One of the important measures to improve the energy efficiency of a house is to insulate the building facade. Until recently, this procedure was very laborious and required many technical measures. Now the task has become simpler due to the emergence of innovative heaters on the market. Thermal insulation Bronya is several times superior in terms of parameters to mineral wool and polystyrene, but at the same time, its application to the surface can be performed with a minimum expenditure of effort, time and improvised means.

What is Bronya thermal insulation?

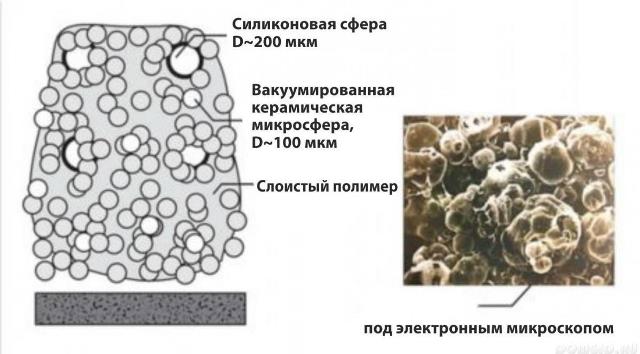

Armor is a liquid thermal insulation containing micro-granules of ceramic

The coating "superfine thermal insulation" is a substance similar to paint in appearance, method of application and structure. This mastic contains the following components:

- base acrylic bond, in a fractional ratio - 5 part of the total mass;

- polymer fixatives;

- catalytic substances;

- a filler made of microspheres, in a fractional ratio - 4 parts of the total mass, has a ceramic origin with micro-thin walls and rarefied air inside (up to 80% rarefaction).

Antiseptic and anticorrosive additives are present in the structure as auxiliary components.

Heat-insulating paint Bronya is more often produced in the form of a white suspension, which, after hardening on the surface, creates a dense film with a matte shade. The material is elastic to the touch; in terms of the quality of interaction with the environment, it is resistant to all types of impact. The thermal insulation effect is due to the inability of the rarefied air limited in the sphere to conduct thermal energy (the principle of vacuum space).

Initially, ceramic-type thermal insulation was planned to be used for the space industry.

Liquid insulation "Magniterm": reviews and specifications

There are several types of Magniterm composition on the market. Liquid thermal insulation, reviews of which will be below, is produced for building facades, balconies, floors and basements.

Magniterm Nord deserves a detailed consideration. This composition can be applied from - 30 to + 80 ° С. The resins that make up the heat insulator create a thin layer on the surface that allows steam particles to pass through. Moisture does not pass through Magniterm Nord.

Before applying thermal insulation, you need to carefully prepare the surface, that is, clean it of loose areas, oil stains and metal chips. It is advisable to cover everything with a layer of acrylic concrete primer.

It should be borne in mind that before use it is necessary to dilute Magniterm. Liquid insulation, reviews of which are not always positive precisely because of the improper conduct of this stage of work, is diluted only with high-quality non-toxic liquids. Otherwise, the smell can cause intoxication among the residents.

Varieties of liquid insulation

Types of thermal insulation depending on the purpose

The manufacturer offers several product modifications. Each type of composite has a base base and certain additives, depending on the purpose of the paint. Options for insulating facades differ from each other in climatic performance, where composites have been developed for more severe regions, designed for a greater number of cycles of exposure to negative temperatures. Specialized mixtures are more focused on protection against moisture, fungal elements and fire.

Basic coatings

The following brands of mastics are produced under the basic ones:

- Classic NG, Classic;

- Facade NG, Facade;

- Anticorrosive;

- Winter NG, Winter.

These are standard modifications of the heat insulator for operation at positive and negative temperatures.

Budgetary coverage

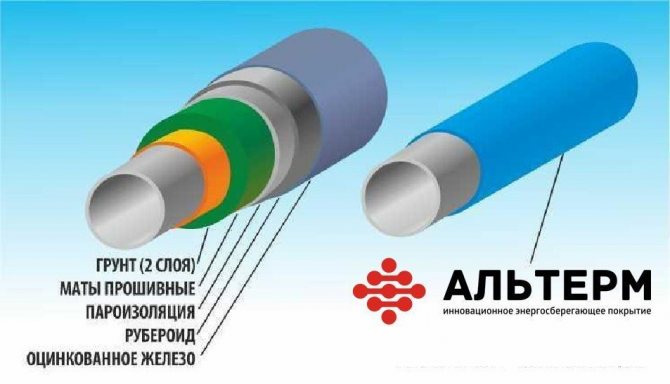

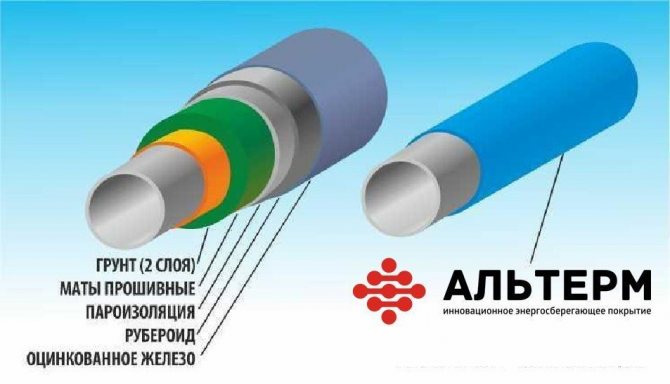

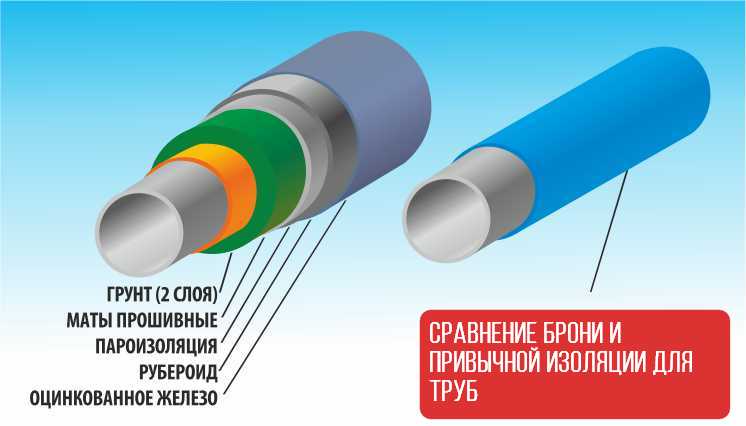

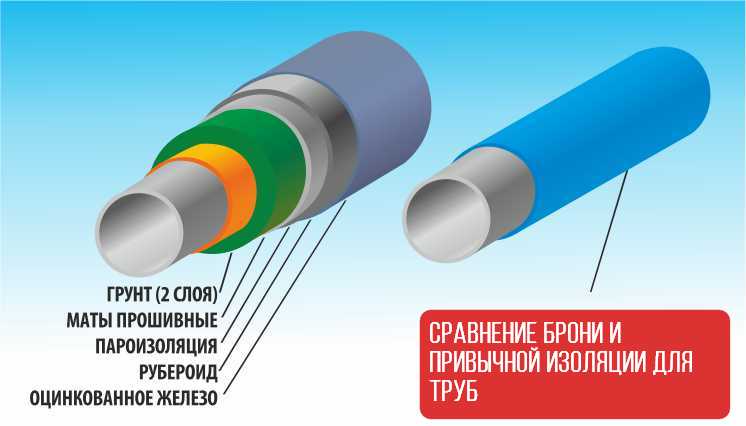

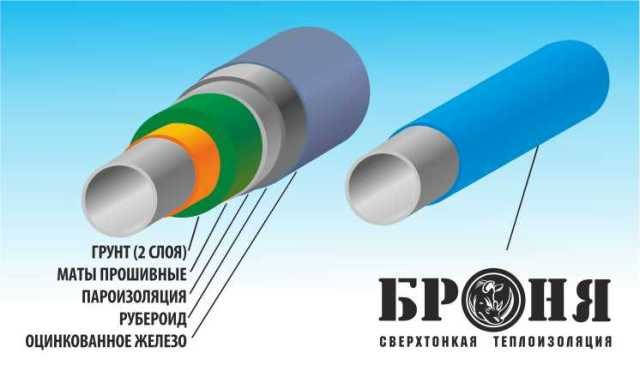

Thermal insulation for metal pipes is cheaper, but has lower quality characteristics

Budget composites brands are represented by the following options:

- Universal NG, Universal;

- Wall NG, Wall;

- Metal;

- Nord NG, Nord.

A series of analogs of basic brands has lower performance indicators and a lower price niche.

Specialized thermal insulators

Modifications of specialized mixtures:

- NG Standard, Standard;

- Light NG, Light;

- Fire protection Nord, Fire protection;

- Volcano.

Thermal insulation coatings have additional properties.

Heat insulator brands

The manufacturer has presented several basic options for a liquid heat insulator.

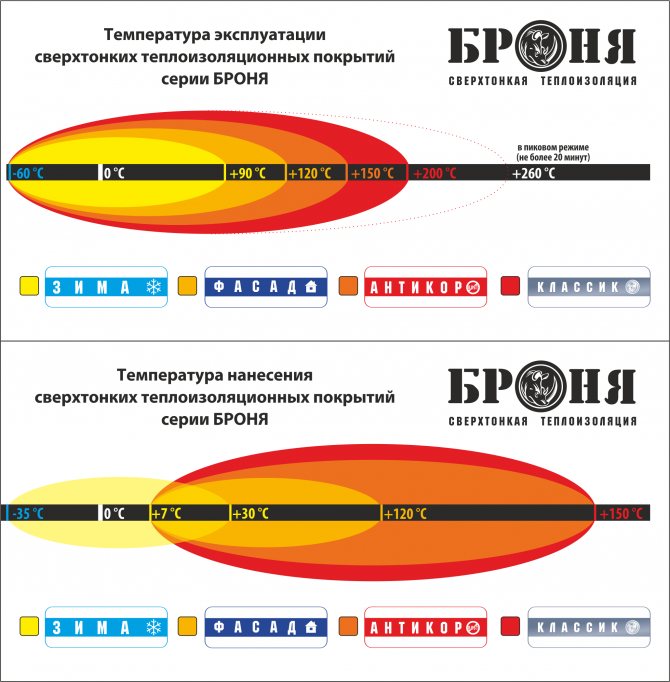

Classic

Bronya Classic is a versatile insulating agent that is ideal for treating traditional coatings.

Withstands exposure to high temperatures up to 200 ° C.

Armor Antikor

Effective for insulating metal surfaces.

It can be applied directly to materials that contain signs of the development of corrosion processes, and without pretreatment with anti-corrosion agents.

Facade

Bronya Facade - reliably insulates the premises from the inside, without interfering with the full circulation of air, which avoids the appearance of rot and the formation of fungi.

Armor Winter

The mixture allows you to insulate objects at low temperatures down to -35 ° C.

Characteristics of paint for thermal insulation Bronya

The composition of the insulation is clearly visible only with an electron microscope

The developer has endowed the product with the following properties:

- the mass has a homogeneous structure of a white shade;

- the composite has a density of 0.558 g / cm3;

- the structure contains non-volatile substances in a mass ratio of 44%;

- vapor permeability for brands of facade mastics - 0.013 Mg / m h Pa;

- heat transfer coefficient - 1,380 W / m, degrees Celsius;

- thermal conductivity coefficient - 0.0012 W / m, degrees Celsius;

- resistance of the film to water and alkali during the day - the film retains its appearance;

- exposure to negative temperatures over 50 cycles - the film retains its properties;

- adhesion to concrete - 1.33 MPa, to steel - 2.20 MPa, to brick - 2.04 MPa;

- resistance to high temperatures up to 200 degrees Celsius - the film retains its integrity and properties.

The substance in question is not a combustible material and a flame propagation medium.

Ultra-thin thermal insulation Thermion

Thanks to Thermion materials, insulation of any surfaces will cost the price of a regular paint!

√ Want to insulate interior walls without wasting living space?

√ How to insulate the facade of an object and keep its aesthetic appearance?

√ Don't know how to navigate among the many facing materials and prices, so as not to go broke before the start of the renovation?

√ It is not possible to perform high-quality and short term thermal insulation of complex wall sections with decorative elements?

√ How to properly protect surfaces with non-standard bends (for example: tanks, containers of different shapes, pipelines, etc.) from overheating or, conversely, from freezing?

- The answer to all these difficult questions is simple - Thermion ultra-thin liquid thermal insulation.

What is called modern thermal insulation today?

Thermion is an innovation in the field of thermal insulation finishing materials. The composition includes: a number of evacuated microspheres, a high-quality antifungal or anti-corrosion component on an acrylic basis. This is a guarantee of reliable protection of walls from freezing, condensation and destructive mold, and metal surfaces from rust.

Thermion insulation materials are resistant to extreme temperatures ranging from -60 ° C to + 600 ° C, depending on the modifications. The buyer can choose the required modification according to the surface characteristics.

If we talk about the usual insulation, where the dew point is in the insulation itself or between the wall and the insulation, then our material completely excludes condensation, has excellent vapor permeability. That is, they allow moisture to evaporate and not accumulate in the walls.

It would be fair to ask how thermal insulation works in the opposite situation, when moisture penetrates the walls from the external environment (for example, rain)? Due to its unique chemical composition, this material is also water-repellent.

In simple terms, walls remain dry even when there is a large difference between indoor and outdoor temperatures or during heavy rainfall. Pay attention to the modification of Thermion FASAD. Also, all types of our materials are resistant to UV radiation.

The insulation can be applied with a roller, conventional spray (airless), or with a flat brush in layers. The thickness of each such layer (in accordance with the modification) can be from 0.4 to 1 mm. For 1-1.5 sq. 1 liter is consumed. , with a coating thickness of 1 mm. After application to walls or containers, the surface dries completely within 24 hours, forming a coating that is flexible, lightweight, elastic. Thanks to this, there is no need to use additional finishing materials, as with traditional insulation.

What does the Thermion ultra-thin liquid thermal insulation look like and how to work with it?

The service life of such a coating is from 15 years, depending on the operating conditions and the quality of the application.

How does it work?

If we consider our material at the molecular level, then amazing insulating properties are achieved by intensively exposing the surface to rarefied air, which is located in hollow ceramic spheres of the French production "3M". Thanks to this "design", the thermal conductivity is only 0.0012 W / ms.

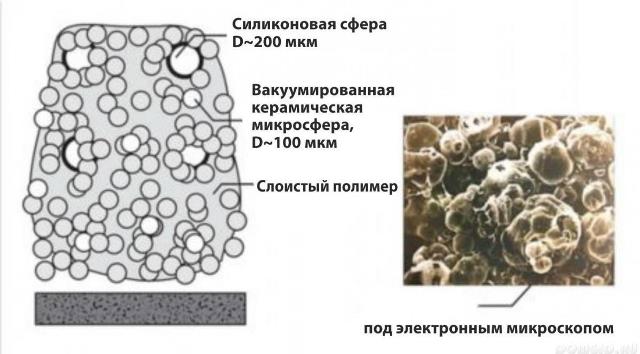

Summing up all of the above, we emphasize once again that such high thermal insulation rates of Thermion are provided due to the complex structure:

√ 80% - ceramic microspheres;

√ 20% - a combination of silicone microspheres;

√ acrylic binder and other additives.

Microspheres under a microscope

The diameter of the spheres is 50-80 microns. If we consider liquid thermal insulation under high magnification, it is clearly seen that each hollow silicone sphere is densely covered with ceramic microspheres. Ultimately, we get a structure called a cluster in scientific circles.

This molecular structure provides good adhesion to different surfaces of all insulation modifications. Thanks to millions of clusters, even one 1mm thick layer is able to effectively reflect heat and protect walls from natural destruction.

Positive and negative qualities of mastic

1 mm of liquid thermal insulation replaces a 5 cm layer of mineral wool

Positive properties possessed by Bronya insulation:

- A thin layer of mastic of one millimeter can replace mineral wool 5 cm thick.

- The product is universal - it is a heat insulator, anti-corrosion agent and a kind of antiseptic.

- The paint can be easily applied with a regular roller, brush or using a fine dispersion spraying unit.

- A wide range of operating temperatures allows the material to be used in all climatic zones.

- The mass of the thermal insulator is negligible and does not exert a load on the supporting structure.

- The mastic has excellent adhesion to any type of surface (with the exception of oily and greasy surfaces).

- The paint does not absorb moisture, it is stable against ultraviolet radiation.

- The coating is elastic, withstands light loads and has good maintainability.

In an example of the negative qualities of a heater, one can indicate its high cost, reaching up to 1000 rubles per liter of paint, a drying period of at least a day and the inability to work as a thermal insulator at an ambient temperature below +7.

Liquid insulation "Bronya": reviews and recommendations for use

Among all brands of liquid thermal insulation "Bronya" is the most popular. This is due to the availability of material at cost and a wide range of products. At official dealers you can find varieties for processing facades, metal structures and other types of surfaces. Each buyer will find a suitable option.

Reviews of home owners about this type of insulation are most often positive. Negative opinions about the coating usually arise because it was applied incorrectly by the builders.

Manufacturers recommend applying ultra-thin thermal insulation with a soft natural bristle brush or airless spray. The preferred brand of the latter must be checked with the regional representative of the company.

Scope of application of the suspension

Liquid thermal insulation is suitable for exterior finishing works

Brands of liquid insulation Bronya effectively insulate the following structural elements of the house:

- external walls of any configuration before finishing work;

- simple and complex roofs, both on the outside and from the attic;

- walls of loggias and balconies from the inside;

- concrete floor surface.

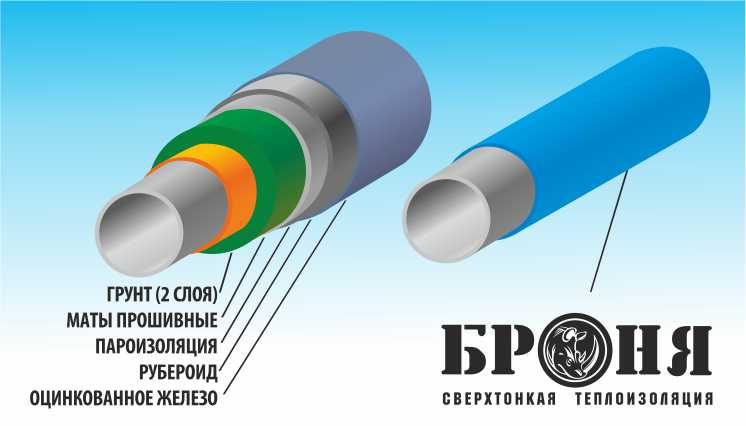

The coating has shown itself well when creating thermal insulation on boiler equipment, cold and hot water supply lines, centralized steam pipelines and heating mains, in air conditioning systems on air ducts, when insulating public and private vehicles, refrigerators, trailers, various tanks and containers, as well as sea transport. Often, the method of applying paint to cold water pipelines gets rid of condensation that falls on them.

Application area

Due to its excellent performance, Bronya insulation is used everywhere. It is used to protect buildings inside and outside. The material is used in the process of insulation of communications, insulation of wires, etc. The scope of the mixture is quite wide:

- Protection of vertical and horizontal structural elements of various buildings (floors, walls, ceilings), roofs.

- The possibility of insulating a residential building and large-sized objects, poorly heated premises (hangars, warehouses, workshops).

- Thanks to special additives, the liquid Bronya mixture is characterized by anti-corrosion properties; it can be used on any metal surfaces.

- Protection of communications of any type from freezing (water supply, sewerage, heating and air conditioning systems, gas and steam pipelines).

- Insulation of the main units of the heating and hot water supply system: boilers, boilers, heat exchangers of various types.

- Oil pipelines that are located below and above the soil level.

- This type of insulation is also suitable for refrigeration equipment.

- Insulation of water storage facilities and containers for chemical reagents.

- The Bronya mixture is used to protect wagons (railway, metro) and tanks from heat loss.

- Thermal insulation of ships, boats, yachts and boats (internal surfaces, engine room).

Operating principle

As we remember from school physics lessons, heat transfer occurs in three ways: heat conduction, convection and radiation. Thermal paint is 20% composed of components that can conduct heat, this is with regard to thermal conductivity.

Convection losses are negligible due to the filler in the form of balls, the structure of which does not transfer heat.Moreover, these ingredients reflect and dissipate heat, which means they do an excellent job of radiation. As practice shows, over 90% of thermal energy does not leave the room, which indicates the high efficiency of Bronya paint.

Benefits

If you study the properties of various heaters, you can find a number of advantages that distinguish the Bronya protective agent and, first of all, these are:

- a minimum of tools for work;

- small thickness of the material, which does not make the base heavier;

- the ability to apply to any surface;

- excellent adhesion;

- long operational period (over 15 years).

Advanced technologies to protect consumer interests

Liquid ceramic coating Bronya is an ultra-thin thermal insulation, which contains several components:

- acrylic binder base;

- clamps;

- catalysts;

- ultra-thin-walled vacuum ceramic microspheres;

- anti-corrosion and antifungal additives.

The technological connection of the listed elements results in liquid thermal insulation, which is characterized by low weight, plasticity and good adhesion. The quantitative ratio of microspheres and binders of 4: 1 significantly minimizes the possible loss of heated air. Low thermal conductivity is provided by a rarefied gas (vacuum).

The consistency is reminiscent of ordinary white paint. After drying, the finest polymer film with a homogeneous matte structure appears on the treated surface. The finished coating is distinguished by reliable resistance to sharp temperature fluctuations, high humidity and atmospheric influences of any nature.