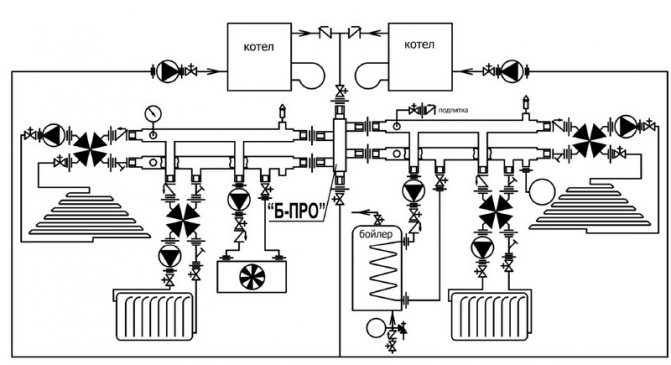

Implemented standard solutions (main heating system + backup):

• with a gas boiler;

• with a gas boiler and with a backup electric boiler;

• with wood / coal boiler;

• with a wood / coal boiler and with a backup electric boiler;

• with a gas boiler and with a reserve solid fuel boiler.

Building a system solely on an electric boiler is economically impractical. Especially if the private house is large enough (from 100 sq.m. and more). Utility bills may be too high. If gas is unavailable, we recommend installing a solid fuel boiler and an electric one as a backup.

Heating system with gas boiler:

The most common solution in home heating is to use gas boiler

... Since this equipment is the most profitable to operate.

Parapet gas boilers Danko are single-circuit boilers and boilers with the function of heating water for domestic needs. Due to the fact that these are chimneyless boilers, they can be used in houses and apartments where it is not possible to connect to a chimney. gas boilers (https://danko.pp.ua/) of this series are designed to heat a room up to 140 sq.m. The boilers are equipped with modern Honeywell and SIT gas automatics with piezoelectric ignition and microflame burners.

System calculation.

The boiler is selected at the rate of 100 W per 1 m² of a residential building plus 2 KW for hot water supply, excluding the costs of ventilation and the pool. This technique for determining the power of the boiler is approximate with an accuracy of 5%. But it allows you to determine the approximate prices for equipment.

For a more accurate determination of the boiler output, a heat calculation performed by a heating specialist is required based on the design, location and required internal temperature of the building.

The heated water enters the distribution manifold and further into the radiators located in the immediate vicinity of windows and outer walls. Knowing the area of the room, it is easy to determine the heat output of the radiators.

In rooms where heated floors are installed, radiators are not required to be installed, only in cases of redundancy and exclusion of condensation on the windows. Depending on the boiler, hot water can be produced by the boiler or heated in the boiler. Usually, a 200 liter boiler or hot water heated by a boiler is enough for 1 family. For an accurate calculation, you need to know how many people will live in the house and how many plumbing equipment is installed.

See also the section - Gas heating at home.

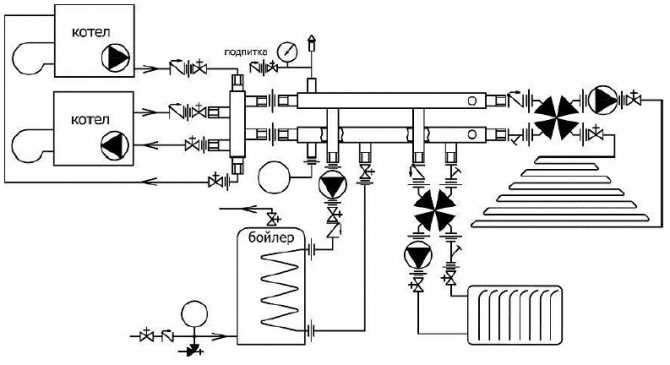

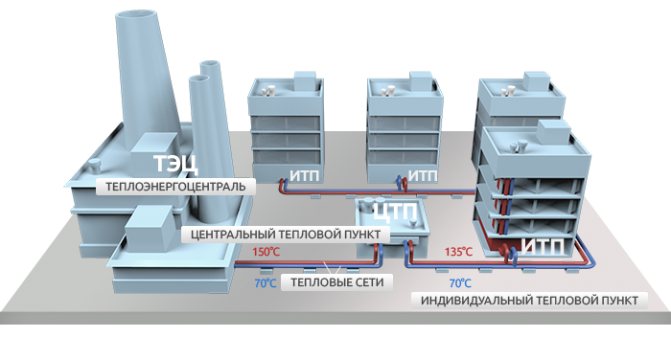

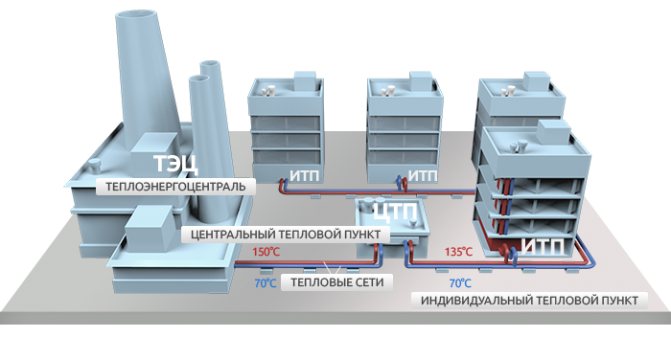

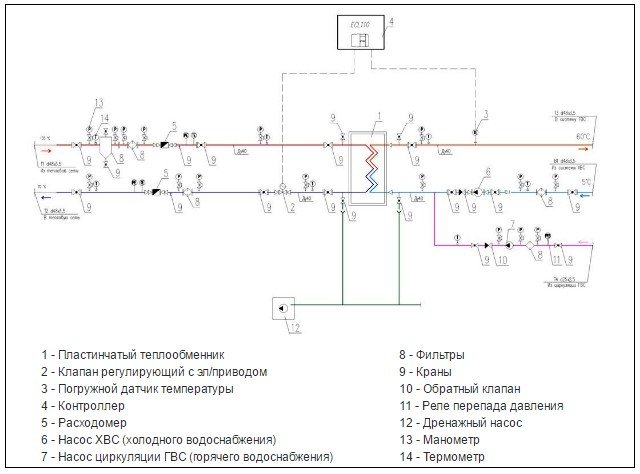

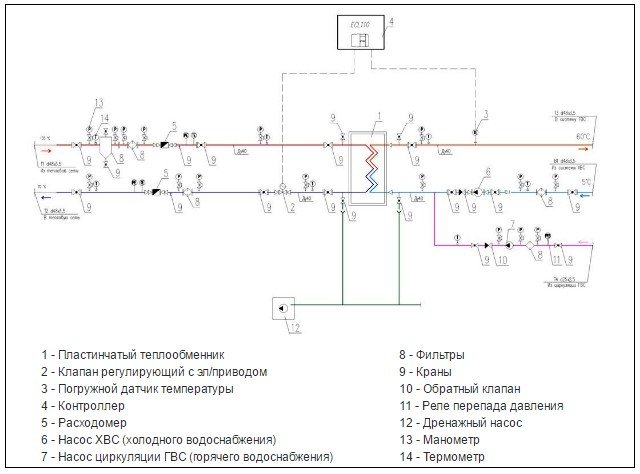

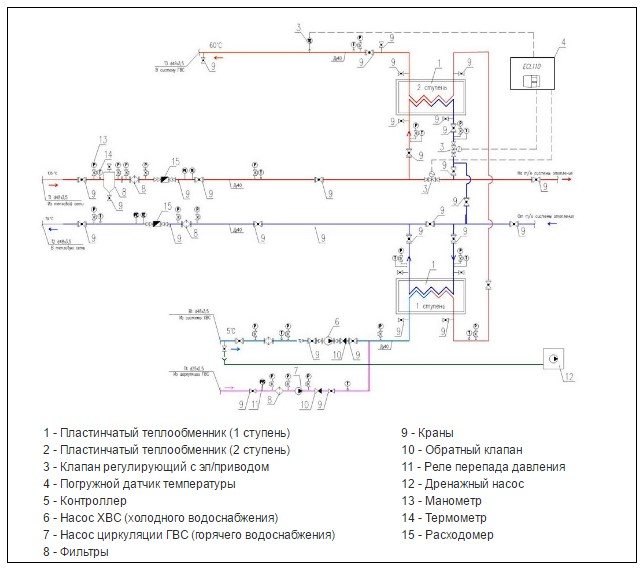

Why do you need a second heat exchanger in an ITP?

ITP is a set of equipment for one consumer (one building), necessary for converting the parameters of the internal systems of the building, as well as for adjusting, accounting and monitoring these parameters.

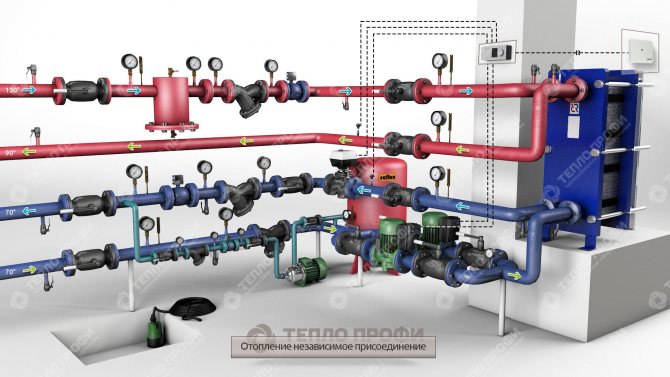

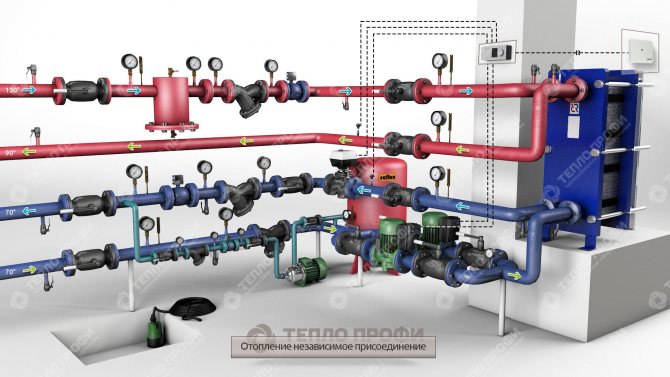

Any heat exchanger in an ITP is needed to separate the heating and heated medium. This can be a separation by temperatures, by operating (maximum possible in this system) pressures, by types of media, or all at once. ITP serves to connect internal engineering systems of a building (heating, hot water supply, ventilation) to external heating networks from a heat source (boiler room or CHP). Connecting the consumer to heating networks through a heat exchanger is called independent.

For example, for a hot water supply system, a heat exchanger is required. Because heating (network) water is always supplied with a high temperature, in order to transfer the greatest amount of heat at the lowest flow rate.And the temperature in the hot water supply system is regulated by sanitary standards and should be in the range from 60 ° C to 70 ° C. Heating below 60 ° C can promote the development of E. coli in water, while at temperatures above 60 ° C, it dies within 15 minutes. Heating water above 70 ° C can cause burns.

But the connection of the heating system can be carried out without a heat exchanger: in old buildings through an elevator unit, and in newer ones - using mixing pumps. With an independent connection of the heating system, the heat exchanger separates the heating network circuit and the internal circuit of the building heating system in all parameters: by temperature, pressure, and sometimes (mainly for cottages, as well as for rooms with the possibility of switching heating to standby mode with minimal heat input - production workshops or warehouses) and the heat carrier (water or antifreeze liquid).

The temperature in the heating system should not rise above 95 ° C for steel pipes, and 80 ° C for polyethylene pipes. This is necessary to increase the service life of pipelines, heating devices and fittings, as well as to avoid burns during the operation of the system. The operating pressure in the heating system is usually lower than in the heating network. This pressure is equal to the maximum pressure that the most vulnerable element of the heating system can withstand. Most often, the most vulnerable are heating devices or plastic pipe connections. For example, cast iron radiators maintain a pressure of up to 9 atmospheres, while in heating networks the operating pressure is 16 atmospheres. The heat exchanger can withstand pressures up to 25 atmospheres and serve as a reliable separator for the heating system circuit and the heating network.

The connection of the heat supply of the ventilation system to the heating networks is most often carried out in a dependent manner, without a heat exchanger. Since in the heat supply of ventilation steel pipes are mainly used and they are located in such a place where their possibility of interaction with a person is minimized, burns in people and thermal destruction of pipes are excluded. And the high temperature of the coolant, on the contrary, allows you to reduce the heating time of the outside air. A heat exchanger in such a system is used when an antifreeze liquid - ethylene glycol or propylene glycol - must circulate in the ventilation system.

Also, heat exchangers are often used in various technological processes to separate two or more media: food industry (pasteurization of milk or beer), metallurgical industry (cooling of oil for quenching parts), chemical industry, as well as in processes related to refrigeration technology.

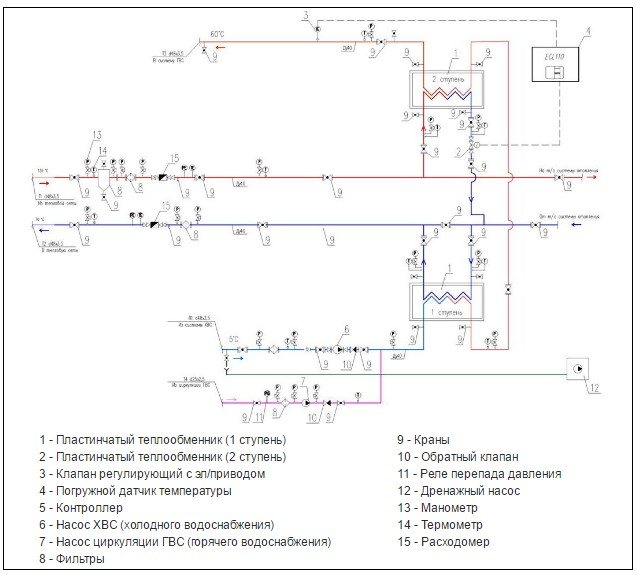

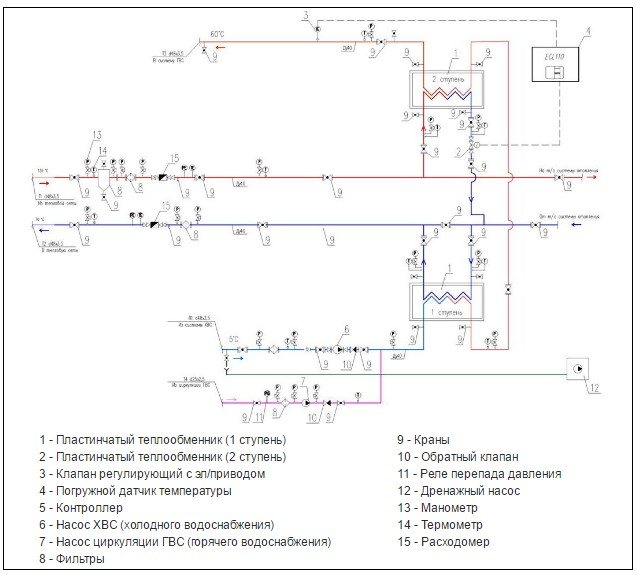

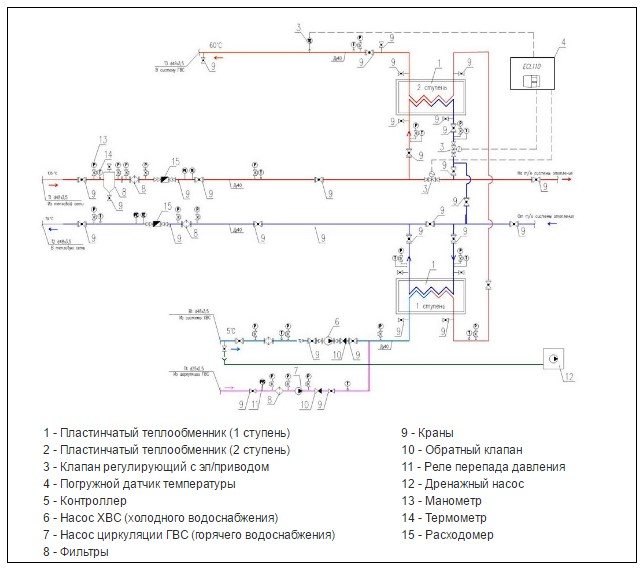

So if you saw two heat exchangers in an ITP, there may be a lot of options. But 90% of them are for hot water supply. Maybe both. Because the connection of the hot water supply system to the heating network is always carried out through a heat exchanger, and it can be one-stage or two-stage.

With a one-stage scheme, the connection occurs through one heat exchanger, and with a two-stage scheme, respectively, after two. The choice of a hot water supply system connection scheme is determined by the ratio of the heat load on the heating system to the heat load on the hot water supply system (this ratio is the technical justification for the application of a particular scheme).

The two-stage scheme, in turn, is divided into two-stage sequential and two-stage mixed. In comparison with the one-stage scheme, both two-stage ones are the most economically profitable for the consumer, but they cannot be used without technical justification.

Two-stage mixed scheme

Two-stage sequential scheme

In the heating system, two heat exchangers can be in the case when the heat load is too large (then it is divided into two simultaneously operating heat exchangers), or when it is necessary to reserve the heat exchanger (at facilities that do not allow interruptions in heat supply - hospitals, maternity hospitals, preschool institutions).

For multi-apartment residential buildings built before the 2000s, dependent heating systems with mixing nodes and two-stage connection schemes for hot water supply systems are most common. For multi-apartment residential buildings built after the 2000s, the heating system is connected independently - through a heat exchanger, and the hot water supply is also connected according to a two-stage scheme.

For administrative, public and industrial buildings, heating systems can be connected differently depending on the heat source. And the hot water supply system for these buildings is almost always single-stage.

We will be very happy if our article clarified the issue of having a second heat exchanger in the ITP. If you have any questions, you can ask our specialist, we will be happy to answer them!

Still have questions?

You can get expert advice by phone in your city. You can also send your question to our e-mail (we will answer within 30 minutes).

Share this post with friends:

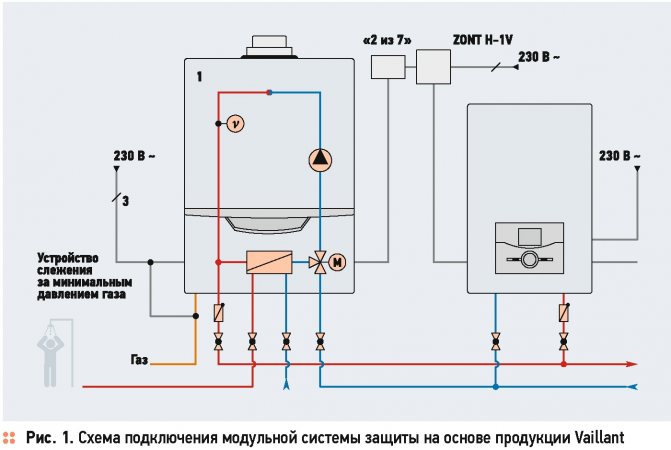

With a gas boiler with a backup electric boiler:

To eliminate problems with heating in cases of accidents on the gas distribution system, an electric boiler is installed as a backup heat source.

The electric boiler is selected based on the electricity limits allocated for the building. To accurately determine the power of the backup electric boiler, a calculation is required based on the expected duration of the accident and the temperature maintained in the building.

To install an electric boiler in a heating system with a gas boiler, additional equipment will be required to eliminate hydraulic problems.

Read more about electric boilers in the section: Electric heating.

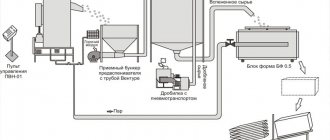

Heating system with wood / coal boiler:

The most common solution in the absence of gas is to use a solid fuel boiler.

For a house with an area of 100 square meters, the minimum tank capacity is 250 liters. For a more accurate calculation, you need to know the parameters of the wood boiler and the duration of fuel burning.

An electric heating element can be installed in the storage tank, which will maintain the temperature at a time when the solid fuel boiler is not in use. If there is an electric boiler, then it can be used instead of a ten.

See section: Heating with solid fuel

Reserve boiler in steam to diesel boiler

The best option for backing up heating on liquid fuel would be either a second diesel boiler or a solid fuel boiler, as well as a gas boiler powered by a gas train - several cylinders connected to supply gas to a heat generator.

The second diesel boiler will work if your main unit is out of order. The backup will be powered from the same capacity as the main heat generator.

If there are problems with the supply of diesel fuel or with the timely purchase and delivery of fuels, then a duplicate boiler on a different type of fuel will help out here.

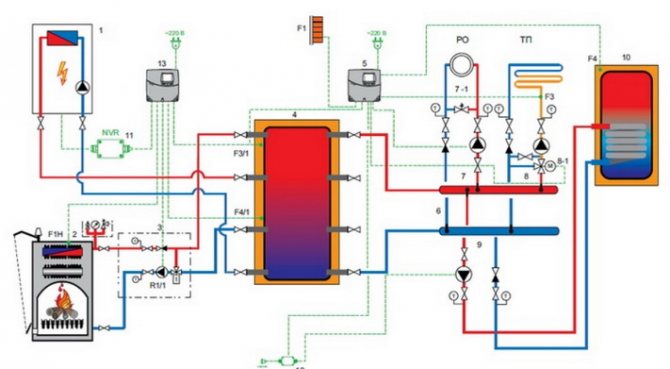

With a gas boiler with a reserve solid fuel boiler:

To eliminate problems with heating in cases of accidents on the gas distribution system, a solid fuel boiler is installed as a backup heat source, which is selected, just like a gas one.

To accurately determine the capacity of a solid fuel reserve boiler, a calculation is required based on the expected duration of the accident and the temperature maintained in the building.To install the boiler in a heating system with a gas boiler, additional equipment will be required to eliminate problems with hydraulics, overheating and long-term heat retention.

You can ask questions to our specialists by phone numbers listed in the Contacts section.

We install heating in private houses and cottages. We carry out design, selection and supply of equipment, installation. We guarantee high quality and reliability of systems.

Terkont Group of Companies Copying without reference to https://terkont.ru/ is prohibited

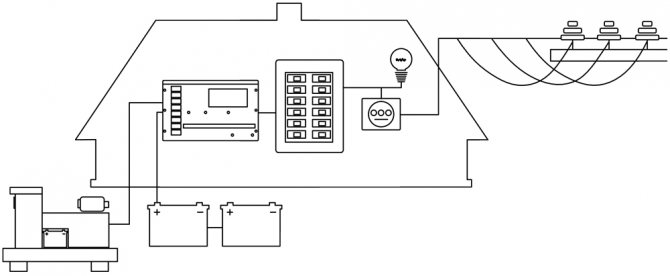

UPS models

PN-1000 energy is a powerful backup power source. Thanks to the built-in stabilizer, the device provides a nominal output voltage when the mains voltage changes within 120-275 volts. The waveform in the form of a smooth sine wave is ideal for supplying reactive inductive loads, such as the electric motor of a heating system pump. The PN-1000 energy together with the Delta DTM 12100L 100A / h accumulator provides uninterrupted power supply for the 150W heating pump for 8 hours. The device has a built-in line noise filter, information display and RS-232 interface.

You can find this and other voltage stabilizers for the heating system from the Energia company on the website of the official representative of the Energiya.ru company.

The compact emergency power supply Teplokom 222/500 is intended for use in heating gas systems. This simple device with a single-phase relay-type regulator allows operation with a load not exceeding 230 W.

The universal stabilizer Skat ST 1515 provides a voltage of 220 V with network fluctuations from 145 to 260 V and a frequency value of 50 Hz ± 1%. If the voltage exceeds the specified parameters, the load will be disconnected automatically.

Summing up

Based on the operational requirements for electric motors of heating pumps, the UPS must provide the following parameters:

- The voltage form is a smooth sinusoid;

- Power reserve - not less than 20%;

- Automatic load disconnection;

- Minimum switching time to reserve.

In addition, the device must operate in a certain temperature range, have a device for indicating modes and physical quantities.

Read with this:

Overview of voltage stabilizers for houses, apartments and cottages

Choosing an electronic voltage regulator: principle of operation and characteristics

Choosing a battery for a UPS: characteristics, features and types of batteries

Industrial voltage regulator: what are the criteria to make a choice?

Did you like the article? Share with your friends on social networks!