The world-famous traditional Russian stove made of solid stone from time immemorial has been a symbol of the Old Russian hut, since it had many useful functions and it was thanks to them that it got into the famous Guinness Book of Records.

The stone stove not only heated the house from the inside, but was also used as a couch and so on. Even now, such a stove is far from rare in modern Russian private houses. During the construction and laying of such a stove, it is necessary to accurately calculate the required number of brick products, both for the foundation and for the stove itself.

It is important to know: such an oven can be used not only for warming, but it can also be cooked, reheated, and it should be noted that all dishes that were cooked on a brick oven always and without exception taste great.

And that is why it is not surprising that most owners of private houses or country cottages are thinking about building their own stove. Such a structure can be built with your own hands without much effort and with a minimum of skills in building masonry. But, the most important question that a homeowner will have is how much building material is needed to build such a structure and what will be the consumption of bricks for a stove, as well as how much does a brick cost for a stove?

Methods for calculating the number of bricks

The required amount of brick must be calculated with maximum accuracy and not to make mistakes in calculations, since if you take too much brick, then the unused material may disappear over time, and if you take too little, then at the end of construction the lack of brick material will make itself felt and you will not be able to finish the job you started.

There are also universal methods through which you can absolutely accurately calculate how much building material you need. But, before that you will need:

- Measuring tape;

- Plumb lines;

- Trowels;

- Rule.

So let's get started. Number one counting method.

Builders - professionals distinguish in a simultaneously simple and universal formula, thanks to which you can easily find out how much building material is needed.

Well, the formula itself is as follows: you need to take the required number of bricks that will be used when laying the first brick row. The amount that we received needs to be multiplied by the number of brick rows (basically, the height of one row is exactly eight centimeters). Subtract one third of the total from the result.

For example, the base of a brick stove consists of three by four bricks, then there will be exactly twenty-four bricks in the bottom row.

It is important to know: this formula is conditional and insignificant errors can be allowed in the calculation.

Further, after we have carried out preliminary calculations, it is necessary to measure the height of the structure. For example, if the height from the floor to the end of the brick structure is exactly two and four millimeters, then thirty centimeters must be subtracted from the resulting size (the height of the cutting itself) and ultimately two and nine millimeters are obtained. Also, we must not forget about the height of this brick row (seven centimeters) and in this way we have exactly thirty centimeters. From these thirty centimeters, one third must be subtracted (approximately ten pieces of building bricks).

Bricklaying the base of the stove

At the end of all calculations, exactly twenty rows are obtained and now this figure must be multiplied by twenty-four (it turns out four hundred and eighty).Also, we must not forget that you will additionally need fifty bricks, which will then additionally need to be added to the general cutting.

During laying, one should also not forget that the required number of bricks for building a chimney must be calculated separately. And the novice builder will ask himself the question - how many bricks are in a running meter. In order to build one running meter of a standard pipe, you will need fourteen brick rows (each row contains approximately six pieces of bricks). It follows from this that there are approximately eighty-four bricks in one running meter.

Example. If you decide to build a brick pipe four meters long, then you need to multiply these four meters by eighty-four bricks and after all these calculations, you get exactly three hundred thirty-six bricks for building four meters of a brick pipe.

A similar formula for calculating building material is distinguished by its simplicity and convenience. But, it is important to remember that such a formula is conditional and you can easily make a mistake in the calculations (therefore, double-check the resulting figures several times).

You can also read about the features of the construction of furnaces here.

stroykirpich.com

One of the first questions a person asks who is planning to make a stove in his house is how much brick is needed for this purpose? The problem is all the more relevant if the brick is made of expensive ones. These kinds of questions usually make sense if a person knows what kind of oven he wants, the rest is just a talking shop. If the furnace is made according to some kind of project, then the number of bricks should be indicated. As a rule, stove-makers also have several ready-made solutions in stock, where the consumption of bricks is also taken into account.

But are there any universal ways how you can find out how many bricks do you need for any stove? With this question, I turned to the professional stove-maker Leonid Shadrin.

After listing everything that has already been written above, Leonid proposed a simple formula for calculating bricks, but with the amendment that it is also rather arbitrary.

Its essence is as follows:

- the number of bricks is taken, which is needed for the first row of the furnace, laid out on a continuous basis

- multiplied by the number of rows in height (height of one row is 7 cm)

- one third of the result is subtracted

For example, the base of a furnace is 3 by 4 bricks. This means that there are 24 bricks in the first continuous row. Now you need to know the height of the oven. Let's say the height from floor to ceiling is 2 m 40 cm. From this size we subtract 30 cm (cutting height), we get 2 m 10 cm. The height of one row is 7 cm. Thus, we get 30. From this number we subtract its third (30: 3 ), that is 10. It turned out 20 rows, multiply by 24, as a result we have 480 bricks. Here we add 50 for cutting, for a total of 530 bricks.

The pipe is calculated separately. In one running meter of a tube, 14 rows of bricks are taken as the norm. For example, if there are 6 bricks in one row of a pipe, then 6 x 14 = 84 per meter. Suppose the pipe is 4 meters long, then 84 x 4 = 336 bricks are needed for the pipe.

Here's a simple formula. Of course, the numbers obtained are somewhat arbitrary, but they already allow us to estimate, how many bricks do you need for the oven and plan for future financial expenses.

___________________________________________________

If there is a choice about which ceiling to make, you do not need to think for a long time, just follow the link, choose and rejoice! Stretch ceilings here https://www.potolok.name/, rich assortment, quality materials and service!

pechky.ru

What is the brickwork calculator based on?

A house of any type of building blocks can be erected only according to a certain scheme, so that the upper rows hold the lower ones. There are several different ways to perform masonry, and they directly depend on how thick the walls are planned to be. The "half-brick" option implies that the blocks in the rows will be joined by short sides (butts), that is, their width will become the only protection of the premises from the external environment... Methods "in one brick", as well as one and a half and two, mean that the thickness of the walls will correspond to the length (spoon) of one block (250 mm), as well as the sum of spoons of one and a half or two blocks (380 and 510 mm, respectively) ...

Of course, the easiest way is to calculate how much material will go to the thinnest version of the masonry. It is only necessary to divide the total height of the wall by an identical indicator for the row and multiply by the number of bricks laid in it. However, multi-layer types of masonry and various types of building blocks do not allow this method to be applied in all cases without exception. The size of a typical single brick corresponds to the following values: 250x120x65 is a spoon, a poke and the height of a brick. One and a half differs only in one, the last parameter, which takes on a value of 88 millimeters. The double version has a standard length and width, but its height is already 138 centimeters.

As you can see from all of the above, so that there are no difficulties with calculating the material, the brickwork calculator must be compiled for one type of building blocks, without mixing standard sizes. It is logical that you need to buy the material in one batch, so that there are no differences in color and it turns out that some of the bricks are with insufficient firing, and some are overheated. To find out exactly how much material is required, we draw up the exact parameters of the house, based on the plan. We need its perimeter and height, these indicators will add up the area of the walls, to which we need to add the dimensions of the internal partitions. You will also need the thickness of the masonry, the area of the window and door openings and, in fact, the size of the brick.

I will answer first to the second part of the question

Indeed, many people ask a similar question when installing the oven in a bath on their own. If you decide to lay out a brick oven, then you cannot do without creating a solid foundation.

From the point of view of construction safety, it is necessary to remember one formula (most stove-makers use it): for one ton of stove mass, 10 cm of reinforced concrete base must be cast. It is quite simple to calculate the total mass of the structure: we multiply the number of bricks by 8 kg (the mass of one brick M - 150 or M - 200) and add 15% to this figure (this is the weight of the mortar and additional furnace devices - heaters, accessories, etc.) ... Be sure to calculate the weight of the chimney, pipe and crown, which will also create additional load on the foundation.

Another additional factor that must be considered when casting a foundation for a brick oven is the type of soil on which you will be laying it. The fact is that if your bath is operated only periodically, then the soil under it will freeze, and, as a result, the foundation of the stove will experience seasonal fluctuations in the soil.

If the bath is on heavy clay soils (builders call such heaving soils), then the ground vibrations will be significant. An improperly cast foundation may not compensate for ground movements and, as a result, the furnace may crack or completely collapse.

On such a soil, a columnar foundation can be considered ideal. It is done in this way:

- The area of the base of the furnace is measured and 10% is added to each edge to the length of the foundation.

- A fertile layer is selected to a total depth of 30-50 cm (a rare sauna stove will be more than five tons).

- In the corners of the pit and in the center of the site, with a drill with a diameter of 12-15 cm, pits are made to the depth of freezing of the soil in your area (even if you drain the wastewater into the sewer, the groundwater, having saturated the soil layers, will swell the soil in winter).

- Pits are vertically reinforced (three rods can be used, four can be used). The diameter of the reinforcement is at least 8 mm (fiberglass reinforcement can be 6 mm) and poured with concrete (standard concrete, grade M-400. If you do it yourself, use the formula: 1: 3: 1 - one part of cement - three parts of sand - one part gravel).

- After the concrete has "set" (48 hours after casting), we make a sand cushion at the bottom of the pit, the thickness of the cushion for casting is at least 5-7 cm. the sand itself is compacted to the maximum shrinkage density).

- The pit walls are waterproofed with roofing felt or other material.

- Above the ground, a formwork with a height of at least 10 cm is exposed.

- After that, the foundation is reinforced. You can use a reinforcing bar, laying it with an interval of 10 cm (the diameter of the bar is at least 6 mm), the second layer is perpendicular to the first, the tie is made by twisting the wire, or with plastic clamps. Many stove-makers use a masonry mesh to reinforce the foundation (the mesh should be no more than 10 cm). Both the reinforcing bar and the masonry mesh are laid at a distance of 5 cm from the sand cushion, as well as in layers every 10 cm of pouring the concrete cushion.

- The concrete must be poured in one go (in one work shift), this will avoid the concrete delamination (it happens that in hot weather the layers set unevenly and as a result the concrete does not have the required strength).

- The total setting time of a concrete pad depends on its thickness. As a rule, the laying of the furnace base is started two weeks after the foundation is cast, but first a strapping from an iron corner is made along the upper edge of the concrete cushion

If you intend to fill the foundation for a brick oven in a bathhouse, which will be built on light soils (sandy loam, sandy, etc.), then the seasonal fluctuations of the soil are not so pronounced here, therefore the depth of the foundation casting is not tied to the depth of soil freezing. You just need to remove the fertile layer and make a depression in the soil equal to the thickness of your foundation, based on the total mass of the entire structure, and then use the algorithm described above.

These, in principle, simple actions will allow you to be sure that the stove you put in the bath will last a long time.

Now regarding the calculation of the number of bricks when laying the heater

It is necessary to be aware that the stove experiences no less temperature loads than the firebox, therefore, we use only fireclay (refractory) bricks for interior decoration. As a mortar for bonding layers, it is best to use a special masonry mixture with fireproof and vapor-repellent properties (as a rule, it is easy to buy it in a specialized store).

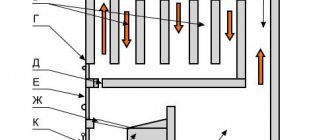

Fireclay bricks are placed on the edge for laying the walls, and flat on the base and vault. An exception is an open stove, there is no ceiling vault in it. Between the fireclay bricks on the walls of the stove and the brick wall, 5 mm thick basalt cardboard is laid (the fact is that fireclay bricks have a higher coefficient of linear expansion than ordinary ones, and basalt cardboard, in addition to thermal insulation properties, also plays the role of a damper cushion).

General formula for calculating the minimum volume of a sauna heater:

- steam room from 12 - 15 cubic meters meters - heater 55 - 75 cubic meters. decimeters - 25 fireclay bricks and 30 M - 250;

- steam room from 15 - 25 cubic meters meters - heater 75 - 100 cubic meters decimeters - 35 fireclay bricks and 40 M - 250;

- steam room from 25 - 35 cubic meters meters - heater 100 - 120 cubic meters decimeters - 40 fireclay bricks and 50 M - 250;

Large-sized steam rooms require special convection chambers for better heating throughout the volume, and this is a topic for a separate answer.

sdelaikamin.ru

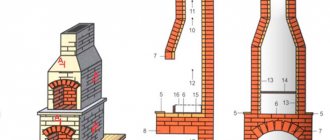

Furnace departments

Any stove, be it Russian, Dutch, Swedish or a construction for a bath, consists of several main departments. For each of them, the material should be selected separately, since certain characteristics are important, which are necessary specifically for a particular part of the hearth.

Foundation

The first step is to build the foundation. Since the structure is usually located on the ground floor, the proximity of the ground must be taken into account. Therefore, a concrete slab is usually laid as the first layer, and below the floor level, and a layer of waterproofing is applied to it.

Thus, we get a layer that will withstand the mass of our future structure, and also will not allow moisture and cold that come from the soil to affect it. On top of the waterproofing layer, solid brick rows are usually laid, there can be from two to four.

This is the second part of our foundation. For it, as a rule, clinker material is used. This is due to the fact that it has a very high strength, it is not afraid of loads, so such a base will calmly withstand the weight of the entire stove.

Firebox

The other department of design that raises the most questions about the selection of material is the firebox. This is the very place where the wood is laid and where the fire is made. The bricks in the firebox are directly exposed to the flame for a long time, and this happens for many years. Therefore, corresponding requirements are imposed on them.

As a rule, fireclay blocks are used to lay out the firebox. They have the highest refractoriness rates of all possible options, therefore they calmly perform their functions throughout the entire life of the hearth.

In principle, the whole structure can be folded from fireclay. But this is very expensive. In addition, the firebox lined with cream-colored chamotte blocks looks very advantageous surrounded by red brick blocks, so this solution is optimal from the point of view of not only functionality, but also design.

Chimney and chimney

The chimney does not come into direct contact with fire and does not bear a particularly high load. Nevertheless, there are certain requirements for it too.

First, from the inside, it is attacked by aggressive chemicals released during combustion. They have a detrimental effect on the state of the building material from which the inner part of the chimney is laid, therefore, special attention should be paid to the stability of these bricks in various destructive factors.

Secondly, the part of the chimney that is located above the surface of the roof of the house - that is, the chimney - is also subject to attacks from the external environment. Rain and snow, frost, wind, sudden changes in air temperature - all this largely erodes brick blocks.

Experienced craftsmen recommend using two different materials for this section of the oven. Clinker, as the most resistant to aggressive chemicals, is used for laying the inner layer. And outside, ordinary ceramic bricks are perfect, which perfectly withstands the effects of the external environment. it is not for nothing that many different structures are being built from it, including residential buildings.

Types of mortar when laying a stove

Masonry bricks

Ordinary cement mortar is not suitable for installing a stove or chimney, since it does not withstand high temperatures, it is used only when erecting the foundation of the stove. For laying a firebox or ash pan, where the solution is in direct contact with fire, a clay composition is used, since the clay only becomes stronger when burned with fire. Lime mortar is used to lay out the chimney and chimney.

Decorative finishing

The appearance of the hearth is also important, especially in modern private houses. In principle, if we are talking about an old hut, then usually the structure is simply covered with whitewash, as in the old days.

But still, as a rule, recently, preference is given to finishing with facing bricks.This option is suitable for a Russian stove, and for a Dutch one, and for other varieties.

When choosing a cladding, two factors must be taken into account:

- heat capacity. It should be tall. A brick is required to accumulate as much heat as possible;

- thermal conductivity. This ability is important so that the stove not only retains heat, but also gives it to the room.

As a rule, both of these indicators are found in second-grade ceramic facing bricks. It is this material that experts recommend using for the exterior decoration of the stove structure.

What is attractive about a brick oven

This design can be done, in principle, with your own hands. But it is not so cheap and easy to just pick up and put.

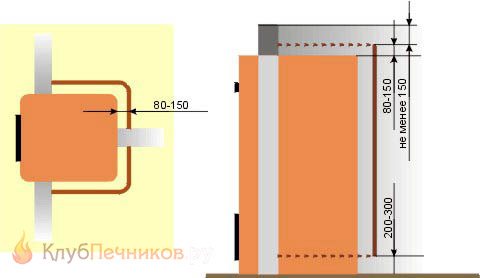

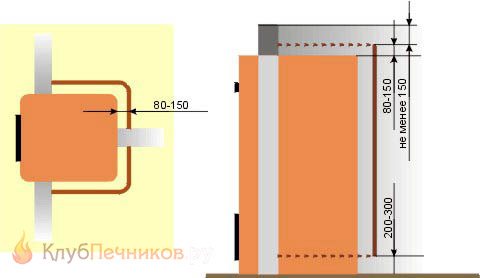

Attention: If a brick oven is being made in a log house, then it is not so easy to take fire safety measures. So there may be problems with permitting systems. And this must be taken into account.

First you need to understand how much it suits you:

- Such designs are very heat-intensive and high efficiency is guaranteed. After warming up, a thick wall keeps heat for a long time. And if the room is insulated, then it can be warmed up in a couple of hours;

- This design is suitable for many buildings. If this is a bathhouse, then you simply cannot think of a better option.

- Even after installation, you can bring in the water circuit and make a stationary heating of the room;

- A fairly large selection of designs. Everyone can choose the option they want. Moreover, some models are quite cheap and everyone can afford it;

- The decoration is done with different materials. So it's hard to ask for more when it comes to design. You can make almost any style.

Calculating the number of bricks

Regardless of the type of brick block, they all have the same standard dimensions. This makes it possible to use several varieties at once in one masonry, without having to rack your brains over attempts to align the rows.

Bricks have the following dimensions:

- single (standard) - 250 × 120x65 mm;

- one and a half - 250 × 120x88 mm;

- double - 250 × 120x138 mm.

There are also other options, but these are usually European standards that do not apply in our country.

For furnace construction, as a rule, a single brick is used, sometimes a one and a half brick. Double is not suitable in this case. The fact is that it is usually hollow, that is, it has a large number of holes in the structure. This is done in order to reduce its mass.

We only need solid blocks. Hollow bodies accumulate heat much worse and are destroyed faster under the influence of various aggressive factors.

Let's go directly to the calculations. For them, we need only two indicators: the number of bricks, of which the lowest solid row is laid out, that is, the base, as well as the number of rows. All this is easy to calculate, knowing the dimensions of the blocks that you are going to use.

After calculating the amount of material in the base, multiply it by the number of rows of which the oven will be composed. In this case, only those departments are taken into account that go to the chimney. Subtract a third from the resulting product, and you will have the required number of bricks.

We make calculations for the chimney separately. There you take the number of bricks in one row, multiply by the number of rows, and subtract nothing.

That's all. It remains to add up the results obtained. Now you know how many bricks you need to build a hearth. Do not forget to add about 5% in case of replacement of broken blocks during the construction process. Good luck and warmth in the house!

seberemont.ru

Helpful hints

Thus, self-counting is not a very difficult matter, and if everything is done correctly, show ingenuity, attentiveness and accuracy, then the result will be positive.

When erecting such a structure, one must take into account the fact that it is important not only how much material is needed, it is also necessary to find it of the highest quality. Today, there is a very large selection on the market, so there is an opportunity to buy goods at a low price. Nevertheless, one should not forget that a miser pays twice and such a product may be of poor quality, which will subsequently very quickly render the entire structure unusable.

The above calculation methods are carried out when everything is being built with your own hands, and if specialists are involved in the construction, they, as a rule, use their own system of calculations. All this will take some time. There is no doubt that you can calculate everything yourself, and then go to the market for everything you need and buy exactly as much as you need, no more and no less.

Methods for calculating bricks per kiln

The required volume of building material must be calculated as accurately as possible without room for error. Because the surplus bricks will lie with you as a dead weight and will disappear over time. The disadvantage will emerge at the most inopportune moment, stalling the process and adding headaches about its acquisition and delivery.

There are several methods for calculating how many bricks are needed to build a stove. However, before starting work, prepare a tool: a construction tape, a plumb line, a trowel and a rule.

One of the most common calculation methods can be expressed by a simple formula that allows you to find out almost immediately how much brick is needed for the furnace. One point to remember: the versatility of the method hides an error that should be taken into account.

The formula can be described as follows: we take the number of bricks of the first (solid) row and multiply by the number of rows. The height of one row is approximately 7 cm. You need to subtract ⅓ part from the piece. For clarity, you need to analyze an example.

The stove is 3x4 bricks in size. Therefore, the base will contain 24 pcs. We find out the height of the furnace, in our case 2.4 m. Subtract 0.3 m from it for cutting and get 2.1 m. Dividing by the height of one row, we have 30 rows. It subtracts 10 (one third) from this value and we get 20 rows, which we multiply by the number of bricks in the base (24 pcs.). The result is 480 pieces, to which we return 50 for cutting and we have a total of 530 pieces.

This calculation does not include the amount of bricks for the construction of a stove chimney, we will calculate it separately. Here the main parameter is the height of the chimney and its cross section. If we take as a basis a pipe with dimensions of 50x50 cm, then each row will consist of 6 bricks. One meter of pipe contains about 14 rows or 84 bricks.

Let's count on a specific example. A four-meter chimney will require 4x84 = 336 bricks to be erected. When calculating how many bricks are needed to build a stove according to this formula, do not forget about its conventions.

Calculating the volume of a brick

In terms of laying the stove, the required number of bricks is usually indicated, and many professional stove-makers know this. But there are options in which you can easily calculate how much material is needed for any stove, for example, a Swedish brick stove, for any home.

The sequence of calculation will be as follows: the number of bricks laid out in solid by the first row is multiplied by the height (the number of rows), and then we subtract 1/3 from the result obtained. Thus, you can make an accurate calculation of the amount of material per project.

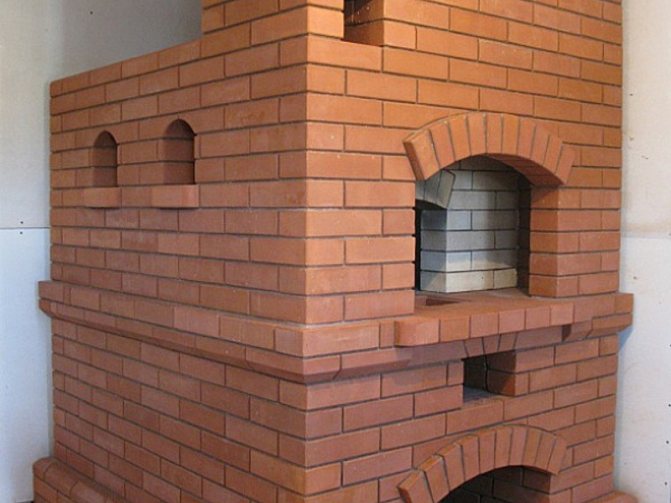

Diagram of a brick oven.

To make the calculation more accurate, you can use numerical data. Here's an example:

- The base of 3 × 4 bricks means that the continuous row will be 24.

- The height is taken from the floor to the ceiling. It can be 2 m 40 cm.But from this height, approximately 30 cm should be subtracted, taking into account the cutting height. In this case, 2 m 10 cm will remain.

- Knowing that the height of one row is 7 cm, it is necessary to use the following formula: divide 210 by 7. We get 30 rows.

- Now 1/3 is subtracted from this number. This leaves 20 rows.

- Then this number of rows is multiplied by the base of 24 pieces, and as a result - 480 pieces. But you also need to remember about cutting, for which you will need 50 pieces. Total - 530 pieces.

We offer you to familiarize yourself with the stove for working off with your own hands: drawings, video instructions

Any stove has a pipe. If it is brick in the project, then it must also be calculated. In 1 m of pipes, there are normally 14 rows, and in 1 row - 6 pcs. So, you need to multiply 6 by 14. It will turn out to be 84. Now this value should be multiplied by the height of the pipe in meters, and we get the required volume of the required building material. For example, we multiply 4 m of the pipe by 84. We get 336 bricks, for the construction of the Dutch oven the calculation will be different.

The obtained values are, of course, arbitrary. There will still be margin of error, but these numbers will give you an idea of the total brick quantity and allow you to plan for future expenses. When the volume of the material is calculated, you need to select its type.

Calculation of the dimensions of the furnace

The stove planned for construction should provide a comfortable temperature in the house. To calculate the size of the furnace, you first need to find out the heat loss of the building. This can be done mathematically and empirically. Let's take a closer look at the second method:

There should be no sun outside and a strong wind is desirable. All electrical and heating equipment in the house must be turned off. Windows, doors and ventilation must be well closed. After 24 hours, you need to take the reading of the room thermometer.

We turn on an electric heater with a power of 1 kW. After 24 hours, the temperature must be recorded again.

The experiment can be carried out at any time of the year. The main thing is that there is no sun, which will give a big error. Find the average temperature with and without a heater. We consider their difference and divide by the set power of the heating device. The resulting number indicates how many degrees a 1 kW heater adds.

Determine the comfortable room temperature. Find the difference between the desired room temperature and the minimum outdoor temperature in winter. Divide the result by the value obtained earlier. The result is the power required to heat the house.

The principle of functioning of a brick stove is based on the accumulation of thermal energy from the combustion of fuel and its return to the room over time. This can be done using a simple formula: the mass of the furnace is equal to the product of the calculated power, the duration of maintaining the temperature from one furnace and the number 85.7.

The main types of brick oven

Brick stoves for home can be of different purposes. So, first of all, you need to understand what exactly you will be doing it for. After all, not only the price of the installation will depend on this, but also its functionality.

Heating

This brick oven in the house will help warm up the space and save money on it. For such a furnace, the volume of the room is important, and its volume will also depend on it.

The case in this version is made of brick and it itself keeps heat for a long time. The larger the furnace part, the larger the volume of the room can be heated.

Heating stove with water circuit

- This oven, in its design, does not provide for cooking;

- At the design stage, you need to think about what kind of heating circuit it will have. After all, if you have water heating, then you need to provide for a water circuit, which will need to be brought into the firebox;

- The most popular here are long-burning stoves. For them, one fuel tab can be enough for a day;

- The heating stove can be fueled by both gas and solid fuel.If you choose the first option, then you should immediately install the automation, which will help maintain the most optimal combustion option.

Attention: It is important for a heating stove how much water it heats up and how long it takes. Therefore, the design of the firebox itself is quite important.

Cooking

A brick oven for a house can be quite small in size and weight. It is not intended for heating, but only for cooking. Most often they are used for installation in summer cottages.

Brick cooking stove

- For such a structure, it will be possible not to install the foundation. It is completely DIY and therefore installation costs can be minimal.

- All street structures can well be attributed to this category. It can be barbecues and barbecues. So the comfortable cooking of the oven is impeccable.

- You can also cook food in the country without any problems. To install it, you will not need a gas supply and make a planned installation.

iz-kirpicha.su

Types of oven bricks

Kiln bricks can be divided into three types:

- Quartz has a low sand content.

- Fireclay is made from refractory clay.

- The main one contains a lot of limestone-magnesian mass.

Refractory brick can withstand high temperatures for a long time. It has high strength, which makes it difficult to machine. Chamotte clay is used in its manufacture. It is produced in various forms, has no cavities or voids inside. A distinctive feature is the metallic ringing when tapped on it. When broken, it splits into large pieces without forming crumbs. Its resistance to high temperatures and chemicals makes it an ideal candidate for laying out the firebox.

The outer layer of the stove can be made of ceramic bricks. It is not so resistant to high temperatures, but it also has some advantages: it lends itself well to processing. It can be shaped into any shape with a pickaxe. When choosing such a brick, you should carefully study its appearance: there should be no cracks, and the geometry should exactly repeat the standard. The shade of the product should not differ over the entire surface.

When purchasing a ceramic brick, look at its name. The old nomenclature called it "red grade 1". Modern technologies make it possible to give the product yellow and white shades.

Material type for the project

The scheme of laying the rows of the furnace.

The outer layer of the project is usually made of ceramic bricks. Such material lends itself well to processing and has sufficient thermal conductivity.

When buying, carefully inspect its surface. Quality stones of this type have no color differences over the entire surface, there are no cracks and chips, the geometry meets the standards.

The furnace firebox needs a special refractory brick that can withstand high temperatures and is highly durable. The last property is both an advantage and at the same time a disadvantage, since it complicates its mechanical processing.

Refractory bricks are produced in various forms. Moreover, it has no voids. This type of artificial stone can withstand temperatures of 1400… 1600 ºС. It differs from the usual form in its composition and characteristic metallic ringing upon impact.

It is made from special refractory clay in industrial furnaces at very high temperatures. Such material has clear edges, which makes it possible to make precise geometric constructions from it. But refractory bricks have a rather high cost. Therefore, it is recommended to divide the building into external and internal decoration.

This allows you to significantly reduce project costs without compromising its safety and thermal conductivity.

The scheme of laying the rows of the furnace.

Refractory bricks are produced in various forms. Moreover, it has no voids.This type of artificial stone can withstand temperatures of 1400… 1600 ºС. It differs from the usual form in its composition and characteristic metallic ringing upon impact.

Recommendations for choosing a brick

In order to acquire high-quality material that will not fail even after several years of operation, it is worthwhile to carefully approach the selection procedure. Simple tips will help you do this:

- The counterfeit contains foreign inclusions in its composition, such as individual stones or pieces of limestone.

- It is advisable to buy the entire amount of material at once from one manufacturer and one batch.

- Brick that has not been burnt has a pale appearance and deviations from standard dimensions.

- The listed recommendations will help you to correctly select and calculate the material for laying the stove. The process itself will require not only quality materials, but also solid experience.

Outcome

Now you know how much brick you need for the oven. It is not difficult to calculate the amount of stone for building a furnace on your own. Errors can only occur in numbers that need to be double-checked. Construction work on the construction of a furnace requires not so much an accurate amount of material as its good quality. There are a large number of seemingly similar materials on sale, but they are all of different quality.

The described methods of performing calculations are used only in cases where the work is planned to be performed independently. The hired workers will carry out all the calculations according to their own methods. Don't be afraid to grab a calculator, and then go to the store and purchase the necessary materials in the right amount.

pluskirpich.ru

Calculation of the amount of materials required

The easiest way to calculate the materials is to hire specialists who will select and provide you with a choice, a suitable furnace project, in which all costs are calculated, right down to the last brick. A project that suits your home, with individual wall and roof layouts. If you decide to build a stove yourself, you will face a lot of problems in calculations, the correct location of the stove, compliance with fire safety, a suitable choice of chimney, calculation of the depth and construction of the foundation, and if you have never done bricklaying, you will not be able to lay out the stove beautifully , with even seams, uniform jointing. In the case when you are confident in your strengths and building skills, you can build your stove, having studied before this a lot of important information on the technique of laying the stove and fire-fighting cutting.

Preliminary work

- If natural gas is installed in your house, you will need to coordinate the location of the stove with the gas and fire service, obtain all the necessary documents and stamps. Since the stove can be built into a wall or adjacent to it, be in a fire hazardous proximity to wooden walls and wooden roofing elements.

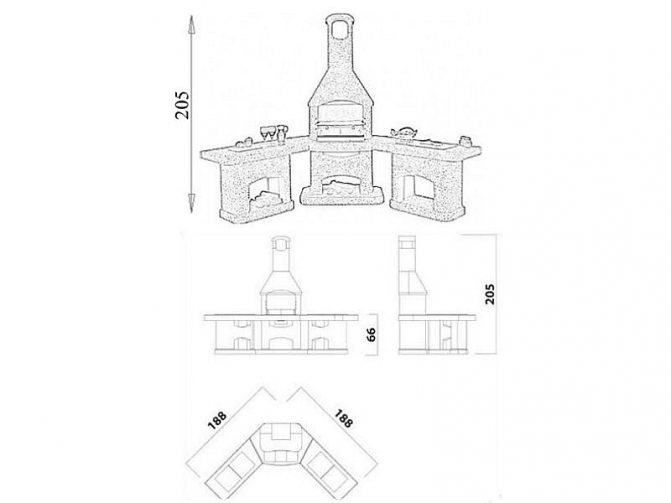

- Calculate the size and bearing capacity of the foundation depending on the kiln weight. The foundation is the basis of absolutely any stove. It should be emphasized that the perimeter of the foundation must exceed the perimeter of the oven itself by at least 5 cm on each side. The foundation can either be poured with concrete, with mandatory reinforcement, or laid out of ordinary silicate bricks. The rows of the foundation are reinforced with masonry mesh to avoid deformation. A sand cushion is mounted under the base, at least 5 cm thick. The soil under the cushion is carefully rammed.

- Ventilation in the room is also a requirement of the fire department if you have natural gas. In addition, ventilation contributes to good traction in the oven, without "back pops". Since there is no air flow, it creates a vacuum in the room during operation.

Next, you need to calculate the amount of materials. The most numerous of them is brick. Moreover, when building a stone furnace, different types of bricks are used.For laying out the firebox or crucible, that is, in places of the highest heating, refractory clay brick (fireclay) is used, we note that it has a rather high price, from this it is used only in those places where it is necessary. For laying a chimney, the use of fireclay bricks is not advisable, it is more appropriate to use refractory bricks, it does not have direct contact with fire, but it can withstand temperatures up to 1000 degrees. For the installation of the outer part of the pipe, which is exposed to climatic aggression, frost-resistant brick is used, it is less susceptible to deformation from temperature changes, for example, silicate brick, in such conditions it can crack. For facing the furnace, ceramic bricks are used, which have a beautiful appearance.

An example of calculating the number of bricks

Let's look at a simple example of calculating a brick as a whole. Whatever perimeter the oven has, the first row is laid out entirely, for example, 4 * 4 bricks. That is, the first row consists of 32 bricks. The number of rows depends on the height of the room, the height of a single brick according to GOST is 65 mm, plus 5 mm for the seam between the rows. We get the height of one row - 7 cm. For example, the height of the room is 2.8 meters, from this figure we subtract 0.3 meters for a fire cut, we get 2.5 meters. We divide the total height by the thickness of one row and get 36 rows. 36 * 32 = 1152 bricks. Since the furnace has hollow parts, subtract 1/3 from this figure. So, we need 768 bricks for a stove with a chimney. Next, we calculate the number of bricks per chimney, take a standard square pipe as a sample, one row of a standard pipe consists of 6 bricks, note that the pipe can be rectangular or even round, and this calculation method will not work, and by analogy with a furnace, the required number of pieces per pipe. The height of the pipe, for example, is 4 meters, it consists of 57 rows, the total number of bricks will be 342 bricks.

Next, we calculate how many pieces are needed for cutting, it depends on the shape of the furnace and its location, if it is built into a wooden wall, the thickness of the wall is taken into account. For example, a wall is one brick thick, the minimum width of the groove is 25 cm, that is, on each side of the furnace, the groove is laid out in one brick, 36 rows on both sides, we get 144 bricks. In the case when the stove is not adjacent to the walls, cutting is done only at the points of abutment to the ceiling and roof elements, in the standard case, from 30 to 50 pieces will be required. You should also take into account the effect of breaking bricks in pallets. Not less than 10 percent. It depends on the delivery method.

pechiexpert.ru

Preparing to equip the furnace

If a gas main is connected to the house, then the location of the stove must be coordinated with the gas and fire service so that the structure can be used absolutely legally

We offer you to familiarize yourself with How to choose a closer for a metal door

In addition to the location, you also need to pay attention to the features of the stove - for example, it can be built into a wall or be located in the immediate vicinity of combustible materials. For the stove, it is imperative to calculate and make a separate foundation. The perimeter of the foundation should protrude beyond the contours of the stove by at least 5 cm on each side

For pouring the foundation, you can use both reinforced concrete and ordinary sand-lime brick. In the latter case, the rows of the foundation must be reinforced with a mesh so that the structures are not deformed. The soil under the foundation must be well tamped, and a sand cushion with a thickness of 5 cm or more should be equipped on it. The room must be equipped with high-quality ventilation.

Stocking up materials

If the type of oven is chosen ("mini" or "maxi"), a firm decision has been made to build a Dutch oven - it's time to stock up on materials and select tools.

The following materials are required

- standard size refractory bricks;

- clay;

- crushed stone;

- sand;

- water;

- roofing material;

- thin steel wire.

In addition, you should take care of the facing materials. The furnace is heated to a very high temperature, therefore, a number of requirements are imposed on the facing materials:

- high strength and heat resistance

- resistance to mechanical stress

- low porosity structure

- thickness from 6 mm.

Several modern and traditional types of building ceramics meet these requirements: majolica, terracotta, tiles, clinker tiles and porcelain stoneware - which differ in the way of installation and design.

The volume of materials used in the construction is taken constructively. In this case, it is necessary to calculate: how much brick is needed to build a Dutch oven.

During construction, the following tools will be required:

- level;

- Master OK;

- roulette;

- container for building materials;

- shovel.

In addition, you will need stove dampers that regulate the draft and combustion rate of the fuel, a furnace door.

Let's move on to calculating the number of bricks required to build a Dutch oven.

How many grams of bricks do you need?

Consider one of the simple and popular calculation methods that allows you to quickly find out how much brick is needed to build a Dutch oven.

Formula

The following formula is used for the calculation:

This formula uses the following parameters:

- B is the planned height of the furnace;

- P is the height of one row;

- O is the number of bricks in the first row.

Let's look at an illustrative example.

Let's say a Dutch woman is planned to be built with a height of 2.4 m, at the base of which there are 24 bricks. The height of one row is 7 cm (the thickness of one brick).

- From the planned height of the furnace, 0.3 m should be subtracted for cutting. This leaves 2.1 m after subtraction.

- The resulting number should be divided by the height of one row, as a result, we get 30 rows.

- We multiply the resulting value by 2/3, that is, subtract 10 rows.

- There are 20 rows left.

- Multiply the resulting number of rows by the number of bricks at the base (24 pieces).

- We get 480 bricks.

- Let's add 50 bricks for cutting.

Arithmetically, it looks like this:

The result is 530 bricks - the required number for the construction of a thirty-row Dutch oven.

The number of bricks for the construction of a chimney is calculated separately. It is determined by the height and cross-section of the chimney. Thus, the formula should be used:

The following parameters are used:

- Chd is the number of rows in the chimney;

- H is the number of bricks in one row of the chimney.

These simple calculations will allow you to determine how much brick will be needed to build a Dutch oven.

Calculation example

To understand the calculation method, it is worth considering it with an example - this will allow you to calculate in the future how many bricks are needed for the furnace, but for an individual project. Regardless of the perimeter of the stove, its first row is still laid out completely - for example, 4x4 bricks, i.e. for a monolithic first row, 32 bricks are required.

To continue calculating bricks for a stove, you need to determine the number of rows, for which the height of the room must be known. The standard single brick is 65 mm high and the joint thickness between rows is 5 mm. As a result, it turns out that the total thickness of one row is 7 cm.With a room height of 2.8 m, 30 cm is subtracted from this value for the fire structure, and the calculated size of the stove as a result is 2.5 m.

The resulting value must be divided by the thickness of one row, and in this case you get 36 rows. Multiplying the calculated number of bricks required to complete one row by the number of rows, you get 1152 bricks. The design of the furnace is one-third hollow, so 2/3 of the total number of bricks is calculated - and this is 768 bricks.

The next step, which allows you to find out how many bricks you need for a stove in a house, is to calculate the number of bricks for a chimney.In a standard square tube, each row consists of 6 bricks - and a 4m tube with 57 rows would require 342 bricks. Here, the calculation methodology is exactly the same as in the case of the main part of the furnace. Of course, this method is not suitable for determining the number of bricks in the case of round or rectangular chimneys.

When deciding how many bricks are needed for the oven, it is imperative to take into account the number of bricks that will be used for cutting.

The quantity directly depends on the design of the furnace, its location and wall thickness, if the furnace is built into it. For a single wall, the minimum groove width is 25 cm, so a single groove is laid out on each side of the oven. In total, we get 36 rows on both sides, or 144 bricks. If the stove is not adjacent to the wall, then cutting is needed only near the ceiling and roof elements. In this case, the number of bricks will vary from 30 to 50 pieces.

Considering how many bricks are needed for a Russian stove, it is imperative to leave a small tolerance for the number of bricks. The thing is that during transportation and work, part of the brick necessarily becomes unusable. As a rule, in calculations, the tolerance accounts for about 10% of the estimated amount of bricks.

Foundation? Foundation!

The Dutch oven, despite its low weight, needs a foundation. You can equip the foundation in two ways - from cement mortar or from bricks. Both options have their own characteristics.

If free sand and gravel is available, then pouring a foundation from a cement mixture will be cheaper than a brick foundation. However, this is a time consuming process, even when using a concrete mixer.

In turn, the Dutch woman's brick foundation will much more expensivebut it is also much easier to do.

Formation of a cement foundation

Consider a method of forming a cement foundation for a Dutch oven.

You need to do the following:

- Prepare a pit, the depth of which is at least 50 cm. The area of the base to be formed must be larger than the size of the planned furnace.

- To make from gravel a pillow 10-1 cm thick and gently tamp it.

- Install formwork and put a reinforcing frame made of metal rods, the thickness of which is 1 cm.

- Prepare cement mixture and gradually pour the reinforcing structure.

- Cover by foundation with cement powder.

And now the solution.

High-quality laying of a Dutch oven with a stove requires the preparation of clay mortar. The strength and heat resistance of the Dutch woman, its tightness during operation, depend on the quality of the solution.

If the proportions of the elements constituting the solution are violated, cracking of the furnace and even carbon monoxide leakage are possible.

The ratio of binders in the composition of the clay solution depends from its destination:

- for masonry work or

- for finishing a stove with a stove.

The cured mixture must have a high level of hardness. Masonry mortar of the correct consistency will be plastic and viscous, it will not crumble and will not be liquid.

What are the furnaces

Diagram of a Dutch heating furnace.

The classic Dutch model is purely heating. The rectangular model has a single brick wall. Subsequently, furnaces appeared in the form of a triangle, a trapezoid, and a round shape.

They can be heating, with a fireplace, with a stove, a tank for heating water. It's easy to create them with your own hands. You need to choose the appropriate option and get to work.

A small stove for a summer residence will take up very little space. Its perimeter is about 50 cm. Moreover, it is capable of heating several not very large rooms. You can lay it out of ceramic bricks. For the manufacture of the firebox, a fireclay refractory type is used.

A Dutch woman with a stove is a rather rare option; it is often used not only for heating, but also for cooking. It is easy to fold it with your own hands using solid ceramic bricks.Fireclay bricks for the firebox.

We suggest that you familiarize yourself with How to lay out a brick chimney with your own hands

A three-turn stove is laid using red ceramic solid bricks. Fireclay is suitable for the furnace zone.

The round stove was quite often used to heat the buildings of hospitals, orphanages, that is, where there were no funds for full-fledged stoves. Usually it was laid out in one brick, and covered with a steel casing on top. This Dutch oven seems simple, but rather complicated in execution, so it is better to entrust its manufacture to an experienced craftsman. Laying it out with your own hands is unlikely to work.

Diagram of a Dutch oven with a stove.

For a house in which they constantly live, it is necessary that the stove can store heat for a long time.

This largely depends on its mass and, as a result, the amount of material spent on construction. The efficiency factor is important, on which its efficiency depends.

For a summer residence, where the owners are only on short visits, the stove must heat up quickly. This is a lighter, more economical option that requires little material. The ideal option in such a case would be a Dutch woman.