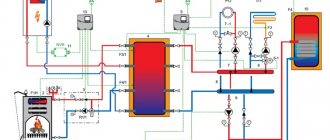

Refusal to use centralized heating and water supply lines, the creation of autonomous heating and hot water supply systems at home is becoming commonplace.

This is convenient for the owners of private houses or apartments, allows you to independently make decisions about the beginning and end of the heating season or heating modes of housing.

Trading networks offer a wide range of gas boilers, on the basis of which the most efficient and economical heating systems are created.

European companies are considered confident leaders in the production of heating equipment, but their colleagues from Southeast Asia have achieved considerable success.

Consider the prominent representatives of heating technology from South Korea - gas boilers Arderia (Arderia).

Main types

Arderia brand is owned by South Korean company Daesung... The products of this company are widely known in the world and are in high demand. The main feature of the company is its approach to the production of heating equipment.

Most of the work operations are performed by automated lines, which eliminates miscalculations or negligence. The Arderia brand was created to place gas boilers on the Russian market, which were produced in the following types:

By type of installation:

- wall... Designed for surface mounting indoors (usually in kitchens).

Floor models are not produced, since they require a separate room and are in less demand.

By feature set:

- single-circuit... Designed only for supplying the heating system with hot coolant at a given temperature;

- double-circuit... The units are prepared for simultaneous heating of the heating medium and the supply of hot water;

According to the type of heat exchanger, the following varieties are produced:

- with separate heat exchanger... These are boilers in which the primary unit consists of pure copper (99%), which demonstrates high resistance to temperature changes and the absence of corrosive processes. The secondary heat exchanger is made of stainless steel, has a high heat dissipation capacity and demonstrates noticeable performance;

- with bithermal (combined) heat exchanger... This is a tube-in-tube design. The coolant and water for the DHW line simultaneously pass through it, without mixing with each other. This design allows you to significantly increase and stabilize the hot water supply at home, but requires taking all possible measures to protect against the appearance of scale. The complex cross-section of the heat exchanger tube is very difficult to flush, and replacing a defective unit is too expensive and not always done.

NOTE!

The design of the boilers meets modern requirements for the functionality and efficiency of heating technology. The units have all the necessary certificates and can be used in residential and public buildings.

Series and models

Arderia gas boilers are produced in the following series:

Series "B"

Units of the "B" series are manufactured in Russia, at Daesung's own production facilities... The model range consists of double-circuit units with a bithermal heat exchanger made of copper.

The power of the models ranges from 10 to 24 kW, which is suitable for heating rooms from 53 to 250 sq.m.

Basic parameters of models:

- modulating burner;

- ability to work with low gas inlet pressure (up to 4 bar);

- silent circulation pump with wet rotor;

- there is a self-diagnosis and flame control system;

- frost protection;

- the units have been adapted to Russian climatic and technological conditions.

Gas boilers "B" series are reliable and economical... Each unit undergoes a separate inspection by the Quality Control Department. There is a multi-stage protection against operational overloads or freezing.

Series "D"

A series of gas double-circuit boilers with a capacity of 10-24 kW, capable of heating rooms from 53 to 250 sq.m. Equipped with two heat exchangers.

Primary (main) copper, secondary (for hot water supply) - stainless steel. In the manufacture of the used parts and materials from the best manufacturers in Europe, as well as the company's own developments.

Specific features of the units:

- the possibility of reconfiguring to liquefied gas;

- the gas valve is adjusted via the control panel;

- two options for installing the chimney - separate or coaxial;

- the ability to remotely control through the application on a smartphone;

- there are contacts for connecting a room sensor.

The design of boilers of this series is practically no different from the device of the best European models.... At the same time, the prices of Arderia boilers are at least two times lower than those of counterparts from European countries.

This increases the demand for Korean units, increases their importance in the eyes of buyers.

ESR 13-20 kW

The power of boilers of this series is in the range of 16-18.6 kW... It includes two models - ESR 2.13 and ESR 2.20. In terms of the set of functions, they are two-circuit units with a closed-type combustion chamber. Designed for space heating from 65 to 200 sq.m.

Manufactured in South Korea, at their own production facilities.

Possibilities of boilers series ESR 13-20 kW:

- there is a possibility of connection to gas lines with low pressure (up to 5 mbar);

- adjustable turbocharging;

- a circulation pump with a "dry rotor" was used, which allows maintenance without draining the coolant from the system;

- a control panel operating at a distance of up to 40 m is used;

- there is a self-diagnosis system;

- built-in voltage regulator, correcting drops from 156 to 280 V.

Units of the ESR 13-20 kW series are adapted for operation in the conditions of Russia... They are equipped with frost protection

ESR 25-35 kW

The range includes ESR 2.25, ESR 2.30 and ESR 2.35 units. Power range - from 12.2 to 40.7 kW... They are capable of heating areas from 122 to 407 sq.m.

Equipped with copper primary and stainless steel secondary heat exchangers, closed combustion chamber, modulating burner.

Main settings:

- electronic flame ignition system;

- the possibility of readjustment of gas equipment for the consumption of liquefied gas;

- automatic maintenance of the heating medium and hot water supply;

- the presence of an ionization sensor that monitors the presence of a flame;

- adaptation of the boiler to Russian conditions.

The units demonstrate reliability, stable operation, are easy to operate and regulate.... Combined with low prices, these qualities make them competitive in the heating equipment market.

Repair and adjustment of the Arderia boiler

I am doing repairs to the Arderiya gas boiler. We checked the pump - centered it, removed the graphite dirt, a slight rustle disappeared (touched slightly), which was working perfectly. They checked the DHW flow sensor (black square with 4 bolts, inside a magnetic valve), was rusty - cleaned, checked for a short circuit - there is a reaction. We checked the 3-way valve as best they could. There is no moisture, they switched it with a screwdriver, the engine works, the relays switch. Everything was assembled again - the result is the same, the first turn on - the gas is on for 30-40 seconds, then the AA error, then the second turn on - the same, but already the A4 error, then everything. I tried to turn on hot water, the pressure starts to twitch, it went crazy, jumps to 3, then again error A4. After experimenting with a three-way one, I tried to switch the remote control to a thermometer, the result is the same as with hot water, only the A6 error popped up.Before the error pops up and the burner goes out, a strong murmur appears abruptly in the area below the pump. From taps with hot water, in the bathroom and in the kitchen, a powerful jet of cold runs. Now I just noticed that there is strong perspiration on the plate heat exchanger. We collected everything again. We are trying to bleed the air. Gas is closed, power is connected, all valves are open. After the first power-up, errors A9, A6. After that, no reaction to on-off. remote control was not. It drips well from the air vent. With the remote control turned off, a hot water tap was opened. There was a crackling sound for a very long time in the pouring water, then, with a loud noise, the pump turned on. The water was turned off, the pump stopped. The body is scalding hot. The remote control was never turned on. Gas too. We are waiting for the pump to cool down. Then we will try to turn on the gas. It continues to drip from the air vent, the pressure decreases, when it reaches 1.2 bar (we collected 1.8 into the boiler), the pump turned on again. It turned off only when water was added with a make-up tap. This is normal? Error AA is the boiling of the coolant, i.e. overheating, A4, respectively, the sensor max. temperature is triggered, Reasons: there is no circulation, the three-way valve is stuck on the DHW, the DHW sensor is stuck on. Error A9 - it is written that the operating mode is anti-freezing, that is, pumping cold water. A6 - ignition error. So far, everything seems to be fine, since you cut off the gas. To make the boiler work again after errors, unplug the power cord. I would go over the 3-way valve. Pull it out completely, scatter it into parts, check for wedges. According to the description, it seems as if it goes crazy: when the heating is turned on, it remains on the hot water supply, as a result, an AA error. Check and clean the relay contacts inside, make sure there is no leakage through the shaft. If you have a closed CO and there is no additional expansion tank, check the pressure in the expansion tank of the boiler. With a single-storey CO, the pressure when the boiler is drained is 0.5 bar. Pump until the water stops pouring from the boiler, then lower it to 0.5 bar. It is normal for the motor to warm up. It wedges when manually rotating - it's magnets. Now, if he still makes noise at the same time, this is a cause for concern. The wall-mounted double-circuit boiler Arderia ESR 2.13 is in operation. I want to remove the DHW heat exchanger for cleaning. The water is lukewarm. The term of operation is six months. The stabilizer is worth it. Reboot doesn't help. The system is iron (old). The water is very hard. I used a make-up. Now the hot water supply is barely warm. The water pressure is unchanged (there is apparently no blockage in the hot water supply line). The console does not show any errors. - is the assumption "clogged DHW heat exchanger in the heating circuit" correct? - how to remove the plate heat exchanger - unscrew the screws on the plastic "tees" or disconnect the pipes? - I'm thinking of ordering a 3-way valve in the ZIP (apparently, the weakest point in this boiler when using hot water). In your case, I would make a zip something like this (in descending order): 1. Three-way valve. 2. DHW and CO temperature sensors 2 pcs. 3. DHW heat exchanger. 4. Control board. 5. Pump. In fact, the three-way valve is a switch for the heating medium flow from the main heat exchanger either to CO or to the DHW plate heat exchanger. In the three-way design, contacts are used (you can call them limit switches), depending on the closed contact, the voltage is applied to the first or second contact when the desired position of the locking ball is reached, the contact is mechanically opened by the el. the engine stops. Accordingly, the CO or DHW circuit works. The reasons for the failure are trivial, poor shaft seal of the locking ball drive. Boiler Arderiya ESR 2.13 is in operation. Now the second day is the adjustment by air. To be honest, I'm not happy. I did not notice savings on gas, but the discomfort from cold batteries is present. Before that, the temperature of the carrier was 48 degrees, and at home it was 21-22 degrees. This is a comfortable temperature for me. If it got hot, he turned off the boiler from morning to evening.Then he turned it on again for the night. Maybe you can't achieve comfort with cast iron? Now the boiler turns on for 10-12 minutes, heats up the batteries, and after an hour and a half it costs. The delta is set at 1 degree in the air. The only plus is that the device hangs in the kitchen, and it is noisy. And now you can hardly hear it - it turns on 15 times in a day. Only during the campaign, the gas blows in this mode to the fullest, otherwise why the counter winds its 4-5 cubes per day. And the parameter for the campaign is still the same - I can feel with my hand that it is not 80 degrees on the pitch. Although I'll go now, I'll make sure - there is a thermometer with a thermocouple from the old floor-standing device, I will tie it to the supply. If there is a minimum coolant limitation of 60 for the air thermostat mode, then the boiler works at full power until it reaches this threshold of 60, and then it reduces the flame and waits until it reaches the set air threshold, after which it goes out and turns off the pump, waiting for a decrease the air temperature is slightly lower than the installation parameters. If the threshold of the coolant is at the maximum - 80, then it burns a little longer at the maximum, and turns off a little faster, heating the air before installation. If the minimum boiler power is higher than the radiators give air, then the device can go out before the air reaches the required parameters, so as not to overheat the coolant above the installation. It will wait a little for the coolant to cool down by 5-10 degrees and turn on again in an attempt to heat the air to the required parameters. My remote control measures the air temperature incorrectly - the reading error is +3 degrees to the real temperature. Maybe you are also lying, so you need to take this into account by setting the temperature 3 degrees higher (or how much you are lying, this needs to be clarified using an additional thermometer). And why the gas consumption is higher, I do not know until I delved into it, in theory, on the contrary, the highest efficiency is achieved at maximum combustion. Maybe there is really too much gas going and it does not completely burn out or the jets are blown off. And then you will need to turn the settings inside the unit. If the reliability of the boards for Arderiya gas boilers is at a height, then why is there a clause about the mandatory presence of a stabilizer in the service agreement? The organization providing warranty service is reinsured, besides, it is strongly recommended to use a stabilizer of a certain brand. No, the fact is that some boiler units are very demanding on the voltage, more precisely on its fluctuations (the fan, the pump, the windings are heating), the stabilizers from the jump, of course, will not help, but I can prevent the failure of the above-mentioned units of the apparatus. I do not yet have an unambiguous opinion about the inverter, but with normal uninterruptible power supplies, the boilers work even with a very poor power supply. Tell me how to limit the temperature of the coolant from above? Do you have instructions? Arderia ESR 2.20 FFCD boiler. I have the air temperature. Was able to reduce only up to 60 degrees. At night, temperature changes in the bedroom are felt. Can you still reduce it? In the kitchen, the water is hot in the tap, but in the bath it is already warm. Water temperature on CO. Why can there be such a difference? Long distance and heat loss. Manages to cool down elementary. I solved my problem. It turned out that the heat exchanger was clogged with lime due to hard water (through the CO line). I will look for where the CO is leaking in order to minimize the make-up. Gas by-pass boiler Arderia ESR 2.20 FFCD, 2012. The unit was not grounded and operated without a stabilizer. The chimney is a separate air duct of 75 mm. On the chimney, first there was a corrugated hose 80 and then a pipe 4 meters by 120 to the roof. In the summer I put a corrugated hose on 100. The heating system is not done correctly (the garage and the bath are heated through the return line, without tees). There is an additional pump and tank. By the end of the second winter, he rarely gave errors. If you remove the cover of the error A3 and A6, it gives out much less often.What is the best way to make a chimney (as I understand it, the draft is too high)? Why has the reservoir pressure started to jump from 1 to 3 with a very large amplitude recently? 3-way valve? Outwardly I looked, there are only a couple of drops on it, the wires are all dry. It is not clear why the boiler sometimes does not turn on if the temperature drops below the set one. For the first time in 3 years I cleaned the burner and the primary heat exchanger outside - the boiler started working. Everything was heavily clogged. Another 3-way valve for replacement, since the secondary heat exchanger is leaking and is warm. Change the 3-way valve, and errors A3 and A6 will completely disappear. A wall-mounted Arderia boiler was installed, which worked without problems for 1 year and suddenly at night there was a loud noise from the pump, as a result, it gave an A4 error. It is clear that the pump (moreover, it starts up at the beginning, and then gets up and gives an error), 2 gas workers came and said that the pump was ejected and it was necessary to buy either a new one, or insert a regular one into the system. I was only embarrassed that sometimes the pump still started to work, namely when water was being drawn into the system. Not believing the gas workers, he took off the pump, disassembled it, cleaned it from all sides, put it back and everything works. Only sometimes this loud noise from the pump still appears, as if it were striking something, but I don’t understand where, or the bearing collapsed, maybe someone collided? When the gas boiler Arderia 2.13 is operating at room temperature, the medium heats up to 80 degrees. I reduced this parameter from 80 to 65 degrees. The boiler rarely turns on until the batteries have completely cooled down. Perhaps I save gas, but the feeling of comfort is gone. While I was adjusting the temperature of the carrier, the batteries were always warm, but now it feels like this is the degree to which the temperature drops before the device is turned on. And the thermal sensor in the remote control is lying by 5 degrees. You changed it, most likely, I will be at home, I will see exactly how it is indicated. In general, it makes little sense to lower the temperature, only if there is a risk of burns, for better matching with the underfloor heating without a mixing unit. To reduce the formation of hydrogen. If the radiator heating and the number of sections is not enough, or if the boiler power is at the limit, and reduce to 60, in the coldest frosts it may not heat the air to the required temperature. The air thermostat mode is much more convenient, set the air temperature, and it holds, and the coolant thermostat will need to be constantly done "more or less" as on ancient devices. The only problem is to choose the location of the remote control, the unit will be guided by the temperature of this particular room. If you opened the ventilation in a room with a remote control, the boiler will add power to compensate, while other rooms (if isolated, with a door) will start to overheat a little. You can put the remote control in the coldest room, and in others you can put thermostatic heads with taps. When the boiler switches to domestic hot water, should it immediately work at maximum power, and after a couple of seconds, reduce the power to the set one. Or is it a glitch? A couple of days ago, it began to hum strongly at maximum power, it seems that when the hot water supply is started, at first there is too much gas pressure, and after a few seconds it decreases. Malfunction of the boiler Arderia ESR 2.20. When operating from a room thermostat, the following happens: the device works for 20 minutes, then rests for 10 minutes and turns on again. The coolant temperature is set at 65 °. At the same time, the air temperature does not change. House 116 sq. m., heated with underfloor heating. I am worried about 2 points: first, the boiler rests for 10-15 minutes even when working on the coolant (for 2 weeks I keep scrupulous records "the dependence of the gas consumption on the unit modes"). In my opinion, it should rest longer, secondly - on what basis does it turn on if the air temperature does not change in the room? So this is great: the air temperature is maintained at a given level, the boiler turns on 2 times per hour.In general, with underfloor heating, the thermal response of the house should be very good. My room temperature drops by 1 degree. between inclusions. This is according to the room thermometer, and on the unit it always costs as much as it exhibited. Installed gas boiler Arderia 2.20 ESR. Is it necessary to regulate the maximum and minimum gas pressure when programmed to reduce its power to minimum values? In operation, the Arderiya 2.13 double-circuit boiler, after installation and start-up on about the third day, the circulation pump was flooded with water when the expansion tank connection tube disconnected, since the clip was not installed correctly. Now the pump makes a loud noise during operation, but the control panel does not issue any errors. When disassembling and inspecting the pump, all the bearings turned out to be intact, and no traces of rubbing were found. Please advise, what could be the malfunction? Bearing noise is quite specific, try listening through a screwdriver where exactly the noise is near the pump, and then decide what to change. Tell me who knows, I'm going to clean the Arderiya boiler heat exchanger with a booster. Is it possible to do this without removing the heat exchanger (just connect the hoses to the supply and return without disassembling anything)? The boiler began to work strangely, you set any temperature, even 60gr, even 70 or 75 without a difference, the room temperature does not rise above 23, warm water (60gr) has disappeared altogether, and hot (80gr) floats (either hot or cold). I suspect that your three-way valve is spinning constantly (listen through a 3-way screwdriver) with characteristic clicks. A priori, we believe that everything worked for you earlier. When scale builds up in the secondary heat exchanger, the symptoms are slightly different. Installed a gas boiler Arderia ESR 2.13 FFCD. Tell me, are there any connections between its capacity and gas consumption? Or will it only affect the health of the device itself due to operation in a more gentle mode? There is a house with certain heat losses per square of enclosing structures (walls, floor, ceiling). Accordingly, this structure loses some watts per square meter per hour. The heating unit, which consumes gas, replenishes the heat loss. What difference will it make whether it is tuned to full power or to minimum? The boiler gas valve must be set to full capacity, limiting the maximum gas pressure on the burner in accordance with the rating data for this model. Must be set for minimum power and minimum gas pressure limitation on the burner according to the rating data. Work is done with a pressure gauge. During operation, the boiler itself chooses the heating power of the coolant. It depends on the difference between the flow temperatures (set) and the actual temperature of the heating medium. The greater the difference, the more power (and gas consumption). As this difference decreases, the power also changes. When the set temperature is reached, it runs for min. power. If the heat consumption corresponds to the min. The boiler works without stopping with a minimum gas consumption. If the heat removal is less, the heating unit turns off when the set temperature is reached plus a few degrees. The maximum power for heating does not matter if it is not several times less than that required for heating a given room. Malfunction of the boiler Arderia ESR 2.13 FFCD. Boils, but does not give an error. As a result, it turns on and off constantly. I will say right away that everything is working, I invited the gas workers, checked all the physical components. Everything is okay. Everything is cleaned, the passage of water through the boiler is ideal. The pump drives (may not be enough). I tried to shut off the gas supply valve while the machine was running until the flame went down. Then it works without shutting down. There is an impression of insufficient water circulation. The pump was disassembled, there is no visible damage, the speed is normal, it turns quickly. The coolant flows not only through the boiler, but also through the heating system.If everything is fine in the heating unit, check it. You can also check the 3-way valve, but it seems like it shouldn't boil then. I set the temperature to 55 (stood at 45) degrees. The needle on the pressure gauge has risen by 2 divisions, that is, it has become 1.2 bar. The heating has run out, the arrow has returned to 1. If the three-way valve lets through, then just a little. To say for sure, you need to turn off the heating. Is it not very dangerous for the boiler if you keep it under control at all times? Most likely, the pressure in the expansion tank is insufficient or the CO volume is more than 100 liters. Unfortunately, I do not know what kind of CO you have, the installers, when putting CO into operation, had to set up CO so that you would not have any questions about non-working devices, in particular PS. If the equipment is working, the main thing is not to interfere. Arderia boiler malfunction, comes out in 2 errors, the first of them is AA, the second is A4. The initially heated water in the heat exchanger did not go beyond the 3-way valve, and the device was triggered by overheating, after manual installation of the three-way valve for heating, the coolant flowed to the batteries, but the boiler also immediately heated the water, and then immediately turned off. This process is continuous. The circulation pump was removed, the pump is working properly, the impeller is clean, the impeller on the back side of the pump is all cracked, plus there is still play. The boiler filter is clean. Now the heating unit heats up quickly and turns off, the water apparently slowly leaves, then turns on again, heats up and so on incessantly. Can there be a blockage in the heating system itself, and what other solutions to this problem can be. Put a jumper between the supply and return (by turning off the CO) and turn it on (after filling it in). The boiler will work, which means the system, no - it means the device. It may be necessary to completely disassemble the hydraulics, followed by cleaning and flushing. Malfunction of the wall-mounted boiler Arderia. When you open a hot water tap, the heating unit turns on. I have never parsed this and do not know how it should work. Wouldn't hurt. It's not summer yet. It is now clear that the three-way valve needs to be changed. With the long open tap of the mountains. water began to heat up CO and very strongly. Usually cooled down. Then he switches to heating, turning on and off a couple of times. This was not the case. Where to find this valve now? This means that the DHW sensor is in order, and you don't need to disassemble anything special; turn off the boiler, remove the lid. On the right side, under the fan, we see a 3-way valve, on which the engine is fixed with two bolts. We unscrew the bolts, remove the engine, remove the rectangular cover (and perhaps we will see that water has seeped there). If yes, then it is necessary to dry it, and make sure that the contacts are not oxidized and if everything is in order, then we put the engine in place (we do not put the cover, it is not needed that way) and turn on the device. Boiler Arderia ESR 2.20 is in operation. I cannot change the values of parameters C5 and L1 on the remote control. Maybe someone came across and knows how to get the boiler to change them? Now it operates in the coolant temperature control mode with a delta of 15 degrees. My decline occurs within 30-40 minutes. In this case, the pump runs intermittently for 5 minutes. I would like to run it on constant circulation or to minimize the downtime as much as possible. In my understanding, this will reduce the temperature on the boiler and reduce the gas consumption. Judging by the service manual, the parameters that will somehow change this situation: L1 - will increase the pump operation period after the burner is turned off; C5 - will reduce the period between burner starts. There are dip switches on the board, with an inscription opposite each. You need a program, enable it and change the parameters as written in the instructions. When finished, return the switch to the off position.

Specifications

Consider the parameters of gas boilers Arderia:

| Characteristics | The values | |||

| Arderia D10 | ESR 2.20 | ARDERIA ESR 2.35 | ||

| Boiler type | Gas heating | |||

| Fuel type | Natural or LPG | Natural or LPG | ||

| Mounting method | Wall | |||

| Thermal power | 10.9 kW | 8.6-23.3 kW | 12.2-40.7 kW | |

| Gas consumption (max) | 1.2 m3 / h | 2.73 m3 / h | 4.49 m3 / h | |

| Power supply | 220V 50Hz | |||

| Dimensions (edit) | 410x652x243 mm | 420x660x200 mm | 460x700x205 mm | |

| Weight | 26.2 kg | 24 Kg | 26 Kg | |

Possible problems

The remote control enables the owner to make certain decisions on the "error code". The following malfunctions can occur with the Arderia boiler most often:

- The pressure sensor turns off, and the chimney blows out - the cause may be clogging or icing of the external outlet.

- The number of revolutions of the fan is greatly reduced - due to improper installation or ingress of foreign particles into the ventilation device.

- The overheating sensor is triggered - it means a breakdown of the circulation pump or closing of the valves that control the flow of liquid.

- Too much pressure drop in the primary circuit - it means that the supply of the heat carrier is insufficient, there may be leaks in the pipes or the pump is faulty.

- Ignition blocked - no gas, damage to the gas valve or gas duct.

- The boiler is off, and there is a flame on the burner - the result of a breakdown of the electronic control unit of the heating unit.

- An unnatural range of working temperatures of the liquid - happens when filters are clogged, pumping equipment breaks down, a fluid flow sensor or valves supplying it.

Error codes and malfunctions of Arderia boilers are presented in this article.

The innovative diagnostics enable the owner to quickly troubleshoot the Arderia gas boiler.

You may well consider a boiler of this brand for arranging a heating and hot water supply system in your own home. In addition to high reliability and long service life, the units have a rather attractive cost for most consumers. Read the reviews of the owners, study the technical characteristics of Arderia gas boilers and make a decision on buying the optimal heating device.

Advantages and disadvantages

Dignity:

- efficiency, a good set of performance characteristics;

- the ability to heat the coolant and supply hot water for domestic needs;

- convenient control, there is a remote control and the ability to remotely influence through the Wi-Fi module;

- the presence of a built-in voltage regulator capable of correcting a drop of up to 150 V;

- boilers are designed for operation in difficult Russian conditions;

- a self-diagnosis system continuously monitors emerging problems and notifies the owner about them;

- there is a multi-stage protection against all overloads, freezing of the coolant, voltage drop, etc .;

- the price of the units is much lower than that of the European counterparts of the same quality.

disadvantages:

- the need to connect the power supply. In case of a sudden shutdown in winter frosts, there is a risk of being left without heating;

- the company was founded relatively recently and has not yet managed to create an extensive network of service centers;

- the power of the units is limited and does not allow them to be used in large rooms.

Judging by the demand and high demand, the shortcomings are not critical and are quite surmountable.

CAUTION!

Some users report a high noise level or some time lag when supplying DHW. However, such features are typical for all models of gas boilers from European and Russian manufacturers.

Operation and setup instructions

The initial (basic) setting of gas boilers is carried out at the factory. During installation and the first start-up, it is necessary to correct the factory settings to match the existing operating conditions with the needs of the mechanics and electronics of the boiler.These actions must be carried out by employees of service centers or warranty workshops.

Independent intervention in the design of gas appliances is prohibited.... Operating settings such as temperature control or heating shutdown for the summer are permissible and must be made by the user.

The operation of the units is not difficult... It is necessary to pay attention to the display readings, if necessary (when an error code appears), call the wizard. To clean the case from dust and dirt, to carry out technical inspection and other procedures in a timely manner. Before starting work, you should carefully study the instructions and follow its instructions.

Major malfunctions

The main malfunctions of Arderia boilers should be considered:

- in case of icing of the outlet, it is possible to disconnect the pressure sensor and blow out the chimney;

- a stop or a drop in fan speed means that foreign objects, particles have entered the working space of the impeller;

- the overheating sensor is triggered when the circulation stops (pump breakdown) or the supply valves are closed;

- the boiler does not ignite. This indicates a failure of the gas equipment (valve) or disconnection of the mains power supply.

All emerging problems are immediately detected by the self-diagnosis system... It issues a special code on the remote control, which indicates a standard situation with a malfunction of one or another sensor, unit, or part. For a complete list of codes, refer to the user manual, which should be kept handy.

Among them, the following designations are most common:

| The code | Decoding | Causes of occurrence |

| A1 | Air pressure sensor malfunction | Short circuit, outlet icing |

| A2 | The rotation speed of the fan axis has dropped | Interference, foreign objects, or debris on the impeller |

| A3 | The pressure sensor was triggered before the pump was started | Sensor clogged with dirt, needs cleaning |

| A4 | Heating agent overheating sensor | Stopping circulation due to a breakdown of the pump or three-way valve |

| A5 | The coolant pressure has dropped | There is little water, the system is airy, there are leaks |

| A6 | No ignition or blocked chimney | The gas pressure has dropped, the chimney is clogged with soot or ice |

| A7 | Gas valve short circuit | The control unit is out of order |

| A8 | There is a flame on the burner, although there is no gas supply | Problems with the gas valve, control unit. Check grounding. |

| A9 | The coolant is frozen | Lowering the temperature to -5 ° |

| AA | The coolant has boiled | Circulation stopped, valves closed, 3-way valve or pump problem |

| AND YOU | Failure of the thermostat | Breakage, poor contact |

| AE | Chimney blocking | Icing, deformation, ingress of foreign objects |

Error codes

In the event of the slightest malfunctions or problems in the operation of the device, a certain error is displayed on the electronic display.

To correctly eliminate the breakdown, it is necessary to know the content of all possible equipment errors.

- Error A1 - failure of the air pressure sensor. This is likely due to blockage or icing of the inlet.

- Error A2 - reduced fan speed, and therefore the boiler does not heat the water well, it also makes noise. The reason can be either poor contact, or problems with the connection of wires, or the ingress of foreign objects on the fan blades. This can cause noise.

- Error A3 - breakdown of the circulation pump, pressure drops. This problem can occur due to dirt getting into the pressure sensor, as well as if it turned on before the pump.

- Error A4 - an increase in the temperature of the device, while knocking out both fuses at once. This can happen if the stopcocks are screwed on, the heating filter is clogged and the valve is leaking, the pump is out of order, the three-way valve does not work, the water flow sensor is damaged.

- Error A5 - the coolant pressure decreases.It may occur due to a decrease in the amount of water in the system, the appearance of air, a pump breakdown or a decrease in its speed, wear of the pressure sensor.

- Error A6 - lack of ignition, the boiler does not ignite, it goes out. It occurs due to blockage of the chimney, low gas pressure, inoperability of the gas valve, breakdown of the transformer, blockage of the gas duct.

- Error A7 - breakdown of the gas valve, as a result of which the unit does not start. This breakdown occurs in connection with a relay closure, errors in the control system.

- Error A8 - flame extinction. It happens due to the presence of residual flame when the gas valve is off, damage to the gas valve diaphragm, failure of the control unit.

Price range

The cost of Arderia gas boilers is much lower than that of similar European-made devices.

For a Russian buyer, they cost 23-36 thousand rubles.... The price of the unit depends on its power and additional functions. Please note that the chimney and remote control devices, room thermostat, etc. sold separately.

IMPORTANT!

You should not skimp on warranty service. The danger of being left without heating in winter is much more serious than the cost of concluding a warranty agreement.

Arderia gas boilers appeared on the Russian market relatively recently. Most users do not yet know about them, although a considerable number of units are already in operation.

They demonstrate stable performance, efficiency, and resistance to external loads.... Self-diagnosis does not allow the boilers to fail, the built-in voltage stabilizer corrects the drops in the network. The quality and low cost of Arderia boilers allow them to take their rightful place among the alternative options.

Features of boilers

The company is constantly improving its devices and takes care of customers, therefore, for the sake of safety, the automated operation of boilers has been established. The design implies several levels of protection. The equipment is characterized, according to the manufacturer, by the following positive aspects:

- two heat exchangers. One is made of copper and is intended for the heating circuit, the second is made of steel, for operation in the hot water supply system;

- automatic power control is provided by the pressurization burner;

- there is a fan for uninterrupted combustion, it draws air into the system;

- elementary and convenient control panel. Setting and adjusting the temperature heating is done with a few clicks;

- remote control can be carried out using a room thermostat;

- built-in electronic display showing the current temperature and error codes;

- The ESR line of gas boilers Arderia is characterized by the presence of some convenient functions: a gas supply sensor, an overheating protection system, etc.

Detailed instructions, which have a section in Russian with a good translation, will help to understand all the features of setting up the boiler.

The owners also confirm all of the above advantages, the good operation of the unit of this brand, as well as its simple operation. However, nevertheless, some disadvantages, according to reviews, are present on the Arderiya gas boiler. For example:

- users complain about the noise during the operation of the boiler;

- for a delay in the arrival of warm water;

- on the weak resistance of some nodes, including the circulation pump, heat exchanger and electronic control board;

- the impossibility of installing a coaxial chimney;

- as well as an unattractive appearance, which is due to the blank front panel.

I must say that at their cost, Arderia gas boilers are a pretty good option when establishing individual heating and hot water supply. The boilers are very economical, characterized by a reliable electronic control system and easy troubleshooting.