Polypropylene pipes are designed for cold, hot water supply and heating systems with a working pressure of up to 1 MPa. The service life of the pipeline is at least 50 years. The use of polypropylene pipes is regulated by GOST R 32415-2013.

For production, only virgin PPR type 3 polypropylene is used.

Pipes made of polypropylene do not corrode, do not overgrow, concealed laying is allowed, they are quick and easy to install, are lightweight, resistant to antiseptic and disinfectant solutions. The high resistance of polypropylene pipes to aggressive media makes it possible to use them in technological pipelines and industrial premises.

All pipes undergo voluntary certification for compliance with the requirements of regulatory documents.

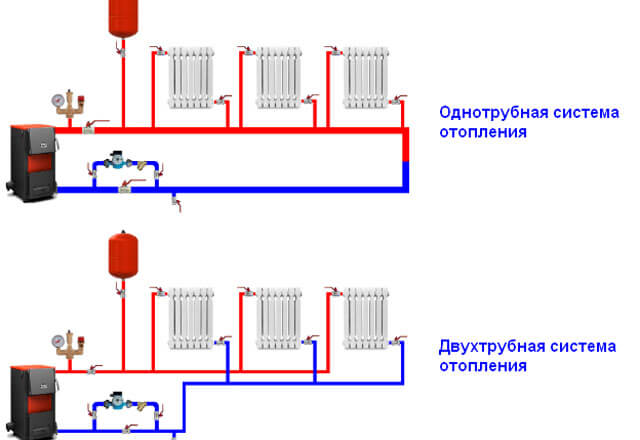

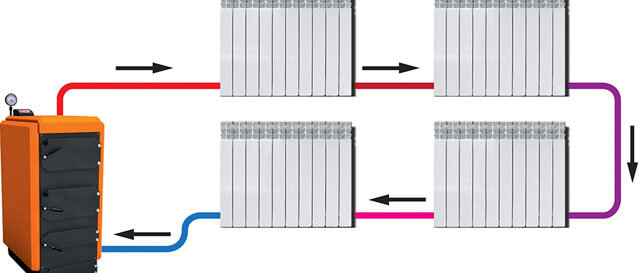

Advantages of one-pipe systems

To determine which heating system is more efficient - one-pipe or two-pipe, it is necessary to study the features of each of them. The strengths of heating circuits with one pipe are usually attributed to:

- Low costs for consumables and fixtures.

- Resistance to hydrodynamic effects.

- Simplicity in the preparation of project documentation.

- Low labor intensity of installation work.

- No special infrastructure requirements.

Although the advantages of a one-pipe system are many, it is difficult to call it the best option for organizing home heating. The main reason for the popularity of such schemes is the cheapness of their arrangement.

What does the heating control system calculate?

Modern control systems calculate the required boiler water temperature (flow temperature) depending on the outside temperature. The relationship between the outside temperature and the flow temperature is shown in the graph as a heating curve. The lower the outside temperature, respectively, the higher the flow temperature should be. There are three types of regulation of the heating

installation:

- outside temperature control

- room temperature control

- outdoor temperature control, taking into account factors affecting the indoor temperature

Illustration no. 2 Heating circuit characteristic curve (example) X - Outside temperature Y - Flow temperature

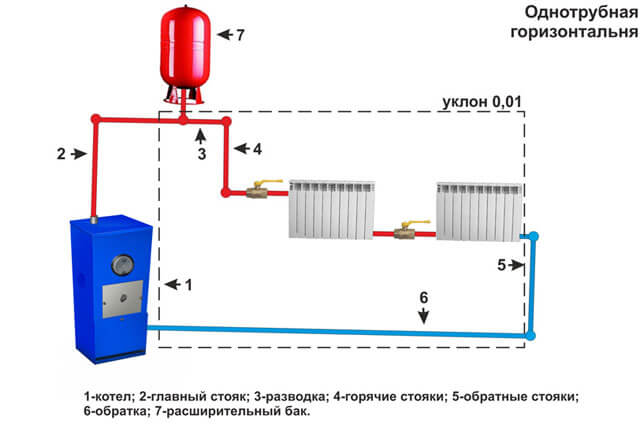

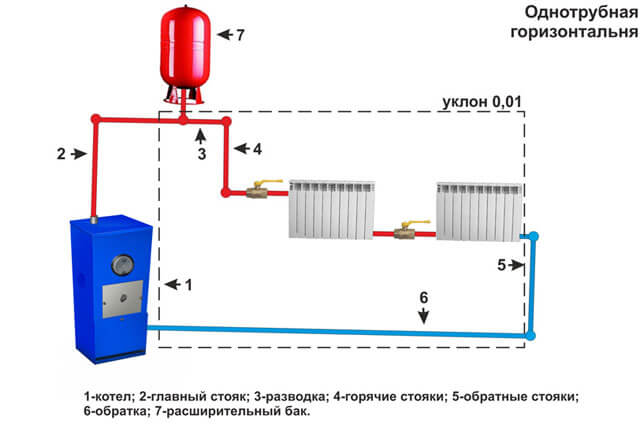

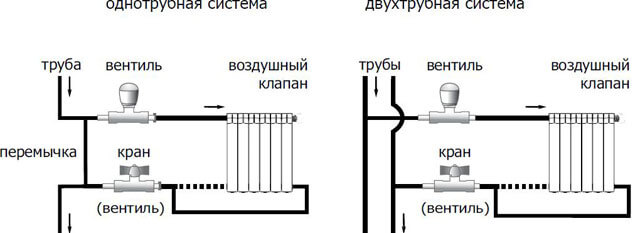

Improvements to single-pipe heating circuits

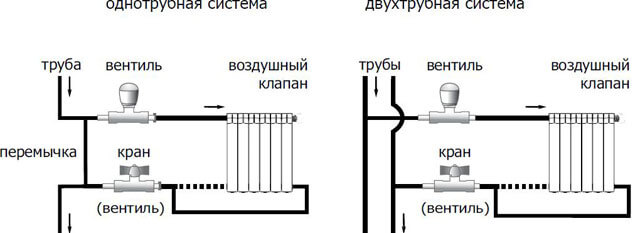

Appropriate technical solutions were developed to control the operation of heating devices. This will require special closing sections (bypasses), after connecting which it becomes possible to integrate automatic thermostats for batteries into the circuit. In addition, the installation of bypasses brings a few more positives.

The main positive effect of this upgrade is the ability to control the heating level of each battery or radiator. If necessary, the supply of coolant to the device can be completely stopped. This allows the battery to be repaired or replaced without shutting down the entire circuit.

A bypass is a bypass pipe that has special valves or taps. If everything is done correctly, water flows can be started up the riser, past the serviced or replaced heating device. As a rule, independent installation of such devices is quite difficult to carry out, even with detailed instructions on hand. In order to avoid miscalculations for this work, it is better to call a professional plumber.In a heating circuit with one main pipe, it is recommended to use particularly durable radiators designed for high pressure and high temperatures.

Types of gas burners

Wall-mounted double-circuit boilers are produced with an open type of gas burner and with a closed one. An open gas burner in the boiler requires the supply of the required amount of air for gas combustion from the room where the gas boiler is installed. For example, the familiar scheme of a typical gas water heater.

A device with a closed burner has an isolated space for combustion of gas from the room. Combustion air is drawn from outside the building. Most often, such devices are connected using a coaxial chimney that goes to the outer wall of the building. It consists of two pipes located one in one. Combustion air is drawn in through the outer pipe, and combustion products are removed through the inner pipe.

It is possible to connect with the discharge of combustion products into the provided chimney of the building and air intake with a lateral pipeline inlet. Boilers with a closed burner are called turbocharged because they have a built-in electric turbine type air blower. The advantage of such gas appliances is that they are safe to use. Their work does not require constant monitoring of the air supply, ventilation of the room, the ingress of combustion products into the apartment or house is excluded. Excessive thrust results in more efficient combustion and faster heating of the water.

Wall mounted gas boiler device.

Double-circuit gas appliances can be connected in boiler mode. This mode of operation implies the heating of water and its subsequent accumulation in the boiler, and from it water already enters the water intake points.

Condensing gas heaters are distinguished by the fact that their design allows condensation of water vapor contained in the gas combustion products. During the condensation process, additional heat is generated, which is used either for the heating circuit or for the DHW circuit. The circuit can include the formation of condensation on a specially shaped primary heat exchanger or on an additional device that is located above the primary heat exchanger.

All gas boilers of a double-circuit type necessarily include an automation unit and control sensors for correct and safe operation. Automation monitors the set parameters for heating water in the circuits, can be used in conjunction with remote air temperature sensors in the room. Traction sensors, gas supply emergency shutdown control allow to operate the boiler in the safest way.

For long-term use of the gas appliance, a competent installation should be performed, including power calculation, installation in accordance with safety standards, and well-performed commissioning operations.

Work on the installation of gas equipment should be carried out only by special gas services that have a certificate for its implementation.

Weaknesses of a one-pipe system

The disadvantages of this scheme are usually:

- The complexity of the implementation of the calculation of thermal and hydraulic parameters.

- A difficult procedure for correcting errors in the calculations of heating devices.

- Influence on each other of all nodes and elements of the system. This is one of the main factors that distinguishes a one-pipe heating system from a two-pipe one.

- Very high level of hydrodynamic resistance.

- One riser is capable of providing a limited number of radiators.

- There is no way to control the heating level of batteries and radiators.

In cases where the vertical riser feeds 10 or more heating devices, then the difference in the heating temperature of the first and last radiators in the series circuit will reach almost 50 degrees. This fact often becomes decisive in determining which heating is better - one-pipe or two-pipe.

How is the heating system in an apartment building

Due to the high cost of centralized heating, many people more and more often give preference to autonomous heating, completely switching to individual heating devices. But many do not realize that an autonomous heating unit in an apartment building is calculated and arranged according to the same principle as the device of a centralized heating main.

- From what date the heating is turned on

- What is the heating system of a high-rise building?

- What is the return line used for?

- Why batteries are often lukewarm

- Purpose of the elevator unit

- The principle of piping a heating main

The use of one-pipe systems in private construction

If we are talking about a one-story house, then when using heating with one main riser, there will be no risk of uneven heating. In the case of a multi-storey building, the upper floors will receive a larger portion of the heat than the lower ones. As a result, it will be cool on the ground floors of the house, and hot on the upper floors. Since mansions rarely have more than two or three floors, there will not be much difference in the heating of radiators in one-pipe or two-pipe heating in a private house.

Fixing the boiler

The installation of a wall-mounted boiler in a house is carried out in this way:

- They study the manufacturer's recommendations and select the optimal place in terms of safety and convenience rules.

- Fix the mount on the wall. supplied with the boiler. To carry out its installation in the house correctly, you should use a level and a slope. Very often, the fasteners are long dowels and threaded hooks at the longer end.

- Where the chimney should cross the wall. make a hole for it.

- Fix the chimney in the boiler. This process is carried out very carefully, since the chimney is coaxial (not only carbon monoxide escapes through it, but also fresh air is supplied). This means that if a mistake is made, air and carbon monoxide will not be able to circulate correctly, which will certainly lead to bad consequences.

- The boiler is hung on the fasteners fixed in the wall.

In the case of a floor-standing boiler, installation is easier, because you just need to make a solid base on the floor with your own hands and place the device against the wall.

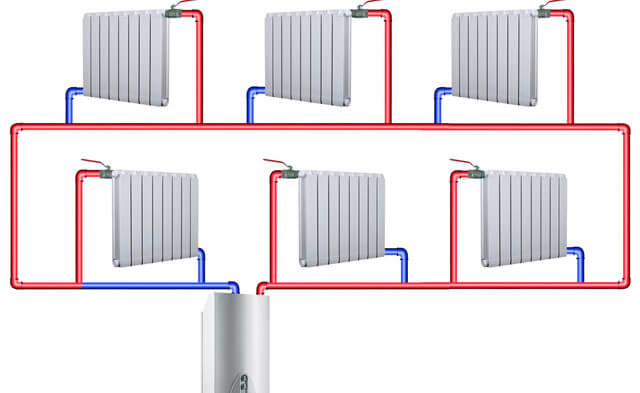

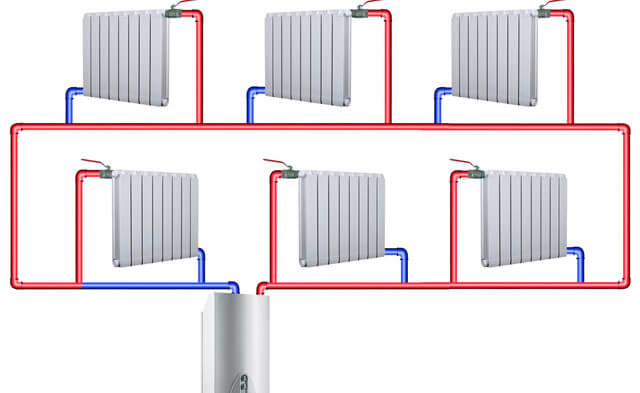

Strengths and weaknesses of two-pipe systems

Investigating the question of which heating scheme is better, one cannot bypass the characteristics of systems with two pipes.

They have the following advantages:

- It becomes possible to use automatic thermostats for batteries or heating radiators. Such moments need to be planned even during the design development.

- In this case, a special collector system is used to distribute pipes to rooms. In the event of a failure or a decrease in the efficiency of any one unit, this will in no way affect the performance of the remaining elements of the circuit.

- The two-pipe system implies the use of a parallel connection for the radiators.

Weak sides:

- It is much more difficult to equip such a heating scheme.

- The cost of developing a project requires significant financial costs.

- Installation works are more complicated to implement.

Areas of use:

- Private housing construction.

- Elite projects development.

- Multi-storey buildings with top wiring.

In buildings with 10 or more floors, it is recommended to use a one-pipe system with horizontal wiring for each floor, or a two-pipe system with an upper vertical wiring. This will guarantee effective circulation.

Positive characteristics of two-pipe collector heating:

- Low level of hydrodynamic resistance.

- You can set the optimal heating level for each room.

Before turning on the collector heating system, it must be well rebuilt. In order for the installation work and subsequent operation of the two-pipe system to be as simple as possible, an appropriate infrastructure will be required.

Diagram with an indirect heating boiler

It is relevant for a single-circuit gas boiler. This scheme can be implemented according to different rules. Most often the boiler is connected in parallel. For this, a three-way valve is used. It is installed on a flexible pipe that connects the boiler supply pipe and heating radiators. Thanks to him, the coolant can both circulate through the indirect heating boiler and move around it. According to this scheme, a flexible pipe extending from the boiler is connected to the return line.

Also, this element can be included in the scheme with a hydraulic arrow often depicted in different photos. According to the rules, this option is in demand for systems with a large number of circuits. But in order to implement it, one requirement must be fulfilled: to install a safety group and a circulation pump on a circuit with a boiler. Some schemes provide for a series connection of the boiler.

All these schemes are suitable for single-circuit and double-circuit boilers. True, the situation with a double-circuit unit has a small exception: the DHW system must be connected to the second circuit. This eliminates the need to use an indirect heating boiler. There is a nuance here, though. A double-circuit boiler is great for homes whose residents consume a small amount of hot water. However, when the volume of consumption of such water is very large, the standard secondary circuit will not have time to heat it. The situation can be mitigated by devices with a storage tank or a layer-by-layer boiler.

If you plan to use a simple unit with two circuits, then to provide the house with a large amount of hot water, you need to use an indirect heating boiler.

As for connecting the boiler to the gas pipeline using a flexible hose or tube, this work must be trusted by the specialists of the gas service.

Connecting a solid fuel boiler and a gas boiler in one system Two boilers in one heating system Connection diagram for heating radiators Installation of a gas boiler with two circuits

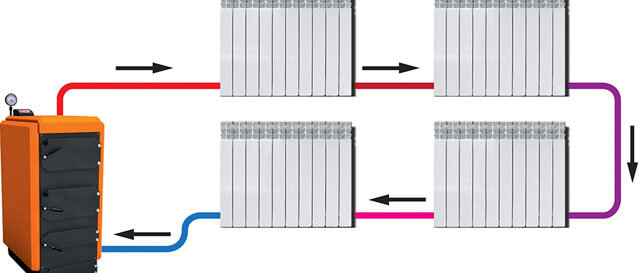

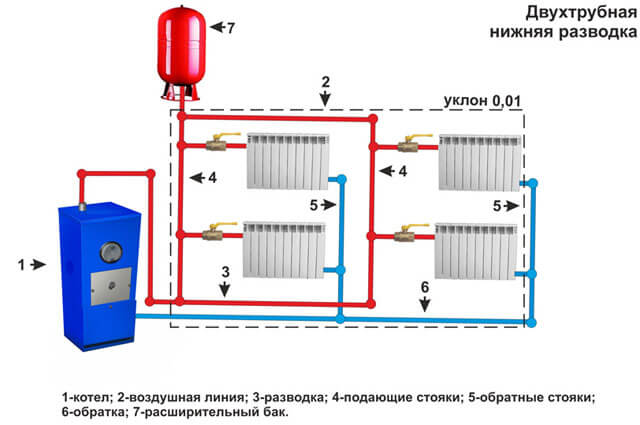

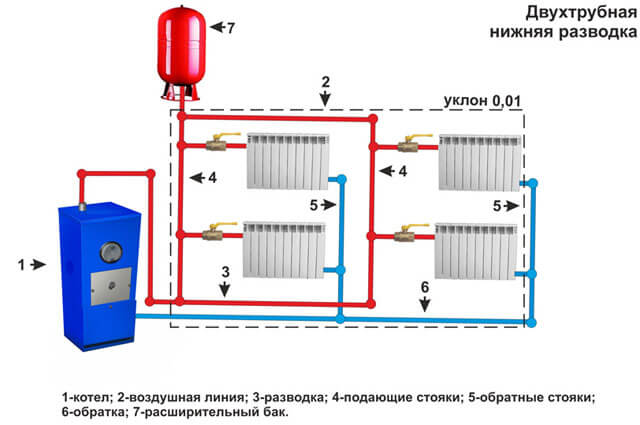

What are the two-pipe schemes

The most popular are the following types of wiring:

- Upper... An excellent option to organize a gravity heating system without a circulation pump. It is characterized by a fairly low hydrodynamic resistance. In the course of work, partial cooling of the upper supply pipe can be observed. As a result, additional pressure of the coolant circulation appears.

- Lower... Here the supply and return pipes run close to each other. The following modifications of the lower wiring are found: "star" and "loop". In the first case, each of the radiators is equipped with a personal supply and return pipe. In the second version, the collectors commute all batteries in series.

Deciding which heating system to choose ― one-pipe or two-pipe, it is necessary to carefully weigh the pros and cons. In any case, preliminary calculations and drawing up a project will be required. This will make it possible to determine both the heating devices and the main pipes. The final conclusion about which heating layout is better in a private house is made by the owner of the home.

Radiators for heating systems of high-rise buildings

Cast-iron radiators, which have been used for more than a dozen years, are familiar to many residents of multi-storey buildings. If it is necessary to replace such a heating battery, it is dismantled and a similar one is installed, which is required by the heating system in an apartment building. Such radiators for centralized heating systems are considered the best solution, since they can withstand a sufficiently high pressure without problems. In the passport to the cast-iron battery, two numbers are indicated: the first of them indicates the operating pressure, and the second indicates the test (pressure) load. Usually these values are 6/15 or 8/15.

The higher the residential building, the higher the working pressure. In nine-storey buildings, it reaches 6 atmospheres, so cast iron radiators are suitable for them. But when it is a 22-storey building, then 15 atmospheres will be required for the working functioning of centralized heating systems. In this case, steel or bimetallic heating devices are needed.

Experts do not recommend using aluminum radiators for centralized heating - they are not able to withstand the working state of the water circuit. Professionals also advise property owners, when carrying out major repairs in apartments, in case of replacing batteries, to change the pipes for the distribution of heat carriers by ½ or ¾ inch. Usually they are in poor condition and it is advisable to install ecoplast products instead. Some types of radiators (steel and bimetallic) have narrower watercourses than cast iron products, so they become clogged and subsequently lose power. Therefore, at the point where the coolant is supplied to the battery, a filter should be installed, which is usually mounted in front of the water meter.

Underfloor heating pipe laying schemes

The closed contour of the warm floor is not its only feature. In theory, it is possible to lay a closed loop of pipes along a chaotic path. In practice, the contour pipe must be laid so that it not only returns to where it started from, but also does not intersect along the route. By the way, this is not an intersection condition. It also applies to different contours of the warm floor.

You yourself can try to draw a line with the two listed conditions, do not intersect and end where it began. You will have schemes for laying pipes for underfloor heating, called "snail", "snake 1", "snake 2". All other schemes will be derived from these simplest schemes.

What is the difference between laying schemes

Let's pay attention to the differences between these schemes. Schemes "snail" and "snake 2" are drawn so that the warm and cold rugs of the contour mix, forming an alternation of branches warm-cold-warm-cold. This scheme ensures uniform heating of the floor without creating separate cold and warm zones.

The snake 1 scheme creates a separate, warm zone and a separate cold zone. This scheme is used in rooms with external walls with windows, for greater heating of the zones of adjoining to the external walls.

Let me draw your attention to the fact that the terms cold and warm zones used are very arbitrary. The coolant temperature in the "cold" zone is above 30˚C.