The boiler operating chart is a document drawn up by the contractor organization upon completion of commissioning and operating procedures. Each boiler must have a completed regime card and be operated according to it. The document applies to industrial and commercial hot water and steam boilers, but is optional for domestic heating equipment.

Requirements for development and are specified in RD 10-179-98, approved by the decree of the Gosgortekhnadzor of Russia dated 09.02.98 N 5.

What is the boiler mode card

Purpose of the document

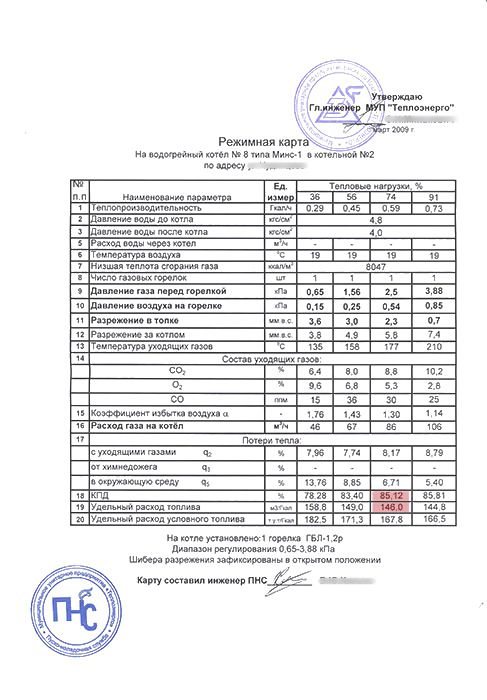

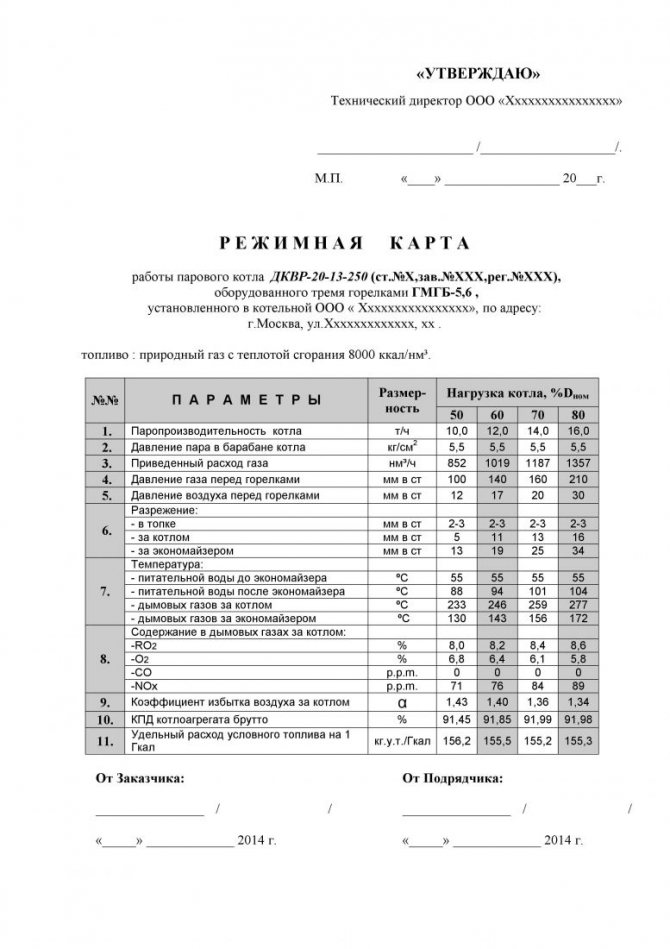

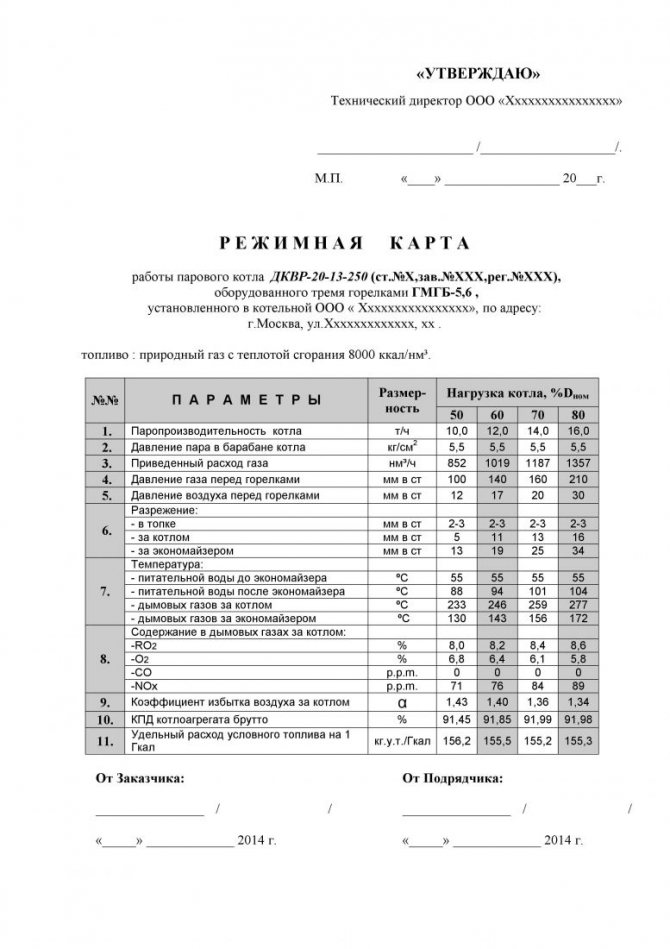

The purpose of the mode card is to show the operating parameters of the boiler unit (gas and air pressure, temperature conditions, etc.) at which the most complete and stable fuel combustion is achieved, and the operation process is the most efficient and safe. The document is drawn up in the form of a table (less often - in the form of a graph) with the operating parameters determined empirically for several operating modes of the boiler. Typically for operating modes at 30%, 50%, 70% and 100% of the boiler unit heating capacity.

The table contains parameters such as:

- heating capacity of the boiler unit;

- water pressure to the boiler, inside it and in the heating system;

- gas pressure and air pressure;

- composition and / or characteristics of the fuel;

- boiler operating temperature;

- Gross efficiency and net efficiency;

- fuel consumption per hour;

- additional hourly energy consumption (power supply, additional type of fuel, etc.);

- vacuum in the combustion chamber;

- heat losses with flue gases;

- heat losses through the boiler drum, etc.

The exact list of items always depends on the characteristics of the boiler equipment. The main requirement is that it must describe all the variable parameters of the boiler operation, be an instruction manual for the operation of the boiler in various operating modes.

The photo shows an example of a boiler mode card blank.

Who develops and approves it

Specialists of organizations engaged in the design, manufacture, commissioning, commissioning and technical diagnostics of steam and hot water boilers develop and draw up a regime map. Its compilation is possible only after identifying the parameters of work empirically, i.e. after testing and adjusting the operation of the boiler.

The document is approved by the technical manager of the operating organization (he is also the chief engineer) or another authorized person representing the owner of the boiler. The controlling body for the operation of steam and hot water boilers is the Gosgortekhnadzor of Russia.

The validity period of the regime card

According to RD 10-179-98 "Methodological guidelines for the development of instructions and operating charts for the operation of pre-boiler water treatment plants and for maintaining the water-chemical regime of steam and hot water boilers", the validity period of the boiler operating card is three years. After the expiration of the specified period, it is necessary to revise and re-approve the card by the owner of the boiler. The revision timeline does not change regardless of the operating conditions.

Conditions for early review

However, the frequency can be violated in the event of an accident or when changing / modifying the boiler equipment, namely:

- when changing the type of coolant or its chemical properties;

- in case of a change in the type of fuel or a serious change in its basic characteristics (calorific value, ash content, dryness, gas pressure, etc.);

- when replacing or modifying boiler unit modules (burners, combustion chambers, heat exchangers, etc.);

- when changing other basic parameters indicated in the regime card - water / air pressure, heat output, vacuum in the combustion chamber, and so on.

If the above changes have been made, re-commissioning work is carried out, the document is drawn up and approved anew, in accordance with the new work parameters.

Purpose and methods of manufacturing an economizer for a hot water heating boiler

More options for compiling this document

This card design method is not the only one. Such an auxiliary form of the card is used when the burner, which is in the boiler, is horizontally slotted, or, in other words, injection. And the structure of the documentation itself has been slightly changed - the usual air pressure has been replaced by the location of individual nodes. These are the units that regulate the air intake:

- Air regulation damper.

- Curtain gaps that are on the blower sheet.

In addition, the location of the profile dampers and the air proportioner on the bypass window is indicated.

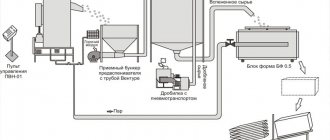

Many community cards come with economizer cards. Such documents are required only when testing economizers, after which a special sheet is drawn up, which demonstrates the results of all tests and measurements. For the most complete description of the capabilities and parameters of the heating boiler (by and large, this is also necessary so that during the repair and adjustment of the unit you can easily figure it out), make up a complete technical. report. This report depends only on what measurements and studies, or, probably, auxiliary procedures, were carried out.

When the unit has a new complete set, and re-equipment was carried out, in those. the report should indicate to what extent the results of the changes obtained correspond to the preliminary tasks of the update. It is good if all the procedures performed are analyzed.

A correctly drawn up operating map of the heating boiler is required in order for a steam, gas or other water heating device to work as efficiently as possible. Experts recommend keeping this document near the boiler at all times - this way, you will not damage the equipment during use and will not confuse any indicators.

The Territory of Heat company conducts operational and commissioning tests of boilers and burners running on gaseous and liquid fuels. These tests are essential to monitor equipment performance, improve productivity and safe operation.

With the help of operating tests, it is possible to identify deficiencies in the condition of the boiler equipment and take measures to improve the efficiency of the processes.

The technical operation rules require that gas boilers undergo operational and commissioning tests at least once every 3 years. Boilers for solid and liquid fuels - every 5 years.

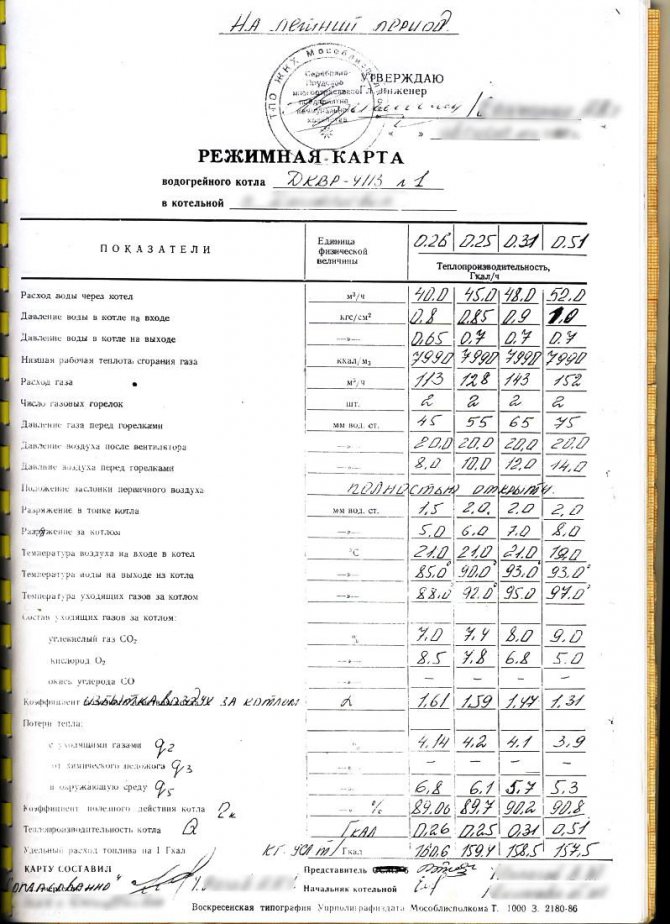

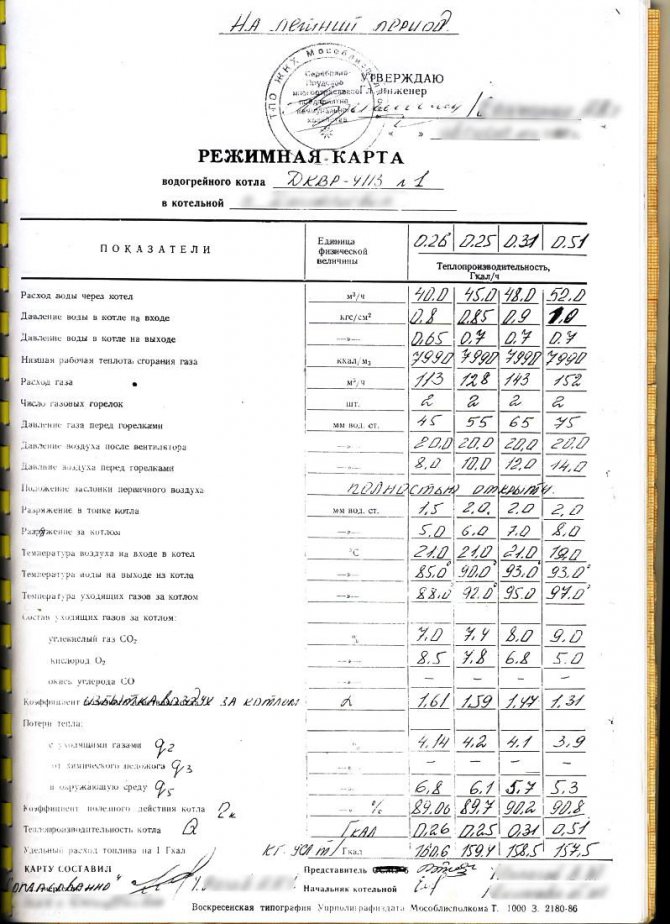

Sample for liquid fuel diesel DKVR-4113

It is worth recalling that there is no universal sample of the regime map for gas, solid fuel or liquid fuel boilers, since the parameters prescribed in the document depend on the type of boiler, its model, modification, piping, fuel and coolant used.

Regime map of a hot water boiler on gas sample

You are using an outdated version of the Internet Explorer browser. This version of the browser does not support many modern technologies, which is why many pages are displayed incorrectly, and most importantly, not all functions may work on sites.

We recommend to read: Loan agreement sample 2020

In this regard, more modern browsers are presented to your judgment.

They are all free, easy to install, and easy to use. When you switch to any of the following browser, all your bookmarks and passwords will be transferred from the current browser, you will not lose anything.

- a document drawn up on the basis of operating and adjustment and balance sheets

tests, containing the main operational and control parameters of the boiler, the value

Efficiency, specific fuel consumption at different performance, etc.

Regime card required for its correct and competent operation.

Boiler control re-compiled or revised every 3-5 years (link).

We draw up regime maps for any type of boilers and equipment.

Samples of boiler regime maps:

Address: Moscow, 1st km.

Kievskoe highway, BP "Rumyantsevo", Building A, office 47.

Compilation prices

You can order the performance of work and the registration of a regime card from any company engaged in setting up, maintaining and repairing power equipment, in the list of services of which there are regime and commissioning works.

The cost strongly depends on the type of boiler (hot water or steam) and its capacity. Some contractors calculate individually. However, the average cost of work for hot water boilers is 20-50 thousand rubles, for steam boilers (1-30 Gcal / hour) - 35-80 thousand rubles. The cost of work on low-power, relatively industrial-scale hot water boilers with a heating capacity of 25-100 kW can be 5-20 thousand rubles. Also, prices are highly dependent on the region.

Boilers

How is the documentation for the boiler compiled?

Each technical equipment requires a serious and careful attitude towards itself. This becomes possible thanks to the skillful and professional use of the instructions and various instructions for use attached to this or that equipment. That is why, as soon as you buy something new, in no case throw away everything that comes with a telephone, refrigerator, gas equipment, and even an iron and an electric kettle. The fact is that even if you yourself are not able to cope with the procedures described there, they may be required by the specialists whom you will hire to fix this or that equipment. It is especially necessary to treat equipment that has a long service life and is not intended to be written off after a short period of time. This equipment includes refrigerators, washing machines and, of course, gas boilers. The documents relating to the last mentioned technical devices include the boiler operation card.

According to the principle of operation, boilers are classic and pyrolysis (gas generating).

Thanks to this documentation, the correct and uninterrupted operation of gas and water heating equipment is carried out. Its form is generally accepted, unified. It was installed back in the Soviet Union, in 1984 by Glavgosgaznadzor.

Table of the regime card of a hot water boiler.

Most of the indicators located in a particular map are measured in percentages and allow you to measure the following:

- the amount of gas is behind the boiler;

- the percentage of heat loss that goes away with the burnt gas;

- the amount of heat released during the operation of the heaters;

- the amount of heat lost due to chemical underburning;

- boiler efficiency (net and gross);

- the percentage of gases such as oxygen, carbon and carbon monoxide.

The rest of the values in the regime maps of boilers:

- gas pressure;

- air pressure on burners;

- the amount of vapors generated in a certain time;

- their outlet temperature.

All quantities are measured in the appropriate units: degrees, kiloPascals, etc.

All boilers have their own regime maps.

They serve to ensure that with their help the most correct and efficient operation of both steam and gas and even hot water equipment was carried out.

The most basic quality of this card, which ensures the aforementioned state of the boiler, is that it allows you to observe all the changes occurring during the operation of the equipment. So, for example, it displays how much gas or air pressure is needed for a particular indicator of the load on the boiler. With all this, the safe operation of this technique must also be ensured, as well as a complete and stable combustion process.

Back to the table of contents

Measurement table during testing.

In order for this document to be created, it is necessary to carry out a sufficiently large number of measurements and experiments (at the stage of production and release of boilers into operation). For this, organizations specializing in commissioning work perform heat engineering tests. This is done every 3 years, and all kinds of calculations and measurements are still being carried out here. Most often, a regime card looks like an ordinary table, which can be drawn up from at least two columns, and a maximum of five. It depends on what operating modes are implied in the operation of the equipment. There are 4 of them in total: 100, 70, 50 and 30 percent modes. As for the number of lines, there are much more of them, since each of them individually indicates the parameters that were indicated above (while their unit of measurement is indicated next to them in the first column, there is no separate column for them). Another option for the design of a regime map is a schedule, but it is used much less often.

The card is usually produced in several (more often in two) copies, one of which must be placed next to the boiler, some even stick it on the boiler. But if you are worried about its safety, then make some additional copies yourself. In order for you to fully trust the data indicated on the card, the company that performed the commissioning works puts a signature or a brand name on it (or directly on the boiler).

In addition to the main indicators, the map also contains indicators of the dependence of gas pressure on boiler performance, as well as how much the air pressure depends on gas pressure. These indicators become necessary so that you (or a master adjuster) can ensure the regulation of a gas or water heating boiler, both with accurate indicators on the map, and with intermediate loads on it.

Back to the table of contents

There is also another option for the design of the boiler regime card. It is used when it is equipped with a horizontal slot burner (injection). Here, instead of such an indicator as air pressure, the location of some devices is indicated. These include those parts that regulate the air supply: the gaps of the curtains on the blower sheet and the air control flap. In addition to them, it can be indicated how the profile dampers are located in it and the air proportioner on the bypass window.

Some general regime maps are supplemented with economizer maps. This is done when the economizers are being tested. After that, you will also need a summary sheet, which reflects the results of absolutely all calculations and measurements. For the most complete description of the technical characteristics and capabilities of the boiler, as well as so that during adjustment or repair you can fully understand the proposed process, a complete technical report is created. It depends on what kind of measurements and calculations (or some other additional measures) were made. For the equipment that was made in a new configuration (in other words, for converted boilers), it is necessary to evaluate in the reports how the work done corresponds to the objectives of the modernization and the entire project as a whole. Here, it will be useful to analyze all the activities carried out.

So, drawing up a regime map is necessary for the full and high-quality operation of various kinds of gas, water heating and even steam equipment. It should, if possible, be located near the boiler, so that you do not confuse some indicators and damage the unit.

1poteply.ru