Home / Solid fuel boilers

Back to

Published: 27.02.

Reading time: 5 min

0

364

The blowing fan is mounted on a solid fuel boiler to optimize the combustion processes, which leads to an increase in the efficiency of the thermal circuit and fuel economy.

A fan for a solid fuel boiler can be made independently, which will allow the owner to save significant funds on the purchase of a factory analogue.

- 1 Purpose of the fan for the boiler

- 2 Design and principle of operation

- 3 Varieties 3.1 Electro-commutated motor

- 3.2 Synchronous motor

- 3.3 Asynchronous motor blowers

What is a fan for? Its main functions

A solid fuel boiler in the usual view is a heating device, where the main work is carried out due to the combustion of fuel. In the presence of draft and natural air flow, the intensity of combustion is weak, respectively, low heat transfer. An example is a fireplace. The natural flow of air does not allow the flame to flare up strongly in the firebox, therefore this heating device has limited technological capabilities.

It's quite another matter when the supercharger is turned on. An additional volume of air is pumped into the furnace of the heater. Combustion becomes intense, the fuel burns out completely, giving up the maximum amount of kilocalories.

Therefore, for modern models of solid fuel boilers, of almost all types and types, the fan is one of the most important elements of the control system. Usually, the set of automatic heating devices today includes a blower, a smoke exhauster and a control unit. Competent and correct installation of such devices and devices on the boiler equipment will provide your unit with reliable and balanced operation.

On a note: the combustion process is 90% dependent on the operation of the blower. Thanks to the action of this device, air is injected into the combustion chamber, the combustion intensity increases, and the efficiency of the heating equipment increases accordingly.

Today, domestic and foreign industry produces a huge number of household fans (coolers), specially designed for installation on heating devices. When choosing a blower for your unit, you need to focus on the power of the boiler and your own, everyday needs. A solid fuel unit with a fan is a high-tech and efficient heating machine. All processes, from the extraction of flue gases to the best performance of the combustion chamber, depend on the operation of the fans.

Device device and types of fans

According to their functional characteristics and parameters, fans are divided into three types, each of which is determined by the design of the engine. The electric motors used for these purposes can operate on both alternating and direct current. The advent of electronic equipment created the preconditions for the active use of AC motors. Unlike DC motors, AC motors have virtually no disadvantages. The simple and unpretentious design of electric motors has made it possible to establish mass production of a wide variety of electromechanical devices. Most of the fans are equipped with just such electric motors.

The following types of fans can be found on the market today:

- devices in electrically commutated motors (EC);

- products equipped with synchronous motors;

- asynchronous motor blowers.

All products have their own clear advantages and disadvantages. In the case of an electrically commutated motor, we can talk about one quality. The device itself is capable of changing the number of revolutions, receiving a corresponding signal from the control unit. Here we can talk about a wide range of fan operation control. However, the device has a significant drawback - the device is not compatible with most domestic temperature controllers. In addition, this technique is expensive in price.

Speaking about fans with synchronous electric motors, we can focus on the following: the devices are quite cheap and easy to manufacture. However, this type of equipment has certain disadvantages. Such devices have a minimum torque during start, and a small range of speed control.

For reference: usually fans with synchronous motors are used to continuously pump air mass into the combustion chamber. Synchronous motors, which the devices are equipped with, are rather large in size. Typically, the blower motor is housed in a separate unit. When operating at low speeds for synchronous motors, overheating of the winding is frequent.

The latter, the third type of fans used in modern heating systems, has a number of advantages. The asynchronous electric motor makes it easy to adjust the number of revolutions. On some models, there is even a ravers. The main advantages of such a device are as follows:

- Such fans are simple and easy to use;

- They have a reliable design;

- Conventional control scheme;

- Supported by all currently available MRI.

The only drawback that induction motors have is their high starting currents.

Classification of solid fuel boilers

The market today offers the widest selection of models with a buffer tank, solid fuel boilers, both domestic and foreign. Components for solid fuel boilers are also widely represented. They can be used both for operation only for the heating system and for heating a boiler for domestic needs.

- by the material from which they are made:

- steel - products are much cheaper than cast iron boilers, easier to clean and maintain. But they are very sensitive to the temperature value in the return circuit (not lower than 60 degrees). Therefore, they require the installation of a block of special boiler valves, which are a kind of control element and maintain the required temperature in it by mixing the coolant from the supply line into the "brother";

- cast iron - more durable, but more difficult to maintain. Recommended only for continuous year-round use. As a backup unacceptable, too expensive;

- by the type of fuel used:

- peat, firewood, woodworking waste, derived from them, supplied in special briquettes;

- pellets (special granules resulting from the processing of needles, resin and other organic matter);

- coal;

- universal "all-fuel" equipment;

- by the implemented method of heat transfer:

- water boiler (most commonly used);

- steam boiler;

- air boiler;

- according to the principle underlying fuel combustion:

- traditional way;

- long burning - the latest developments and innovative solutions implemented in heating technology have been used. Structurally, they are designed in the form of a vertically elongated firebox (firebox) around which a water jacket is located, with a control unit.

What is long burning

The specificity of the principle of long burning is that the fuel burns from top to bottom (analogue of a candle), which ensures more complete combustion and increases the burning time of each bookmark. In some models with a buffer capacity, it can reach almost seven days. At the same time, a decent efficiency, high and stable temperature of the water in the boiler, which plays the role of a heat carrier, is ensured.

To ensure safe and uninterrupted operation, the boilers of these blocks of systems have smoke exhausters, special fans for a solid fuel boiler intended for emergency extinguishing, a circulation pump built into the heating system and safety valves (and accessories for them), as well as control units.

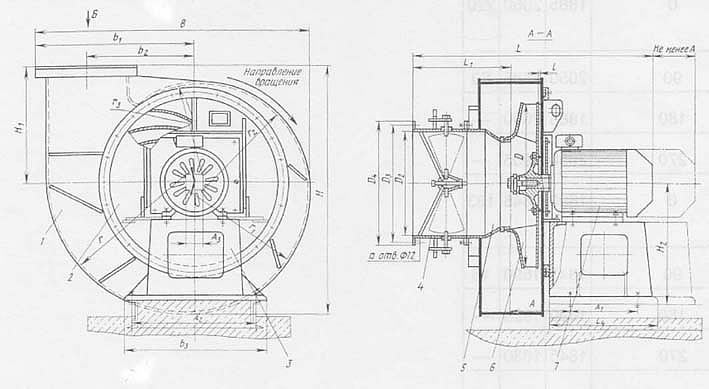

Fig. 2 Centrifugal smoke exhauster

All boilers of this type have pre-installed automation, which also includes a fan for a solid fuel boiler. This means that they need a source of electricity.

Fig. 3 Household smoke exhauster

In order to understand what kind of components with a fan you may need for a medium or overhaul of an installed boiler with a factory-made fan, or for its self-production, you need to have an idea of its structure and the principles underlying its work.

When you need a smoke exhauster

Manufacturers of heating equipment complete their products with traction fans due to the increased resistance of the heat exchanger, where the gases change their direction of movement through the flame tubes several times. The goal is to select the maximum heat from the combustion products and increase the efficiency of the boiler plant.

Nuance: the operation of the smoke exhauster in the factory-equipped boiler is coordinated with the combustion process and is controlled by an electronic unit. When installing the fan unit on a "brainless" heater, such consistency is excluded, you need to buy an automation unit or adjust the speed manually.

Organize supply ventilation in the boiler room, and only then think about purchasing a smoke exhauster

We list the situations when the smoke exhauster will help to improve the operation and maintenance of a solid fuel heat generator:

- traction problems - blowing out by the wind, air locks in the gas duct, many turns, narrowing of the diameter;

- due to the design features, the boiler smokes into the room when the door is opened;

- the height of the chimney is insufficient, or the cut of the chimney fell into the zone of the wind support behind the ridge of the roof or other building;

- cracks appeared in the brick chimney, from where smoke seeped.

An important point. Not a single fan will save the day if there is no inflow from the street in the boiler room. At first, a working impeller will create a slight vacuum, but then the blades will begin to mix the air in place. Supply ventilation is a prerequisite for the normal operation of any heater.

Some designs of wood-fired boilers (for example, shaft type) tend to emit smoke through an open loading hatch.A similar picture is observed in heat generators with a three-way high-resistance fire-tube heat exchanger. The solution to the problem is to install a traction or blowing machine controlled by a controller.

Strengthening natural draft with the help of a smoke exhauster also has a downside. If, after warming up the pipe, the natural exhaust has not recovered, the unit cannot be turned off - you can burn out. Now imagine that the power supply is cut off in the middle of the night, the fan stops. While the chain thermostat closes the damper, smoke will fill the boiler room.

Recommendation. The smoke exhauster should not be a panacea. Be sure to take measures to restore traction - repair or alter the flue according to the requirements specified in the boiler manual.

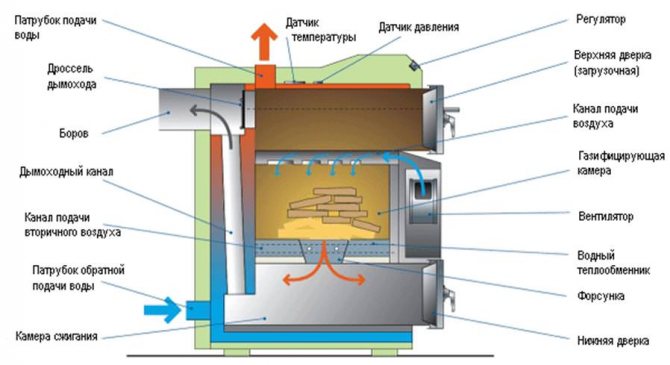

Solid fuel boiler device

Firebox

It is the main element of any component equipment that performs a dual function: a heat exchanger and a combustion chamber.

Detailing its design, it should be noted that the product has:

- exhaust fan opening, providing air access to the combustion site;

- ash pan;

- grate grate;

- domed upper part of the smoke exhauster (for collection and subsequent removal of gases and combustion products that are in the volatile stage);

- a portal through which fuel is supplied.

Combustion in the furnace, solid fuel heats up the walls of the equipment with a fan and heats the water to a high temperature, which is in the water jacket of the boiler with a buffer tank. For better performance, it is often equipped with a smoke exhauster.

Water jacket

In almost all models of solid fuel equipment with a fan, the shirt is located between the double walls of the firebox. The water acting as a heat carrier (in the overwhelming majority of cases), passing through the jacket, takes heat from the firebox, thereby protecting it from overheating, and carries it to the heating system. Hot water leaves the jacket through the nozzles of its upper part, and cooled down in the system enters the jacket through the lower nozzles.

Solid fuel equipment with a fan is capable of operating when the coolant moves along the heating system lines by gravity (the so-called open systems). Although technically it is possible to equip boilers with circulation blocks and pumps of various capacities and capacities (in this case, you always need to have the necessary components for them). The presence of system blocks significantly increases the heat transfer of the unit.

Despite this, open systems with a fan are in high demand, as they are independent of external power supplies, economical and very reliable. Equipment with a buffer tank equipped with a fan, used not only for heating the premises, but also for providing consumers with hot water, have boilers connected to them and must be equipped with a control unit.

Gas removal system

A lot of smoke is generated inside a boiler with a fan during the combustion process. Therefore, if you do not provide it with a properly working smoke exhauster, all this will get inside the room. As a rule, the role of a chimney is performed by heat-insulated pipes that remove combustion products outside the building. Smoke exhausters and / or a fan for a solid fuel boiler are often installed here.

Temperature control and monitoring unit system

A constant supply of fresh air by the smoke exhauster to the combustion site is a prerequisite for any combustion process. The more air flow, the more intense combustion can be achieved.

That is why, the design of any solid fuel equipment necessarily has mechanical gates and dampers used to regulate the air supply (and components for their prompt repair and replacement). Smoke exhausters are often installed.

Fig. 6 UPS for solid fuel boiler

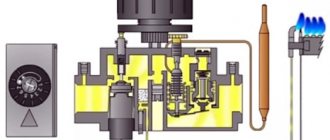

Control unit systems based on the use of such control methods are simple and very reliable. The smoke exhauster damper is specially fixed on the regulator. When the set temperature is significantly exceeded, the walls of the regulator expand, which leads to a lowering of the damper (the flow area of the supply air duct decreases), which contributes to the cooling of the furnace and protects it from overheating.

During the reverse process, the walls of the regulator, respectively, are compressed and initiate the rise of the damper. The burning intensity increases again.

Despite the very venerable age of this technical solution, it still remains one of the most effective and efficient. Therefore, it is implemented in the vast majority of models of solid fuel boilers. Although new models often have special systems and a control unit for them.

Technical characteristics and calculation of parameters

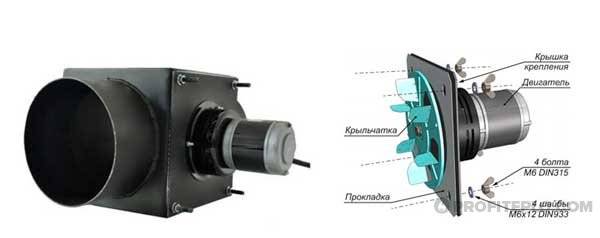

The design of any smoke exhauster for household solid fuel boilers looks like this:

- Impeller housing or casing made of heat-resistant steel with a thickness of at least 1.5-2 mm;

- AC motor, usually located outside the enclosure. This placement guarantees its stable operation, while the motors installed in the chimney itself fail faster;

- The shaft that connects the impeller to the motor. Mounted on bearings and can have hermetic seals to eliminate smoke leakage;

- Inlet and outlet nozzles and outlet dampers;

- A special bunker in which ash and large unburned fuel particles will settle;

- The impeller or impeller is the main element of the circulation pump, made of alloy steel. Withstands temperatures of 250-300C and aggressive environment of hot exhaust gases. Must be well balanced and high performance. There are vane and centrifugal impellers.

The smoke exhauster for a solid fuel boiler has the following parameters:

- electric motor power,

- productivity (cubic meters per hour),

- generated pressure.

All these characteristics can be found in the instruction manual for a specific model.

For the correct calculation of the hood, we will also need to know the fuel consumption per hour, the cross-section of the gas-air duct channels and the amount of air for its complete combustion. The following indicators are calculated by the formulas:

- The actual volume of combustion products passing through the chimney;

- The maximum pressure developing by the device, taking into account the height of the chimney;

- Electric motor power;

These data can be taken in reference books or SNiP, as well as catalogs of equipment sold.

It is advisable to purchase a smoke exhauster with a margin for all indicators.

What components and assemblies may be required for self-manufacturing of the boiler or its repair

Components for solid fuel boilers have varying degrees of demand. Some are guaranteed to serve until the boiler is decommissioned. The latter have a certain resource. It is about the latter that will be discussed below.

First of all, it is required to provide guaranteed, protection of the solid fuel boiler from overheating. In this case, it is necessary to take into account the inertia of fuel combustion inherent in solid fuel boilers, the presence of which excludes the possibility of a safe shutdown of the entire control unit system until the fuel is completely burned out. You cannot stop the process of burning wood or coal, you can only reduce the intensity of combustion. This is what determines the need for mandatory protection against possible overheating.

Protection of a solid fuel boiler from overheating is carried out by using the following technical solutions:

a. cooling heat exchanger

Through the installed thermal valve, which is a control element, the cold coolant is supplied to this product, which does not lose its performance almost to 95 degrees above zero. When the equipment warms up to the set limit temperature, the thermal valve is triggered and the coolant is redirected to the heat exchanger, where it is quickly cooled by the fan to the permitted level. The cycle is repeated until the water temperature drops to +60 degrees.

Fig. 7 UPS for boilers

The heat exchanger can be structurally built into the boiler, or mounted between the heating system and the outlet of the water heater. The use of this method initially provides for the presence of an irreducible required supply of cold coolant. In the event of an emergency shutdown of the unit without such a protection system, it may fail due to overheating. That is why it is very important to make sure of the quality of all components.

b. switching valve

The shut-off (aka changeover) valve (control element) is used to cut off (block) the water supply when the boiler overheats. As soon as the temperature of the coolant in the system exceeds the permitted one, it is drained into the sewer. At the same time, cold tap water is supplied to the boiler. In order for it to be guaranteed to enter the supply pipe system, it must be supplied at a certain pressure (up to 3 bar).

Automation for solid fuel boilers

This group of equipment with a fan combines control units and fans. Currently, you can select both the first and the second with the parameters required for your boiler. Thanks to the buffer capacity, namely the indicated structural elements in the heating system, it is possible to maintain a given temperature without the constant presence of a person.

Control block

Thanks to the use of a solid fuel boiler control unit, the heating control system in your home can be fully operated in automatic mode. At the same time, the set temperature is maintained in the system with a buffer tank.

The solid fuel boiler control unit is selected taking into account the brand of the product you have installed and monitors the correct functioning of the fan and the built-in circulation pump (if the latter is available).

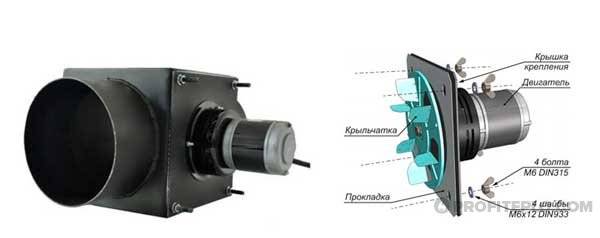

Fans

A fan for a solid fuel boiler is the second most important device used to automate a boiler control system with a fan. Some fan models are called turbines. They pump air into the combustion chamber (into the furnace) of the boiler and are used to ventilate the used technological equipment with a buffer tank, different rooms, and to stabilize the temperature.

Draft regulators

This is the third group of products with a fan related to the means of automating a solid fuel boiler. Nonvolatile draft regulators in their traditional design are widely used in solid fuel equipment. They are easy to install. They are easy to operate. They are reliable and affordable.

These devices with a buffer tank are used to adjust the temperature of the water (another heat carrier) circulating in the heating system, which is carried out by changing the position of the damper depending on the required temperature. Accordingly, the supply of air to the combustion site increases or decreases. This affects the speed and intensity of combustion, and through this, the temperature of the coolant in the line.

The use of such regulators with a buffer tank makes it possible to increase the efficiency of boilers by 15 - 20 percent.

Element design

The smoke exhauster device is as follows

:

- A casing or housing in which air flows.

- The impeller, formed by two plates, is an active movable element, the rotation of which leads to forced air injection.

- Drive shaft, impeller, hopper, damper, branch pipes.

Depending on the specific model of the exhauster, the set of parts, their structure and materials of manufacture may differ.

Smoke exhauster design

At the same time, the basic principle of operation of this equipment is always observed.

:

- As a result of the rotation of the impeller, air tends to the center of the exhauster.

- There it is thrown by the walls of the structure, falling into the boiler furnace.

- Further, a gradual rarefaction occurs, as a result of which the inflow of air masses is carried out.

For the vortex movement of the air flow in the direction of rotation of the fan, the blades inside the exhauster are responsible. This ensures continuous circulation of air flows: oxygen supply, exhaust of combustion products.

When choosing a device, it is important to pay attention to such parameters as efficiency, productivity, power (W), pressure. All information must be indicated on the device itself

Uninterruptible Power Supplies (UPS)

The source of a UPS (uninterruptible power supply) for equipment operating on solid fuels, otherwise called an uninterruptible power supply, is selected taking into account the total electrical power required for it.

In the simplest version, when the version of the installed boiler has manual fuel loading, the oxygen supply to the combustion site is regulated by mechanical rotation of the blower door, and the system operates due to the temperature difference between the supply and return heat carrier, only the energy consumption of the circulation pump will be considered. In this case, the power of an uninterruptible boiler for a solid fuel boiler is calculated taking into account the number of pumps, their power, the likelihood of simultaneous switching on, etc.

This is the first component of the assessment. The second is due to the fact that in case of a possible prolonged power failure from the external network, an uninterruptible power supply for a solid fuel boiler (UPS) must guarantee the operation of the boiler during the entire shutdown period, which can be several hours.

Taking into account all of the above, the uninterruptible power supply of the following models is considered the most acceptable for solid fuel boilers:

- uninterruptible power supply line-interactive (for example - INELT Intelligent 500LT2) with one or two batteries;

- UPS with double conversion (East EA910 LCDH type).

Features of blower fans

Blowing fans are made of left or right rotation, in the abbreviation this is indicated by the abbreviation Лв. or Ex. Right - rotation of the wheel clockwise, looking from the engine side. The volute can be installed at a turning angle of 0 - 270 degrees in 15-degree increments. At the same time, the ribs are mechanically cut, preventing installation in the desired position. For servicing the impellers in the wall of the fan casing, there are special holes in the volute - hatches. There is a condensate drain plug at the bottom of the volute.

In blower fans of execution according to scheme 5 and 3, bearings of a large standard size are installed on the side of the impeller hub, which increases the reliability and durability of the unit. To improve maintainability, the bearing assembly is made split, while the replacement of the bearing in the housing can be performed without removing the impeller. The bearings are lubricated through an oil bath. In smoke exhausters of standard size more than 9, a water oil cooling coil can be installed.

The complete set with a guide vanes and a two-speed motor allows to increase the energy efficiency of the unit.