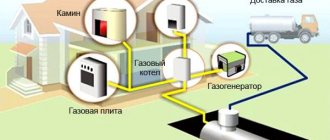

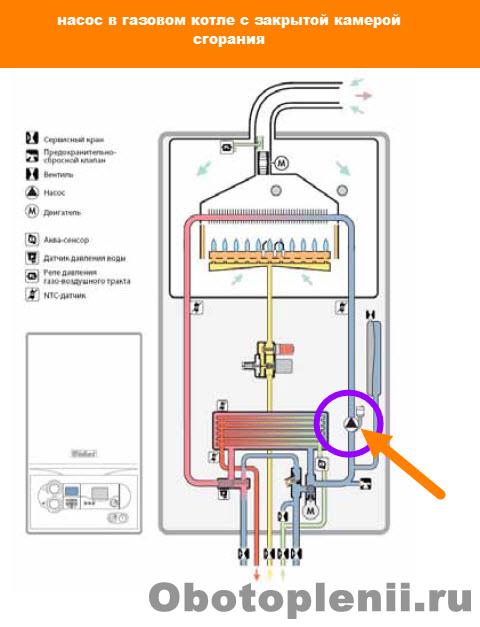

Circulation pump in a gas boiler

The circulation pump in the construction of a gas boiler accelerates the coolant through the heating system, due to which the coolant is cooled in the system more slowly and returns to the boiler in a "heated" form. Since heating in the boiler occurs to a certain temperature, the next heating cycle of the coolant will be shorter. Hence, lower gas consumption and fast water heating cycles (higher efficiency).

It is believed that the installation of circulation pumps is not required for hydraulic heating systems, however, it does not interfere at all in old heating systems with large diameter pipes.

When buying a gas boiler with a circulation pump in the design, you no longer need to install a separate circulation pump in the heating system.

Why does the gas boiler turn off

In most cases, this is activation of the protection system... Simply put, smart electronics or thermomechanics “Decides” that his further work is dangerous.

This may be due to the triggering of one of the numerous sensors (draft, burner flame), inoperability of the exhaust fan, breakage of the solenoid valve coil for gas supply and much more.

Some of these problems can be fixed on my own: for example, in the event of an error in the draft sensor, the check the condition of the chimney (remove icing, remove foreign objects, etc.).

Airlock as a Cause of Pressure Rise in Closed Systems

When a closed system is operating, it is not uncommon for the pressure to rise, while it may be accompanied by a decrease in the overall temperature of the coolant, and blocking of the boiler. All this leads to an imbalance in the operation of the circuit, the failure of its individual elements.

Why is the pressure in the system increasing or is there a sharp increase in pressure? Usually, in closed heating circuits using gas equipment or other types of boilers, such differences occur due to airing. Trapped air is a common cause of pressure drop. Typically, the presence of such problems is determined in the following cases:

- equipment breakdown;

- incorrect system startup;

- malfunctions of automation;

- the presence of cracks in the boiler heat exchanger.

Does the pump in the heating system in the house have to work constantly?

When organizing the heating of a country house, it is important to take into account the footage of the dwelling. If this is not a small dacha, but a two or three-story house in which the total area is hundreds of square meters, then the natural circulation of the coolant will not be enough to solve heating problems. In such systems, the pressure in the pipeline will not exceed 0.6 MPa, and for the effective movement of hot water in the system, a circulation pump must be connected. In order to correctly choose such a unit, choose a suitable place for installation, you need to understand the principle of operation of this device.

The principle of operation of circulation pumping equipment is based on the creation of continuous circulation of liquid in the system without changing the pressure indicator

A circulation pump is a device that works in a closed heating system and moves water in a pipeline. The unit maintains a certain temperature of the coolant in the system. The device does not replenish the loss of the coolant and does not fill the system. The system is filled with a special pump or a certain pressure in the pipes.

The principle of operation of circulation pumping equipment is based on the creation of continuous circulation of fluid in the system without changing the pressure indicator. Since the device works constantly after installation, the main requirements for such pumps are low noise level during operation, economical energy consumption, reliability, durability and ease of use.

Important: circulation pumps are compact devices that do not take up much space and do not create noise during operation.

The scope of use of circulation units for heating systems is quite extensive. They are installed:

- in traditional radiator systems;

- when arranging a water heated floor;

- in geothermal systems;

- when organizing hot water supply for cottages and summer cottages.

Unlike forced circulation systems, this pumping equipment does not need oversized pipes. In addition, the device has the following advantages:

- the speed of heating the room;

- the boiler can be installed in any suitable place;

- coolant losses and air locks are minimized;

- due to the thermal relay, automatic control of temperature conditions is provided;

- energy costs are reduced due to the use of automatic rotor speed control;

- since liquid is constantly supplied to heating devices, their service life is extended.

The pump with a "wet" rotor is made in a housing made of stainless steel, cast iron, bronze or aluminum. Inside there is a ceramic or steel motor

To understand how this device works, you need to know the differences between the two types of circulation pumping equipment. Although the principle of a heating system based on a heat pump does not change, two types of such units differ in their operating characteristics:

- The pump with a "wet" rotor is made in a housing made of stainless steel, cast iron, bronze or aluminum. Inside is a ceramic or steel motor. The technopolymer impeller is mounted on the rotor shaft. When the impeller blades rotate, the water in the system is set in motion. This water simultaneously functions as a coolant for the engine and as a lubricant for the working elements of the device. Since the "wet" device design does not provide for the use of a fan, the operation of the unit is almost silent. Such equipment works only in a horizontal position, otherwise the device will simply overheat and fail. The main advantages of a wet pump are that it does not require maintenance and also has excellent maintainability. However, the efficiency of the device is only 45%, which is a small drawback. But for domestic use, this unit is perfect.

- A pump with a "dry" rotor differs from its counterpart in that its motor does not come into contact with the liquid. In this regard, the unit has less durability. If the device works "dry", then the risk of overheating and failure is low, but there is a threat of leakage due to abrasion of the seal. Since the efficiency of a dry circulation pump is 70%, it is advisable to use it for solving utility and industrial problems. To cool the engine, the circuit of the device provides for the use of a fan, which causes an increase in the noise level during operation, which is a disadvantage of this type of pump. Since water does not function as a lubricant for working elements in this unit, it is necessary to periodically inspect and lubricate parts during operation of the unit.

In turn, "dry" circulation units by the type of installation and connection to the engine are divided into several types:

- Console. In these devices, the engine and housing have their place. They are separated and firmly fixed on it. The drive and working shaft of such a pump is united by a coupling.To install this type of device, you will need to build a foundation, and the maintenance of this unit is quite expensive.

- Monoblock pumps can be operated for three years. The body and the engine are located separately, but combined in a monoblock. The wheel in such a device is mounted on the rotor shaft.

- Vertical. These devices can be used for up to five years. These are hermetically sealed advanced units with an end-face seal made of two polished rings. For the manufacture of seals, graphite, ceramics, stainless steel, and aluminum are used. When the device is in operation, these rings rotate relative to each other.

Also on sale there are more powerful devices with two rotors. This dual circuit design improves the performance of the instrument at maximum load. If one of the rotors leaves, the other can take over its functions. This allows not only to enhance the action of the unit, but also to save energy, because with a decrease in heat demand, only one rotor works.

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant due to the capture of liquid from one side and injecting it into the pipeline from the other side.

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in a heating system, then it will cause the movement of the coolant by capturing liquid from one side and pumping it into the pipeline from the other side. All this happens due to the centrifugal force that is generated during the rotation of the wheel with blades. During the operation of the device, the pressure in the expansion vessel does not change. If it is required to increase the level of the coolant in the heating system, a boost pump is installed. The circulation unit only helps the water to overcome the resistance force.

The installation diagram of the device looks like this:

- A circulation pump is installed on the pipeline with hot water coming from the heater.

- On the section of the line between the pumping equipment and the heater, a bypass valve is mounted.

- The pipeline between the overflow valve and the circulation pump is connected by a bypass with a return pipeline.

Such an installation scheme implies the release of the coolant from the device only if the unit is filled with water. To keep the liquid in the wheel for a long time, a receiver equipped with a check valve is constructed at the end of the pipeline.

Circulating pumps used for domestic purposes can develop a coolant speed of up to 2 m / s, and units used in an industrial field accelerate the coolant up to 8 m / s.

It is worth knowing: any type of circulation pump is powered by the mains. This is a fairly economical equipment, since the engine power of large industrial pumps is 0.3 kW, and for household appliances it is only 85 W.

Since the stator of the motor is energized, it is separated from the rotor by means of a glass made of stainless steel or carbon material.

The main elements that make up the circulation pump are:

- body made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- paddle wheel or impeller;

- engine.

Typically, the impeller is a design of two parallel discs that are connected to each other by means of radially curved blades. One of the discs has a hole for fluid to flow through. The second disc fixes the impeller on the motor shaft.The coolant passing through the motor acts as a lubricant and cooler for the rotor shaft at the place where the impeller is fixed.

Since the stator of the motor is energized, it is separated from the rotor by means of a glass made of stainless steel or carbonaceous material. Glass walls 0.3 mm thick. The rotor is fixed on ceramic or graphite plain bearings.

The private houses in which our parents live were built with their own hands, which is noticeable from the illiterate layouts of the premises, not always even windows and doors, and heaped up walls. Everyone installed the heating as they understood, the principle was the same: a slope must be maintained so that water could continuously circulate through the system.

The operation of the circulating pump takes us into a new era of heating systems. Its presence in the system makes it much more economical. The pipe diameter can be significantly smaller, which significantly reduces the volume of the coolant. The liquid moves through the heating system at a certain speed, which allows you to evenly heat the premises, maintain the most comfortable temperature in them, and it heats up, if necessary, quite quickly. The automatic mode of operation of the circulation pump allows the device to instantly respond to various changes in the system, changing the settings of the device and making the operation of the heating equipment more economical. Heating a house with several floors is unthinkable without such a pump, and the continuous circulation of the coolant, in addition to all these advantages, also protects the heating boiler from erosion.

You don't need to be a big expert to understand how a circulation pump works. Its task is to overcome friction inside the heating system and organize the non-stop movement of the coolant. The motor pushes the liquid through the pipes with the help of a rotor. If the circulation pump does not work, the coolant by inertia will still move through the system for some time, and then it will completely stop. On an industrial scale, pumps are produced with two types of rotor, the so-called dry or wet. The first type of rotor is used for heating industrial premises with a large area, where the noise level of a running pump is not of fundamental importance. The high performance level of the device compensates for the need for constant lubrication of the moving parts of the pump. A pump with a wet rotor is used for heating residential premises. The coolant in which the rotor is immersed simultaneously lubricates and cools the engine. The absence of a fan and the presence of a protective casing makes the operation of the unit so quiet that you can hardly hear how the circulation pump works.

The principle of operation of a circulating pump with a wet rotor is such that the unit can operate in a room with low air pollution and pump purified water or a water-glycol mixture. Oil is not used as a heat carrier in a heating system with a circulation pump.

Despite the seemingly simple principle of operation of the circulation pump, it is possible to select the desired device only with the help of a specially trained employee who can correctly calculate the parameters of the required unit and connect it to the heating system. A pump with excessive power will create unpleasant noises in the heating system, caused by the increased speed of the coolant and uses more energy.

The question of the need for a pump power reserve is still controversial among specialists. Some believe that the pump operates at full capacity only a few days a year, and the rest of the time it consumes additional energy, which is absolutely not rational. Others argue that working at the limit of capabilities, the unit will quickly wear out and fail.

To correct the operation of the pump, devices with power control are produced. The pump can be adjusted manually or automatically. Manual adjustment has three modes of rotor speed, each of which affects the speed of the coolant. In warmer weather, you can save energy by setting the pump to its lowest power.

More expensive modern pumps with automatic power control can be successfully used in a floor heating system or a heating system with heating temperature controls on radiators. Automation is able to catch the slightest changes in the system and adjust the appropriate pump settings.

How to install a circulation pump for heating

For owners of country houses with a local heating system, the issue of uniform heat distribution between all rooms is especially acute. For this, systems of natural circulation of the coolant and are used.

The circulation pump is heating

In heating systems, circulation pumps are used for uniform circulation of the coolant. The pumps pump the working fluid from the boiler to the heating devices, and when the fluid cools down, back to the boiler. Everything.

- Circulation pumps Circulation pump types

- Circulation pump device

- The principle of operation of circulation pumps

- The device and principle of operation of modern pumps

If the area of the room for heating is very large and is not located on one floor, then the use of natural circulation as heating is impractical. For the efficiency of the heating system, you can replace the pipes with wider ones or a circulation pump.

Connection diagram for KIV-1A with a surface centrifugal pump.

Pumps operating in a closed ring heating system, moving water and creating its circulation, are called circulation pumps. Their task does not include filling and replenishing the losses of the coolant, raising the level of the liquid. Filling with water is carried out due to the pressure in the external pipelines or a pump.

As you know, the circulation pump was invented at the beginning of the twentieth century. Over time, his device became more and more technological. Its principle of operation is based on setting a continuously circulating fluid in motion without changing the pressure level. Its main task is to ensure constant circulation of the coolant and maintain a stable temperature of the liquid in the heating system. Since this device works constantly, it must have such qualities as low power consumption, reliability, noiselessness, simplicity of the device.

Such a unit is widely used: in radiators, geothermal heating systems. warm floors, hot water supply of houses.

Doing well with their purpose, they do not occupy a large area and do not deliver noise.

Unlike forced circulation, the pump does not need large diameter pipelines and has such advantages as:

- rapid heating of the room;

- installation of the boiler in any convenient place;

- the minimum amount of losses and air congestion;

- installation of automatic temperature control (by means of a thermal relay);

- auto-adjustment, in turn, adjusts the required rotary speed, which halves the cost of electricity and finance;

- constant supply of liquid extends the life of the heating device.

There are two types of circulating pump devices:

Diagram of a heating system based on a heat pump.

- a wet rotor, consisting of a cast iron, bronze, aluminum or stainless steel casing that houses a steel or ceramic motor. A technopolymer impeller, which is a wheel with blades, is fixed on the rotor shaft.The impeller blades set in motion the water installed on the rotor shaft, which also has a lubricating effect between the working elements and performs the function of cooling the engine. There is no fan in the device of a wet pump, this ensures quietness. The unit must be placed horizontally in order to constantly circulate water, otherwise the pump will overheat and become unusable. Such a device does not require maintenance, moreover, it will not be difficult to repair or replace some elements of the rotor. The main disadvantage of a wet pump is its efficiency, which is only 45%. It is advisable to use such devices in medium-sized heating systems, air conditioning, ventilation, hot water supply, small houses;

- the dry type of the pump has the difference in the non-contact of the engine with the liquid, therefore it is less durable in comparison with the wet one. In the case of idle use of a dry unit, the occurrence of overheating and major repairs is unlikely, but there is a possibility of leakage due to abrasion of the seal. For repair in this case, it will be necessary to replace the sealing rings. At the same time, the efficiency of a dry rotor reaches 70%, which determines their use in large heating systems. The disadvantage of a dry pump is that air can enter the pipes, resulting in noise.

Depending on the type of connection to the engine, dry pumps are divided into:

Circulation pump installation diagram.

- cantilever, the bodies and the engine of which are disconnected and each fixed in its place. In this case, the coupling combines the working and drive shaft of the pump. Maintenance of this type of dry pump is costly, their installation is advisable on a foundation;

- monoblock, the service life of which is up to three years. Here, the engine and housing are located separately, but assembled into a monoblock, and the wheel is installed on the rotor shaft;

- inline pumps - service life up to 5 years. Improved pumps are more leak-tight. They also have a face seal consisting of a pair of polished rings. The seal is made of ceramics, stainless steel, graphite, aluminum, etc. During operation, these rings rotate relatively from each other.

In the case when an enhanced action of the unit and a considerable amount of heat is required, the circulation pump is made in a double form. At maximum load, two pumps work at once.

When a small amount of generated heat is required, then one acts, and the second remains in stock. This significantly saves energy costs.

Quite often it happens that an old heating system, operating on the principle of natural circulation of the coolant - water, ceases to cope with heating the house. Sometimes, the heating system is initially designed incorrectly and requires much more fuel (gas, coal, wood, etc.). Perhaps you did not notice this, but comparing the fuel costs for heating a similar house from a neighbor - you understand that "somewhere you have something wrong." Is it possible to increase the efficiency of the existing heating system without high costs. In most cases, yes.

One of the reasons for the decrease in the efficiency of the heating system can be a gradual change in the heating scheme as a result of repairs and alterations, as well as the fouling of the inner walls with rust and scale. As a result, there is a decrease in pipe diameters and an increase in the roughness of the inner walls, which leads to an increase in the hydraulic resistance of the heating system and the loss of circulation in it completely, or in some areas. The natural circulation system must have a slope along the entire length of the line. This slope can change in a year or two after the construction of the house as a result of the foundation subsidence.

The radical cure for such a heating system is a complete overhaul.But this is not always possible, moreover, it is associated with significant costs and subsequent refurbishment of the premises.

Another way is to limit yourself to minimal surgical intervention - tie-in circulation pump.

Modern circulation pumps for small private houses are inexpensive, reliable, quiet and economical, therefore it is worth installing a pump in the heating system for preventive purposes, to revive the old gravitational heating system with natural circulation and give it vitality and second youth.

Almost always, after installing the pump in the heating system, you will get an increase in boiler efficiency. In addition, the room heats up several times faster and evenly. It is especially noticeable in the off-season, when the boiler does not turn on constantly, but out of necessity. All rooms will warm up quickly and evenly. All this saves fuel costs and is quite significant.

- increasing the efficiency of the system;

- rapid heating of air in all rooms, an increase in the heated area;

- alignment of temperature indicators in the pipeline;

- exclusion of airborne pipes;

- reduced fuel consumption;

- the ability to install heated towel rails, thermostats;

- the use of small diameter pipes;

- low cost of equipment and installation.

Circulation pump - this is an opportunity to quickly improve the quality of home heating without dismantling the entire system and large financial costs.

The only drawback of this solution is the dependence of the pumping equipment on electricity, but the problem is usually solved by connecting a UPS for a circulation pump. Another way is to install the pump in a bypass scheme. Then, in the absence of electricity, you can switch to the operation of the circuit without a pump. This scheme will be discussed in more detail below.

Installing a pump in the heating system of a private house is justified both when creating a new and when modifying an existing heating system. Heating systems with forced circulation of the coolant provide faster and more uniform heating of all sections of the water circuit, regardless of the distance from the water heating unit.

If you have a solid fuel boiler, then, when inserting a pump into an existing system, it is best to install it on the return line, next to the boiler, so that it is not adversely affected by too high water temperature in the supply from the boiler, fired up at full power. In order to preserve the ability of the boiler to operate without a circulation pump, it is advisable to install the pump according to a bypass scheme - this is a bypass section of the main line, providing for the possibility of switching the heating system to natural circulation, bypassing the pump.

The bypass unit can be made by yourself, or purchased ready-made, they are often commercially available in the markets, semi-handicraft production. Do not be afraid that it will not fit the pump you purchased. It is enough to measure the installation dimension of the gap of the bypass unit, between the ball valve and the filter, intended for the installation of the pump. It should be 180 millimeters.

The standard size of the circulation pump is exactly 180 millimeters. There are also short versions, 130 millimeters, designed for installation in quick-assembly pump units, but such pumps are practically not found in a regular retail network.

Important! When using a bypass circuit to install a pump, the outlet to the expansion vessel and the safety valve ALWAYS be installed before or after the valves that cut off the pumping or bypass section. The expansion tank and the safety valve must not be cut off from the heating system in any operating mode, pumping or natural!

So, as you remember, you have an old heating system full of sludge and rust, which must be removed if possible. In most cases, only elementary flushing is available. It is not enough to simply drain the water from the system, since it is drained through a small diameter drain valve. At the same time, water moves through the system very slowly, because the main diameters of the pipelines are much larger than the diameter of the drain valve and all sludge and rust calmly settle in the pipe.

Steel pipes are most prone to clogging. This is due to their rough surface, which becomes more and more imperfect over the years. Polypropylene, plastic, galvanized pipes are smoother and less susceptible to rust settling on them - it is simply washed off by the flow of coolant.

Therefore, when you opened the return pipeline, cutting out a section for installing the pump, flush the system by connecting it to the water supply through hoses. Try to ensure the maximum flow through the heating system, with the maximum possible head. You will still not be able to create a good high-speed flow in large-diameter pipes, so spend a little more time on flushing than you would like, let the maximum possible amount of sludge and rust flow out.

An important point that needs to be paid some attention. When designing new systems, pumps are selected based on the total thermal power of the heating system, the total flow (flow rate) of the coolant required for such power through the system is determined and the required performance of the circulation pump is equated to it.

Then the total hydraulic resistance of the heating system and calculate the required circulation pump head... Full calculations are complicated and unnecessary for a small private house. For small houses (and for large ones too), there are simplified calculation methods available even for completely unprepared people. There are quite a few methods on the Internet - choose which one you like best and calculate the parameters for choosing a pump. The heat output of an existing heating system is even easier to determine - look at the nameplate of the boiler.

For buildings with a relatively small area, there is a method for calculating the pump without formulas. Select the power of the circulation pump yourself as follows:

- By boiler performance. The calculation of the circulation pump for the heating system of a private house is carried out taking into account that 1 kW of power of water heating equipment corresponds to a coefficient of throughput equal to 1 l / min. Accordingly, for a 25 kW boiler, you will need to install a pump with an indicator of 1500 l / h.

- Calculation of the pressure of the circulation pump of the heating system. The technical documentation indicates the head parameter in meters of the water column. Using this parameter, you can determine the length of the water circuit and calculate the required number of pumps in the system. It is believed that for 10 r.m. pipeline, you need 0.6 m of the head of the water column. The optimal choice of a pump for a 1-storey building is standard models with 6 m. Art. The stations are suitable for premises with pipelines up to 100 running meters. If the pressure is not enough, a second pump is installed or a more powerful model is selected. The same calculation principle is used when choosing a pump for a 2-storey building.

The main passport indicators of the circulation pump are performance, head and flow. First of all, the flow rate should be of interest, it is determined by the formula:

N - the power of the heat generating unit. If there is no nameplate, very, very approximately, you can take as a basis the average data for the heat energy demand for heating - 0.1 kW / m2, multiplied by the heated area in m2. t1 - coolant temperature at the inlet (return), on average 65 ºС t2 - design temperature of the coolant at the outlet (supply), for conventional systems on average 90 ºС.

The pump head is approximately determined based on an indicator of 100 watts of power per square meter of area.

There is one more important point to consider - the peculiarity of installing the pump in a system with natural circulation.

For a forced, pumped circulation system, your old system has very thick pipes. When designing new heating systems, the diameter of the pipes is chosen so that the flow rate in them is in the range from 0.4 to 1.5 meters per second. At a lower speed, air will not be removed from the system and air bubbles will remain hanging in the pipes, at a higher flow rate, pipes humming and accelerated wear of elements of the heating system are possible. High speed with buzzing in the pipes does not threaten you, but very low speed with poorly evacuating air from the system is quite likely.

But it is not all that bad. After all, you have a system with, albeit poor, but natural circulation and the system is flushed! Therefore, there is no need to select a pump based on the diameter of the pipes, just take the pump model one step higher in the nomenclature.

Boiler pump repair steps

The coolant circulation pump in the home heating system requires repair, periodic maintenance during the inter-heating season. In the event of a breakdown of this unit, you must call a repairman through the online service "Myguru" to carry out a quality repair.

The foreman performs troubleshooting of a gas water heater, removal, disassembly, troubleshooting, replacement of failed parts. The final assembly, checking the functionality of the home boiler is carried out in the presence of the client. The final cost of the work is announced by the field adjuster upon completion of all activities.

The repair and service scheme is as follows:

- Diagnostic measures to establish malfunctions.

- Disassembly of the product, removal of the damaged unit.

- Dismantling of parts with extreme wear.

- Installation of new spare parts.

- Assembly of a technical unit, installation at the place of destination.

The recovery time of the gas boiler pump depends on the complexity of the malfunction that has arisen. In any case, the visiting master will do it quickly, efficiently within a few hours. For each model of the coolant circulation pump, there are high-quality parts, a structural element for quick replacement.

Common breakdowns and their causes

5 reasons why the boiler does not turn on when firing up

The repairmen identified 5 reasons why the boiler does not turn on. The first, most easily repairable, and not requiring repair - the equipment is not plugged in or the mains power is disconnected.

The boiler may not turn on due to blown sensors and fuses that need to be replaced. As a rule, this happens when the wiring is short-circuited. The devices are included in the so-called "safety group" and take over voltage surges, protecting the main systems from breakdown. But sometimes the surges are so strong that even the fuses do not save, and then the varistor fails. Upon examination, the master will immediately see it.

The third reason why the boiler does not turn on is clogging of the coarse filter. In order to bring it back to normal, the equipment must be disconnected from the mains and the gas must be shut off.

If the batteries in the thermostat run out or the room sensor is inadvertently turned off, the equipment may also not turn on. The fact is that all systems of a gas boiler are combined into one circuit, a failure even in one link is critical.

And the last, fifth reason why there is no way to warm up the batteries in the house is the failure of the pump that pumps the coolant. Typically, this is due to stagnant air, which is malfunctioning in the rotor.

The flame in the open combustion chamber goes out - check the draft and chimney

The first thing to check in an open combustion chamber is the presence and type of thrust. You can check its presence or absence using a special device or a piece of paper. In the absence of a special device, bring a piece of paper to the smoke or ventilation duct. If there is a thrust, then the sheet of paper will be pulled inward, if the sheet of paper is blown out or it does not move, then there is no thrust. We do not recommend checking the presence or absence of traction with an open fire, since only an employee of a specialized organization can make sure that there is no gas pollution in the room where the gas-using equipment is installed using special devices, such as a gas analyzer or a gas leak detector.

If there is no draft, first of all, you need to check the chimney and clean it from blockages. If, on the contrary, the air flows are very strong, it is necessary to adjust them with dampers. The chimney can not only become clogged with soot, but also freeze over in winter.

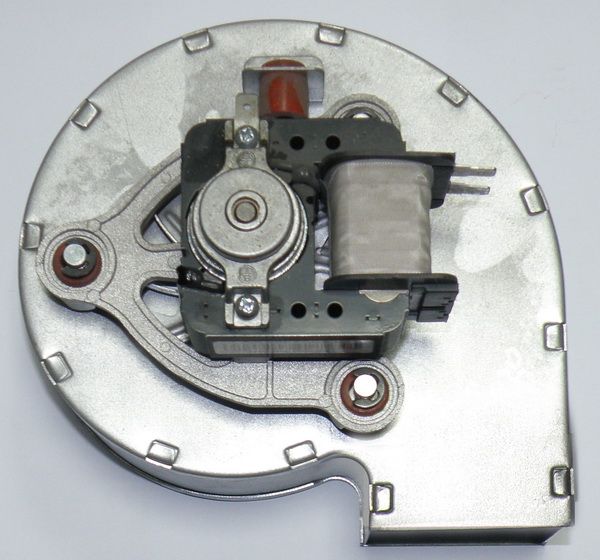

5 reasons why the burner does not work in a turbocharged boiler

The turbocharged boiler differs in that there is a fan inside the device, which provides draft for gas combustion and forced smoke removal. The experts identified 5 reasons why the burner may not ignite in a closed combustion chamber.

The first reason is power surges, which can cause damage to the circulation pump. If the network drops appear too often for reasons beyond the control of the homeowner, then installing a stabilizer will help here. But we immediately note the second reason, also associated with the circulation pump - when the phase and zero are reversed when connected. A specialist will help to correct the situation.

The third reason is that the igniter may be faulty. To check it is necessary to check the condition of the ignition electrodes. The fourth reason why the burner in a gas boiler does not ignite is a malfunction of the draft sensor. To make sure the assumption is correct, you need to ring the sensor. And the fifth, last reason may be a broken piezo ignition button.

2 reasons why the boiler starts to smoke

Sometimes, after ignition, soot starts to come out of the combustion chamber. It occurs due to the fact that the gas does not burn completely. This happens when there is too little air in the chamber. To increase it, it is necessary to equalize the flow with the burner on. The required amount of air can be easily identified by the flame. If there is enough of it, then it has an even bluish color, if not enough, then the fire will be red with yellow dots, if too much, it will vibrate and make a lot of noise.

The second reason for the appearance of soot in the chamber is the clogging of the burner with combustion products. It is enough to clean it for the flame to ignite again normally.

2 reasons why the fire goes out in the summer and the flame comes off from the nozzles

Even though the house does not need to be heated in summer, the boiler must maintain draft. It often happens that in summer a fire can spontaneously extinguish for two reasons: The traction sensor is broken - it must be replaced. There is too much temperature difference in the house and outside. The problem can be solved by warming up the exhaust pipes.

For the same reasons, another malfunction occurs - the separation of the flame from the nozzles. But, in addition to traction, it may be necessary to replace the injectors themselves.

4 reasons why the coolant does not heat up

If the fire in the boiler is on, and the batteries remain cold and hot water does not flow in the tap, this means only one thing - the coolant does not heat up. The masters identified 4 reasons why this happens.

- First, the boiler settings are not matched to the season of the year. It is enough to adjust them to warm up the batteries.

- The second - the pump does not work. See the reason above.

- The third is the accumulation of scale in the heat exchanger. You can remove it using special tools.

- Fourth - breakdowns of thermal sensors.

If the batteries are warm, and there is no hot water in the tap, then the reasons may be a malfunction of the three-way valve, leakage in internal systems, or in the very low-quality coolant that caused blockages.

Additional overview of the three types of boiler breakdowns

If the device makes a suspiciously loud noise or whistle, then the main reason is the accumulation of scale or too much air accumulation in the area of the nozzles. If the boiler systems wear out before the manufacturer's warranty expires, the reason may be the clock. The fact is that the systems work to maintain a predetermined coolant temperature. Upon reaching it, the boiler turns off, and as the coolant cools down, it turns on again. But if the working fluid cools down too quickly, then the on and off cycles are also accelerated. The problem is eliminated by installing additional thermoregulation devices. Overheating of the boiler is usually caused by the accumulation of scale and blockages.

Why can a gas boiler leak

Leaking from a gas boiler can be associated with both the simplest malfunctions and with a serious breakdown. Minor costs will arise in case of loss of tightness of connections water supply pipes, wear of oil seals, seals.

In a situation where the cause of the leak becomes heat exchange chamber - in most cases, the owner will face serious material costs, since this unit has extremely low maintainability, and its cost can be up to 50% of the total cost of the boiler.

Also, the cause of the leak can be built-in circulation pump.

Important: if there are signs of a leak, disconnect the power supply immediately to avoid other damage.

Heavy leakage sometimes occurs as a result of failure safety valve water pressure. This block is for water discharge when the pressure in the system is exceeded. If it malfunctions, direct stream water from the make-up system (water supply system) to the room.

Rules for the operation of circulation pumps

The circulating pump can only last long enough if the following set of rules is observed:

- The pump can only be started if the system is filled with coolant;

- The pump should not run when there is no supply;

- The volume of the pumped liquid must correspond to the range that the pump is able to handle, otherwise the equipment will wear out too quickly (you can find out the required value in the technical documentation for the pump);

- To prevent the pump from oxidizing in the warm season, you need to start the heating system for 20 minutes at least once a month;

- The temperature of the liquid pumped by the pump should not be higher than 65 degrees - exceeding this level will lead to the precipitation of solid salts.

There are two types of pumps on the market - "dry" and "wet". The classification depends on whether there is direct contact between the rotor of the device and the pumped medium. For dry pumps, high noise levels are common. The thing is that such devices are equipped with a fan that makes a lot of noise during operation, so such equipment is not used in private houses.

Of course, sometimes developers make a mistake (sometimes deliberately, and sometimes not) and install a pump with a dry rotor in a private house. Usually, the main argument of such developers is the high efficiency of such equipment - and they prefer to keep silent about the main drawback, which is expressed in the fact that the heating pump makes too much noise. In this case, it will be possible to solve the problem of noise only by high-quality soundproofing of the room, or by replacing the pump with a more suitable one.

In wet pumps, the rotor is constantly inside the pumped medium, which also provides cooling of the working elements of the equipment.There is no fan in these devices, so they do not make noise during operation, and they can be safely installed in residential buildings.

First of all, you can guess about some problems with pumping equipment by the various sounds that it starts to make. If the heating circulation pump is noisy, you need to figure out what the problem is and try to fix it.

How to prevent damage to the boiler pump

In order to avoid malfunctions with the heating boiler circulation pump, adhere to the technical requirements set out in the operating instructions for the product. Compliance with the main points will allow owners of household appliances to avoid serious problems with the operation of gas AGV.

In the event of mechanical knocking, rattling in a home heating system, turn off the power supply to the engine, close the feed gas supply to the boiler. If possible, switch to backup sources of heat supply at home. Immediately call an adjuster from the "Myguru" service, he will quickly restore the operation of the gas boiler.

During operation (especially in cold weather), owners should periodically monitor the normal functioning of their home heating system. Periodically call the foreman for service prevention of the operation of the gas heating boiler. It is recommended to do this before the beginning and end of the heating season.

We recommend contacting the technical service of the city of Moscow for preventive maintenance, repair of household gas boilers at affordable prices for our customers. The methods of maintenance are individually selected in each specific case, guided by general technical standards when repairing heating systems at home.