Features of Koreastar boilers

The boilers are designed for space heating and hot water supply

The company manufactures double-circuit units designed to implement two tasks - home heating and hot water supply. Floor standing units are available for wall mounting. The liquid for heating the home and for household needs is prepared separately for most devices. To neutralize the associated heating slowdown, the products are equipped with a three-stroke solenoid valve.

When the coolant is cooled to +5 degrees, the gas boiler is turned on by means of automation. This prevents the water from freezing in the pipes. Decrease in gas pressure (up to a certain limit: minimum - 4 mbar) and changes in the mains voltage do not affect the stability of the boiler.

About company

KoreaStar is an enterprise founded in 2003. On the Russian market since 2004. The company produces a variety of household and industrial equipment. One of the activities is the production of gas heaters, which are sold all over the world. The brand supplies several dozen models of different designs and capacities to Russia. During the assembly, Korean and European components that meet ISO 900 standards are used. The "Korean Star" works closely with the German company Wilo. The latter supplies circulation pumps to its eastern partner.

Specifications

The power of Koreastar gas boilers, depending on their design and the volume of prepared water, varies from 10 to 40 kW. Parameter setting and operation control are carried out remotely by means of the remote control. The microprocessor board withstands voltage surges well. Also, the boilers are equipped with a remote thermostat, whose function is to turn off water heating when the temperature reaches the desired level. The design uses German-made circulation pumps and a liquid crystal display.

The performance of a specific model of the Coreastar boiler is indicated in the instructions. For the least powerful variations, it is approximately 13 l / min. The heat exchanger is equipped with additional protection, due to which the unit lasts longer. Some types of boilers are produced in versions with a closed and open combustion chamber, others - only in the first version.

Major error codes

Error a01 - there is no signal about the presence of a flame. Gas does not flow or the gas valve or electrode ignition of ionization is faulty. The control board may be malfunctioning.

It is necessary to check all stopcocks and, if necessary, bleed air from the water supply. Check the gas pressure on the valve - it should be 20 mbar (2 kPa), as well as the gas valve itself (replace if necessary).

Check the electrode for contamination and the gap between it and the burner. It should be 3 mm ± 0.5 mm.

Error a02 - a false signal about the presence of a flame. Control board or ignition electrode defective. Check for mechanical damage on the electrode itself, it is possible that it touches the burner. Also set the required gap between the burner and ignition / ionization - 3.5 ± 0.5 mm. Replace the control board if it fails.

Boiler ignition electrode Coreastar

Error a03 - the boiler is overheating. A bimetallic overheating sensor (or it is also called an emergency thermostat) blocks the operation - the threshold temperature is about 90 degrees. Air has entered the heating system and / or insufficient circulation in the heating water.

It is necessary to cool the boiler down and restart it. Replace the sensor if necessary. Remove air from the circuit.Check the pump - open all shut-off valves, check the pump blades for contamination and the voltage supply to its contacts. Replace the pump if necessary. When a03 reappears, the control board should be replaced.

Error a08 - the extract air overheating sensor is faulty. The temperature limiter gives an incorrect value. Check for open or short circuit and replace if necessary.

Error f05 - a failure has occurred in the smoke exhaust system. Fan or air relay not working correctly or defective. Chimney is clogged.

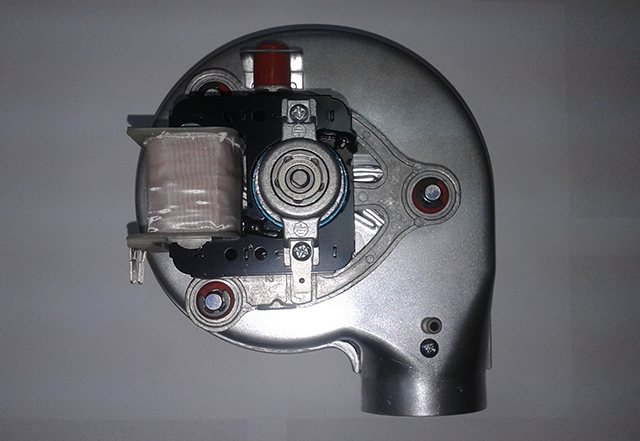

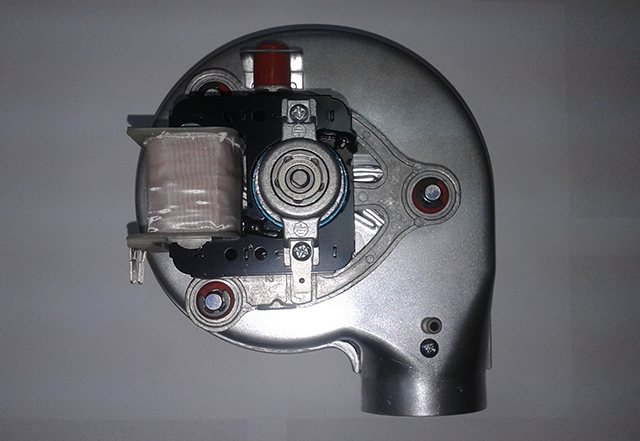

Boiler fan Coreastar

Check the correct connection of the connectors to the contacts of the air relay and make sure that the air diaphragm does not stick. Replace relay if necessary.

Error f11 - the NTC sensor of the extract air temperature is faulty. Open circuit or short circuit of the device. Check the semiconductor resistance - it should be 10 kOhm. There may be no signal between the control board and the temperature sensor. Disconnect the sensor and then reconnect it. Replace if defective.

Error f37 - NTC DHW temperature sensor. Open circuit or short circuit of the corresponding device. With such an error, the burner will not be able to ignite only in DHW mode. The boiler itself will be able to continue its work. Check the resistance of the sensor and the quality of the connection of the connectors. Replace parts if necessary.

The same code indicates a low pressure in the heating system. The extract air pressure sensor is defective or the circuit pressure has dropped below 0.8 bar. Check the sensor, replace if necessary, and find a leak. Eliminate the problem and recharge with water.

Error f41 - the heat exchanger is overheated. Poor heat exchanger circulation or trapped air. Remove air and check the pump according to the procedure described in the instructions, with the shut-off valve open. Replace the circulation pump if necessary.

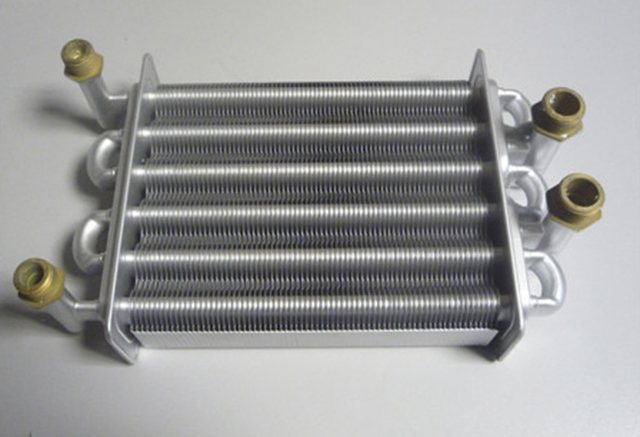

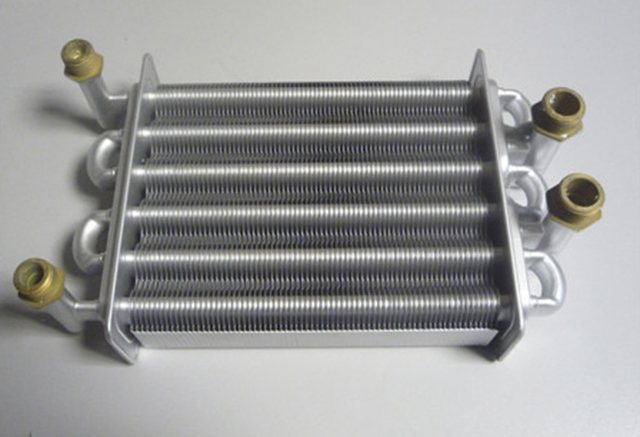

Heat exchanger for Koreastar boiler

Error f50 - the control board has malfunctioned. Malfunction of the control board. Check the absence of "breakdown" on the case, grounding, and in case of failure, replace the board.

Advantages and disadvantages

The equipment prevents smoke from the premises

When choosing a Coreastar boiler, buyers are attracted by the reasonable cost of these devices and the price-quality ratio: few can afford to buy a German-made unit. Well-coordinated work in the conditions of cold winters inherent in a significant part of the territory of Russia is also of interest to the owners of private houses.

Other advantages of these devices are:

- low noise level from a running pump;

- high-quality automatic control unit;

- climate control option;

- optimization of gas supply (initiation - when the burner ignites, termination - when it goes out), which saves fuel;

- the use of a device that prevents smoke from the premises;

- a mechanism that prevents the freezing of the coolant.

The downside is that sometimes voltage surges still cause malfunctions of the microprocessor board, despite the manufacturer's instructions on stable operation with drops within 15% on both sides of the nominal. You can prevent such incidents by installing an uninterruptible power supply.

When the owner of a boiler with a closed chamber turns on the device, he may encounter noise - this is due to the type of burner used. Such a unit should be installed in a separately equipped boiler room.

Testimonials

Premium 24E: Raisa P., Dedovsk

I liked it for its capabilities and affordable price. Worked well, kept the temperature at a given level. But in the second year of operation, the pressure switch broke down, which could not be found. And it’s good that it wasn’t winter, otherwise we would have had to freeze.

Premium-24E Turbo: Leonid J., Kostroma

Has been working for two years.During this time, I showed an error twice - a work failure. It was eliminated by rebooting. Before the start of the heating season, the DHW flow sensor broke down, so they could not turn on the boiler: information about hot water supply was constantly on the screen. The master, having arrived two days later - due to workload, changed the spare part free of charge, under warranty. Pros - compact, hangs on the wall and does not bother anyone. No need to build a chimney. Consumes little electricity. Of the minuses, it depends on the power grid. It is difficult to regulate the water temperature with a low head. Lack of specialists, we have to wait for a master for a long time.

The efforts of the manufacturer and its marketers were crowned with success - KoreaStar products have won their niche in the Russian market. Consumers are attracted by the affordable cost and reliability of Korean boilers. There are usually no problems with the operation of equipment, but there are maintenance and repair problems. This is due to the insufficient coverage of the territory of the Russian Federation with service facilities.

Installation and operation

It is better to entrust the boiler installation to a professional.

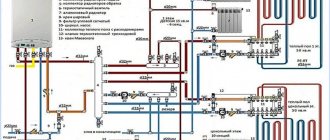

The boiler connection diagram is given in the instructions. It is determined by the characteristics of the device of this model. Some units are volatile, others do not need power supply. In the first case, a voltage of 220 V with a frequency of 50 Hz must be supplied to the connection point. Do not use tees, extension cords, connect other devices to the source. If a specific model needs to be provided with liquefied gas, a changeover is carried out by inviting a foreman.

In the boiler room, supply ventilation must be provided using equipment that creates a continuous movement of air flows. The use of gas fuel imposes a ban on the storage of chemically active and fire hazardous compounds and materials in the room where the boiler is installed. Do not place the unit next to a window, flight of stairs or in a wall opening, and do not place heaters and air conditioning devices next to it. In case of malfunctions, the display shows an error code (the decoding of the numbers is given in the instructions).

Selection rules

When choosing a boiler, you first need to calculate what power is required to service the dwelling. The roughest method is based on area: it is assumed that 1 kilowatt of energy is needed for every 10 square meters. To achieve greater accuracy of calculations, it is necessary to take into account the climatic features of the region where the dwelling is located, the material of the walls and the influence of various sources of heat loss. The manufacturer indicates to work with what dimensions of the premises this or that model is designed with a certain power value.

Products equipped with a bithermal heat exchanger heat the liquid faster, but do not last as long as versions with two insulated coils. Heating a living space of 300 m2 requires 3 cubic meters of gas per hour. With smaller rooms, the consumption will be lower. Using economy mode cuts spending by almost half.

Popular models

Premium 16E

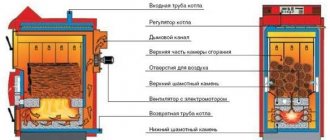

The actively positioned lines are Buran and the parapet non-volatile President. But earlier series continue to sell: Ace and Premium include closed chamber models (Turbo) and open wall units (Atmo). The Bravo Turbo range only includes closed chamber units designed to be placed on the floor. The company also produces indirect heating boilers that are connected to a floor-standing or suspended boiler.

Premium 16E

The 16E mark in the name means that the maximum power of the unit is 16 kW, it has a closed combustion chamber and is placed on the floor. As with other manufacturers, the name of a particular boiler model informs about some of its characteristics. The figure denotes the power indicator, letter A accompanies mounted boilers with an open chamber, and E - floor-standing boilers with a closed one.In Eco mode, the 16E consumes approximately 8.15 kW. It will effectively heat 160 m2 of living space. Boiler weight - 32 kg.

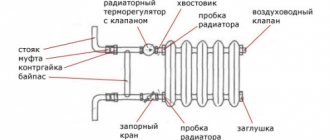

The efficiency of the devices of the Premium line is 93.1%. All of them are equipped with two heat exchangers: the one that works for heating is made of copper, and the one that warms water for domestic needs is made of steel. Performance allows you to prepare a shower at a cost of up to 13 liters per minute. Adjustable parameters are displayed on the LCD screen. The bypass valve protects the device from water hammer during pressure surges. Premium line models consume both natural gas and LPG.

Koreastar ace

Koreastar ace

This series is sharpened for the fastest possible heating of water. The devices have a bithermal copper heat exchanger. When operating in water heating mode, even low-power versions show a capacity of 10 liters per minute. The boilers have a built-in bypass (bypass), which makes them suitable for use with radiator equipment equipped with temperature controllers. The efficiency of the models is in the range of 90-91.2%, the power is in the range from 10 to 32 kW.

Koreastar boilers are well suited for servicing premises up to 320 m2, also providing hot water supply. The devices are equipped with blocks that ensure operational safety: protection against freezing of the coolant, against water hammer, anti-blocking of the main components.