Airiness of the heating system leads to heat loss in the house, which affects comfort. In order to air the heating system, it is enough to carry out a few simple manipulations with the drain valves, the only difficulty may be the release of air in a private house, but if you carefully watch the video below, you will succeed!

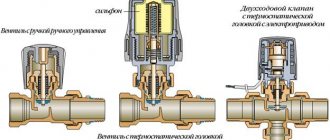

For use in different heating systems and under different operating conditions, there are three types of needle valve radiator:

Mayevsky manual crane - the simplest and most reliable. This faucet has found its application in centralized heating systems, where the quality of the coolant usually leaves much to be desired. When clogged, such a tap can be easily cleaned with a regular sewing needle. Typically, these valves are installed in upper floor heating radiators.

Fuse valve standard Mayevsky crane automatic crane

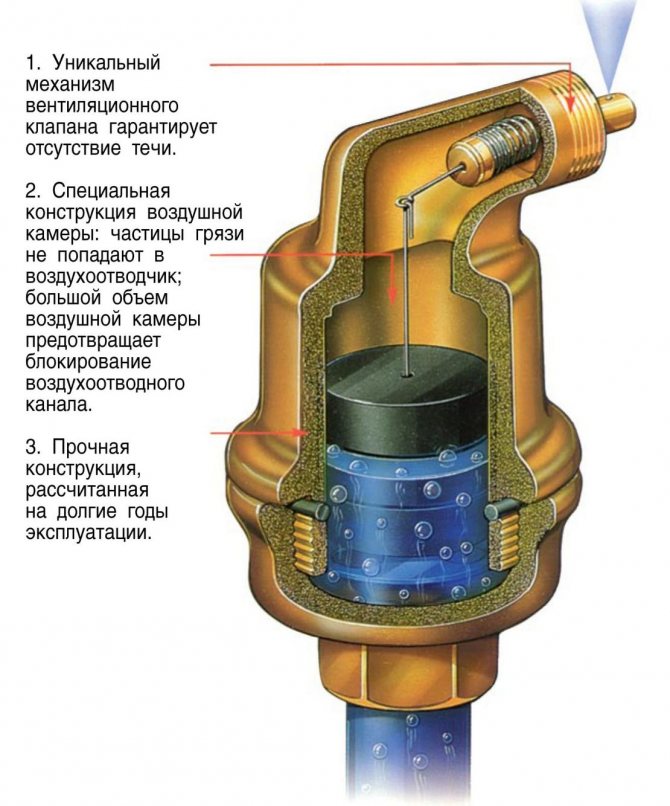

Automatic faucet - it is arranged somewhat differently and does not require manual control for its operation. Such a faucet consists of a brass cylinder fitted with a plastic float. Depending on the presence of air in the system, the float moves inside the cylinder, allowing the valve to open and close. The whole process takes place automatically. But such devices are very sensitive to the quality of the coolant and are easily clogged if there is dirt in the system. Therefore, all automatic cranes are equipped with manual control. These devices are usually used in private houses, where the quality of the coolant is guaranteed by its high-quality cleaning.

Safety valve purpose

Unlike heating systems with an open expansion tank, where pressure drops lead to an increase in the volume of the coolant in the tank or, in emergency situations, the evaporation of water into the environment, in a closed loop all processes take place inside the boiler and the pipeline. To remove the surplus of the expanded working fluid from the closed system, automatic valves are used, tuned to its physical parameters, more precisely, pressure.

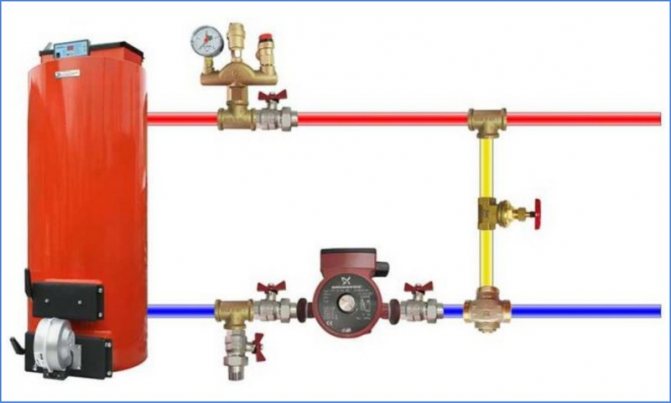

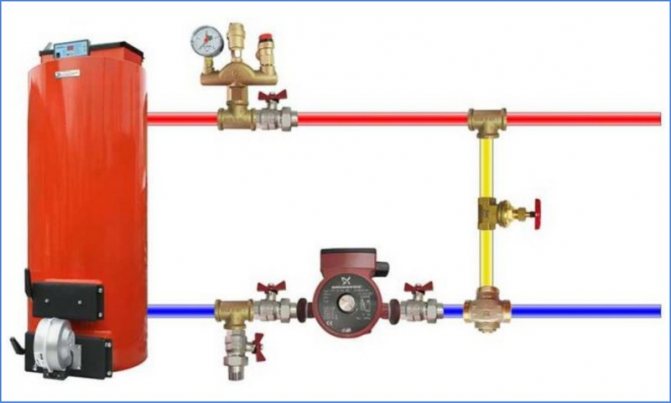

During operation, the heat carrier has the highest pressure and temperature at the boiler outlet, besides, heating equipment is the most expensive in the system - because of these factors, a safety valve of the heating relief system is installed next to the boiler and is designed to protect it.

How the relief valve works

Removing air from the heating system of a private house

In private houses, the device of heating systems is different, it depends on the features of the layout of the buildings. For different types of systems, appropriate expansion tanks are used - open or closed. Therefore, individual homeowners often have to think about how it is more expedient - to bleed air from a heating radiator or through an expansion tank. In an open system, air bubbles can freely exit through an expansion tank installed in the attic. If the heating works normally, there is no need to bleed air from the system, since it comes out on its own. But the liquid gradually evaporates, and the water level in the open expansion tank can drop so low that an air lock will appear at the top of the supply line. In this case, the circulation of the coolant will slow down or completely stop, and in this situation it should already be a question of how to release air from the heating system.

To expel the airlock, you can add water to the expansion tank from above, but it is better to replenish the volume of liquid in the system through the lower tap connected to the water supply. Water entering from below will fill the void in the pipe and force the air out through the opening of the expansion tank.

During the heating season, it is necessary to ensure that the expansion tank is constantly filled with water to about 2/3 of its volume, and when the level drops, top up with water.

In closed systems, diaphragm expansion vessels are used. Sometimes a membrane rupture occurs in them, and then the system

air enters. If it is possible to establish that the cause of airing is a faulty expansion tank, it will have to be replaced. But before starting the repair, before draining the water from the heating system, you need to prepare everything you need so as not to leave the house without heat for a long time.

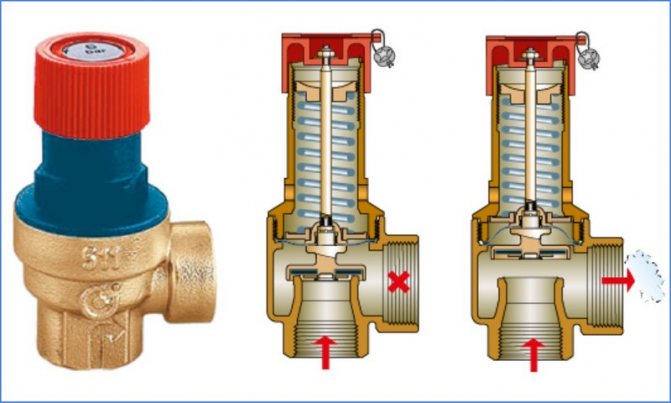

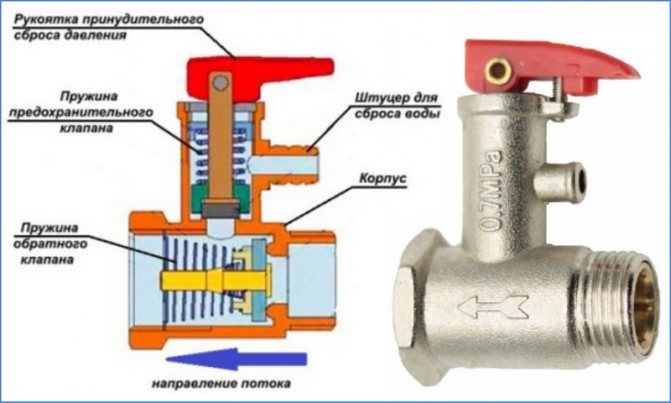

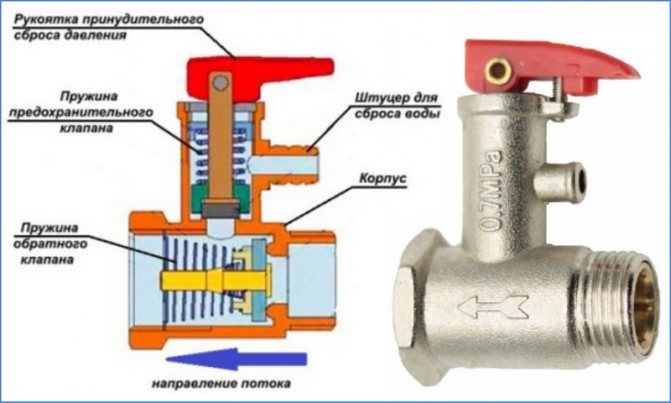

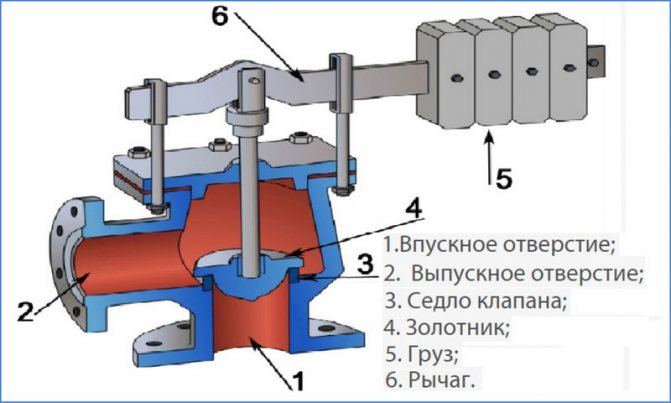

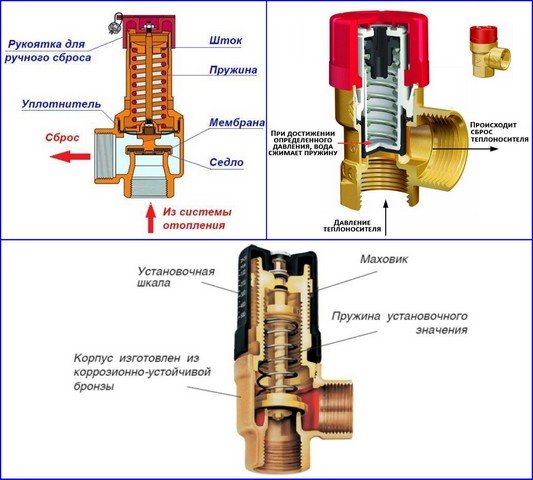

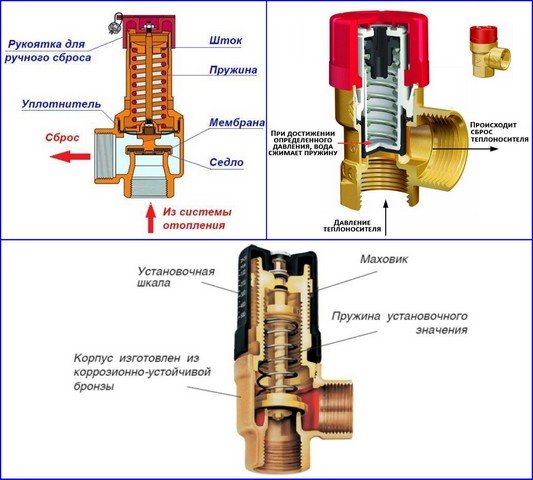

Principle of operation

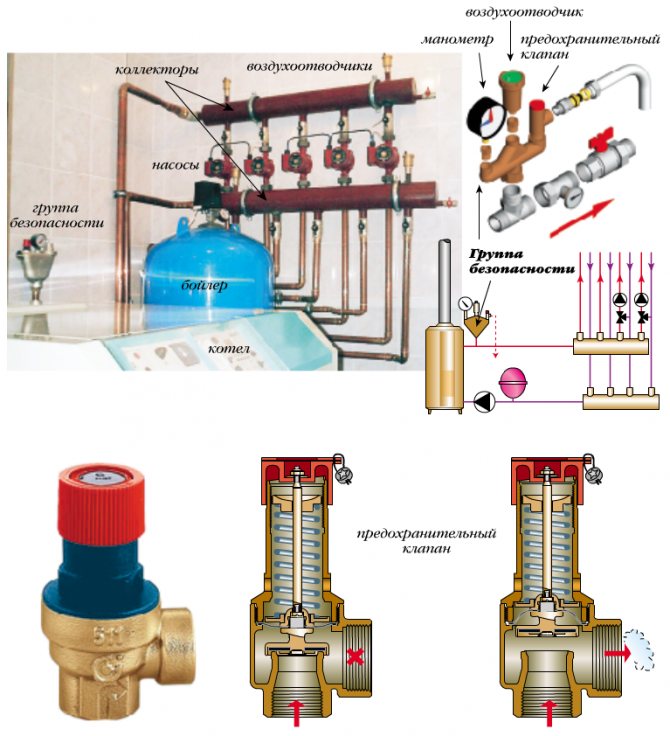

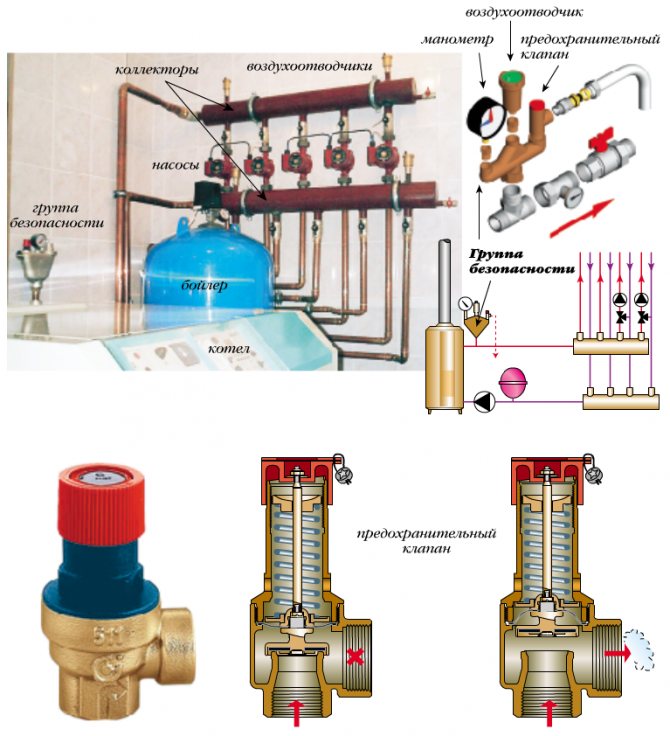

The valve protecting the boiler has a simple design and works according to a principle that is understandable even for a schoolchild. The instrument consists of a straight fitting with a 90 degree elbow and a spring-loaded, pressure-tight seal that closes off the side passage. When the pressure in the system increases from overheating, exceeding the clamping force of the spring holding the valve in a stationary position, it rises up and opens the side hole.

Excess liquid begins to pour out from the side and is sent to a container, drainage or sewer system. After venting part of the coolant, the pressure in the system and on the valve weakens, the spring puts it in place, blocking the side pipe.

Spring type constructive device

Selection and installation recommendations

Since not all manufacturers of heating equipment complete their products with a safety group, often the choice of a safety valve for the heating system has to be done independently. To do this, it is imperative to study the technical characteristics of the boiler plant, namely, to know its thermal power and the maximum pressure of the coolant.

For reference. Most well-known brands of solid fuel heat generators have a maximum pressure of 3 bar. An exception is STROPUVA long-burning boilers, whose limit is 2 Bar.

The best option is to purchase a pressure regulating valve that covers a certain range. The regulation range must include the value for your boiler. Then you need to select a product according to the power of the thermal installation, but it is difficult to make a mistake here. The manufacturer's instructions always indicate the limits of the thermal power of the units, with which a valve of one diameter or another can work.

On the section of the pipeline from the boiler to the place where the overpressure relief valve is installed, it is strictly forbidden to install shut-off valves. In addition, you must not put the device after the circulation pump, do not forget that the latter is not able to pump the steam-water mixture.

In order to exclude water splashing around the furnace room, it is recommended to connect a pipe to the valve outlet, which leads the discharge into the sewer. If you want to visually control the process, then a special drain funnel with a visible gap of the jet can be placed on the vertical section of the tube.

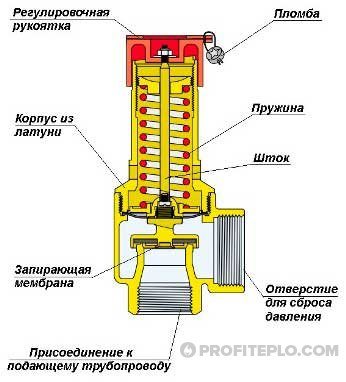

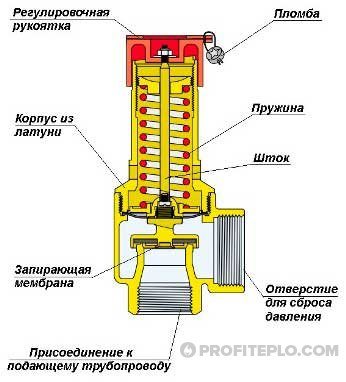

Design

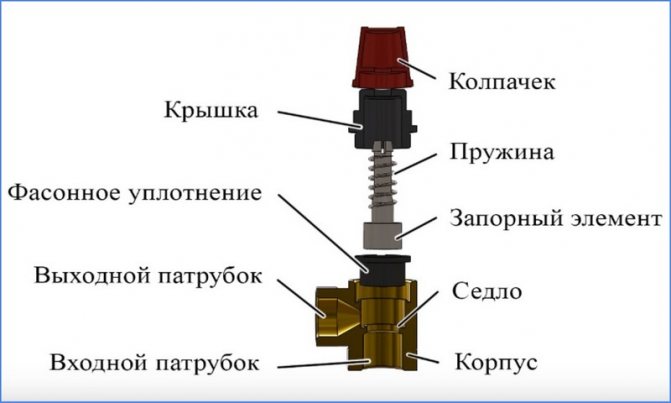

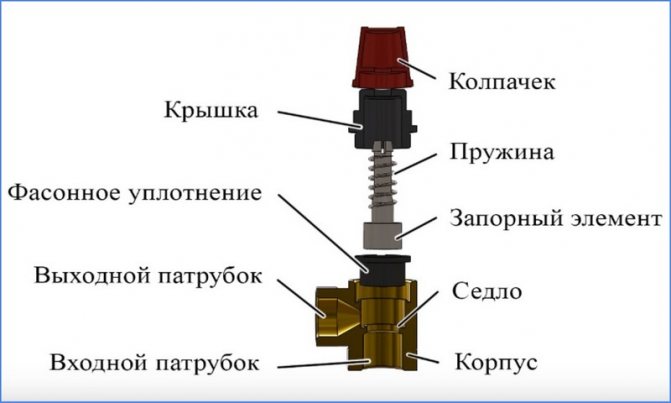

A typical boiler safety valve has a collapsible design and consists of the following main elements:

Housing... It is usually made of brass and looks like a tee. On its sides there are a lower inlet threaded hole, a lateral outlet pipe and an upper seat, on which the shaped seal is seated.

Locking group... It is a spring-loaded pulley with a cylindrical (disk) end locking element, on which an elastic rubber seal in the form of a cup (disk) is put on.

Cap... A black heat-resistant polymer cap is screwed into the upper threaded branch pipe of the brass body, which holds the spring-loaded stem in the working position. On the upper edges of the lid there are projections along which the top cap shaped in the lower part, connected to the shut-off rod, slides. When turned through a certain angle, the cap rises together with the stem and opens the side branch pipe - this allows the safety valve to be used for heating always open in manual mode.

Cap. The polymer part is usually red in color with a ribbed side surface, screwed to a hollow stem with a screw. The shallow protrusions in the lower part of the cap, as it rotates, fall on the teeth of the cap - the handle rises together with the spring-loaded shutter and opens the side channel, allowing manual pressure relief.

Adjusting washer... The inner wall of the cover has a thread, in which the adjustment nut rotates, when it is lowered down, it compresses the spring - thus increasing the valve response threshold. By unscrewing the nut upwards, the spring is weakened and the response pressure decreases. For turning, the nut is equipped with a transverse slot in the upper part for a flat screwdriver.

Valve for water heating boilers - design and appearance

Varieties

The existing types of valves are able to work with boiler equipment from leading foreign (Vaillant, Baxi, Ariston, Navien, Viessmann) and domestic (Nevalux) manufacturers on gas, liquid and solid fuels in situations where automatic control over the operation of the system is difficult due to the type of fuel. or broken when the automation fails. Depending on the design and the principle of operation, safety valves are divided into the following groups:

- According to the purpose of the equipment in which they are installed:

- For heating boilers, they have the above design, they are often supplied on fittings in the form of a tee, in which a pressure gauge for checking the pressure and a vent valve are additionally installed.

- For hot water boilers, there is a flag in the design for draining water.

- Containers and pressure vessels.

- Pressure pipelines.

- According to the principle of actuation of the pressure mechanism:

- From a spring, the clamping force of which is regulated by an external or internal nut (its work is discussed above).

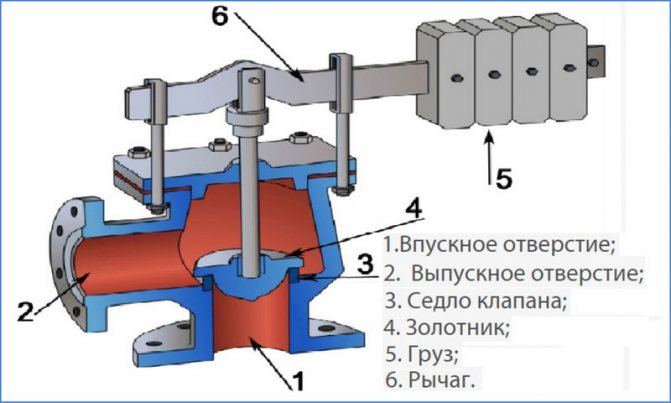

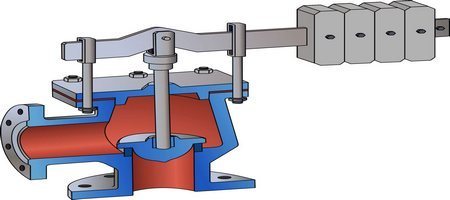

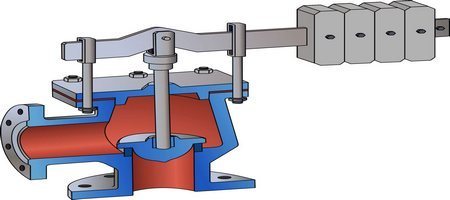

- Lever-cargo, used in industrial heating systems designed to discharge large volumes of water, their response threshold can be adjusted with suspended weights. They are suspended from a handle connected to the shut-off valve by the principle of a lever.

Lever-load modification device

- Locking mechanism response speeds:

- Proportional (low-lift spring) - the sealed lock rises in proportion to the pressure and is linearly related to its increase, while the drain hole gradually opens and closes in the same way with a decrease in the volume of the coolant. The advantage of the design is the absence of water hammer at various modes of movement of the shut-off valve.

- Two-position (full-lift lever-cargo) - operate in open-closed positions. When the pressure exceeds the response threshold, the outlet opens completely and the excess volume of the coolant is vented. After the pressure in the system is normalized, the outlet is completely closed, the main design flaw is the presence of water hammer.

- By adjustment:

- Non-adjustable (with caps of different colors).

- Adjustable with screw parts.

- According to the design of the adjusting elements for spring compression with:

- An internal washer, the principle of operation of which was discussed above.

- Outside screw, nut, models are used in household and communal heating systems with large volumes of coolant.

- With a handle, a similar control system is used in flanged industrial valves, when the handle is fully raised, a one-time drain of water can be performed.

Designs of various models of drain valves

Purpose and place of installation

Closed-type heating systems operate at a certain pressure. Significant increases in operating pressure will lead to equipment failure. Connections may leak, plastic parts and elements may burst. In the most unfavorable situations, the boiler heat exchanger can explode. This is already very dangerous and threatens not only the floor flooded with hot coolant, but also burns. After all, the temperature is serious.

Protect the heating system from excessive high pressure and there must be an overpressure relief valve. While the parameters of the system are within the normal range, it does not manifest itself in any way. Although from the moment the boiler is started, the pressure in the system rises smoothly, it is compensated by the expansion tank, maintaining a stable state of the system. But he may not do this indefinitely, although, with the correct calculation, he is enough for regular situations. If the expander fails, the pressure starts to build up. When it exceeds the threshold, the overpressure relief valve is triggered here. It simply releases some of the coolant, thereby stabilizing the emergency.

That is, the overpressure relief valve in the heating system works in emergency situations. Therefore, it is also called "emergency". And also - "discharge", "drain", "protective" and "subversive". These are all names for the same device.

What does a safety (emergency) valve for heating look like?

As is clear from the description, when the pressure rises above a certain limit, a certain amount of heat carrier is simply released from the system. If you came to the boiler room, and a puddle formed under the emergency valve, it means that there was an abnormal situation during which the pressure increased. No other alarm

So these traces are worth paying attention to. It is worth immediately checking the operability of the valve itself and the membrane tank

Most likely, the reason is in them. If you do not pay attention to these symptoms, after a while you may run into problems: either something will "fly" in the system, or it will rupture the hot water boiler.

The installation location of the heating emergency valve is on the supply pipe, not far from the boiler

Of all the equipment for an individual heating system, the most dangerous is the boiler. Therefore, an overpressure relief valve is installed either directly on the boiler itself (if there is an appropriate outlet for the installation) or on the supply line immediately after the boiler. The distance is small - 20-30 cm from the body. If the boiler does not have this type of fittings (indicated in the description), then it is installed in the so-called safety group or separately. The safety group is installed on the outlet from the supply line immediately after the boiler (before the first branch and any other device), on which a pressure gauge, an automatic air vent and an overpressure relief valve are installed.

How to choose a valve for a heating boiler

When choosing a safety valve for heating, they are guided by the following considerations:

- The decisive factor for the selection of a safety valve is its set pressure. The usual standard for household appliances used in a heating system is calculated to be 3 bar. This indicator is due to the fact that in most individual closed circuits with radiators using circulation pumps, a heat carrier is transported with a standard pressure of 1.5 bar. Its fluctuations when heated to the highest temperatures can reach 2.5 bar, and a limit value of more than 3 bar indicates overheating of the coolant and can become critical for polymer pipelines (the boiler can withstand significantly higher hydraulic loads).

- Among the models on the market, there are a lot of products from China of little-known brands. The Russian-Italian product Valtex possesses a good ratio of price and quality, valves from the Italian manufacturer of boilers Baksi. Many well-known suppliers of electric boilers with the brands Vailant, Ariston, Baksi additionally produce related equipment, which also includes safety valves.

- In terms of cost, ease of installation and functionality, it is best to purchase a security group. The unit additionally includes a pressure gauge (allows you to control the tuning process and pressure in the system) and an automatic valve for bleeding air in the circuit.

Note: Some manufacturers (Valtex) make the handle of the non-adjustable safety valves red, yellow and black to indicate the maximum allowable pressure (e.g. black handle 1.5 bar, red handle 3 bar, and yellow handle 6 bar) ...

Safety valve installation diagram

Types of valves and how they work

Any modification of the safety valves in the heating system includes a shut-off element and a force action mechanism. According to the design features, several types of fuses are distinguished.

Separately classified are valves for dumping the thermal potential with a bellows, a temperature-sensitive liquid that compensates for load drops. There are models that include a safety group in the form of a blast valve with a part responsible for air discharge and a pressure gauge.

The check relief valve for the heating design can be spring-loaded or gravitational. Due to the built-in mechanisms, the contactor is kept closed, which ensures the movement of the coolant flow in one direction.

Closures are bivalve, petal, disc, pressing against the saddle, bushing, other main base. It is necessary to get a sealed shutter.

Inside view

The principle of operation of the fuse lies in the fact that in the normal state, the diaphragm layer fixed between the stem and the spring tightly adheres to the seat, hermetically closing the outlet. In the case when the coolant boils, expansion of the liquid is observed, the load inside the system rises, but is partially regulated by the expander.

At the maximum allowable load level, the spring is strongly compressed, releasing the diaphragm, which immediately opens the passage.

The lid rises to release as much hot steam as is required to stabilize the equipment.

When the work is normalized, the spring returns to its original position, the membrane tightly closes the release hole, the cap returns to its place.

If the owner is near the instruments, you can perform an emergency reset with your own hands by turning the upper handle.

By pressing method

When heating a private house, apartment or industrial premises where low-power equipment is used, a spring-loaded valve for emergency relief of excess water pressure for the heating system is often chosen.

They are simple, compact, inexpensive but reliable models that can be combined with other equipment for safety.

The compression ratio of the spring is related to the load parameter at which the valve is actuated. The spring elasticity affects the setting range.

The principle of operation of the device: a water stream exerts pressure on the shutter, as it intensifies, the degree of compression of the spring increases greatly. From this, the spool rod rises up, releasing excess steam, and the in-line fluid volume is stabilized. In the meantime, the spring returns the unit to its original state.

Spring modifications are made of high-strength brass, hot stamping technologies are used. The spring itself is steel, and the membrane, seals, and the handle are polymer.

You can choose models with factory settings or those that need to be customized individually during installation.

Lever fuse

Lever-weight safety devices are used less often, since the stem lifting provides an external suspended weight that moves along the entire lever, regulating the degree of pressure of the stem against the seat.

By the degree of opening the shutter

Low-lift valves assume a valve lift of no more than 0.05 times the seat diameter: the opening mechanism is fully proportional.

The product is characterized by low throughput and primitive design. The fuse is installed in installations with a liquid medium.

Full lift modification

The full lift variation contributes to the maximum allowable lift of the gate, which improves throughput as a large amount of steam is discharged at a time.

By response speed

The proportional safety valve for urgent relief of excess water pressure in the heating system assumes that the valve rises gradually, according to the degree of internal load. As the damper rises, the volume of the released steam increases smoothly. Such installations can be used with any type of boiler, but most often they are installed in systems with water or other liquid.

The on / off valves operate instantly, opening fully when the pressure rises. It is recommended to place such devices in a compressible environment. The main disadvantage of the safety element is the presence of self-oscillations of the bolt.

On-off valve

Installation of on-off valves should be carried out taking into account the discharge of a large amount of water with a sudden opening. It turns out a very quick release of pressure, closing the shutter, as a result - a water hammer, which is absent in proportional fuses.

You can learn more about the valve device, the principle of its operation, in the following video:

How to install

When installing the safety drain fittings, observe the following rules:

- Usually, a pressure relief valve in the heating system is installed in a household circuit in a single copy. Its main points of placement are directly above an electric, solid fuel, gas boiler at its outlet or next to a horizontally located pipeline. If this is not possible for technical reasons, the main condition for correct installation is installation in the supply line up to the first shut-off valve.

- The outlet side pipe is usually connected to a sewer or drainage system, if it is technically difficult or the volume of the coolant in the circuit is not high, you can use a flexible hose, which is lowered into a container of a suitable volume.

- The liquid must be removed with a rupture of the jet through a funnel or a hydraulic seal to ensure the system is operational when the sewer is clogged.

- For installation in a pipeline, use a BOTTOM tee of a suitable diameter, the standard being 1/2, 3/4, 1 and 2 inches. The diameter of the pipeline inlet to the valve must not be less than that of the system.

Valve safety groups - varieties and price

Criterias of choice

The safety valve in the heating system performs a critical function - it prevents the boiler from boiling up and reduces the pressure that has risen to the limit values.

It is recommended to choose a spring device, while it is important to pay attention to the following points

:

- the range of values at which the valve is able to operate (selected in accordance with the parameters of the heating system);

- type of valve - open or closed (in the first case, the coolant is discharged into the atmosphere, in the second - into the return pipeline);

- lifting height of the plate (selected based on the throughput).

The selection of a pressure relief device is based on the technical characteristics of the heating system - the heat output of the boiler unit and the maximum pressure of the medium in the pipeline.

Mechanism

The emergency relief valve must operate in a timely manner, depending on the characteristics of its mechanism, the key elements of which are the stem, spring and poppet.

Safety valve device

The main characteristic of the valve is the percentage difference between the pressure in the pipeline at the moment the stem begins to move and the pressure when the passage is fully open to discharge excess coolant. This parameter also depends on the nominal pressure in the heating system. The response speed of the device depends on the operating pressure in the system - the higher it is, the faster the valve should open.

It is important that the adjustment mechanism does not come into contact with the coolant. The spring coils must not touch each other. If the valve is idle for a long time, the spring may "stick" - in this case, the device will not be able to work in time. A special stem for manual retraction of the spring makes it possible to check the valve's performance from time to time. The relief valve is also provided with frost protection.

Note! The valve opens fully when the pressure in the heating system rises by 10% of the set value, and fully closes when the pressure level drops by 20% relative to the response parameter. It is recommended to choose a model for installation, the response pressure of which exceeds the operating parameters of the heating system by 20-30%.

Pipeline supply

So that the hydraulic resistance does not affect the operation of the safety device, the valve diameter must match the diameter of the inlet pipe or be large.

Pipeline supply option

Attention! To reduce hydraulic losses at the pressure of the coolant on the plate, the emergency valve is mounted with a slope towards the boiler unit.

Manufacturing material

For the manufacture of the case, brass is usually used, since this material is characterized by low thermal expansion, corrosion resistance, strength and an affordable price.

The regulating block is made of heat-resistant plastic, which does not change its geometry and retains the required rigidity even under the influence of the heating agent brought to a boil.

Why the valve can leak

The pressure relief valve in the heating system can leak for various reasons. In some situations, this is an acceptable natural process, in other cases, a leak indicates a malfunction of the device.

Leakage of the protection valve can be caused by the following reasons:

- Damage to the sealed rubber cup, disc as a result of repeated use. If during repair the replacement part cannot be found on sale or it is not included in the package, you will have to change the device completely.

- In spring types, the opening of the side drain pipe occurs gradually, with boundary pressure values or short-term surges, the valve may partially work and drip, which does not indicate a malfunction.

- Leakage can be caused by incorrect settings or malfunctions of the expansion tank - damage to its membrane, air escaping through a depressurized housing or a damaged nipple. In this case, sudden pressure surges are possible as a result of water hammer, causing periodic short-term flow of the coolant through the safety valve.

- Some adjustable valves are leaking because fluid seeps down the stem from the top during actuation.

- If a back pressure is created at the branch pipe above the instrument response threshold, a leak also occurs.

Appearance, cost of some brands of drain valves

The safety valve of steam boilers is designed to protect them from overpressure in the system caused by various factors, and is an indispensable element in the operation of this type of equipment. A wide range of safety devices from Chinese, domestic and European manufacturers are available for sale at a relatively low cost. When buying, it is rational to choose a protective group from several devices, which additionally include a pressure gauge and an air bleed valve.

Types of emergency valves

Various types of emergency devices for boilers are produced, which differ

:

- By the mechanism of the plate clamping:

- spring;

- lever-cargo.

- Lift height of the locking mechanism:

- low-lifting (the height of the plate lifting does not exceed 5% of the diameter of the saddle, the devices are intended only for systems filled with liquid);

- full-lift (the shutter rises high, allowing a large volume of medium to be discharged; the device is suitable for systems designed to transport liquid and vapor).

- By response speed:

- proportional (the gate opens smoothly, in accordance with the increase in pressure in the pipeline, closing does not cause a water hammer);

- two-position (they open abruptly and are able to discharge a large volume of the medium, due to a sharp closure they provoke a water hammer).

Spring type valves

A spring-loaded safety valve for heating is the most common option, designed for operation as part of autonomous heating systems. Differs in simple design and reliability. The spool stem is pressed with a spring, the clamping force depends on the degree of its compression. A regulating mechanism is provided for setting the parameters of the emergency device actuation.

Spring Type Safety Valve

Lever-weight valves

The lever-cargo pressure relief valve is intended for use on pipelines with a diameter of at least 200 mm and is rarely used for heating systems in private houses where a boiler serves as a heat source. In such devices, a weight is used to reinforce the rod. To set the pressure level at which the valve should operate, the adjustment is made by changing the weight of the weight on the device lever.

Lever-weight valve