At the next stage, the entire space between the beams is filled with slab or roll mineral wool. On top of the mineral wool, on top of all the bars, a second layer of PVC film is mounted with a stapler. The warming of the floor of the summer cottage is completed with padding on the existing beams of the floorboard.

Of course, it is advisable to insulate the ceiling from the outside. That is, slate or ondulin sheets are dismantled, mineral wool is laid and the roofing material is installed in its place. However, if this operation cannot be performed, the ceiling insulation in the cabins is made from nutria. If the ceiling is upholstered with wooden clapboard on a crate made of a bar of at least 50x50 mm, then the space in the crate can be safely used for filling with insulation. But, if there is no cavity in the ceiling base, the ceiling is insulated in the same way as the floor, followed by finishing with clapboard.

When insulating the walls of a summer cottage, work begins by covering the wall planes with an antifungal solution. When the walls dry out on their surface, a 50x50 mm beam is mounted vertically at a distance of 100-150 cm from each other. Further, mineral wool is mounted between the bars with the help of brackets or a raspor. You can, of course, use expanded polystyrene for insulation, but a wooden building "wrapped" in polystyrene can quickly begin to bloom. Styrofoam is great for insulating any walls, except for wooden ones. Having mounted mineral wool, a film is stuffed on top of it and the front board or wide lining is stuffed.

Insulation of a wooden change house for a summer residence

It is better to insulate wooden cabins with mineral wool, as it allows the wood to breathe.

Insulated trailers for summer cottages are on sale, their price starts from 20 thousand rubles for a room of 1.5 by 2 meters, while thermal insulation is paid separately. Naturally, the larger the area, the more expensive. Making it with your own hands is not so difficult, and even more so to insulate it, so there is no point in overpaying. Regardless of the design, thermal insulation is laid from the inside, only the method differs.

Panel and frame structures are insulated according to the same scheme, since in both cases the thermal insulation is placed in the cavity of the frame. Do-it-yourself insulation of the change house must be carried out with materials that let steam through, since this is important for wood. Any thermal insulation that is applicable for insulating frame houses is suitable:. PPU; penoizol; loose insulation; ecowool; polystyrene in sheets and crumb.

- PPU;

- penoizol;

- loose insulation;

- ecowool;

- polystyrene in sheets and crumb.

Those materials that are afraid of moisture need to be protected with special films (vapor barrier and waterproofing). They must be laid in such a way that the steam from the room does not enter the thermal insulation layer, and the one that nevertheless penetrates could leave the walls without hindrance. Humid air always moves from a warm environment to a cold one, and not vice versa. Carefully look at what is written on the film, it is indicated there which side it should be laid on. Many films are made in the form of membranes and allow air to pass in only one direction. Incorrect installation is fraught with obtaining the opposite result from the use of protective films.

In addition to wall insulation, work on the floor and ceiling insulation must be carried out without fail, the materials are the same. The only problem that almost all owners of insulated cabins face are mice. I will simply not save from them, especially in such a small area, therefore, perhaps one should give preference to materials in which rodents do not live. Alternatively, you can insulate with penoizol, but not liquid, but in sheets, so it will be cheaper.

A lot has been said about how convector heaters work, because this method of heating the air is the fastest.

You can read about what is the most compact heater in the room.

Door insulation

When insulating the change house, it is necessary that about 20-25% of the heat can be lost through it. It is important to separate the door from the main room by erecting a vestibule that acts as a buffer between the street and the trailer.

The most reliable in terms of thermal insulation are:

- Solid wood doors;

- Frame doors filled with mineral wool or foam.

When installing the door frame, all joints are filled with foam. In order not to miss the slightest areas, it must be applied in zigzag movements. Too deep cavities in the doorway are pre-foamed. Excess is easily cut off.

Watch the video:

If the trailer has standard doors, you need to glue the door frame around the perimeter with a special sealing rubber with a self-adhesive layer. A snug fit will significantly reduce heat loss.

Related work

Reducing heat loss and, as a result, reducing the cost of heating the change house will allow the implementation of additional insulation not only of the ceiling, but also, which is no less important, of the floor and walls. Professional builders also recommend sealing door and window fillings, through which a significant amount of heat is also lost. Only a comprehensive solution to the problem of insulation will lead to the achievement of the necessary energy efficiency and guarantee a positive final result.