Gas prospects

The use of gas for heating houses and apartments is one of the most promising trends in the development of engineering communications today. Boiler equipment manufacturers have offered so many options that you can choose the right unit for absolutely any room. An example is the BAXI boilers.

Gas boilers BAXI can be installed in any room. They are suitable both for installation in apartments and for heating a large country house. Naturally, the room where the mini-boiler room is installed must meet the existing requirements:

- The room must be at least 15 cubic meters in volume.

- Ceiling height - at least 2.2 meters.

- Good ventilation, capable of providing three times air exchange.

The existing requirements for the organization of the chimney can be disregarded if you choose a BAXI boiler with a closed combustion chamber for heating your home. Such a unit is a full-fledged mini-boiler room that has all the necessary elements and does not harm the ecology of the house. The models of this manufacturer differ in power indicators, so that BAXI boiler units can be used for heating and supplying hot water to a wide variety of premises.

Main characteristic

Heating system manufacturers can offer a huge selection of different models for home and industrial premises. One of the best options is Baksi gas boilers. This equipment can be used both in country houses and in a city apartment.

However, before installation, you need to make sure that the room meets the following criteria:

- The size of the heated room must be at least 15 m³.

- The ceiling height is not less than 2.2 meters.

- Good ventilation is essential.

In this video you will find out the causes of errors in the Baksi boiler:

When operating Baksi equipment with a closed combustion chamber, these rules can be disregarded. Such a system includes all the necessary elements and does not pose any harm to the environment. The model range of this manufacturer differs in terms of power, thanks to which the devices can be used for heating and supplying hot water in various types of premises.

The following models of Baxi boilers are very popular: Main 5 (Main 5), Main Four 24 F (Main Four 24F), Luna 3 (Luna 3). These units have many positive reviews and are distinguished by a good price-quality ratio in comparison with systems from other manufacturers (for example, Alfa Color).

Installation features

Baksi equipment uses gas as a fuel, which, with all its advantages, is dangerous. The installation of such a heating system requires a professional approach. Even the slightest mistake can lead to very unpleasant consequences, so only qualified specialists should install the equipment.

It is worth repairing such boilers to professionals, because serious problems may arise.

Here is just a small list of problems that can arise with the intervention of a layman:

- The ingress of carbon monoxide into the airspace of the house.

- Explosion occurs.

- Combustion.

- Freezing of the system in the winter season.

If we consider less serious consequences, independent installation of the boiler can lead to improper functioning of the equipment. The device may not start and display an error.

The units of this manufacturer are volatile. They are unable to function without a source of electricity.The connection rules are quite simple. The device is connected to a 220 V network, grounding is required. It is also best to consult a professional for this procedure.

Lack of grounding will not lead to disastrous results, but it will affect the performance of the system. Very often, the boiler can issue error codes for this reason. If at the moment there is no way to ground the device, you need to install a stabilizer with galvanic isolation.

Important nuances

In addition to grounding, other factors must be taken into account when installing the equipment. Consider the following:

- In order for the boiler to function properly, 170-250 V is required. At a lower voltage, the device will turn off, and at a higher voltage, the varistor will burn out.

- The equipment is very sensitive to voltage surges. Professionals advise installing additional voltage stabilizing devices. It is not necessary to use a UPS when installing gas boilers.

- The connection must be made through a separate functionality.

- For phase-dependent varieties, the phase and zero must be observed.

It is required to supply sufficient power for the boiler to function normally

Installation nuances

At first glance, the installation of the appliance, especially the indoor wall models, may seem very simple. In practice, this is not entirely true. BAXI boilers use gas as a fuel, and it, with all its undoubted advantages, remains dangerous. Gas equipment requires a professional attitude. One, even the smallest installation error can lead to serious consequences. The equipment should only be installed by qualified personnel with the required access.

Even a short list of the consequences of tampering with gas equipment looks daunting. The most frequent ones are:

- Freezing of the system in winter.

- Explosions.

- Fires.

- The release of carbon monoxide into the air of residential premises.

Front panel display

Of course, BAXI boilers, like any modern gas equipment, are equipped with security systems, but even automation cannot always cope with mistakes made by a non-professional. If we talk about less tragic consequences, the main problem of self-installation is the incorrect operation of the boiler. For example, the equipment does not turn on and issues error codes, despite the fact that all elements are in working order.

Gas boilers BAXI - volatile equipment. They cannot work without being connected to the mains. The connection requirements are very simple, do not differ from the rules for the installation of conventional electrical household equipment... The unit is connected to a 220V network, and must be grounded... It is also better to entrust the grounding to specialists. Even if the lack of grounding does not lead to serious consequences, it can affect the functionality of the equipment. Often, the device gives out error codes and the burner does not light up due to trivial errors in the electrical connection.

In the event that there is no possibility to fully ground the equipment (there are also such cases), it is necessary to install a stabilizer that provides galvanic isolation. In some cases, the potential can pass through the gas pipe. This situation is already becoming dangerous, and the connection must be made through a special adapter with dielectric properties.

A little more about electricity

In addition to the need for grounding, there are other nuances when connecting boilers:

Baxi luna 3 comfort 240 fi

- Gas boiler equipment provides stable operation in the range of 170-250 V. When the voltage drops, the boiler turns off, when the voltage rises, the varistor burns out.

- The sine wave in the mains must be free of interference. Such devices do not tolerate power surges well.Experts recommend connecting additional voltage stabilizers. It is not necessary to use UPS for installation of gas heaters.

- The connection must have a separate machine.

- For phase-dependent models, it is important to ensure that zero and phase are matched.

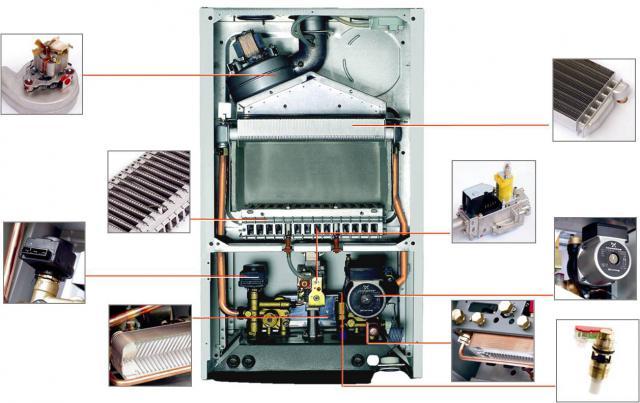

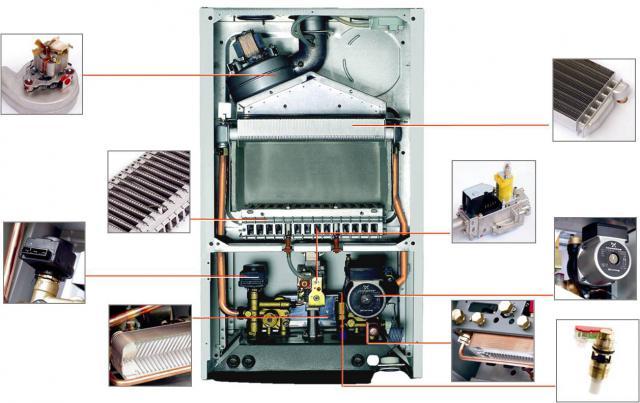

Electronics

The heart of the boiler is sophisticated electronics. It is she who ensures the normal operation of the device and turns it off in the event of a malfunction. The automation will inform the owner of the problem by displaying an error code. These alphanumeric codes are essentially a description of the problem. They talk about what is disturbed in the operation of the unit, and how the situation can be corrected.

Before talking about the most common error codes, it is worth recalling that self-intervention and repair attempts are not the best solution. Troubleshooting without specialist intervention is permissible only within the limits limited by the manufacturer's instructions.

Why does the pressure in the boiler drop

The main reason for the pressure drop is a coolant leak.

There may be various reasons involved:

- The boiler relief valve or one of the system radiators is open... If this happens, the coolant is constantly removed from the system, which causes a drop in pressure. The solution to the problem is obvious - turn off the tap, or repair it.

- A leak has appeared, into which the coolant leaves... This case is much more difficult, since it is not possible to detect a leak immediately. Sometimes it is only found by wet spots on the floor or on the ceiling of neighbors. The detected leak is immediately eliminated by changing the pipeline or the problematic radiator.

- Failure of the expansion tank diaphragm. In such a situation, the pressure drop continues only until the entire volume of the tank is completely filled with liquid. After that, the pressure stabilizes for a short time, and then begins to rise to a critical value. According to these signs, the problem is usually determined. The solution is to replace the expansion tank (or repair if possible).

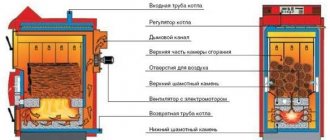

Automation

Automation for boiler equipment is very diverse. Some of it is pre-installed by the manufacturer. This category includes all sensors and electronic devices that ensure the safe operation of the equipment.

The simplest example is a sensor that monitors normal gas flow. When the gas is turned off, the sensor is triggered, the boiler is automatically turned off. Restarting will take place after the gas supply is resumed.

Systems ensuring operational safety also include:

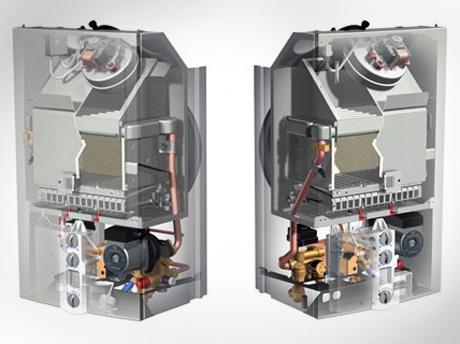

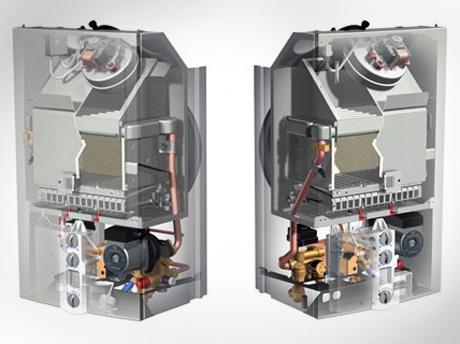

Boiler device

- Frost protection (starts to work if the temperature outside is below 5 degrees).

- Protection against blockage of circulation pumping equipment.

- Protection against blockage of the three-way mixing valve in the event of prolonged downtime.

- Protection against limescale build-up in the heat exchanger and boiler.

- Overheat protection.

- Voltage protection in the mains.

- Parasitic flame control.

- Combustion and draft control.

- Coolant pressure control.

In addition to the pre-installed automatic systems, additional electronics can be installed:

- Outside temperature sensor.

- Room temperature sensor.

- Thermostat.

- Electronic thermostat.

- Remote panels.

- Weather-dependent sensors.

- Elements for remote control.

- Water quality sensors, etc.

Solution of problems

Consider solutions to the most common problems:

- 01... This error was discussed above, it is a consequence of gas supply failures or incorrect power connection.

- 03... There is a problem with the smoke exhaust sensor or thermostat. Check the functionality and connection, in a difficult case, replace the sensor.

- 04... No standard load resistance at the terminals. Strip the contacts, check the connecting wires.

- 10... The heating circuit pressure has dropped. The error indicates a lack of coolant, the need to recharge the system and eliminate leaks.

- 11... Fume pressure thermostat malfunction. Check the operation of the fan or the condition of the flue.

- 27... Low circulation rate. Check the condition of the circulation pump. Particular attention should be paid to the impeller blades, which are made of plastic and may fail.

- 28... Leakage in the DHW circuit. Check the taps, connections, inspect the water intake devices - perhaps a tap is left open somewhere. You should also pay attention to kitchen or plumbing fixtures connected to hot water supply - perhaps the cause of the leak lies in them.

- 31... Incompatibility or malfunction of the electronic control board. Here the fault can be either a software failure requiring a flashing of the board, or a purely mechanical malfunction, burnout of microcircuits due to a voltage surge, etc. Replacing the control board is an expensive procedure, so you should protect it from external influences as much as possible (install a voltage stabilizer).

IMPORTANT!

Some errors appear randomly due to power surges. Large fluctuations cause a series of errors on the display, which almost never repeat. To avoid such situations, you should immediately connect a power stabilizer (or better, an uninterruptible power supply).

Errors and their codes

Breakage of pneumorel

All error codes can be roughly divided into two groups:

- Complete blocking of equipment operation.

- Switching the device to standby mode.

A complete lockout in most cases will require a manual restart of the unit. It turns on in case of serious malfunctions that can bring danger to health and life of people.... Such failures include lack of traction, overheating of equipment, lack of gas supply, etc. In rare cases, the error can self-eliminate without human intervention, and the automation will turn on the device on its own.

Error E01

E01 is one of the most common mistakes. This code is displayed when the flame monitor is triggered. The reasons for the appearance of the failure can be:

- Lack of gas supply.

- Lack of correspondence between phase and zero in phase-dependent models.

- Lack of contact with the flame sensor.

- Malfunction or contamination of the sensor itself.

- Malfunctions in the ignition system.

- Failure of the gas valve, electronic board.

- Insufficient air supply for normal combustion.

- Insufficient gas pressure in the system.

Gas-burner

When the E01 code appears, you need to check the correctness of the sensor connection, the gas supply (often its absence is due to trivial reasons, for example, the gas valve is shut off). If these items are normal, you can press the R button for 2-3 seconds. If the actuation was accidental, the operation of the equipment is normalized. In case of repeated operations, contact the service center. Perhaps the problems with the E01 code are related to the electronics, and the intervention of a non-professional into it is fatal to the boiler.

Error E10

E10 is another common problem. Unlike error E01, it is associated with sensors that monitor the circulation of water in the system and the operation of pumping equipment. Automation will work in the following cases:

- Lowering the pressure of the coolant in the system.

- Lack of contact between the board and the pressure switch.

- Faulty pressure switch.

- Malfunction of the sensor of the pumping equipment.

- Pump malfunction.

- Clogged filter system in the heating circuit.

- Clogged heat exchanger.

Cause of error E10

It is also not always advisable to fix the E10 error on your own. Of course, if the pump does not work, the only way to solve the problem is to replace it, which can be done without the intervention of specialists. You can clean the filter system yourself. All other failures should be eliminated by a professional.

Errors E96, E97, E98

The appearance of errors E96, E97, E98 says only one thing - an urgent intervention of a specialist is required.Unlike other malfunctions (E01 or E10), intervention in the operation of the boiler in the event of such malfunctions is strictly not allowed. The prohibition of intervention is simply explained - these three codes appear when the electronic board is inoperative.

Codes of common errors in gas heating boilers

Anarchy reigns in the principles of coding errors in heating boilers - each manufacturer establishes its own rules for encrypting fault codes. It is generally accepted to use a combination of letters of the Latin alphabet and numbers from 0 to 9 for coding errors. Most often to interpret this or that code, it is enough to resort to the help of the technical documentation for the product. As a rule, it contains tables with the name of the error, the cause of the malfunction and a list of measures to be taken to eliminate it.

.

Problems with boilers usually arise against the background of untimely maintenance of components and assemblies, therefore, it is necessary to take it as a rule from time to time to arrange for the heating equipment a thorough check by the specialists involved. You should also contact them for all problems with boilers. Except for some elementary troubles that can be solved on their own.

In gas heating boilers, a gas burner requires close attention, since it is it that clogs up most often. It is also important to periodically clean the inner surfaces of the working chambers from contamination and maintain the chimney. It is noteworthy that the risk of failure or malfunction in double-circuit products is several times higher than in single-circuit models. This is due to the more complex design of devices of the first type, in addition, the water heater as part of such a boiler has to work all year round without respite.

An important point!

Do not trust the installation and piping of a gas boiler to amateurs. The mistakes made in this case may not be detected immediately, however, they will gradually disable the elements of the heating system.

Some heating units are not equipped with a display, however, they can also be diagnosed as faults. In the event of a problem on the panel of such boilers, colored lamps light up or flash. Their ins and outs are disclosed in the accompanying documentation for the device. Do not be lazy to look through it - studying the data sheet of the model will go exclusively for the future.

Below is a list of the most common error codes and their descriptions for the six major players in the heating market. The names of the manufacturing companies are listed alphabetically:

BAXI boilers

E 01 - failed to ignite the gas burner in normal mode.

The error belongs to the category of general ones - the most diverse factors lead to its appearance: inconsistency of the gas inlet pressure with the established standards, non-compliance with the polarity of the boiler connection, malfunction of the gas valve or electronic board, etc.

E 02 - activation of the emergency overheating thermostat.

Most often, boiler overheating is caused by clogging of the heat exchange circuit. Less often, the problem should be looked for in a thermostat or temperature sensor on the heating supply.

E 03 - there are problems with the supply or discharge of air from the combustion chamber.

In boilers with an open chamber, an error with almost 100% probability indicates a lack of proper traction, but in turbocharged models, everything is not so simple: the cause of the error E 03 on the screen can be either the fan not starting up or the banal accumulation of condensate in the tubes.

E 05 - malfunction of the temperature sensor on the heating circuit flow.

Often, when this error occurs, the aforementioned sensor asks for a replacement.

E 06 - the temperature sensor of the DHW system is faulty.

Similar to the previous point.

E 10 - unacceptable pressure in the heating system.

The error "pops up" due to low water pressure in the circuit, poor contact between the sensor and the control board, or the cause of its occurrence is a malfunction of the minimum pressure switch. In the overwhelming majority, the problem is reduced to naught when the system is filled with a coolant.

E 25 - exceeding the maximum boiler temperature.

The reason must be sought, mainly, in poor circulation of the coolant or in a malfunction of the temperature sensor of the heating system, which is installed at the outlet of the primary heat exchanger.

E 35 - parasitic flame (intermittent).

The code can be seen on the boiler display in the event of a malfunction of the electronic board, as well as an incorrect location of the flame detector electrode.

E 40, E 41 - chimney clogged or gas inlet pressure too low.

The occurrence of a tandem of these errors is influenced by many factors: from a really low pressure of the "blue fuel" supply to a malfunction of the gas valve.

E 96 - undervoltage in the supply circuit (less than 170 V).

If the error appears with enviable regularity, it will be useful to acquire a voltage stabilizer in order to equalize its value and protect the device from possible power surges in the power supply.

E 00, E 99 - internal error of the electronic board.

Popular boilers BAXI

BAXI Eco-4s 10 F from 12 550 UAH. BAXI Eco-4s 24 F from UAH 12,000. BAXI Eco Four 1.14 F from UAH 12 720 BAXI Eco-4s 24 from UAH 12 890 BAXI Eco Four 24 F from UAH 16,000. BAXI Eco-4s 18 F from UAH 12 400 BAXI Duo-Tec Compact 24 from UAH 22 699. BAXI ECO-4s 1.24 F from UAH 12 499. BAXI Eco Four 24 i from UAH 14 250 BAXI Duo-Tec Compact 28 from UAH 25,502. BAXI Eco Four 1.14 from 16 005 UAH BAXI LUNA-3 310 Fi from 23 323 UAH BAXI Duo-tec Compact 1.24 from UAH 24,039. BAXI Eco Compact 18 Fi from UAH 13 268 BAXI Duo-tec Compact 20 from UAH 22 699. BAXI LUNA Duo-tec 1.24 from UAH 30 264. BAXI SLIM 1.490 iN from UAH 38 691 BAXI Eco Four 1.24 F from UAH 17,000 BAXI LUNA-3 Comfort 310 Fi from UAH 27 306. BAXI LUNA Duo-tec 28 from UAH 32 433.

Bosch boilers

For Bosch Gaz 6000 series:

A7 - malfunction of the DHW temperature sensor.

The sensor must be checked and replaced if necessary.

Ad - no boiler temperature sensor detected.

You will need to check the sensor itself and the connecting wire.

C1 - low fan speed.

It can be caused by both low voltage in the mains and related problems in the flue gas system.

C4 - the differential pressure switch does not turn off when the fan is off.

It is necessary to inspect this relay.

C7 - fan malfunction.

Ways to solve the problem: check the performance of the fan and its wires with plugs. If necessary, the fan is replaced.

E2 - malfunction of the temperature sensor in the supply line (open circuit).

This error is usually caused by damage or short-circuiting of the aforementioned sensor.

E9 - activation of the temperature limiter in the heat exchanger.

The E9 code appears on the boiler screen due to many factors - from damage to the temperature limiter to problems in the heating circuit.

EA - no flame detected.

This is one of the most common mistakes in Bosch boilers. There are a lot of reasons for the error, as well as ways to solve the problem. But first, it is better to check the opening of the gas valve, the gas supply pressure and the flue gas discharge system. Does not help? We start cleaning the heat exchanger and, if necessary, change the gas fittings.

F7 - the boiler detects a flame when it is off.

The reason must be sought in the contamination of the electrodes, in parallel with which it is advisable to check the control board for moisture.

FA - the boiler detects a flame when the gas supply is shut off.

The gas fittings and the flue gas system are subject to inspection.

|

| Bosch gas boilers are in harmony with most modern interiors. |

For ZSC / ZWC series:

A7 - malfunction of the temperature sensor of the hot water supply (DHW) circuit.

The problem is often in him, i.e. the sensor needs to be replaced.

A8 - BUS connection interrupted.

The problem is solved by checking the connecting cable and regulators.

A9 - incorrect installation of the DHW temperature sensor.

If this error appears, it is worth checking the mounting area of the sensor and reconnecting it using heat-conducting paste.

Ad - no boiler sensor detected.

It is necessary to diagnose the sensor or replace it.

C1 - during the operation of the boiler, the differential pressure switch has opened.

The diffrels, the exhaust system and the connecting pipes are subject to inspection.

C4 - the differential pressure switch does not turn off when the fan is off.

It is necessary to inspect this relay.

C6 - the differential relay does not open.

When an error occurs, the first point in the program is to check the relay and the flue gas pipe.

d4 - too large a temperature difference.

When the code appears, you need to pay attention to the circulation pump, bypass hose and check the pressure in the system.

EA - no flame detected.

This is one of the most common mistakes in Bosch boilers. There are a lot of reasons for the error, as well as ways to solve the problem. But first, it is better to check the opening of the gas valve, the gas supply pressure and the flue gas discharge system. Does not help? We start cleaning the heat exchanger and, if necessary, change the gas fittings.

F0 is an internal problem.

In this case, you need to diagnose the electronic board.

F7 - the boiler detects a flame when it is off.

The reason must be sought in the contamination of the electrodes, in parallel with which it is advisable to check the control board for moisture.

FA - the boiler detects a flame when the gas supply is shut off.

The gas fittings and the flue gas system are subject to inspection.

Popular Bosch boilers

Bosch Gaz 2000 WBN 24C from UAH 13 841 Bosch Gaz 6000 WBN-18C RN from 15 128 UAH. Bosch Condens 2500 WBC 28-1 DC from UAH 19,013. Bosch Gaz 6000 WBN-24C RN from UAH 17,258. Bosch Gaz 4000 ZWA24-2K from UAH 14 654. Bosch Tronic Heat 3500 12 from UAH 16 652 Bosch Tronic Heat 3500 6 from UAH 16 363 Bosch Condens GC7000i W 14/24 C from UAH 34,043. Bosch Tronic Heat 3500 9 from UAH 16,507. Bosch Gaz 3000 ZW28-2KE from UAH 18 053. Bosch Solid 2000 K32-1 S62 from UAH 29,471. Bosch Tronic Heat 3500 15 from UAH 18 686. Bosch Gaz 6000 WBN-24H RN from UAH 16,234 Bosch Condens GC7000i W 30/35 C from UAH 41,250. Bosch Tronic Heat 3500 18 from UAH 18 833 Bosch Solid 2000 B-2 SFU 20 HNS from UAH 25 230 Bosch Solid 2000 B-2 SFU 12 HNS from UAH 20,511. Bosch Condens GC7000i W 24/28 C from UAH 35 763. Bosch Condens GC7000i W 35 P from UAH 40 186 Bosch Tronic Heat 3500 4 from UAH 16,212.

Buderus boilers

Errors that occur in Buderus gas boilers are encrypted in a special way. First, the main code is indicated (what kind of malfunction occurred), then the additional code combination (this number uniquely identifies the malfunction signal), and at the end the class of malfunction is indicated.

There are several classes:

- ABOUT

- operating messages during normal boiler operation; - R

- non-blocking faults, in the event of which the system continues to work; - B

- blocking faults that lead to a time-limited shutdown of the heating system; - V

- locking faults that block the operation of the heating system.

|

| For Buderus boilers, a special error coding system is provided. |

The list of possible errors with Buderus boilers is very extensive. However, most often the user sees the following fault codes on the service screen:

2E 357 О - the function of removing air is active

or the temperature of the supply stream rises rapidly.

3C 217 V - the fan does not work.

It is important to determine at what stage the problem occurs: if the fan starts up, but the relay does not click, the problem lies in the supply pipes or a clogged chimney. If the fan does not start at all, you need to check if voltage is supplied to it. If the fan works and there are no problems with the chimney, it is necessary to check the pneumatic relay. Its permanently closed contacts or their opening during the burner operation will also be regarded by the safety system as a malfunction.

4C 224 B V - activation of the heat exchanger temperature limiter or flue gas temperature limiter.

Both sensors are inspected, the power loop to them, and if the pressure in the system is insufficient, the boiler must be fed. Also, the problem can be caused by problems with the circulation of the coolant or the appearance of an air lock.

4Y 351 B V - breakage of the temperature sensor.

Continuity of contacts and installation of a new part helps to overcome the malfunction.

6A 227 B V - flame not detected.

In most cases, it is better to entrust the solution of the problem with ignition to specialists. The simplest thing that an ordinary user can do is visually inspect the combustion chamber and electrodes for contamination. If necessary, they are cleaned. And if the boiler is kindled, but after a while it goes out, the disagreements are often associated with the failure of the electronic board.

Popular boilers Buderus

Buderus Logamax U072-24K from 15 210 UAH. Buderus Logamax plus GB062-24KD from UAH 26 441 Buderus Logamax Plus GB172i-14KD from UAH 36 402 Buderus Logamax U044-24K from 15 650 UAH. Buderus Logamax Plus GB172i-24 from UAH 35 775 Buderus Logamax U072-24 from UAH 16 965 Buderus Logamax U072-35K from UAH 18,561 Buderus Logano S111-2-16 from UAH 19 635. Buderus Logamax plus GB172-42i from 59 502 UAH. Buderus Logano S111-2-12 from UAH 18 623. Buderus Logano S111-2-20 from UAH 22,511. Buderus Logamax U072-35 from UAH 20,925 Buderus Logamax Plus GB172i-14 from UAH 32 670 Buderus Logamax Plus GB172i-20KD from UAH 39 785. Buderus Logamax plus GB172-30iK from UAH 46 494. Buderus Logamax plus GB172-35 from UAH 47 196 Buderus Logamax plus GB172-24 T50 from 54 555 UAH Buderus Logano S171-50W from 69 863 UAH. Buderus Logano S171-30W from 58 390 UAH. Buderus Logano S131-22H from UAH 25 455

Hotpoint-Ariston boilers

101 - activation of the overheating protection system.

There are several main reasons for the appearance of an error code: increased pressure at the outlet of the gas valve, contamination of the coarse filter, poor circulation of the coolant in the heating system, poor permeability of the heat exchanger due to the formation of scale, malfunction of the circulation pump.

108 - the pressure drop in the heating circuit is below the minimum.

There is probably a leak in the system somewhere.

109 - the pressure in the system has risen over 3 bar.

The error sometimes occurs in the second heat exchanger of double-circuit boilers. Due to a malfunction, hot and cold water mixes in it, which leads to an increase in pressure.

201 - there is no contact with the sensor on the supply to the DHW circuit.

You will need to tighten the contacts or replace the sensor.

302 - loss of communication with the display and the electronic module.

The problem often lies in the wiring.

501 - no flame during ignition.

This is one of the most common mistakes. First and foremost, check if the gas supply valve is closed. Also, a malfunction sometimes manifests itself due to a breakdown of the flame sensor.

SP3 (5P3) - flame separation.

With enviable regularity, a problem occurs in the area of the coaxial chimney. To nullify it, adjust its position and clear of debris.

601 - lack of traction in the system.

If the sensor is working properly, you will have to start cleaning the chimney.

604 - low fan speed.

6P1, 6P2 - delay in closing the contacts of the air pressure switch.

Occurs due to damage to the Venturi tube. The difference between the codes is that 6P2 is highlighted when the boiler is operating, and 6P1 is displayed when trying to ignite with an already damaged pipe.

Popular boilers Hotpoint-Ariston

Hotpoint-Ariston Clas One 24 RDC from UAH 20 800 Hotpoint-Ariston Cares X 24 FF from UAH 10 100 Hotpoint-Ariston Clas X 24 FF from 12 200 UAH. Hotpoint-Ariston Clas X 24 CF from 12 200 UAH Hotpoint-Ariston Alteas X 24 FF from 17 100 UAH. Hotpoint-Ariston Cares Premium 24 from 19 355 UAH. Hotpoint-Ariston Clas 24 CF from UAH 2,723. Hotpoint-Ariston Clas X 28 FF from 12 200 UAH. Hotpoint-Ariston Alteas One Net 24 from UAH 31,900. Hotpoint-Ariston Genus X 24 FF from UAH 13 790. Hotpoint-Ariston Cares X 18 FF from UAH 10 950 Hotpoint-Ariston Clas One 30 RDC from UAH 22,500 Hotpoint-Ariston HS X 24 FF from 11 500 UAH. Hotpoint-Ariston Cares X 24 CF from UAH 10 420 Hotpoint-Ariston Genus One Net 24 from UAH 31,507. Hotpoint-Ariston Genus One 24 from UAH 26,400. Hotpoint-Ariston Alteas One Net 30 from 34 810 UAH. Hotpoint-Ariston Clas X System… from 13 600 UAH. Hotpoint-Ariston Clas X System… from UAH 18 323. Hotpoint-Ariston Egis Premium… from UAH 21,780.

Protherm boilers

F00 / 01 - heating temperature sensor malfunction.

The sensor must be checked and replaced if necessary.

F13 - boiler sensor malfunction.

Similar to the previous point.

F20 - overheating malfunction (temperature over 97 ° C).

To eliminate the error, you need to check the circulation pump, make sure that the heating taps and the bypass valve are open, and also diagnose the heat filter.

F22 - there is no coolant in the boiler.

Fill the system and check for leaks.

F24 - malfunction of the coolant circulation.

The problem in this case lies both in the pump and in the closed heating taps.

F26 - lack of the required current through the gas valve motor.

The stepper motor needs diagnostics and subsequent replacement.

F28 / 29

- no flame was detected during ignition and loss of flame during burner operation. Everything is like with peers - you need to check the opening of the gas tap with your own hands, and to solve more serious problems you will have to seek help from qualified specialists.

F84 - constant temperature difference between the flow and return sensor.

The sensor will most likely need to be replaced.

Popular boilers Protherm

Protherm Gepard 23 MTV from UAH 13 403. Protherm Panther 25 KTV from 15 384 UAH. Protherm Skat 9K from 15 390 UAH Protherm Skat 12KE / 14 from 15 840 UAH. Protherm Lynx 24 from 12 950 UAH Protherm Skat 6K from UAH 15,000 Protherm Skat 14KE / 14 from UAH 16 940 Protherm Skat 18K from UAH 17 650 Protherm Gepard 23 MOV from UAH 13,231. Protherm Skat 18KE / 14 from UAH 17 650 Protherm Panther 30 KTV from 15 649 UAH. Protherm Panther 12 KTO from UAH 14 391. Protherm Panther 25 KOV from UAH 14,400 Protherm Lynx Condens 18/25 MKV from UAH 21,520. Protherm Skat 12K from 15 800 UAH Protherm Lynx 24 BA from UAH 12 639 Protherm Lynx Condens 25/30 MKV from UAH 23,134. Protherm Skat 14K from UAH 16 940 Protherm Skat 6KE / 14 from 15 050 UAH. Protherm Skat 9KE / 14 from 15 390 UAH.

Vaillant boilers

F.10 / 11 - short circuit in the flow / return sensor.

The sensor needs diagnosis or replacement.

F.13 / 14 - short circuit in the hot start sensor.

Similar to the previous point.

F.22 - insufficient amount of water in the system or its complete absence.

In the vast majority, the problem is reduced to naught when the system is filled with a coolant.

F.28 - malfunction in the electronic board.

F.29 - the gas burner does not light up.

One of the most common problems with gas boilers. Its appearance is influenced by the discrepancy between the gas inlet pressure and the established standards, non-observance of the polarity of the boiler connection, malfunction of the gas valve or electronic board, etc.

F.36 - Emission of gaseous combustion products into the room.

The error occurs when the air duct or gas outlet is closed. It manifests itself due to poor draft and ventilation, as well as due to the increased temperature in the room where the boiler is installed.

F.61 - error in the control of gas valves.

The essence of the problem lies both in the valves themselves, in the wiring to them, or in the electronic control board.

F.75 - the gas boiler pump is running, but the pressure does not change.

In order to rectify the situation as soon as possible, the adjustable bypass, pressure sensor, circulation pump and the correct connection to the expansion tank line must be checked.

Popular boilers Vaillant

Vaillant ecoTEC pure VUW 246 / 7-2 from UAH 23,414. Vaillant atmoTEC pro VUW INT 2… from UAH 16,995. Vaillant turboTEC pro VUW 242 / 5-3 from UAH 18 054. Vaillant eloBLOCK VE 6 from UAH 16 547 Vaillant atmoTEC plus VUW 280 / 5-5 from UAH 23,146. Vaillant turboTEC plus VUW 242 / 5-5 from UAH 23,920. Vaillant turboTEC pro VUW 282 / 5-3 from UAH 18,285. Vaillant eloBLOCK VE 12 from UAH 17,432. Vaillant turboTEC pro VUW 202 / 5-3 from UAH 17 732 Vaillant ecoTEC plus VU INT 24… from UAH 26 307. Vaillant ecoTEC pure VUW 286 / 7-2 from UAH 24 405 Vaillant atmoTEC plus VUW 200 / 5-5 from UAH 22,028 Vaillant ecoTEC plus VU INT 38… from UAH 50 691. Vaillant ecoTEC pro VUW INT 23… from UAH 32,967. Vaillant eloBLOCK VE 9 from 17 012 UAH Vaillant atmoTEC pro VUW 240 / 5-3 from UAH 17 686. Vaillant ecoTEC plus VU INT 16… from UAH 25,511. Vaillant eloBLOCK VE 14 from UAH 19,224. Vaillant turboTEC plus VU 282 / 5-5 from UAH 22,007. Vaillant ecoTEC plus VUW INT 3… from UAH 40,222.

A complete list of errors and possible troubleshooting solutions, as mentioned above, should be sought in the accompanying paper documentation for the heating boiler.

Warmth to your home!