[contents]

There are several reasons why why does the water boil in the boiler heating. For example, boiling is often a consequence of the fact that the liquid heats up in the boiler faster than the heat energy is transferred to the heating main. This happens due to:

- incorrect installation of the system;

- the fact that there is no circulation (or its speed is low) - usually occurs in open-type systems with an expansion tank;

- too much power of the device compared to batteries;

- low amount of water in the line.

Low circulation rate

So, if the coolant circulates too slowly, then the coolant will not fully transfer the received heat and, as a result, the water in the boiler will boil. This only applies to systems in which there is natural circulation of liquid, and the angle of inclination or diameter of the pipes is not selected correctly.

Note! In systems with forced circulation, this happens only in those cases when the pump power is too low or it has completely failed.

Boilers with automatic ignition.

The water circulation in the heating circuit is interrupted.

Due to the slow movement of the coolant in the heating system, the water in the heat exchanger overheats, and the boiler stops in emergency mode. The speed of fluid movement in the system can be affected by reduced performance or breakdown of the pump, contamination of the filter installed on the "return" of the heating circuit, improper operation of the three-way valve.

The performance of the circulation pump is reduced due to contamination of the turbine blades or internal cavity.

Photo 1 - gas boiler circulation pump module with automatic ignition.

To revise it, you need:

- Smoothly stop by moving the knob of the water temperature regulator to the extreme zero position and, after waiting for the process to complete, disconnect the boiler.

- Dismantle the front part of the housing.

- Determine where to install the pump.

- Close the shut-off valve (No. 2, No. 3, No. 4, photo 2) of the supply, return, and cold water supply.

- Drain the boiler through the drain cock and leave it open.

- Loosen the pump fasteners until air enters the circuit to drain the residual fluid from the system.

- Dismantle the mount, power plug and remove the module (engine with turbine).

- Clean the blades, inner cavity and rubber seal of the mechanism from dirt.

- Assemble the pump.

- Open the cold water inlet tap.

- Open the make-up valve slightly to check the tightness of the hydraulic part of the boiler.

- Open the flow and return valves.

- Fill the system with water to a pressure of 1 bar.

- Turn on the boiler in recirculation mode to remove air.

Photo 2 is an example of the piping of the heating system.

In boilers with electronic control, in the event of a pump breakdown, the corresponding fault code will be displayed on the dashboard, which is deciphered using the boiler passport or electronic catalogs posted on the manufacturer's website.

Checking and cleaning the filter:

- Shut down the boiler smoothly.

- Using the taps (No. 1, No. 2) installed in front of the filter and behind it, shut off the water supply.

- Using the filter drain valve, drain the water from the isolated area.

- Unscrew the flask and clean the strainer.

- Collect all filter components.

- Open previously closed valves.

- When the system pressure drops, recharge the circuit.

- Switch the boiler on to the venting position.

Checking the three-way valve.

In double-circuit wall-mounted gas boilers, switching from heating mode to the position of hot water supply is carried out using a three-way valve. It consists of a servo (gear motor), stem, rubber seals, valve and body with inlet and outlet ports. A malfunction of this device can lead to the cessation of the circulation of the coolant and, as a consequence, the overheating of the heat exchanger is formed.

To check the condition of the three-way valve, it is necessary to smoothly stop the boiler and disconnect the system from power. Check the serviceability of the engine, and for this, connect the ohmmeter probes to the power terminals. If it shows 80 - 300 Ohm, then the engine is in good order, and if other readings (0 or 1), then it is faulty.

The three-way valve may not switch due to a jammed actuator gearbox or deformation of the valve itself. If a valve malfunction is detected, it is changed to a serviceable one, or it is subject to revision.

Little coolant

If there is too little water in the system or air locks have formed, then this can also be the reason why the water boils in the heating boiler. If there is an expansion tank, then you just need to add water. In other cases, it is enough to bleed the air (if there is no automatic valve, of course).

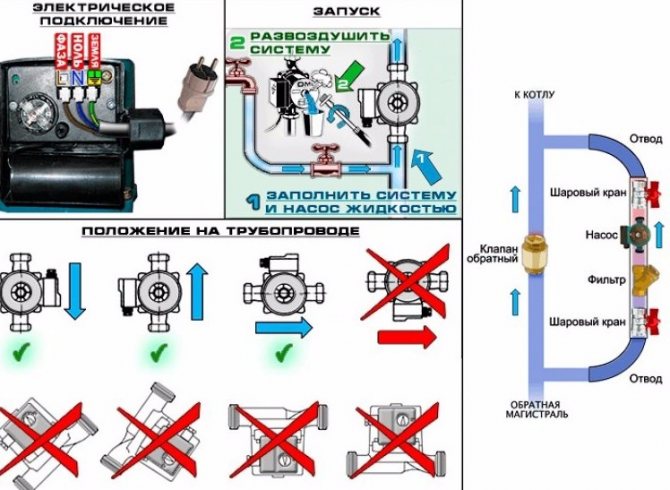

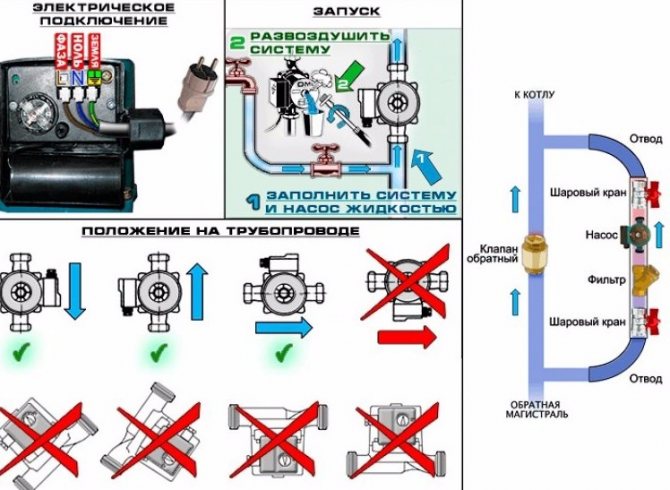

To increase the intensity of circulation, the heating system should be re-equipped, and it is better, if possible, to install a circulation pump. In this case, even if the pipes are not tilted correctly, the water will circulate properly.

Circulation problem

If you have a circulation pump, but the system is unstable, then the problem may lie in it. To check the performance, put your hand on the battery - if you feel a slight vibration, then the pump is working normally, if not, follow these steps.

- Check and clean electrical contacts.

- Check pump parts for wear and lime deposits (if using regular tap water).

- Finally, you can turn off the pump, unscrew the plug and turn the shaft with extreme care. This should help for a while. Citric acid can be used to remove deposits.

Hopefully now you know why does the water in the boiler boil... To avoid similar problems in the future, we advise you to watch a thematic video, and you can learn more about the boilers here - https://formulatepla.com.ua/7-kotly-dlitelnogo-goreniya.

High boiler output

If the power of the device is higher than the heat transfer of the line, this can also lead to boiling of water. Especially if the air supply control system is broken or missing at all. There are several options for solving the problem:

- put an automatic adjustment system;

- put a similar, but semi-automatic;

- change the boiler (if it is made by hand);

- increase the number of batteries;

- increase their power.

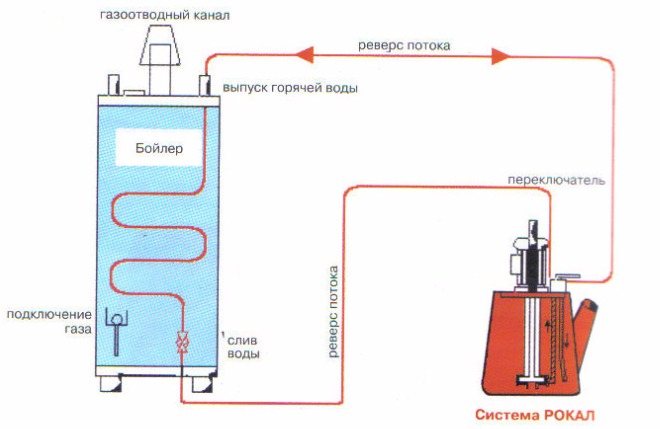

Note! In addition, you can embed an indirect heating boiler into the main line - this device will "absorb" some of the energy from the water heating system and will serve as a kind of heat accumulator.

How to restore boiler operation

If the equipment overheats, do not delay the repair. There are times when a gas boiler explodes, so fix the problem as soon as you notice it.

Clogged and airy system

If the water stagnates and does not circulate in the circuit, it will boil. You can hear the liquid bubbling inside. Turn off the device, wait for the coolant to cool. Filters on both sides are often blocked by valves, so you don't have to drain all the water from the system.Tighten the taps, remove and rinse the filters.

If the strainer is heavily clogged, immerse it in the citric acid solution. Additionally, you can clean the part with a soft brush.

Filters that are worn out and cannot be cleaned are best replaced.

An air lock slows down the movement of the liquid or stops it altogether. How to deal with it:

- Open Mayevsky's taps - they are on every radiator. Substitute containers under them first;

- You will hear the hiss of air coming out of the circuit. Then water may pour out. Do not close the taps right away. Wait until the liquid has been drained and all the air has been vented;

- Repeat the procedure until the air lock is completely eliminated.

Scale deposits

Magnesium and potassium salts are deposited on boiler parts when heated above 55 degrees. Most of all scale settles in the heat exchanger, because the liquid circulates and heats up in it. As a result, the passages in the tubes narrow, the pressure decreases, and water boils in the unit. This leads to overheating and damage to the heat exchanger.

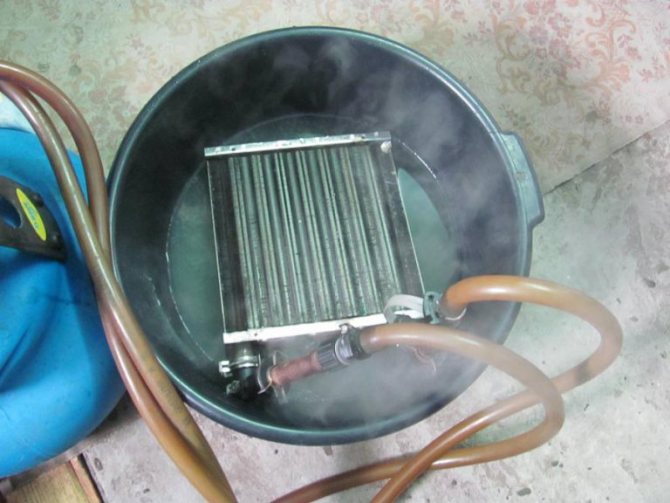

Dismantle the assembly to clean it. The most effective way is to connect a pump to the unit and pump it with a reagent. After that, the radiator is rinsed with running water, dried and installed in place.

At home, the radiator is placed in a metal container with warm water. A solution of citric acid is poured into the coil. The container is placed on the stove, where it heats up for half an hour.

Install magnetic filters to prevent limescale build-up. It is enough to change their cassettes once a month, but they soften the water well.

Pump problems

When turning on the boiler after a long idle period, check the pump. Its parts could get stuck and the holes could get clogged. Clean and replace defective parts.

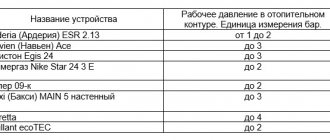

Reasons for overheating and boiling of heating boilers

Reasons for overheating of boilers

There are many different reasons why this can happen, let's try to consider them using examples of boilers with different modes of operation.

Gas

The first reason why the gas boiler overheats and the liquid boils in it is the lack of circulation in the heating circuit. The reason for this lies in the clogging of the filters, or the heating circuit has been airy. It is necessary to view all filters, rinse them, and, if necessary, replace them with new ones. If the problem lies in the airing, it is necessary to remove the air. Very often this situation occurs in old gas devices from Navien.

The next reason may be a banal clogging with scale, that is, particles of plaque peeled off and clogged the duct. At the same time, during operation, clicks may occur, or such sounds as if he were knocking. The solution is quite simple - you need to clean the device using special chemicals, or using acids.

It is also possible that there was a prolonged non-use of the system, and then its start-up without first running the ventilation system. At startup, noise sounds are possible, and the device gives an error about insufficient circulation. This can be caused by sticking in the pump due to downtime. It is necessary to disassemble the pump and rinse, then restart it again.

A poor-quality gas-air mixture can cause an explosion, there are lower and upper limits at which an explosion occurs.

Another reason is non-compliance with the recommendations for the installation site of the equipment. If the room has high air humidity or low temperature, the metal from which the boiler is made will deteriorate. Corrosion may occur if sour fuel is used.

After all, there are areas that cannot be completely cleaned with the help of blowing, for example, the clearances of pipes and partitions.If the boiler is constantly in working condition, moisture cannot damage it, and when it is turned off, ash, as well as the lining surface, absorb moisture, which then leads to corrosion, and this, in turn, can lead to gas leakage and explosion.

Often users have a question why the water gurgles, there may be several reasons. The first is that the pump is out of order or wedges, the coolant boils and similar sounds are heard. Second, the battery is clogged.

If your device overheats, you need to follow these steps to fix:

- Check if the heating medium is circulating in the heating circuit.

- Cleaning and replacing filters.

- Check the serviceability of the radiator taps.

- Check the serviceability of the circulation pump.

- Cleaning the heat exchanger.

Flushing the heat exchanger

- Check the draft in the chimney, pay attention to the smell of carbon monoxide during operation.

- The thermostat is faulty, and, as a result, the heating element does not turn off, but continues to heat the liquid, the temperature rises. As a result, all plastic elements inside the device melt, the power buttons melt. In practice, there have been many cases where this led to the explosion of the device.

- Limescale clogging. Often with this malfunction, the boiler seems to be breathing.

- The membrane has deteriorated.

Three-way valve diaphragm - The circulation pump does not work, as a result, the coolant does not circulate, and its temperature rises.

- Insufficient amount of coolant.

- Return valves closed.

Solid fuel

Very often, the abnormal operation of a solid fuel heating boiler is associated with the wrong choice of model. That is, when choosing a wood-burning boiler, the user prefers a device that has a large furnace, which is designed to heat an area of over 150 m2.

However, if you have a heated room of only 70m2, this will lead to the device overheating. And also to an increase in pressure in the boiler, which can ultimately lead to an explosion. Another reason may be an incorrect installation, because often such a responsible business is not entrusted to qualified specialists, but to people from the street.

The next situation that can increase pressure is if the electricity is suddenly cut off, and, as a result, the circulation pump stops. The coolant stops circulating through the heating system, the pressure rises sharply, and the liquid begins to boil quickly, all this can lead to an accident.

Circulation pump in the heating system

What if this happened? Shut off the fuel supply to the combustion chamber; it is strictly forbidden to extinguish the flame with water, as this can lead to a thermal burn of the skin and an explosion of the boiler. To safely extinguish the flame, you can use sand, ash.

Steam

Consider what are the main reasons why a boiler can explode. If the liquid level in the steam boiler is drastically reduced. This reason is the most frequent, due to a decrease in liquid, the walls overheat above the maximum permissible value. The chemical structure of the metal changes, its resistance decreases, and when pressure is applied to the walls, they are blown out, which ultimately leads to an explosion.

When the water level drops, in no case should it be filled with cold water, this will lead to a coma, that the metal will lose its plasticity, its fragility will increase and cracks will form. If water drops are detected, it is necessary to gradually turn off the device, cut off the fuel supply. After it cools down, fill it with liquid to the set rate, then start again.

To prevent the liquid level from dropping to a critical value, it must be equipped with a device that monitors the upper and lower boundaries of the liquid level, and if a discrepancy is found, stop the fuel supply.

Liquid of inappropriate quality. It occurs as a result of a change in the chemical composition of water, and most often, an increase in its hardness, since scale deposition increases. If the water that flows in your pipeline does not correspond to the characteristics stated in the instructions, it is necessary to purify it.

To do this, use a soda-lime solution, sodium, phosphate precipitation, can also be purified by cationization, this method involves filtering water through a special cation material.

Scale build-up on internal elements, which forms as a result of the accumulation of salts contained in the feed fluid. This can be avoided by using cleaning filters that are installed before entering the device. If it has already accumulated, it is necessary to clean the boiler in order to avoid overheating. The scale layer must not exceed 0.5 mm for the device to function properly.

Accumulation of explosive gas in the combustion chamber, resulting from improper operation of the ventilation system, or the ingress of fuel.

Defects or malfunction of the main units, a decrease in their safety margin due to improper operation, breakdown of control sensors, as well as measuring devices are often the cause of device explosions.

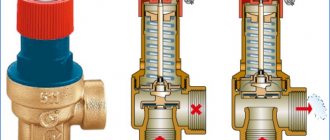

Increase in working pressure. The main reason for such a malfunction is the failure of safety elements, as well as non-compliance with the established regime.

Heating boiler safety group

In order to identify a malfunction in a timely manner, it is necessary to periodically subject them to a technical examination (once a year), as well as tests; for greater safety, carry out them not only according to the plan.

Electrical

Reasons for overheating in electric boilers:

Overheating Prevention and Prevention

The measures to prevent and prevent emergencies include the following:

- Install an additional circuit to cool the solid fuel boiler. In a double-circuit boiler, with an increase in the coolant, the liquid can be cooled due to the water supply system.

- Installation of a buffer tank, it will prevent the boiler from boiling, take on excess temperature, and can also store heat for the heating circuit.

- You need to install an uninterruptible power supply. If a power outage occurs, the UPS will automatically turn on, power will be drawn from the battery, and the system will continue to operate.

- Clean the ventilation system periodically.

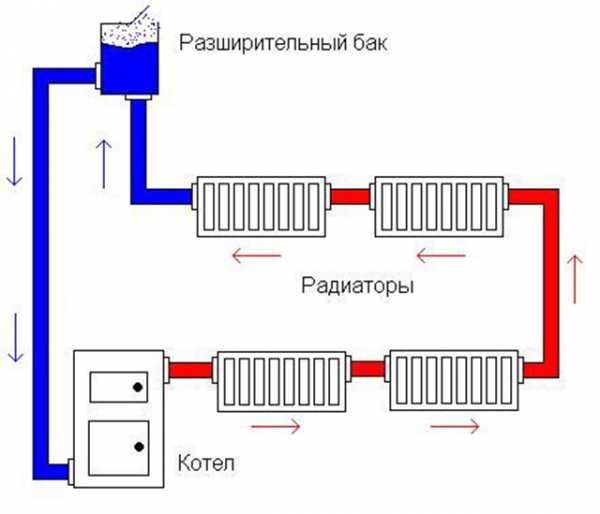

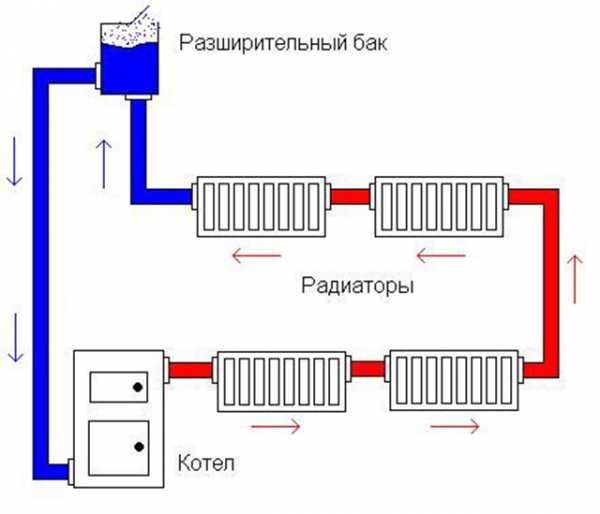

The principle of operation of the heating system

To describe it very briefly, then the principle of a heating system in a private house is that a certain liquid, be it water or frequently used antifreeze, heats up in the boiler to a temperature set by the user.

Heating system diagram

Then it flows through the heating main (pipe) to the radiators, in which it gives off its heat, then circulates back through the return circuit to the heating device. It warms up again, it is essentially a closed circuit.

There are two flavors of the system:

- One-pipe. It is the most economical and simple to implement. It looks like a ring in which heating radiators are sequentially mounted. The coolant circulates in a circle, while the most heated liquid enters the first radiator, which shares heat with it and at the same time loses several degrees, while the already significantly cooled coolant reaches the fifth or sixth radiator.

The way out of this situation, so that the batteries are not cold, is an increase in the number of sections with each subsequent radiator, so that heat losses are not so noticeable. Or increase the temperature of the coolant in the boiler, and this will entail significant costs.However, it is possible to install a circulation pump that will artificially increase the speed of movement of the coolant and, accordingly, reduce heat loss, and this will also slightly reduce the heating interval. However, there is also a drawback, namely, the cost of electricity.

- Two-pipe, several times superior in energy performance. It involves branching the coolant into two outlets, as a result of which the heat loss is halved. They have a common return path.

However, to build such a system, you will need twice as many pipes, valves, sensors. Most often used in gasified premises.

boilervdom.ru

Extraneous sounds in the heating boiler

Sometimes boiler lighting is also accompanied by some sounds. When cold equipment heats up and begins to crack, then the characteristic clicks should not cause panic - the metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur when there is not enough coolant in the pipes. In this situation, it is enough to add water to heat evenly.

Cotton

You can hear such sounds if the gas pipes are clogged. This happens when the boiler is fired up: the accumulated gas, not having time to go outside, creates a pop. This is dangerous as a violently escaping flame can cause burns or fire.

If the boiler is gas, then the reasons for this noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

Knock

The occurrence of knocking in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump works unevenly, moving the coolant in jerks, a resonance occurs between the boiler and the pump, accompanied by a characteristic knock. In this case, it is necessary to regulate the pump.

Sounds in different boiler models

Noise can arise for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners. To avoid such a nuisance, it is necessary to choose boilers with atmospheric burners and an electronic control system.

When choosing a model of a solid fuel or electric boiler for heating a house, it is always necessary to get acquainted with the technical characteristics of the equipment. Often the reason for the noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also sin with noisy work: although not clearly, the overflow of water and the filling of the system are always accompanied by sounds.

ZOTA boilers are very sensitive to the quality of the coolant, therefore, the cause of unpleasant effects can be:

- clogged mud sump;

- oxygenated water;

- scale on working elements;

- broken bearings on the fan.

Therefore, it is worth stopping the choice on single-circuit models, and purchase a boiler for heating hot water.

Prices for boilers ZOTA

boilers ZOTA

Prophylaxis

Timely prophylaxis of all components of the boiler equipment can minimize the likelihood of noise.

So, flushing the system once a year is a prerequisite for trouble-free operation. Moreover, this is becoming a mandatory requirement of many resource supplying organizations in preparation for the heating season.

You can flush the system yourself or use the services of specialists.

Depending on the coolant, the type of cleaning is selected:

- Flushing with water under pressure generated by the compressor. Sometimes this is enough.

- In case of deposits of iron oxides on pipes, appropriate chemicals are used. They eliminate the problem and additionally create a protective barrier against further exposure to an aggressive environment.

- You can use the services of a specialized organization that has the equipment and means to carry out the work.

Each operating manual for heating equipment provides a recommendation for preventive inspection and cleaning of the working parts of the boiler from corrosion and all kinds of contamination with partial disassembly - at least once a year. If you do not carry out maintenance, the manufacturer will void the warranty.