About company

Beretta has been manufacturing heating equipment for over half a century. The company is part of the RIELLO S.p.A concern, which manufactures goods for various purposes.

The history of Beretta began in 1950. At first it was a metalworking enterprise, which later turned to the production of heating devices. Having started with the production of diesel boilers, "Beretta" soon started producing gas analogues. Now the Italian brand is among the leaders in its sector. The brand's products are sold in dozens of countries around the world.

How to check the sensors

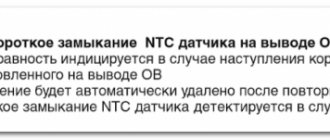

All sensors of the Beretta boiler are part of the self-diagnosis system. They not only perform control functions, but are themselves objects of observation.

This means that in case of failure, short circuit or wire breakage of any sensor, the corresponding error code will immediately appear on the display of the boiler control panel. The system polls the sensors automatically at the moment of switching on, no special actions are required from the user.

Most of them are thermistors that respond to changes in temperature conditions or indicators outside the established operating mode of the frame. The design of the elements is simple, replacement, if necessary, is not difficult and does not take much time.

It is not recommended to change any elements of the boiler yourself, you need to call the master from the service center.

What are the Beretta boilers?

The manufacturer tried to satisfy any needs - the company produces several lines, in each of which heaters are presented in a wide range of capacities. You can find models for a huge country cottage, a small apartment, or a production facility. All devices manufactured by Beretta can be classified according to the following criteria:

- Installation method - floor and wall. The latter are compact, they can be installed in residential premises. Floor standing ones are more powerful and bulky, they are installed in houses of a large area, in a separate room.

- The principle of operation is classic and condensation. The second, in addition to the energy obtained from the combustion of fuel, use the heat of the exhaust gases to heat the coolant. The efficiency of condensing units reaches 107%.

- The type of combustion chamber is atmospheric and turbocharged. The first ones have the letter "A" in the marking, the second - "S".

- The number of contours - with one and two contours. Single-circuit in the marking usually have the letter "R", it comes first, double-circuit - "C". Heaters with two circuits can also differ in the type of heat exchanger: it can be separate or bithermal. A single-circuit boiler is designed only for heating, but just in case it is equipped with a special outlet for connecting a boiler.

The design is directly related to heating performance. The company offers boilers:

- Wall mounted. The power range is 11,000–32,000 watts.

- Cast iron. With atmospheric (open) burners. 24,000-279,000 watts.

- Flowing. 18,000-29,500 watts.

Prices for Beretta gas equipment depend on the capacity. The price range is 30,000–95,000 rubles.

How to choose a boiler

- Define a goal. What do you intend to use the heater for - only for heating the house or also for heating hot water. In the first case, take a single-circuit, in the second - you need a double-circuit apparatus.

- Specify the area to be heated. Depending on the area, the power will be selected.

- Which installation option is more convenient for you - wall or floor.

- Do you need additional functions.

All models from the Italian brand are compact and quiet, they do not bother the owners with their work at all. They have a stylish design and fit perfectly into modern interiors.

Protective systems

- From freezing. It is possible to work at a lower temperature. If necessary, there is a start to warm up the system.

- From lack of traction. The device turns off when there is a shortage of it.

- From blocking the pump. Automatic shutdown when idle for a long time. The shutdown frequency is once a day.

- From improper ignition. There is a built-in flame control device.

Features of the operation of gas boilers

In areas where it is possible to connect to the central gas supply main, gas boilers of various designs and performance indicators are actively used. Below it is proposed to consider what a gas boiler is, the basic principles of its operation and possible problems that arise during operation.

What is a gas boiler and how does it work?

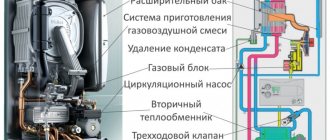

A gas boiler is a device made with the aim of obtaining thermal energy, capable of providing heating for objects of various purposes. Thanks to it, the heat carrier (liquid) is heated to the desired temperature.

The fuel in most cases is methane, the alternative is propane-butane. After the gas is supplied to the boiler, piezoelectric ignition is switched on (a small spark ignites the igniter, then the flame goes to the burner, which heats the structure).

The heating medium in the boiler is heated to the required temperature, and the water is then transferred to the system.

Single-circuit gas boiler

As standard, single-circuit boilers operate exclusively to provide the heating process. When you also need to prepare hot water for household needs, it will be necessary to connect a storage water heater, which works according to the indirect heating method.

Double-circuit gas boiler

It is a double-circuit boiler, a special equipment capable of simultaneously providing both room heating and hot water heating, which is then used for various domestic needs.

The process of heating the circuit is carried out in a special flow-through heat exchanger, which can be made as a coaxial bithermal, and a split plate.

An alternative is to heat the circuit in a built-in storage heater.

Condensing gas boiler

A condensing boiler is usually understood to mean equipment that uses the highest calorific value of the fuel used by condensing the combustion products directly on the walls of the economizer element.

In order to achieve the maximum effect, it is necessary to achieve an optimum lowering of the supply temperature "to the dew point".

The ideal option would be a low-temperature underfloor heating system, but various auxiliary mechanisms can be used to ensure that the temperature is lowered.

Parapet gas boiler

It is a parapet boiler design that combines all the advantages of traditional heating equipment and a convector.

It is used both in a private house and in an apartment, where it can easily perform the function assigned to it.

For its stable operation, sufficiently soft water is required, a stable supply of gas, electrical energy, it is required to maintain an optimal pressure.

Turbocharged gas boiler

It is a turbocharged boiler, a fairly compact equipment, which is mounted on the wall.Designed for use in closed-type heating systems, while providing adequate forced circulation of water in the system. It is widely used in small houses, cottages, apartments.

https://www.youtube.com/watch?v=Kvgt3YoxHpE

The gas boiler is installed exclusively by specialists who have the necessary qualifications for the performance of these works. It is taken into account that the equipment must be installed in a pit, preferably if a room for it will be allocated separately (for example, a gas water heater can also be installed in it).

Which filter to put in front of the gas boiler?

Ideally, reverse osmosis filters should be installed in the heating system to provide an adequate level of equipment protection against the negative effects of hard water. Special filters operating on ion-exchange resins will also help, but their cost is quite high.

Gas boiler malfunctions

During operation, the boiler can present unpleasant surprises to its owner. Let's look at common problems.

Uneven water heating

The reason for this problem is a malfunction of the thermocouple, temperature sensor. The boiler cannot work stably in automatic mode, it is necessary to ensure that the damaged equipment is replaced with a new one.

As practice shows, the occurrence of an uneven temperature also indicates the need to adjust the relay, sensor, if you postpone this process on the back burner, a situation may arise with the failure of the element completely.

Gas boiler does not heat water

The reason may be due to several factors. The first is a poor gas supply (possibly due to a low level in the system, but burner elements may be clogged).

The second is that there is not enough water in the boiler, therefore, it is necessary to completely fill the system.

The temperature indicator is also affected by the faulty state of the temperature sensor, it gives incorrect readings, the owner of the equipment is simply not able to correctly set the required value of the heat level in the boiler.

The gas boiler does not turn off

The main reason is that the hardware cannot fully warm up the system. The reasons that influenced this situation can be noted in the presence of hidden leaks, incorrect connection of the equipment itself. Finally, the presence of contamination in the pipes is noted, which negatively affects the operation of the entire system.

The boiler works with claps

One of the reasons the equipment works with cotton is because it is dirty. To avoid such a situation, it is necessary to regularly clean the equipment from the accumulated elements of soot and burning. As a result of incorrect operation, the burner can also become clogged, individual outlets stop supplying gas in the required amount.

The gas boiler “discharges” water

A typical reason that causes the boiler to discharge water will be a drop in pressure in the system. In this case, it is recommended to start pumping air into the expansion vessel.

For this, special pumping equipment is used, which, preferably, should already be installed in the system.

There is no need to pump up water, the problem can be eliminated by working with air supply to the expansion tank.

The gas boiler turns on and off frequently

The first reason why the boiler often turns on and off is the incorrect selection of the equipment itself. In particular, its power is designed to work in a large room, but is forced to function in a small room.

Errors during the installation of a special circulation pump also have an impact. Also, the temperature range may be incorrectly set, as a result of which the boiler does not get the desired indicator and turns on again.

There is no thermostat in the room, and the equipment operation is adjusted exclusively according to the indicators of the coolant itself.

When and how should the gas boiler be cleaned?

The boiler must be cleaned at least once every two seasons. The first "symptom" of equipment that needs to be cleaned is the lack of uniform heating.

For example, during operation and in case of severe pollution, some models begin to work unstably, tongues of flame come out of the viewing window, and fumes begin to accumulate on the inner surface (above the burner), filling the entire space and making it impossible to fully operate the equipment.

Companies from the TAM.BY catalog offer to buy a gas boiler with the possibility of delivery and installation.

Installation and operation

The installation of Beretta gas equipment is entrusted to the representatives of the company. Otherwise, the owner of the heater will lose the right to warranty service.

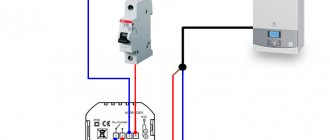

The operating rules prescribe the mandatory installation of protection against voltage surges. All mounted and turbocharged modifications are volatile. They need to install an uninterruptible power supply and grounding.

Requirements for the room in which the gas equipment will be installed:

- There must be at least 0.5 m between the upper end of the smoke exhaust pipe and the ridge of the roof.

- Door opening in width - from 0.8 m.

- Ventilation is a must.

- Between the gas appliance and the wall - at least 0.4 m.

Installation instructions

If the listed requirements are not met, the gas service will not allow the boiler to be connected to the central line. However, the need to comply with these requirements is dictated not by bureaucracy, but by experience, as well as fire safety. The restrictions apply not only to equipment and installation work, but also to the room where the boiler is supposed to be installed.

It must be remembered that the area of the boiler room must be equal to 4 square meters or more, and the ceilings must be at least 2.5 meters. When installing the door, keep in mind that its width should be 80 cm or more. If you decide to prefer, the gas boiler of this company will meet all safety requirements, however, it is important to comply with the established rules. They involve the need to illuminate equipment in a natural way through a window opening. For 10 square meters of one room, there should be 0.3 meters of a square window opening. It is very important to organize intensive ventilation, because gas combustion is ensured by the principle of fresh air inflow. To ensure the supply of outside air, it is necessary to provide a hole of 8 square centimeters per 1 kilowatt of device power.

How to use the Beretta boiler

Gas appliances "Beretta" are easy to use. The instruction manual explains how to make the connection. After the installation is completed, the temperature of the coolant is adjusted.

When the winter season ends, the double-circuit versions should be switched to the "Summer" mode, only the DHW circuit remains in operation. This is done simply by turning a mechanical switch.

The coolant is salt-free water: if you put a regular water into the system, scale will quickly appear in the heat exchanger. Water with increased hardness must be passed through softening devices.

All series, except for Novella Autonomous, can work only with a circulation pump.

In emergency situations, the devices themselves diagnose the cause of the malfunction, displaying a coded error indication on the screen. The instruction manual will help to decipher the codes. If there is an inscription "contacting the service department", you must immediately abandon self-repair: intervention in such situations is strictly contraindicated.

Benefits: moderate cost, functionality, the possibility of switching to an alternative type of fuel.

Disadvantages: sensitivity to power surges.

Popular breakdowns and their elimination

The lower the serial number of the error, the more often it occurs during the operation of the Beretta boiler.

Let's consider the most common errors and possible ways to fix them:

- A01. Blockage due to lack of flame. There may be several reasons - problems with the gas supply in the main line, the gas supply valve to the boiler is closed, the burner nozzles are heavily clogged. Find out if there is gas in the line, clean the burner and nozzles.

- A02. Overheating of the heat exchanger indicates a lack of water. Check the operation of the circulation pump and the extract air pressure, add fluids to the system.

- A03. High pressure in the chimney indicates blockage of the outlet with ice, frost, accumulation of soot. Weather factors are possible - strong gusty wind.

- A 04. The drop in coolant pressure may be caused by a lack of fluid. Check the system for leaks, if found, repair.

- A05. Malfunctions of the DHW line thermistor are eliminated by replacing the sensor.

- A06. A defective heating circuit thermistor must be replaced immediately.

- E33. It is necessary to swap the electrodes in the power plug. Beretta boilers are phase-dependent, do not work if the phase wire is incorrectly connected.

- E46. Exceeding the permissible coolant temperature indicates problems in the circulation of the liquid. CHECK the operating mode of the circulation pump.

- The bell symbol (bell, p) flashes. This is a signal from the chimney pressure sensor, indicating that there is an obstruction to the exit of smoke, the formation of ice or frost at the exit of the chimney.

IMPORTANT! The Beretta boiler error is reset by pressing the shutdown button and restarting the boiler after 5-6 seconds.

Specifications

Almost all modifications include the following:

- With a small readjustment, natural gas can be replaced with liquefied gas.

- The material of the burners is stainless steel.

- Weather-dependent automation - after connecting the temperature sensor, the device selects a mode based on weather data.

- The built-in circulation pump has an automatic air vent.

- Due to the operation of the hydraulic unit, the safety valve is activated.

- Equipped with pressure gauges.

- Expansion tank of membrane type.

- Electronic ignition for volatile versions.

- Self-diagnosis is provided: tests the traction and water pressure, checks for the presence of gas.

- Frost protection starts: if the coolant cools down to +5 ° C, it automatically turns on and the water is heated to +21 ° C.

Heat carrier temperature:

- minimum - +40 ° C;

- maximum - +80 ° C.

DHW temperature:

- minimum - +37 ° C;

- maximum - +60 ° C.

In the heating circuit, a pressure of no more than 3 atm is allowed. For built-in boilers - 8 atm.

Wall mounted

They can be hung in the kitchen, and the boiler does not need a separate place, it will perfectly fit right above the table or sink. The brand has four main series of mounted type:

- Beretta City. Has many advanced features. Boilers are comparable to premium equipment but are cheaper. They can be completed with a sensor or mechanical control unit. If desired, you can connect a remote control and a temperature sensor controller. Convertible for liquefied gas. Power - up to 50,000 watts.

- "Beretta Chao". The compact device is ideal for high-rise apartments. The maximum power in the line is 28 kW. Boilers are manufactured with open and closed furnaces. Belong to economy class.

- "Boiler" is a heating boiler with a built-in storage tank.

- "Exclusive" - devices up to 35,000 watts.

Floor standing

Their main difference from the mounted versions is their high power. The power range in the Novella Avtonom and Novella RAI series is 24,000–71,000 watts. The most powerful series is Novella Maxima, which includes floor heaters with a heating capacity of up to 290,000 watts.

The floor-standing version has natural ventilation.Only devices with the RSI marking are equipped with forced ventilation: they have a closed firebox, they are connected to a coaxial chimney. Floor-standing models are capable of heating rooms up to 700 m². Single-circuit versions can be equipped with a BKN (indirect heating boiler) with a capacity of 120/220 liters.

Model overview

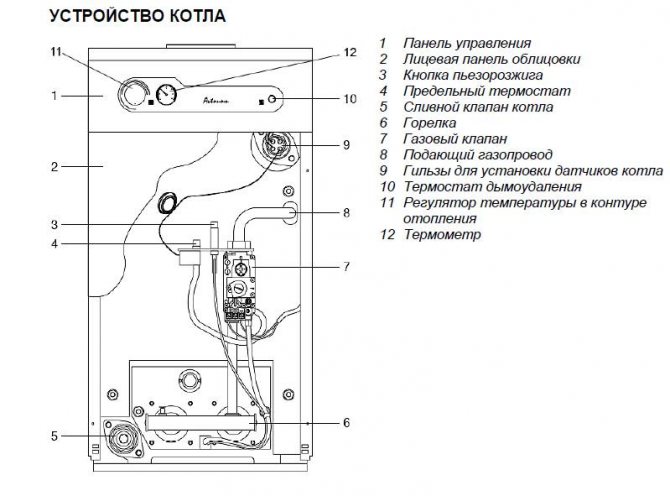

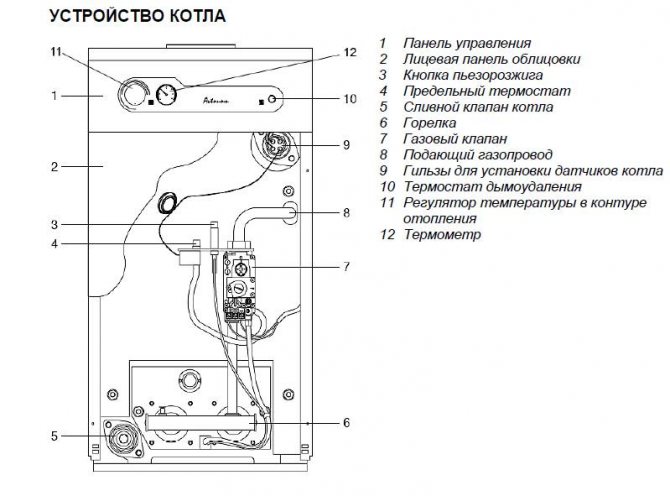

Fabula 31 CAI 80

"Fabula" is a double-circuit floor boiler. Atmospheric burner. Volatile, there is an auto-ignition. Characteristics:

- Heating capacity - 31 kW.

- The efficiency is 90%.

- Built-in boiler with a capacity of 80 liters.

- Weight - 126 kg.

- Dimensions (HxWxD) - 135x45x78 cm.

- Gas consumption - 3.5 m³ / hour.

City

Multifunctional devices, single and double circuit. With closed or open fireboxes. Power range 24-50 kW. General characteristics of the series:

- LCD display;

- boiler connection;

- work in condensation mode;

- separate outlets for air intake and chimney;

- circulation pump;

- electric ignition;

- smooth tuning and power regulation;

- blocking of the pump when the temperature drops;

- flame intensity control;

- cast iron heat exchanger.

For example, here are the characteristics of the City 35 CSI:

- Heated area - 350 m².

- Separate heat exchangers. Heating - copper. DHW - steel.

- Turbocharged type.

- The efficiency is 92.9%.

- Heating capacity - 37 600 W.

- Heating rate in hot water supply - 20 l / min. Designed for 3-4 points of water intake.

- Weight - 42 kg.

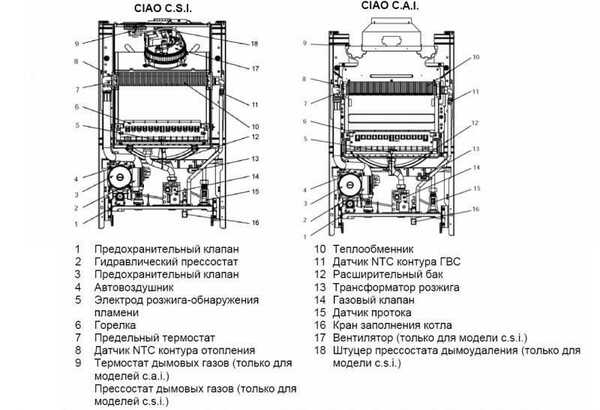

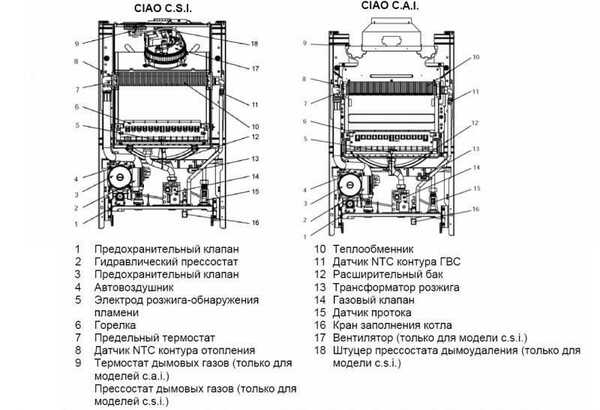

CIAO

Wall models. Double-circuit. The combustion chamber is closed or open. Usually used in apartments. Capacities - 16, 24, 28 kW. General characteristics are almost the same as those of City. Versatile - they work on any gas, natural or liquefied. Specifications CIAO 24 CSI N:

- Heated area - 240 m².

- Gas consumption - 2.78 cubic meters. m / hour.

- Heating capacity - 24,000 watts.

- The efficiency is 91.7%.

- Closed firebox.

- Auto ignition.

- Flame modulation.

- Weight - 32 kg.

- Dimensions (HxWxD) - 74x40x33.8 cm.

Novella

Outdoor execution. Single-circuit only. Cast iron heat exchanger. Two stage stainless steel burner. The range is 90–280 kW. Heaters from 174,000 W have two cast iron heat exchangers. Novella 45 RAI characteristics:

- Open firebox.

- Heating capacity - 45,000 watts.

- Natural gas consumption - 5.1 m³ / hour.

- Weight - 154 kg.

Boiler

"Boiler" is produced in one version - two circuits and a closed firebox. Boiler 28 BSI parameters:

- Heating capacity - 28,000 watts.

- Efficiency - 91%

- Wall execution.

- Weight - 68 kg.

- Dimensions (GxHxW) - 46.5x94x60 cm.

Mynute boiler

"Mine Boiler" produces only double-circuit ones. At 24,000 and 28,000 watts. Stainless steel. The firebox is open and closed. The functions are similar to the previous models - there are protection systems, self-diagnostics, etc.

Exclusive

"Exclusive" is produced with one or two circuits. Combustion chamber of both types. Wall-mounted only. Atmospheric models - 24 and 28 kW. Turbocharged - 26, 30 and 35 kW. Exclusive 24 CAI parameters:

- Double-circuit.

- 26.7 kW.

- 90% efficiency.

- Open camera.

- Dimensions (GxHxW) - 33.2x80.5x40 cm.

- Weight - 30 kg.

Beretta CIAO 24 CAI

This device is designed for wall mounting, it has two heating circuits - heating and hot water circuits, with an open combustion chamber. What are the main advantages of this equipment? We indicate with the following list.

- There is an information display.

- The power can be adjusted smoothly.

- Automatic adjustment of the temperature regime of the coolant.

- The circulation pump has three speeds and is fault-proof.

- Possibility to reconfigure equipment for liquefied gas.

- The wall thickness of the heat exchanger has been increased on the latest models.

- The installation has an ionization type flame control.

- The water pressure is controlled by a hydraulic pressure switch.

- There is also a smoke exhaust control.

In order to understand how this unit works, we give a brief instruction on this Beretta wall-mounted double-circuit gas boiler.

- The operating modes are indicated by special icons on the indicator panel of the unit.

- To activate the operation of the equipment, it is necessary to turn on the power supply, open the gas valve, adjust the room temperature regulator and set the "winter" or "summer" mode according to the situation.

- Disconnection is made by a special "off" button.

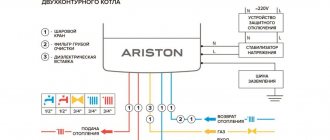

In the original, the instruction for the wall-mounted gas boiler Beretta has an electrical, hydraulic diagram, possible malfunctions and a description of installation rules with drawings.After eliminating minor problems, the boiler starts up with the reset button.

The described device has some relative disadvantages. We list them below:

- since the combustion chamber is open, it is necessary to have an equipped chimney in the room;

- clogging of sensors is possible.

We have dealt with this model, and now we will study another model.

Wall mounted Beretta CITY 24 CSI

This equipment is also designed for wall mounting. There are also two circuits here, but the combustion chamber is closed, respectively, the smoke extraction is forced. Power is 24 kW, and the area of the heated room can reach 240 m2.

The main best quality equipment is listed below.

- copper primary heat exchanger;

- protection against freezing and overheating;

- automatic diagnostics of equipment errors;

- the heating temperature of the coolant is automatically regulated;

- power is smoothly regulated;

- frost protection and pump blocking.

As you can see, this model has functions similar to those of the previous model. Now we will give a short instruction manual for the described Beretta gas boiler.

- The indicator panel also uses icons, conventional images are deciphered in the technical passport.

- Connection of a remote control is possible.

- Installation rules are detailed on the pages of the technical data sheet.

- The passport contains a connection diagram for a horizontal coaxial chimney, which must be purchased separately.

- To start the equipment, it is necessary to fill the system with water, turn on the power, open the gas valve, set the regulator to room temperature. Switch on the "winter" or "summer" mode.

- Disconnection of the equipment is carried out by the shutdown button.

It also lists error codes. That is, these are encrypted faults that the Beretta double-circuit gas boiler can show on the display panel. However, we will now talk about them in more detail.

Comparison and problems

To summarize, we made a pivot table for the two described models. The bottom line is this: boilers are roughly similar, and both are very attractive to consumers. This table is:

The table below includes information about the faults of one or another Beretta gas boiler that have occurred among consumers. Let's write down what you can try to do in case of certain problems with your own hands.

- Among the malfunctions of the Beretta gas boiler, there may be breakdowns in which the unit does not turn on. Most likely, the reason is either the lack of water, or the lack of power supply. The worst case scenario is the failure of the motherboard. Only the service department will help here.

- Blockage is possible due to overpressure of the chimney, but this can happen due to strong street wind.

- The automatic system must determine the malfunctions of the sensors itself.

- The equipment may not turn on also due to condensation in the chimney, the latter must be checked, among other things, if the unit does not turn on.

- There are cases of equipment failure due to frost at the chimney outlet. The sensor is triggered, as a result, the equipment does not work.

These are the main problems that can be encountered when operating the described boiler equipment.

Have you faced problems with central heating or hot water supply for a long time? These issues can be solved by installing a gas boiler.

Testimonials

CIAO 24 CSI: Konstantin A., Voronezh

Heats and heats water at the same time. Reliable, but not particularly economical - a lot of gas and electricity are consumed. I did not install a stabilizer, but the device works stably without it, it tolerates voltage surges normally. Electricity consumption monthly - 60 kWh. I put a thermal sensor, I save 50% on electricity. Water at a minimum heats up to 40 degrees. You can open two taps at the same time - wash and wash dishes, for example. The downside is volatility. When you turn off the light, you have to freeze.I'm not going to install an uninterruptible power supply, it costs a lot of money. Not a bad heater, but I would not choose it anymore - too serious disadvantages.

Avtonom 24 Novella 24 RAG: Polina T., Korolev

Has been working for 6 years. He doesn't need electricity - that's a plus. It is quiet. Cons: poor piezo ignition performance. It happens that the flame is blown out. Somehow in winter, due to unfortunate circumstances - the direction of the wind and icicles - the combustion products began to blow back. Because of this, the smoke sensor was triggered. To get out of the situation, we changed the circuit: removed the sensor by directly connecting the contacts. The door was closed and the window was opened. When the thermocouple burned out, I had to order and wait for a new one. We waited a long time, but the installation itself lasted 15 minutes.

Gas boilers of the Beretta brand make a good impression: consumers appreciate their technical characteristics, functionality and low cost. All products are adapted to domestic conditions - heaters can operate at low gas and water pressures. Belonging to the class of inexpensive heating equipment, Italian boilers meet all international quality standards.