The cooling process in refrigeration units occurs as a result of the boiling of freon, a gaseous substance that acts as a refrigerant (heat exchanger). This material is not only the main functional element, but also serves as a lubricant for the compressor of the device.

The boiling point of freon directly depends on the ambient pressure. In order for a refrigerator or air conditioner to maintain a cycle of condensation and evaporation of a substance, it is necessary to maintain a set pressure level in the system.

In refrigeration units, different types of freon are used, which have their own chemical composition and characteristics. The most commonly used refrigerants are of the following types:

- R-22.

- R-134a.

- R-407.

- R-410a.

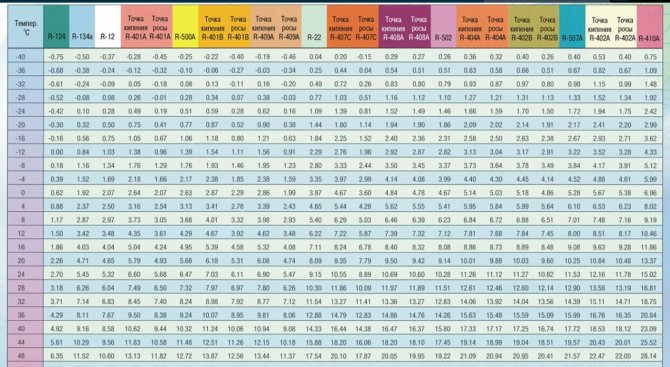

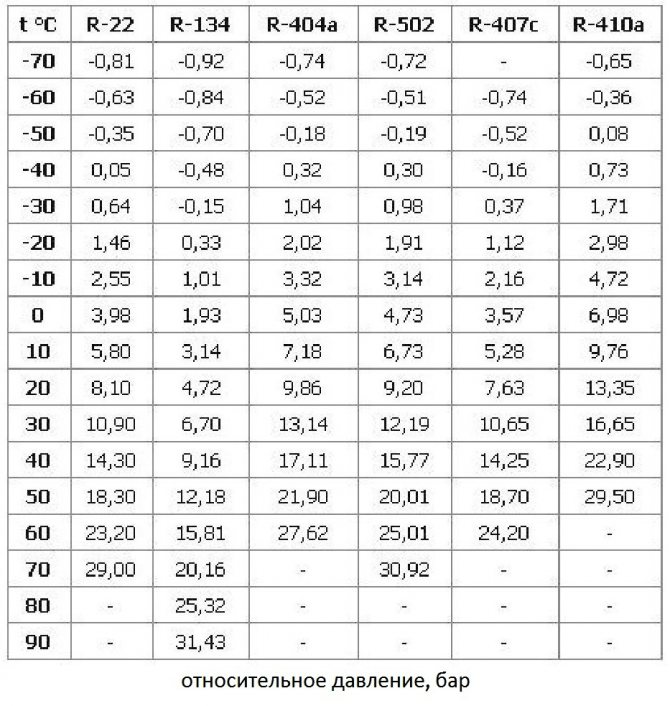

The boiling point of refrigerants differs, it can be determined from special technical tables. To refuel one or another refrigeration device, you need to take into account the type of freon that it uses in its work. If necessary, freon can be replaced with a refrigerant with similar pressure and boiling points.

Boiling point versus pressure

How do I use the table?

- Determine the type of freon in the system (look at the nameplate, valves or documentation)

- We measure the pressure in the system with a gauge manifold

- We look at the table for the temperature value for a given freon at this pressure

For example:

- refrigerant R22

- suction pressure 4.5 bar, discharge pressure 16 bar

- accordingly, the evaporation temperature of freon is +3.1 degrees C, the condensation temperature is +44.7 degrees. FROM

It is only necessary to measure the condensing pressure after the condenser, before the expansion valve or capillary tube, otherwise it will not correspond to reality.

Safety rules for handling freon

Freon R404A is the safest refrigerant for human health and the environment. By following the rules of use, dangerous situations can be avoided. Due to the anisotropic structure, the maintenance of the performance of the composition is ensured. For safety reasons, it is not allowed to mix the composition with air. During the operation of the equipment, it is required to avoid high temperatures and increased operating pressure, which provoke the ignition of freon.

The refrigerant dissolves with essential oil, but does not mix with mineral lubricant. When replacing freon, the manufacturer also recommends always changing the oil. When diagnosing the system to identify a leak, do not add air to the R404A circuit to increase pressure. Due to the stability of the structure and proportions, the mixture can be refilled when servicing refrigeration equipment.

The composition does not require observance of restrictions during transportation and it can be transported in cylinders by any type of transport in compliance with safety rules. Containers with gas are under pressure, therefore it is forbidden to store in the open sun in order to prevent heating above 50 ° C. Storage of freon in sealed containers should be carried out at a safe distance from open sources of fire and heating devices. The warehouse is equipped with efficient ventilation for ventilation.

The ZIKUL online store of spare parts for refrigeration equipment offers to purchase R404A freon supplied by the manufacturer in special cylinders with a gas weight of 10.9 kg.

Temperature glide

At the moment, many types of refrigerants have been synthesized (more than 70 types), many of them are multicomponent and consist of parts with different physical properties.

For this reason, the temperatures during evaporation and condensation are different.

There are two scales for such freons:

- dew - to determine the condensation temperature

- bubble - to determine the evaporation temperature

For example:

- freon R407c

- low pressure 4.5 bar, high pressure 16 bar

- we determine on the bubble scale the evaporation temperature -1 ° C, on the dew scale the condensation temperature is +43.8 ° C. FROM

R507 refrigerant applications

Freon R507 has been approved by most compressor and refrigeration system manufacturers for use in new equipment. Applications for the R507 include supermarket showcases, food storage, ice machines and transport refrigeration. R-507 can also be used in a variety of low and medium temperature industrial refrigeration systems with high energy consumption, where long term replacement of R-502 and R-22 with R-507 is a highly efficient solution.

Freon R-507 is also suitable for retrofitting in existing commercial refrigeration systems using R-502. At the same time, changes in the equipment design to optimize the operation of R-507 freon in these systems will be required only in rare cases.

To buy refrigerant r-507 wholesale or retail, leave a request in one click, and we will call you back to clarify the details of the order.

Prices for freon 507:

Programs for determining the dependence t / P

At the moment, many manufacturers of refrigeration equipment and refrigerants have released handy applications for phones on different operating systems (including the iPhone).

It is more convenient to use them, as they have an interactive scale that imitates the popular "refrigerator ruler" and also allow you to enter the exact value from the keyboard.

In their database there are more than 70 types of refrigerants produced at the moment.

You can get acquainted with the most popular of them and download it in this article.

Freon types for air conditioning systems

For about half a century, freon 22 was the main refrigerant in household air conditioning systems. From about the mid-80s of the last century, serious persecution began on its use, since supposedly chlorine, which is a component of this gas, affects the ozone layer that protects our planet from hard ultraviolet radiation. Although this stuffing was not 100% proven, this information led to the development of new and safer refrigerants: freons R410 and R407.

New types could not completely displace R22 from the HVAC market due to the ease of maintenance and some of the physical properties of this gas. Today, in household split systems, the following are most often used: R22; R410 and R407.

Freon R22 can most often be found in air conditioning systems used in everyday life, production and transportation of perishable goods. Since this type of refrigerant was used by almost all refrigeration equipment produced until the end of the last century, filling air conditioners with this gas is most in demand.

Freon R410 is a colorless gas that is a complete replacement for its predecessor. Now it is used in new climatic technology, regardless of its purpose. One of the features of this zaza is that when it leaks from the air conditioner, more than 35%, a complete refueling of the equipment is required.

Freon R407 is nothing more than a mixture of several gases, each of which is responsible for certain physical properties of the refrigerant. Most often used in multi-zone or semi-industrial split systems. This type of gas cannot be used to refuel climatic equipment: in case of leaks, it must be completely drained and only then the refueling procedure must be carried out.

Pressure temperature table for freons

| t ° C | R22 | R12 | R134 | R404a | R502 | R407c | R717 |

| -70 | -0,81 | -0,88 | -0,92 | -0,74 | -0,72 | — | -0,89 |

| -65 | -0,74 | -0,83 | -0,88 | -0,63 | -0,62 | — | -0,84 |

| -60 | -0,63 | -0,77 | -0,84 | -0,52 | -0,51 | -0,74 | -0,78 |

| -55 | -0,49 | -0,69 | -0,77 | -0,35 | -0,35 | -0,63 | -0,69 |

| -50 | -0,35 | -0,61 | -0,70 | -0,18 | -0,19 | -0,52 | -0,59 |

| -45 | -0,2 | -0,49 | -0,59 | -0,11 | -0,14 | -0,34 | -0,44 |

| -40 | 0,05 | -0,36 | -0,48 | 0,32 | 0,30 | -0,16 | -0,28 |

| -35 | 0,25 | -0,18 | -0,32 | 0,68 | 0,64 | -0,06 | -0,24 |

| -30 | 0,64 | 0,00 | -0,15 | 1,04 | 0,98 | 0,37 | 0,19 |

| -25 | 1,05 | 0,26 | -0,06 | 1,53 | 1,45 | 0,75 | 0,55 |

| -20 | 1,46 | 0,51 | 0,33 | 2,02 | 1,91 | 1,12 | 0,90 |

| -15 | 2,01 | 0,85 | 0,67 | 2,67 | 2,53 | 1,64 | 1,41 |

| -10 | 2,55 | 1,19 | 1,01 | 3,32 | 3,14 | 2,16 | 1,91 |

| -5 | 3,27 | 1,64 | 1,47 | 4,18 | 3,94 | 2,87 | 2,6 |

| 0 | 3,98 | 2,08 | 1,93 | 5,03 | 4,73 | 3,57 | 3,29 |

| 5 | 4,89 | 2,66 | 2,54 | 6,11 | 5,73 | 4,43 | 4,22 |

| 10 | 5,80 | 3,23 | 3,14 | 7,18 | 6,73 | 5,28 | 5,15 |

| 15 | 6,95 | 3,95 | 3,93 | 8,52 | 7,97 | 6,46 | 6,36 |

| 20 | 8,10 | 4,67 | 4,72 | 9,86 | 9,20 | 7,63 | 7,57 |

| 25 | 9,5 | 5,39 | 5,71 | 11,5 | 10,70 | 9,14 | 9,12 |

| 30 | 10,90 | 6,45 | 6,70 | 13,14 | 12,19 | 10,65 | 10,67 |

| 35 | 12,60 | 7,53 | 7,93 | 15,13 | 13,98 | 12,45 | 12,61 |

| 40 | 14,30 | 8,60 | 9,16 | 17,11 | 15,77 | 14,25 | 14,55 |

| 45 | 16,3 | 10,25 | 10,67 | 19,51 | 17,89 | 16,48 | 16,94 |

| 50 | 18,30 | 11,90 | 12,18 | 21,90 | 20,01 | 18,70 | 19,33 |

| 55 | 20,75 | 13,08 | 14,00 | 24,76 | 22,51 | 21,45 | 22,24 |

| 60 | 23,20 | 14,25 | 15,81 | 27,62 | 25,01 | 24,20 | 25,14 |

| 70 | 29,00 | 17,85 | 20,16 | — | 30,92 | — | 32,12 |

| 80 | — | 22,04 | 25,32 | — | — | — | 40,40 |

| 90 | — | 26,88 | 31,43 | — | — | — | 50,14 |

| t ° C | R410a | R507a | R600 | R23 | R290 | R142b | R406a |

| -70 | -0,65 | -0,72 | — | 0,94 | — | — | — |

| -65 | -0,51 | -0,61 | — | 1,48 | — | — | -0,94 |

| -60 | -0,36 | -0,50 | — | 2,12 | — | — | -0,9 |

| -55 | -0,22 | -0,32 | — | 2,89 | — | — | -0,83 |

| -50 | 0,08 | -0,14 | — | 3,8 | — | — | -0,8 |

| -45 | 0,25 | -0,02 | — | 4,86 | — | — | -0,66 |

| -40 | 0,73 | 0,39 | -0,71 | 6,09 | 0,12 | — | -0,62 |

| -35 | 1,22 | 0,77 | -0,62 | 7,51 | 0,37 | — | -0,4 |

| -30 | 1,71 | 1,15 | -0,53 | 9,12 | 0,68 | — | -0,2 |

| -25 | 2,35 | 1,67 | -0,38 | 10,96 | 1,03 | — | -0,1 |

| -20 | 2,98 | 2,18 | -0,27 | 13,04 | 1,44 | — | 0,2 |

| -15 | 3,85 | 2,86 | -0,18 | 15,37 | 1,91 | — | 0,4 |

| -10 | 4,72 | 3,54 | 0,09 | 17,96 | 2,45 | 0 | 0,8 |

| -5 | 5,85 | 4,42 | 0,33 | 20,85 | 3,06 | 0,22 | 1,1 |

| 0 | 6,98 | 5,29 | 0,57 | 24 | 3,75 | 0,47 | 1,6 |

| 5 | 8,37 | 6,40 | 0,89 | 27,54 | 4,52 | 0,75 | 2,1 |

| 10 | 9,76 | 7,51 | 1,21 | 31,37 | 5,38 | 1,08 | 2,6 |

| 15 | 11,56 | 8,88 | 1,62 | 35,56 | 6,33 | 1,46 | 3,3 |

| 20 | 13,35 | 10,25 | 2,02 | 40,11 | 7,39 | 1,9 | 4,0 |

| 25 | 15,00 | 11,94 | 2,54 | 45,03 | 8,55 | 2,38 | 4,8 |

| 30 | 16,65 | 13,63 | 3,05 | — | 9,82 | 2,94 | 5,7 |

| 35 | 19,78 | 15,69 | 3,69 | — | 11,21 | 3,55 | 6,7 |

| 40 | 22,90 | 17,74 | 4,32 | — | 12,73 | 4,25 | 7,8 |

| 45 | 26,2 | 20,25 | 5,09 | — | 14,38 | 5,02 | 9,1 |

| 50 | 29,50 | 22,75 | 5,86 | — | 16,16 | 5,87 | 10,4 |

| 55 | — | 25,80 | 6,79 | — | 18,08 | 6,81 | 11,9 |

| 60 | — | 28,85 | 7,72 | — | 20,14 | 7,85 | 13,6 |

| 70 | — | — | 9,91 | — | 24,72 | 10,23 | 17,3 |

| 80 | — | — | — | — | 29,94 | 13,07 | 21,5 |

| 90 | — | — | — | — | 35,82 | 16,4 | — |

Freon R32. New generation of refrigerants.

Freon properties and characteristics R32.Why manufacturers started using new freon R32.

The novelties of air conditioners in 2020 are already equipped with a new generation of freon R32 and show quite good results in improving the technical performance of air conditioning systems and reducing the impact on the environment. This primarily concerns the global warming potential (GWP). Compared to refrigerant R410A with R32, the latter has a reduced GWP of more than 65 percent. This means that the environment is less affected by the evaporation of the new refrigerant. Also, R32 has a reduced viscosity and density. Due to the lower density, the intensity of freon consumption decreases, taking into account the same power indicators. The density of difluoromethane is almost 30% less than that of the R410A refrigerant. The reduced level of viscosity leads to a decrease in pressure losses in the refrigeration circuit, which ultimately contributes to an increase in the total energy efficiency of the air conditioner by 5%. As for thermal conductivity, R32 is superior to R410 in this indicator. This positively adds up to the cooling capacity, which is increased by 4%. If we compare freons, then R32 is a one-component substance, and therefore it is very convenient to use due to the possibility of additional charging of the system without focusing on the amount of refrigerant contained in the circuit.

Table 1 reveals the characteristics of R32, R410A and R22. The physical properties of R410A and R32 are very similar and therefore for the functioning of the split system, identical diameters of copper pipes are used. You also need to say about the use of similar oils.

Table 1. Comparison of the characteristics of refrigerants used in climatic equipment

| R32 | R410A | R22 | |

| Category | HFCs | HFCs | HCFCs |

| Formula | CH2F2 | CH2F2 / CHF2CF3 | CHClF2 |

| Composition (% by mass) | – | R32 / R125 (50/50) | – |

| Evaporating temperature (° C) | -51,7 | -51,5 | -40,8 |

| PIU | 0 | 0 | 0,055 |

| GWP | 675 | 2100 | 1810 |

| Butter | Synthetic | Synthetic | Mineral |

Along with the features, R32 freon differs from the freons that are commonly used in climatic equipment, so the installers' personnel must have additional knowledge and experience in working with this refrigerant.

According to the classification of the ASHRAE 34 standard freon R32, it is a representative of the A2L class - low-flammable and non-toxic substances.

table 2 introduces the classification of refrigerant systems common on the market, taking into account their flammability. This classification shows that R32 is a substance with a low burning rate. In order for it to ignite, it is required to provide conditions that are difficult to achieve in a practical aspect.

Table 2. Classification of refrigerants, taking into account their degree of flammability according to ASHRAE 34

| Class 1 | Class 2L | Class 2 | Class 3 |

| Non-flammable | Low-combustible, burning rate less than 10 cm / s | Combustible | Highly flammable |

| R744 (CO2) | R717 (ammonia) | R152A | R290 (propane) |

| R410A | R32 |

Three main parameters of gas flammability:

The first parameter is the edge of fire. This applies to the maximum and minimum concentration of combustible substances in the air mass, contributing to the combustion process. If the concentration of combustible elements is outside the established limits, the mixture of air with them is not capable of igniting. If we consider R32, this freon will ignite if its content in the volume of the air mixture is in the range of 13.3-29.3 percent. This percentage range is very narrow given the fairly high lower concentration limit.

For example: a room with an area of 20 square meters must be filled with the volume of freon contained in 14 split systems in a short period of time so that a dangerous concentration of R32 will form in it.

Second parameter associated with the minimum energy required to ignite.The amount of minimum energy that the air mass will receive in a mixture with the refrigerant R32 and the combustion process begins is 15 megajoules. In comparison, acetylene will ignite at an energy of 0.017 megajoules. The difference between these substances, taking into account the energy potential, is more than 88 thousand percent. For example, you can designate the energy of a spark that occurs as a result of contact of a metal product with a concrete floor covering. It is 0.6 megajoules and, if exposed to acetylene, will ignite the latter. If this amount of energy is transferred to R32, this refrigerant will not ignite.

Third parameter associated with the temperature of spontaneous combustion. R32 will start burning at a temperature of 648 degrees Celsius.

Thus, the ignition of a mixture of an air mass and a combustible gaseous substance can occur only if the following conditions are created:

- the concentration of the refrigerant in the air mixture corresponds to the established fire limits;

- there is an external energy source or the mixture is exposed to a certain temperature.

If any of the above criteria is not met, the combustion process will not start, and accordingly, the operation of the air conditioner on R32 freon in normal household conditions is absolutely safe!

You can find out about the new products of 2020 of air conditioners on R32 freon by clicking on the link "The first air conditioners on R32 freon".