Do I need to ground the gas boiler

Even though the gas main is itself grounded, the gas pipe is not grounded enough. An additional system must be provided. It is done not just "at random", but according to typical examples of structures, which are quite simple. Let's consider them in more detail.

The need to ground the equipment of gas boilers is mandatory

Selecting a ground electrode

Grounding means a conductor in contact with the ground. The main feature of its design is as large an area of contact with the ground as possible. The soil, although it is a conductor, is very bad. That is why, in order to ensure a low grounding resistance (requirements of the standards for the operation of gas boilers), a large contact area of the ground electrode with the ground is required. The grounding of the gas pipe is not the grounding of the boiler; it requires a separate grounding circuit.

Many options for the design of grounding electrodes have been proposed, both industrial (for example, for substations) and for private use. The main characteristic for selection is the maximum current that must be diverted to the ground in case of complete breakdown, that is, the value at which the protective automatics are set.

Before making grounding for a gas boiler in a private house, keep in mind that the design of grounding electrodes, wires, contact connections will be checked by certified specialists and based on the data obtained, a "Protocol for checking grounding electrodes and grounding devices" will be drawn up.

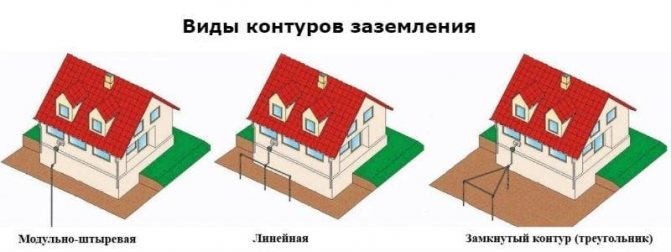

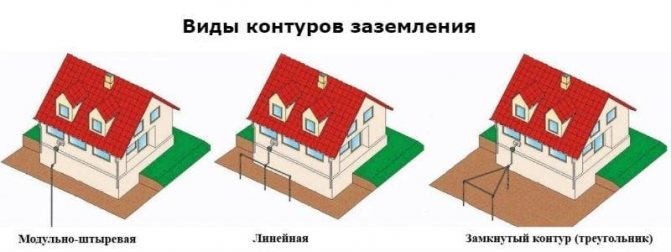

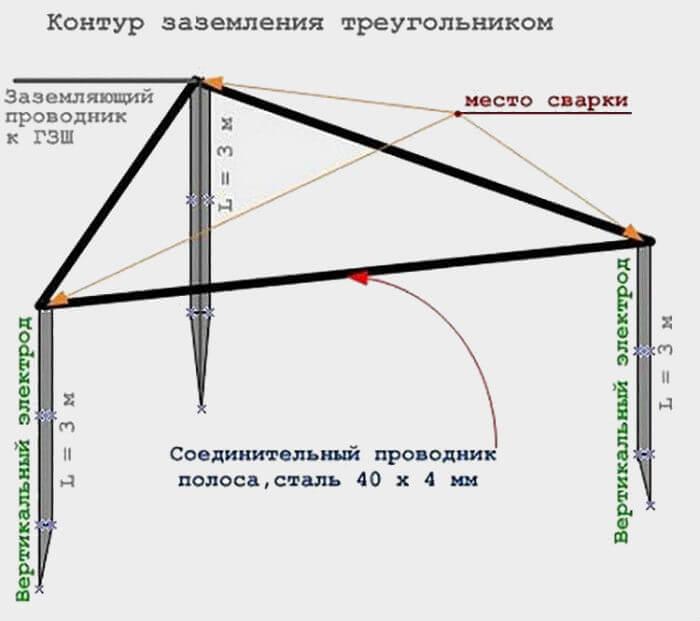

Three types of ground loop: delta, linear circuit, modular-pin ground

At the facility where the boiler is grounded, the resistance to current spreading of the ground loop is measured. This procedure allows you to obtain objective data on the quality of ground electrodes, which have long been hidden underground. That is why you should not try to make a grounding scheme for untested objects of unknown configuration: water supply, fittings, gas pipelines, sewers. In this there is a risk that you will not be able to obtain an act on the grounding of the gas boiler, and everything will have to be redone again. The norms for the grounding of gas boilers and gas pipelines have been developed by the PUE (Rules for the Arrangement of Electrical Installations). They establish the characteristics of grounding: resistance, conductor cross-section, materials and technologies used.

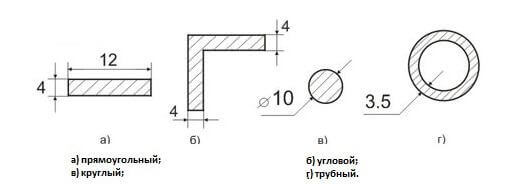

The most common are columnar ground electrodes. This is any metal product: pipes, corners, channel bars, I-beams. A prerequisite is sufficient rigidity of the elements used so that they can be driven into the ground. If yamobur is used, then this requirement is optional. The columns are placed in a triangle, which is done to limit the dimensions of the place on the site.

Ready-made sets of grounding electrodes have a rather high cost, therefore they are rarely used. They have exactly the same columnar design. Their advantage is that they can be assembled without a welding machine (with brass connecting sleeves), however, such a connection is less reliable.

Columnar ground electrodes for a gas boiler in a private house are used only for the reason that they can be driven into the ground to a considerable depth. In fact, this is far from the best design, because reliable electrical contact can only be in wet soil, in the last quarter of the buried part of the pillar. If the site is not rocky or rocky, then you can dig a trench about 1 m deep and 3 m long or more (longer is better).A metal conductor is placed in it, which can also be made from any black or non-ferrous rolled metal. However, this scheme is not classical, but it can also pass certification.

How to ground a gas boiler in a private house - details

The operation of gas heating equipment is only possible after a lengthy coordination process. In turn, for the approval to be successful, all equipment must be installed in accordance with the norms. One of the requirements of these standards is the grounding of the gas boiler. How to make grounding for a gas boiler will be discussed in this article.

The need for grounding

During the operation of a gas boiler, static voltage always occurs, and this factor does not depend at all on the availability and quality of the installed automation elements. To eliminate the likelihood of related problems, the gas boiler must be grounded.

The presence of grounding prevents the following situations from occurring:

- Failure of automation... Gas boilers are equipped with electronic systems that react very painfully to voltage drops in the power grid. In addition, the automation does not withstand the ingress of static discharges, therefore, if there is no grounding, the electronic filling of the boiler can simply burn out - and the cost of such elements is usually about half the cost of the boiler itself.

- Explosion probability... An increase in the concentration of static voltage is one of the most common causes of fires or explosions in gas boilers. Grounding completely eliminates the possibility of the smallest sparks, which eventually become the cause of an explosion when in contact with gas.

Gas boiler grounding technology - how to ground correctly

The standards stipulate the need for grounding the boiler, but they do not impose any requirements on the way of doing this work. It is thanks to this that it becomes possible to create a ground loop with your own hands. However, if you have a budget, it will be much easier to purchase a ready-made grounding kit, which is recommended by the gas service.

For self-arrangement of grounding, you need to take into account a number of parameters:

- Type and features of the grounding circuit;

- Resistance parameters;

- Materials that are best suited for the installation of the ground loop;

- Construction cost.

In addition, the grounding of a gas boiler must comply with all standards for this design.

This point is very important - if, when checking the circuit by a gas service representative, inconsistencies with the requirements are found, he simply will not sign a document on putting the grounding into operation.

For example, it is impossible to ground the boiler to a water supply, sewerage or gas mains, and if this prohibition is violated, the system will not be put into operation.

Grounding a gas boiler in a private house can be equipped in the following ways:

- Depending on the type of device... Gas boilers require their own grounding loop, which significantly distinguishes such devices from various household appliances. Higher requirements are imposed on heating equipment - in particular, if the boiler is to be grounded through a socket, then it must be connected directly to the grounding circuit, and not to the switchboard.

- Depending on the characteristics of grounding... Here we are talking about the method of installing the grounding loop, which can be presented as a ready-made kit specially designed for connecting gas boilers, and devices assembled independently.

Resistance of the ground loop in a private house

Before making grounding to the gas boiler, you need to calculate the resistance value, which is influenced not only by the heating equipment, but also by the characteristics of the soil located near the building.

According to the standards, soil resistance rates are as follows:

- Clayey... For clay soil, the maximum resistance is 10 ohms. This value is relevant for single-phase current and line voltage (380 V).

- Sandy... In the case of sandy soils, the ground loop may have a resistance of no more than 50 ohms.

In order to know exactly how to properly ground the boiler, it is advisable to additionally familiarize yourself with all the standards - the gas service may use earlier or later versions of the standards.

Grounding materials

Grounding of gas boilers can be carried out using the following materials:

- Ground wire... The cross-section of copper wires should exceed 10 mm, aluminum - 16 mm, and steel - 75 mm.

- Vertical pins driven into the ground... As a rule, steel pipes or corners are hammered into the ground, which are connected to each other using a welded bus. However, before grounding the boiler, you should inquire about ready-made grounding kits - they usually have galvanized or copper electrodes for welding.

- Automation and RCD... The boiler is connected to a panel with installed electrical fittings. According to the standards, the boiler cannot be put into operation without an earthing loop - but this does not apply to the backup loop, which is designed to automatically shut down the boiler in the event of a malfunction.

In modular boiler rooms, there is a special element to which grounding is connected from all metal and electrical assemblies. The connection of this element is carried out by means of electrodes lowered into the ground, which are connected to the system circuit.

The cost

Before grounding the gas boiler, you need to inquire about the cost of this work, which is influenced by a number of factors:

- Features of the soil;

- Characteristics of electrodes and wire cross-section;

- Ground loop type.

Also, the cost of grounding should include the cost of the services of an organization that will check the finished system for compliance with the standards.

Checking the boiler grounding

A representative of the local gas service can issue an act on the commissioning of a gas boiler (this act also takes into account the admissibility of using the existing grounding circuit).

At the same time, according to the standards, to check the grounding resistance, it is necessary to call specialists from the electrical laboratory, who will also check the quality of the lightning protection system.

In practice, it usually happens that only one service performs the check.

The grounding check can be carried out at different intervals, the norms of which are established by the relevant regulatory documents. Usually the check is carried out at least once a year. The need for regular checks is due to changes in soil characteristics, the intensity of the passage of groundwater and a number of other factors.

In any case, if the resistance of the grounding loop and its integrity comply with the standards, then the owner will be issued an act or protocol allowing the boiler to be put into operation and its further use.

Conclusion

Grounding for a gas boiler is quite simple to set up. Before grounding a boiler in a private house, you need to familiarize yourself with the relevant standards and requirements for such devices.

Types of gas heating boilers

According to the method of installation, modern gas-fired boilers are divided into wall-mounted and floor-standing. The wall-mounted version is used to heat small rooms.

Wall-mounted heating devices are compact and are made either with a combustion chamber or with a flow-through heating system.Floor gas heating units are installed in specially equipped rooms with an area of about 9 square meters.

The boiler is mounted at a distance of half a meter from the wall. The figures show options for floor-standing and wall-mounted boilers.

| Floor | Wall |

For the manufacture of heat exchangers for gas-fired boilers, steel, stainless steel or cast iron are used. Structurally, boilers are made with a closed firebox or open combustion chamber.

Products differ in the number of contours. Single and double-circuit boiler systems have their own advantages.

But one indispensable requirement is imposed on gas boilers of any model and modification - they must be grounded.

Selection of materials for the ground electrode

Grounding can only be made from metal elements. All other materials are not conductive. Theoretically, it could be made from graphite or carbon rods, but this is also not an option due to their too high resistance. Dry soil does not conduct current. The conductivity of the soil depends on its moisture content, when salt solutions (electrolytes) are formed in it, which conduct electric current very well.

Any rolled metal: pipes, corners, channel bars, I-beams

The best possible earthing materials are copper and stainless steel. Ordinary steel is also used, but it must be borne in mind that the service life of such a structure will directly depend on its volume, i.e. the metal corrodes at a certain rate (mm and fractions of a mm per year). The steel parts of the ground electrode must have a large cross-section: thick reinforcing rods, pipes and any metal rolling. If you choose stainless steel, then thin corners can already be used. They will provide even greater efficiency than massive steel parts.

Calculation of the parameters of the grounding device

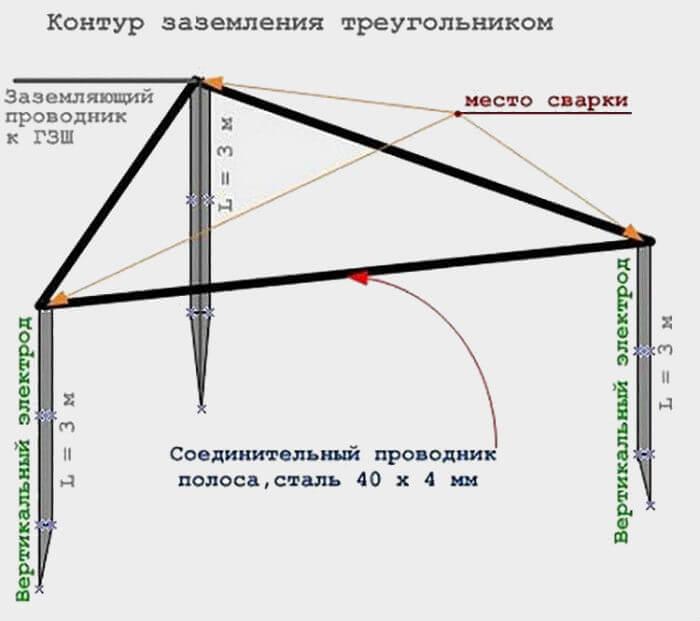

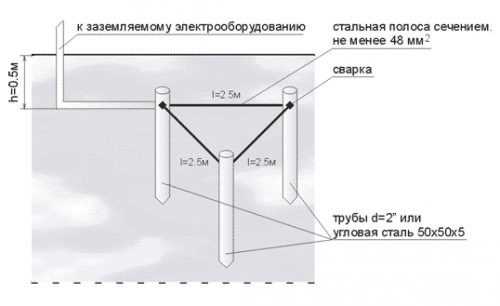

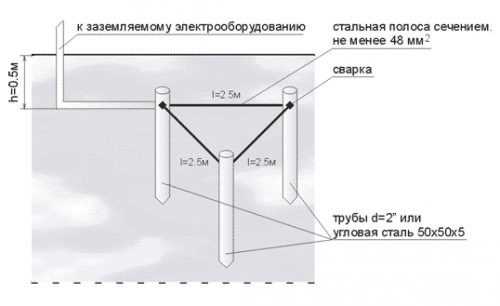

Household gas boilers (single-circuit and double-circuit) are connected to a grounding structure in the form of a triangle with a side of 2.5 m or more.The depth of the rods in the corners is 2.5-3 m. the area of contact with the ground, is typical and easily passes certification when checked by experts. The same scheme is used when installing other gas equipment, for example, a boiler. It, like the boiler, needs grounding.

The calculation of the elements of the ground loop can be done using our ground resistance calculator.

An equilateral triangle grounding loop is the most common type of grounding device

The cross-section of steel horizontal lintels should not be less than 48 mm2. The larger it is, the better, the ground loop will have less resistance, which will be surely noted by experts when passing the test. In the triangle scheme, not only vertical rods, but also horizontal ones have contact with the ground. They are covered by 20-30 cm. Deeper is better, but in practice it is difficult to dig a deep trench.

The most common is clayey soil. It holds moisture well and is easy to work out. Grounding in it is easy, and thanks to its high conductivity, it is also effective. In domestic conditions, it is difficult to obtain data on soil resistivity, therefore, they use averaged values.

To pass the test, the main thing is not to take less immersion elements than standard ones. The metal is not so expensive as to save on the length of the rods. Just make the immersion depth of the rods at least 2.5 m and the side of the triangle at least 2.5 m and the grounding is guaranteed to work and from almost 100% you will receive an act for grounding the gas boiler.

Gas boiler grounding instructions

Before starting the main work, you need to take care of creating an independent external ground loop near the building.Although this work is quite laborious, it does not require special qualifications and can be done independently.

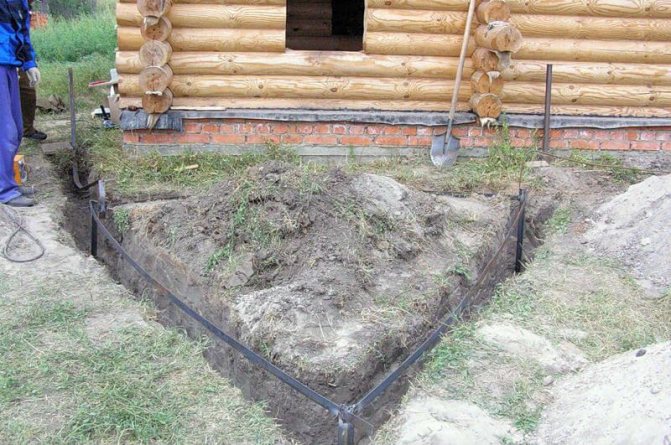

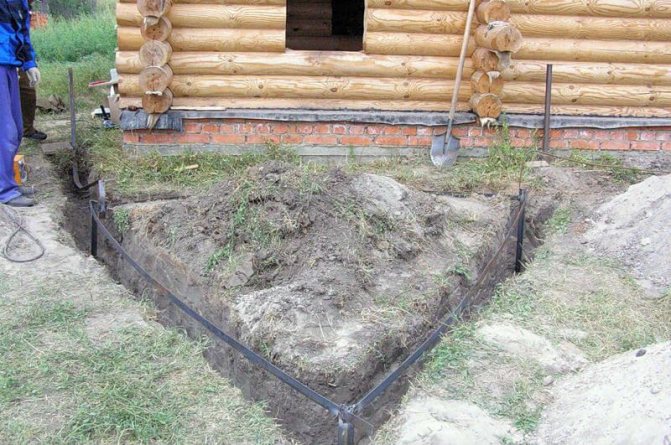

The outer contour is created in the following order:

- Marking is made no more than one meter from the wall of the building. In shape, the marking should be in the form of an equilateral triangle with a side of 2 meters.

- A trench about 50 centimeters deep and 40 centimeters wide is being dug according to the markings made. The triangle connects to the trench building at the previously specified depth.

- Deep pits are drilled in the upper part of the trench with a motor-drill. The drill bit is selected 1.6 m.

- Ground electrodes are driven into the drilled holes. In this example, steel corners (60x70 millimeters and 3 meters long) are used as ground electrodes. The corners must be installed so that the distance from them to the bottom of the trench is approximately 15 centimeters.

- The next step is to connect the ground electrodes at the tops of the triangle with a metal strip (40x4 mm). In this case, the strip acts as a ground electrode located horizontally. After joining the closed loop, the same steel strip is laid along the trench directed towards the building. There it needs to be raised above the level of the blind area by about 50 centimeters.

- The final action is to weld the strip to the base of the house. This requires a metal rod.

Ground loop installation process

According to the standards of the PUE, in the indicated scheme, the value of the resistance of the grounding system should not exceed 4 ohms. After creating an independent circuit, it must be correctly connected to the power panel. For this, it is recommended to use a copper grounding conductor. On the one hand, the conductor is securely bolted to the basement of the building, on the other hand, it is connected to the protective zero on the shield.

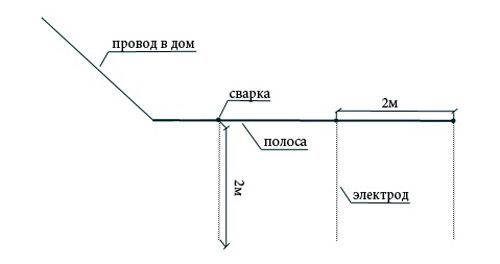

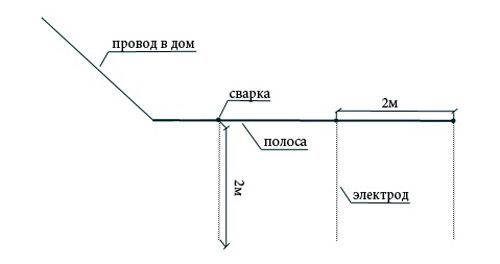

The above scheme is applicable in a situation where the size of the land allows it. However, it happens that neighboring buildings are located almost end-to-end and it is impossible to create a triangular outer contour. In this case, the outer contour can be made according to the pattern shown in the figure below.

Linear diagram of the external ground loop device

The order and essence of the work remain the same as indicated in the instructions above. However, there is a difference: a 4 meter long trench is dug along the building, and ground electrodes are nailed down at a distance of 2 meters from each other.

Sources of

- https://samelectrik.ru/kak-zazemlit-gazovyj-kotel-v-chastnom-dome.html

- https://www.stroy-podskazka.ru/kotly/gazovye/zazemlenie-v-chastnom-dome/

- https://assistentus.ru/forma/akt-na-zazemlenie-gazovogo-kotla/

- https://fb.ru/article/277408/dlya-chego-nujno-zazemlenie-gazovogo-kotla

- https://klivent.biz/otopleniye/zazemlenie-otopitelnogo-oborudovaniya.html

Grounding installation

The most difficult thing in the installation of grounding is earthwork. The immersion depth of the rods is 2.5-3 m. This does not mean that a three-meter hole must be dug. It is enough to go half the depth, and the rest is obtained by driving the rods into the soil. Much here is determined by the presence of stones in the ground. In rocky soils, this method of immersion is not possible at all.

First, a triangle with sides of about 3 m is marked on the site.It is desirable to place it on the side of the house where the boiler is installed, but this is not necessary. It is much more important that this place is not passable. The presence of people in the area of current spreading in the event of triggering is undesirable.

Installation of a ground loop in the form of a triangle

A trench is being dug along the sides of the triangle, and pits are dug in the corners, into which the grounding rods will then be immersed. Any tool can be used here. The most practical yamobur, albeit manual, or gasoline. The lease is the same model that is used for drilling for lightweight screw piles.

A grounding structure is immersed in a dug hole of complex triangular shape. First, the racks are hammered at the corners of the triangle.After they are submerged below ground level (their length should be 1.5-3 m for vertical immersion), horizontal conductors are welded to them. The cross-section of the horizontal conductors must not be less than that of the vertical posts.

Ready-made gas boiler grounding kits are often made for bolted connections.A welded connection is better than a bolted one. This is especially important, since in conditions of constant soil moisture, intense corrosion develops, and the junction may stop conducting electric current. The efficiency of grounding will decrease, but outwardly it will not be noticeable. Thus, poorly made connections in the future can provoke an emergency situation when the ground resistance is suddenly too high to effectively divert the current from the breakdown.

If, when digging a hole, large stones were removed, then they should not be used when backfilling, since the stone does not conduct current. Another fine-grained soil is poured, which will absorb soil moisture and become a conductor. The soil is compacted flush with the ground.

It is convenient to place the grounding triangle under the drainpipe. There, the soil is more humid and its conductivity is higher, therefore, the grounding of the gas boiler will work effectively with the same amount of materials used.

How to ground the gas unit?

How to properly ground a gas boiler? First, you should consider a number of important nuances:

- For a grounding metal structure installed in the ground, the following are suitable: a corner, a channel, a profile pipe.

- The metal surface must be protected against corrosion: galvanized, copper plated or anti-corrosion paste.

- The cross-sectional area of the wire connecting the zero phase of the shield with the ground loop for a gas boiler depends on the type of metal. For copper, 1 cm² is considered optimal, for steel - 7.5 cm², for aluminum - 16 cm².

- The resistance of the ground electrode for sandy soils should not exceed 50 ohms, for alumina - up to 10 ohms.

- The electrodes should be made of a material that matches the loop resistance. The best option is two-inch pipes or corners with a length of 2 m and a cross-sectional area of 6 cm².

- The busbar should only be made of steel or copper strip.

Compliance with the listed conditions will relieve you of claims from the inspection authorities.

Simple calculation of contour parameters

The easiest way is to ground a gas boiler empirically without the use of complex formulas and calculations. In this case, the work is performed according to the following algorithm:

- a contour of three rods 3 m long in the form of an isosceles triangle is taken as a basis;

- connect conductors;

- take an ohmmeter that measures the resistance, and measure the readings of the circuit - the optimal value is 4 ohms;

- if the result is significantly higher than the optimal one, then one more element is added to the circuit and the resistance is measured again; continue to add until the value approaches the ideal or at least the maximum allowable 10 ohms.

If desired, you can determine the number of electrodes using formulas that are available in specialized literature. But for optimal operation of the gas unit, the simplest calculation of parameters is sufficient.

Grounding installation

The installation of the system for grounding the gas boiler should be carried out no closer than 1 m and no further than 5 m from the house. This place cannot be further used for outbuildings, land cultivation or other purposes. It is better to enclose the site with a curb and decorate it with a stone composition.

In the selected area, a contour diagram is first drawn. In most cases, it has the shape of an isosceles triangle, but if there is not enough free space, it can take the form of a square, line or polygon. The shape depends on the number of electrodes and the position of the house.

For installation, you need the following tools:

- welding machine;

- grinder for cutting and adjusting pipes;

- drill or hammer drill;

- shovel, sledgehammer or yamobur.

Now let's take a step-by-step look at how to properly install and connect the circuit:

- Trenches 35-40 cm wide and 50-70 cm deep are dug along the lines of the lined layout. From the apex of the triangle closest to the house, a trench is made to the foundation.

- With the help of a sledgehammer or a hole drill, electrodes are hammered at the vertices of the triangle - metal rods from pipes and corners about 3 m long.It is necessary to drive them so that they protrude 15-20 cm from the ground.

- Then the electrodes are connected together. For this, steel strips with a section of 4.8-5 cm² are laid along the bottom of the trench. Connect the structure by spot welding.

- Now a metal strip is welded to the electrode closest to the house, which is brought out along the trench to the place where the grounding will enter the building itself. This strip should extend from the ground by at least 50 cm.

- Then the system is brought into the house: a hole is made in the wall with a puncher, a copper wire is introduced through it, which is fixed with one side to the terminal on the grounding bus, and the other to the metal plate on the base.

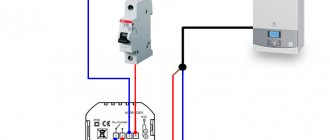

- Now the gas boiler is connected to the panel through the machine using a three-core wire. It is also recommended to connect a voltage regulator.

Before you bury the structure, you need to check the resistance of the current divergence along the circuit. If the result is less than the permissible indicator of 10 ohms, then you can bury it. If the resistance is greater than the reference value, more electrodes should be added until the indicator reaches the norm.

Common reasons why a gas boiler makes noise

All about possible malfunctions of a gas boiler and how to eliminate them here

What should be the best double-circuit gas boiler?

There is one more correct method of checking the obtained grounding for operability. This requires a 100 W light bulb inserted into a holder with a carrier. One end of it is connected to the 220 V phase, and the other is connected to a metal strip on one side of the system. If the paw is on fire, as if plugged into an outlet, then the grounding is working. If the light is dim or flickering, you should check the joints of the system. If the light is off, you need to check the entire structure.

Ground loop connection

The copper grounding conductor goes to the PE bus - the main grounding bus

The ground loop is connected with a large stranded copper wire. It is best to use a special wire with yellow-green insulation, which is sold specifically for grounding and is color-coded accordingly. The cross-section of the grounding wire must be larger than all other wires (phase and neutral) that were used to connect the boiler. This is necessary for minimum resistance in case of activation.

A powerful screw terminal with the corresponding symbol is specially provided for the connection of the ground loop on the boiler. Connection is necessary precisely to this point, and not to others, even if they are on a common housing.

Checking work

Checking must be given special attention. The made grounding of the gas boiler is checked by experts in order to obtain the appropriate act. The call of experts is paid, therefore, in order to pass the test for sure, you need to check the grounding system yourself several times. This can be done both with the help of special devices and without them.

First, we will consider an interesting test technique using a tester and a 220 volt network. The method is that you connect a load, such as a 100 W light bulb, to phase and neutral. Then the consumed current is measured. Then, the neutral is turned off, and the existing ground is connected to the free end of the wire. The current is measured again and will always be less than the original value. The smaller this deviation between the currents, the better the grounding of the gas boiler is done. Having calculated the difference in current according to Ohm's law, we find the grounding resistance.

Various methods of measuring the parameters of grounding devices are discussed in detail in the article "How to measure grounding resistance".

The described method has two disadvantages.This is the need to measure currents with a life-threatening voltage, and the second is an error, since the resistance of the soil to the substation (or other place where the neutral is connected to earth) is also added to the resistance of your structure. Therefore, let's consider another way. For him, it is necessary that some kind of grounding has already been done in the house, for example, metal water pipes.

A low-voltage circuit is connected to the existing ground, for example, from a car battery with some kind of load. The open circuit must be between the ground and the new ground of the gas boiler, to which the ammeter probe is connected. Knowing the current at zero resistance of the wires, it is compared with the value obtained through the ground.

Finally, there is a third way to check the boiler grounding using special devices. They allow you to measure spreading currents in the soil, soil resistivity. Experts use them. At the household level, such equipment is not available, but simpler methods of measuring grounding resistance give a reliable result.

Types of heating boilers used in a private house

The grounding system can be natural or artificial. The first option includes structures made of metal or reinforced concrete, which are in direct contact with the ground. This can be the foundation of a building, a pipeline or other underground communications.

But for a gas boiler, natural grounding provides for at least two contacts with separate parts of the body, and in this case, sewage, heating and gas pipes are excluded. Therefore, during installation, an artificial system is often used, the organization of which we will consider.

For artificial grounding, rods or pipes become conductors-electrodes, which are interconnected by metal strips. They are installed vertically in the soil to ensure the operation of the system even in the winter season, when the top layer of the earth freezes over. An important condition is that metal elements must not be protected from corrosion by an insulating material.

The service life of the ground loop largely depends on the presence of anti-corrosion protection on its electrodes - copper-plated and stainless elements will last the longest

On the market, you can also find ready-made kits for the grounding system, which consist of steel rods (usually with a copper coating) and special pointed tips for different soil densities.

The set also includes an anti-corrosion agent for treating the system before installation and connecting elements - brass couplings, clamps. The main advantage of this solution is that the contour can be assembled without welding and lengthy preparation.

Although the controlling services advocate ready-made kits for grounding, it is feasible to make the structure on your own - this will not be a violation, but it will cost several times cheaper

To assemble a system from scrap materials, several important nuances should be taken into account:

- Metal structures intended for installation in the ground can be made of a profile pipe, I-beam, channel, angle.

- The metal of the ground electrode must be protected from destruction by galvanizing, copper plating or, in extreme cases, by anti-corrosion paste.

- The cross-sectional area of the wire connecting the zero phase of the shield to the ground loop depends on the type of metal from which it is made. For copper, the optimal value is 1 cm2, for steel - 7.5 cm2, and for aluminum - 16 cm2.

- The resistance of the ground electrode for sandy soil should not exceed 50 Ohm, for clay soil - a maximum of 10 Ohm.

- The materials for the electrodes should also be selected taking into account the loop resistance. The best option is two-inch pipes or corners with a length of 2 m and a cross-sectional area of 5 cm2.

- The grounding bus is made of copper or steel strip (aluminum is not allowed in this case).

Compliance with these requirements and the correct installation of the circuit will help eliminate claims from the inspectors of the gas service, regardless of whether you used a ready-made modular system or assembled it yourself.

In the list of requirements for the arrangement of grounding there are several indicators, the algorithm for obtaining which may be incomprehensible to a beginner in the business of an electrician - for example, how many electrodes are required for the system to work properly or how to measure the loop resistance. Let's try to clarify the basic principles of determining these parameters.

You can find out the resistivity of the soil, grounding devices of any configuration, and even the presence of a connection between the electrodes using a special meter

Most often, the grounding of a gas boiler in a country private house is performed empirically. This practical method is suitable for those who are afraid to get bogged down in complex theoretical calculations.

The algorithm for performing the work is as follows:

- Let's take as a basis the contour in the form of an isosceles triangle of three metal rods 3 meters long.

- We connect the conductors.

- We take an ohmmeter (a device for measuring resistance) and measure the indicators for the circuit. The ideal value is considered to be 4 ohms.

- If the result obtained significantly exceeds the optimal indicator, add one more element to the contour, check the resistance again. We continue until we get an ideal indicator, or at least the maximum allowable value for the boiler circuit of 10 ohms.

But you can determine the required number of electrodes using formulas, choosing the appropriate options for your case.

Using this formula, you can find out the resistance for one electrode, if on the site where the house is located, the soil is homogeneous, and does not lie in layers

In the formula, you need to substitute the average value of the resistivity, depending on the type of soil in which the ground electrode will be located:

- wet sand - 500 Ohm * m;

- clay gravel and sandy loam - 300 Ohm * m;

- clay-sand mixture - 150 Ohm * m;

- loam - 100 Ohm * m;

- semi-solid clay and black earth - 60 Ohm * m;

- garden land - 40 Ohm * m;

- plastic loam - 30 Ohm * m;

- peat - 25 Ohm * m;

- plastic clay and salt marsh - 20 Ohm * m.

Read more: Installation of a gas tank for a private house installation on the site

Stone and rocky ground are the least suitable for installing the ground loop. In this case, an artificial embankment will have to be erected.

For a heterogeneous soil, it will be more difficult to calculate the resistance for one electrode, but this can also be done by substituting your data into the indicated formula

The value of the seasonal climatic coefficient of soil resistance depends on the area where your house is located. They are conventionally divided into 4 groups.

Correction for climatic features is especially important for areas with cold winters, since grounding efficiency is significantly reduced in frozen ground.

There are also more complex algorithms for the precise determination of the parameters of the electrodes and even special programs for their calculations. But for the correct operation of the gas boiler, it will be enough to follow the general recommendations for arranging a standard ground loop.

There are various types of boilers at the choice of the homeowner:

- - Electric heating, which does not require the installation of a chimney. They are as easy to manage as possible.

- Gas heating. The main advantage of such a boiler is its efficiency.

- Solid fuel devices, which are considered to be the simplest. The solid fuel boiler runs on coal, coke, wood.

Regardless of which boiler is chosen - gas, electric or solid fuel, it must be grounded in any case.

According to the PUE, in order to make grounding by means of the outlet directly yourself, it must be connected according to the scheme not to the switchboard, but directly to the circuit.

One of the main requirements for the grounding loop is that the resistance of the system as a whole should not exceed 4 ohms. To do this, you need to correctly connect the circuit with the power shield using a conductor made of copper. One side of it is attached to the plinth of the house, and the other - to zero on the shield.

Photo 2. A ready-made grounding kit for a wall-mounted gas boiler with all the necessary accessories.

For self-introduction of a grounding device, you can use the following methods:

- Buy a ready-made kit for grounding a gas boiler. It includes all the necessary components. Installation takes place quite quickly and does not take much time. You will need a small plot of 0.5x0.5 m2. Grounding can be carried out in basements or a few meters from the house itself.

- Make an earthing switch on your own. To do this, you need a welding machine and a steel corner. The created structure, in the form of a triangle or an inverted W, is dug into the ground to a depth of more than 1 meter.

Reference! Before starting work, it is necessary to conduct an independent external ground loop near the house.

The process is done thanks to the following tools:

A trench is dug according to the markings made with a shovel.

- Ground electrodes are driven into the drilled holes with a hammer.

- With the help of a motor-drill, deep pits are drilled in the upper part of the trench.

- A metal tape is used to join the corners between the horizontal elements of the ground loop. Electrical welding is required for the connection.

- At the end of the conductor entering the room, an M6 or M8 bolt is welded. A wire ring is put on it, which is responsible for the internal grounding of a private house.

Materials used:

- Metal corner (size 50x50x5 mm). The house ground loop is an equilateral triangle, into the corners of which metal ground electrodes are driven.

- Steel tape 40 mm wide and 4 mm thick. In order to dock the corners with each other, a metal tape is used.

- Metal wire rod with a diameter of 8-10 mm. It fits into a trench and rises 50 centimeters above the blind area.

For proper and effective grounding of the gas boiler, it is necessary to make an external circuit.

Contour making process:

- Marking is done at a distance of one meter from the house. An equilateral triangle with sides of 2 m is drawn.

- A trench 50 cm deep and 40 cm wide is dug along the lines drawn.

- This is followed by a connection to the house using a trench of the same size.

- Deep pits are made with a drill.

- Ground electrodes are inserted into the pits. The distance to the bottom of the trench should be about 15 cm.

- Connect the ground electrodes to each other using 40x4 mm metal strips.

- Place the metal strip in the trench leading to the house.

- A strip of metal is welded to the base with a metal rod.

Attention! Such equipment of the grounding system is possible only if there is a sufficient amount of land near the house. If it is not possible to ground the boiler using a triangular loop, use line grounding.

- electric heating, which do not require the installation of a chimney. They are as easy to manage as possible.

- gas heating. The main advantage of such a boiler is its efficiency.

- solid fuel devices, which are considered the most simple. Solid fuel boiler runs on coal, coke, wood