Most homeowners choose to build a self-contained heating system.

Sometimes this decision is made even if it is possible to connect to a centralized network.

The reasons for this choice are the desire to independently regulate the heating mode and too high utility rates.

There are a lot of gas heating boilers on the market, which are recognized as the most efficient and economical of all the alternatives.

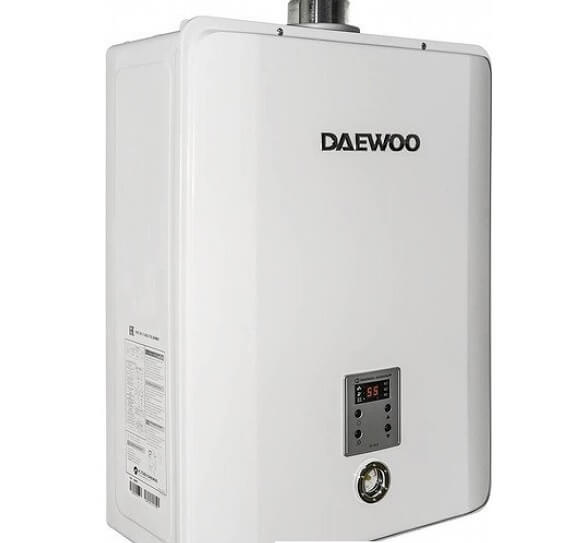

Consider Daewoo gas boilers, which are one of the most advanced groups of heating equipment.

Daewoo gas boilers

The Korean industrial giant Daewoo is known all over the world primarily for its cars. However, the range of products is much wider and includes many different positions and directions.

The name of the Daewoo company is translated into Russian as "The Great Universe". It was founded in 1967 and the first gas-fired boiler left the assembly shop in 1988. Today the company is a global corporation with many branches and related companies.

Active research and development is underway, the result of which is the emergence of new designs, assemblies and parts.

For example, the electronic ignition system was first implemented on Daewoo gas boilers..

The range of heating boilers manufactured by the company is wide enough. All the most promising designs are produced, capable of providing stable and trouble-free operation for a long time.

The company aims to produce relatively inexpensive, but very reliable units. This is achieved by eliminating minor or low-demand components that increase the cost of equipment without bringing any noticeable benefit.

In addition, more efficient and inexpensive models of important components have been developed - for example, a new type of three-way valve, more reliable and easier to manufacture.

A feature of Daewoo boilers is a relatively low power, designed for use in small private houses. This approach demonstrates targeting the mass customer, and it yields positive results.

For example, it was possible to reduce fuel consumption by 7-10% by reducing the number of gas burner sections.

From the history of the company

The history of the manufacturer begins in 1967. The translation of the brand name means "The Great Universe". Currently, this is a whole group of companies that owns their own research laboratories, develops and patents innovative technologies there. Let's say Daewoo first used an adapted ignition system - MICOM electronics, which control the ignition of the burner. The organization produced the first gas boiler in 1988. Daewoo is a major exporter - the equipment is known in more than a dozen countries.

Views

Daewoo produces the most popular and convenient wall-mounted gas boilers for use in a private house.

There are no floor models in the company's arsenal, which is not a drawback, but it demonstrates the approach of the company's engineers to creating the most compact and multifunctional models.

There are two options for the type of combustion chamber:

- Atmospheric boilers... The combustion chamber is open, and the intake of air necessary for combustion and smoke removal is carried out directly from the room in which the boiler is installed. They are connected to a common house chimney and require the creation of certain conditions for work. DO NOT tolerate drafts or strong gusts of wind outside - the flame may go out.

- Turbocharged boilers... The air is supplied by a turbocharger fan. This design makes the boiler completely independent of external factors, and the operating mode is stable and stable. Connecting the boiler to a common chimney is not required, special chimneys of the coaxial type ("pipe in pipe") of the horizontal type are used, which can be led directly from the room through the wall. Forced air units are stable and in higher demand.

By the type of heat transfer, there are:

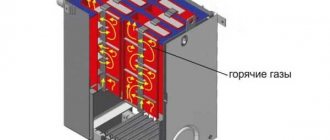

- Convection boilers... They work on the usual principle - heating the coolant in the burner flame.

- Condensing models... Construction of a new type, which uses a two-stage heating of the coolant. First, the thermal energy obtained from the condensation of water vapor from the exhaust smoke is used. Then the coolant, which has received some heating, is sent to the primary heat exchanger, where it is finally heated to a predetermined temperature.

The use of condensing boilers has started recently, but statistics have already been collected. They provide significant fuel savings through the reuse of thermal energy.

It becomes possible to reduce the heating intensity of the heat exchanger, which saves gas and increases the service life of boiler components that are not exposed to too much stress.

NOTE!

Condensing boilers require specific operating conditions. The temperature difference outside and inside the building must not exceed 20 °, otherwise the condensation process will become impossible. Because of this feature, the use of condensing boilers in Russia does not make sense. When purchasing such installations, you should know in advance about the existing restrictions so as not to pay extra money.

Errors and methods of their elimination

The number of automatically detected malfunctions for Daewoo boilers is grouped into 19 events, each of which has its own code. Seeing the display, you can try to solve the problem yourself or give the called masters a first idea of the problem.

Some malfunctions of gas boilers do not depend on the type of combustion chamber or other features of the equipment. And there are problems that are specific only to a certain line. The Daewoo Altoen (Gasboiler) boilers have sequential numbering of errors, and the methods for eliminating them are almost the same for all models.

Error type "E0"

This code signals an error in the room temperature sensor, which is built into the control panel. The example of this malfunction shows that it is far from every time that you need to call a repair team.

It is necessary to disassemble the device, clean the contacts and check the sensor with a tester. It must be replaced if necessary. If you do not have the skills to disassemble and repair such products, then you can take the remote control to any workshop specializing in electronics.

Error type "E1"

A decrease in pressure in the heating system was recorded. The simplest case that leads to this problem is the breakdown of the minimum pressure switch or the lack of a signal between the sensor and the control board. However, the first step is to immediately check the heating circuit for leaks.

Leaking pipes or radiators can occur in places where the presence of water is not immediately noticeable. These are interfloor ceilings, storage rooms or a basement. Therefore, you need to consistently bypass the entire circuit.

A coolant leak can occur not only in the circuit, but also in the units of heating equipment, such as:

In this case, the hydraulic system will have to be changed, although sometimes replacing the gaskets may be sufficient.

Also, the make-up may be cut off for any reason.Although in this case, the issue of leakage also arises, which is gradual.

A decrease in pressure in the circuit without leakage of the coolant can occur in the event of a pressure drop in the closed expansion tank, which is installed in the boiler. In this case, it will have to be repaired.

After eliminating the cause of the leak, the circuit must be filled with the restoration of the operating pressure.

Error type "E2"

A gas analyzer has triggered, signaling an incomplete combustion of the supplied mixture or the ingress of smoke outside the chimney.

The problem lies in insufficient traction, which can be caused by:

There may also be a problem with the fan. Most often it is contamination of the blades, which can be seen or a violation of rotation, which is easy to hear.

The chimney for a gas boiler has parameters that are different from the hood of a stove heating. The fact is that the temperature in the boiler burner is relatively low, so the traction force will be less

The problems described above can be identified on your own. If the chimney and fan function normally, then there is a possibility of sensor breakage. It will have to be replaced.

Error type "E3"

The error occurs when fixing the fact of overheating of the coolant. There are two main reasons:

If such an error occurs, you need to wait until the device cools down, reset it (turn it off and on) and start it again. If the error repeats, then this means that the operation was not false (this happens) and you will have to figure it out.

First of all, it is necessary to determine whether the circulation rate of the coolant is sufficient. To do this, start the boiler without heating and listen to the pump. Its hum should be normal.

Problems with this node can be caused by several reasons:

It is also possible that the contacts of the signal wire from the pump to the board are disconnected, or the central board itself may break.

Poor circulation of the heating medium can be caused by a clogged dirt filter. It needs to be cleaned periodically, but not everyone completes this procedure on time.

If the pump is running at full capacity, the cause of the poor circulation is in the circuit. She may be:

If the pump is working normally, and the circuit regularly passes the coolant, then the temperature sensors need to be replaced. Most likely, they are out of order.

Error type "E4"

This code signals the actuation of a pressure switch - a draft sensor in the chimney. The main reasons are the same as for the error with the “E2” code.

If the chimney of the gas boiler and the fan are working normally, then the problem may lie in the signal from the sensor. First of all, you need to check the tightness of the connection of the contacts to the sensor and to the central board, as well as ring the wiring.

It is also possible for condensation to form in the pipes or poor connection to the sensor. Breakage of the pressure switch itself is unlikely.

Error type "E5"

Alarm received from the flame sensor. If, visually, when the boiler is turned on and off, ignition proceeds normally, then the flame sensor must be checked.

First of all, you need to make sure that it is in good contact with the main board (check the wire connection and ring it). You also need to make sure there is a voltage of 5 volts between the terminals of the CN05 sensor.

Reading now

The most popular house designs of 7 by 9 m with an attic

How the coronavirus pandemic will affect architecture and design ...

If there is no ignition, the problem may not be in the boiler. The position of the gas shut-off valve should be checked first.

If the sensor is working properly and the ignition does not cause problems, then there is an error in the central board. It will have to be replaced.

If you can visually detect a problem with ignition, then you must perform the following steps:

If the problem is in the gas valve, then it will have to be replaced.

Often a break in the gas valve coil (top) and other electrical faults can be recognized visually or by the characteristic smell of burnt wiring.

The example of this error shows that sometimes knowledge in several areas is needed to repair a Daewoo gas boiler: electrical, electronics, mechanics. Therefore, in case of complex mistakes, it is still better to call experienced masters of the gas service, with which an agreement has been concluded for the supply of blue fuel and maintenance of the units.

Error type "E6"

Gas leakage sensor triggered. If there is a smell of gas in the boiler room, then it is necessary first of all to turn off the shut-off valve at the entrance to the house. Then you need to check the gas pipeline (up to the boiler valve) and fittings for damage. If you find them, you should contact the gas service.

If the smell of gas is not felt, the boiler can be restarted after a while. It is advisable to be nearby at this time and have a gas analyzer with you. If the sensor is false, then it needs to be replaced.

Error type "E7"

This code is displayed if the board has “lost” the remote control. The problem may be a breakdown of the control panel or the board unit responsible for communication.

Control devices from other Korean manufacturers (Navien, Hydrosta, etc.) are suitable for Daewoo boilers, so there is no particular problem in replacing this part.

Error type "E8"

Interruption of communication between the temperature sensor of the heating circuit and the central board. Typically, the problem occurs when the thermistor breaks down.First, of course, you need to see if the contacts have come off, then ring the wiring. If it is intact, then the sensor should be replaced.

You can replace the sensor yourself. All modern measuring devices of this purpose are equipped with special sockets, so nothing needs to be soldered

It is theoretically possible for the central board unit to break down, although usually in this case it is completely, rather than partially, out of order.

Error type "E9"

Leakage in the boiler. The water sensor has triggered. You need to open the boiler and look where the fistula has formed. There may also be a problem in the gaskets of the nests where the heating and hot water temperature sensors are installed.

Error type "EA"

The circuit is replenished with water more often than once every 5 minutes. This indicates a leak. Its volume is not so significant as to stop the boiler as a result of water boiling or pressure relief.

This situation cannot be ignored, since a small leak at any time can turn into a full-fledged rush with an emergency stop of the boiler and serious consequences for objects in the house.

Error type "EC"

Central control boards are universal for all models within the same range. The error code “EC” indicates an incorrect choice of the boiler model. This usually happens when the main board is replaced or when the parameters are reset due to a sudden power outage.

It is customary to install a stabilizer in front of the gas boiler. This avoids damage to expensive electronics and equipment downtime during the heating season.

To solve this problem, it is enough to configure the parameters using the service menu.

Error type "Ed"

The second letter of this code is the lowercase “d”. Manufacturers have moved away from the template so that users do not confuse the uppercase "D" and the number "0", which have similar outlines. An error means that the built-in stabilizer has detected a deviation in the frequency of the current.

If the electricity parameters often deviate from the standard values, then the boiler electronics may fail.

Error type "EE"

This code indicates a problem with the operation of the smoke exhaust fan. The RPM sensor shows a low value.

The malfunction can be caused by:

Also, a board error cannot be ruled out, although this option is unlikely.

Error type "EF"

Signal that the three-way valve responsible for switching the water flow has been open for more than 90 minutes. This indicates its jamming. To prevent this damage, it is necessary to install a filter that will prevent clogging.

The three-way valve is equipped with power wires and a communication loop with the central board. If an “EF” error occurs, first of all, you need to ring the wiring and fix the contacts well

The most serious failure is a burnt out valve servo. In this case, it is better to replace the entire distribution unit.

Error type "U0"

The flame sensor does not “see” the fire. Ignition problem. If the flame ignites and goes out, then the reason may be the quality of the supplied mixture, the gas pressure or the absence of a hood.

The chemical composition of liquefied gas differs from the main one. Each specific mixture has its own set of burner nozzles. Don't forget to put the right kit

If the flame ignites, the auto-ignition electrode continues to click, but the error still remains, then the reason may be a defect in the sensor or a poor-quality connection to the board.

One of the defects of the sensor is just its pollution. If you wipe this part, then the problem is often solved.

Error type "U1"

The buttons on the control panel are lit. Such repairs do not directly relate to the gas boiler, but any electronics specialist can carry out it. To do this, it is necessary to disconnect the panel from the boiler body and take it for repair.

Error type "U8"

Hot water temperature sensor error.The reasons for the breakdown and the necessary actions in this case are similar to the situation with the error “E8”. The boiler does not stop its work, but only functions in the heating support mode.

During the replacement of the sensor, the boiler will need to be stopped and disconnected from the power supply.

Error type "U9"

Signal from a temperature sensor located in the chimney. The most likely situation is pipe clogging. They need to be cleaned. If no contamination is found, the problem may be with the faulty sensor.

Almost half of the Daewoo gas boiler shutdowns are associated with problems that have arisen at other nodes of the heating circuit.

In addition, many boiler malfunctions can be eliminated on your own if you have at least minimal skills in repairing any equipment. Therefore, it is necessary to analyze the type of error and only after that make a decision either to repair it on your own, or to call specialists.

Series and models

Daewoo produces the following series of gas boilers:

- Daewoo Gasboiler DGB... Consists of models DGB-100, 130, 160, 200, 250, 300 and 350. Their power is 10, 13, 16, 20, 25, 30 and 35 kW. Double-circuit boilers of atmospheric type, capable of heating rooms from 100 to 350 m2. Equipped with copper primary heat exchanger with high efficiency and long service life. Secondary heat exchanger of plate type, made of stainless steel.

- Daewoo mcf... Wall mounted boilers with an open combustion chamber. Equipped with a separate heat exchanger, they have the ability to work up to 3 days in emergency mode. The power of the boilers is in the range of 10.5-29 kW.

- Daewoo msc... Double-circuit units with a closed burner. The extended model range consists of boilers with a capacity of 7-45 kW. Equipped with a separate heat exchanger. They can be controlled from a remote control, which has a range of up to 50 m. There is a weekly programmer, which makes it possible to plan the operation of the boiler with high accuracy.

- Daewoo MES... Condensing boiler series. The power of the models ranges from 19.8 to 40.6 kW. For normal operation, it is required to provide the units with appropriate conditions, which is possible only in certain climatic conditions.

All boilers are made in accordance with the most efficient and advanced production methods, have a balanced package.

Daewoo consistently embodies the principle of simplicity, low cost and high quality products..

Review of the best models

The most popular model from the line of this brand among Russian buyers is the boiler Daewoo DGB 100 MCF.

Main technical characteristics:

- Working power - 10 kW, enough for heating an individual residential building with an area of up to 100 m2.

- A closed combustion chamber with a turbine flue gas removal system prevents carbon monoxide gases from escaping into the boiler room.

- Ignition of the boiler with an electronic igniter, which not only starts the DEU boiler into operation, but also controls the quality of the combustion process during operation. The electronic burner control takes part in the automation and safety control system, as well as regulating the operation of the boiler depending on the outside air temperature and the set parameters of the coolant.

- To increase the durability of the boiler equipment, the pipe system of Daewoo boilers' heat exchangers is made of copper.

- The network circuit is equipped with a built-in forced circulation system, which allows working with low gas pressure in the main line or low pressure of tap water.

- The computerized control unit allows you to adjust the basic parameters and integrates well into the “Smart Home” system.

- Cost, RUB 29,900

The next standard size is a non-volatile condensing boiler Daewoo DGB 160, which provides a high level of heat supply to individual houses of increased area.

Technical data:

- The maximum heating load is 18.8 kW.

- Maximum load in hot water heating mode - 23.3 kW.

- The maximum heated area of the heating facility is 160 m².

- Boiler efficiency in operating mode, efficiency - 90.3%.

- The number of contours is two.

- The combustion chamber is closed.

Interesting atmospheric mounted model DGB 200 MCF provides heat and hot water to thermal facilities with a heating area of up to 110 m2.

Technical data:

- The system is open, double-circuit for heating and hot water supply.

- Low-noise, compact weighing 33 kg.

- The heat exchanger is made of copper.

- The efficiency is 92.0%.

- Power - 23.3 kW.

- Heating area - 186 m2.

- Cost - 34,590 rubles.

Since the unit has an open firebox and operates with natural circulation, it is installed in a separate room with an internal air temperature above +7 C, otherwise the boiler will only work for self-heating.

The principle of operation of the condensing boiler Daewoo DGB 200 MCF:

- Electronic ignition of the gas nozzle.

- When a gas is burned, its hydrogen content turns into water vapor. The condensing device of the boiler is capable of converting the formed steam into liquid while extracting additional heat and increasing the efficiency of the steam-power cycle.

- The infrared sensor of the unit monitors the combustion process in the furnace, setting the optimal combustion conditions in the ratio "fuel-air" according to the color of the flame, which leads to significant gas savings. The system runs on two types of fuel: natural gas and liquefied gas.

- Water is supplied by a circulation pump to two heating circuits: heating and hot water supply, where it is heated and supplied to consumers.

- The control panel controls the operating mode of the boiler. The shut-off valve turns off the gas supply to the heating boilers, when the alarm values for the temperature and pressure of the coolant are reached, the process is accompanied by an audible alarm, while the operating mode parameters are saved.

- The diagnostic system will display an error code on the screen so that maintenance personnel can take action to eliminate the mode failure.

Completing the range of this type of units, the boiler Daewoo 400, which by the principle of operation does not differ from the previous boiler, but is capable of heating 500 m2 of area and has a unique Japanese-made EN-US combustion automation, the cost of the model is 53,200 rubles.

Specifications

Consider the technical parameters of Daewoo boilers:

| Parameter | Value | |

| Daewoo 110 MCF | Daewoo 100 MSC | |

| Boiler type | Gas heating | |

| Fuel type | Natural or LPG | |

| Efficiency | 91 % | |

| Functions | Heating and hot water supply | |

| Power | 12.8 kW | 11.6 kW |

| Boiler type | Atmospheric | Turbocharged |

| Heat carrier temperature | 40-85° | |

| DHW temperature | 35-60° | |

| Power supply | 220V 50Hz | |

Advantages and disadvantages

The advantages of boilers include:

- High efficiency of the units.

- Reliability, durability of boilers.

- Resistance to external influences.

- Ability to independently identify problems and notify the owner of them.

- Together with space heating, hot water is supplied.

- Low fuel consumption without affecting the performance of the units.

The disadvantages of Daewoo boilers are considered to be:

- Volatility. If the power supply is cut off, the system will stop working.

- Sensitivity to water quality, stable supply voltage, requiring the use of additional equipment.

- Some users report an increased noise level when heating water.

Most of the disadvantages can be attributed to the general features of gas boilers.

Device and specifications

The Korean company is ready to offer the buyer two main models of gas equipment: atmospheric type and turbocharged.

Regardless of the internal solution, the general technical parameters that characterize all the equipment of the Daewoo brand are still there:

- Control over the ignition of the burner.The mode is selected depending on the gas pressure in the main line, on the state of the smoke extraction system, as well as on the presence of traction and voltage of the mains. The flame is regulated by the control panel or by means of a mechanical regulator.

- Remote control. Control over the functioning of boiler equipment can occur from any room in the following ways: with a remote panel or a remote control.

- Circulation pump device. The technical characteristics of the boiler, simplicity and high efficiency contributed to the replacement of the traditional three-way valve. DEU developers have introduced a two-way pump with a "ball-switch" system. Large throughput of the hot water supply circuit - warm water warms up evenly. The simultaneous number of users, as well as the pressure in the water supply system, does not affect the degree of heating.

- Boiler self-diagnostics. Test data is displayed on the remote control unit, which has a digital display.

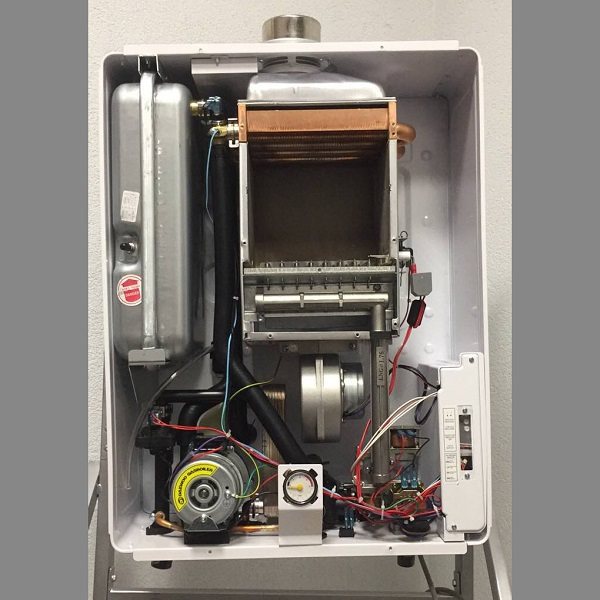

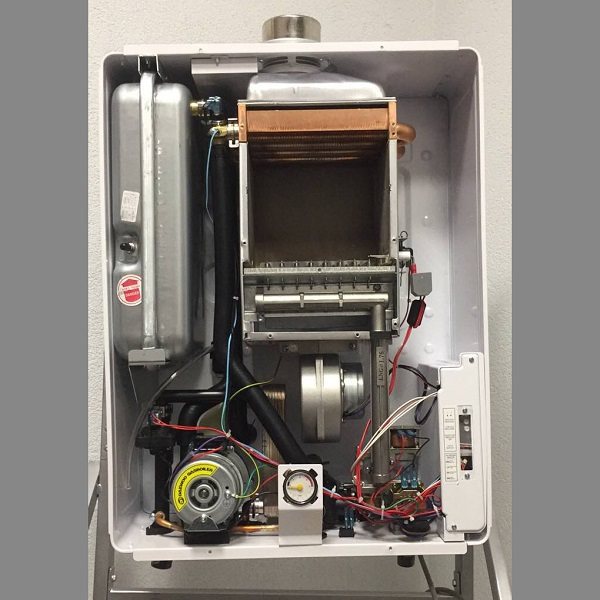

One of the distinctive features, as well as the advantages of Daewoo gas boilers, is their constructive simplicity. According to experts, it will not be difficult to disassemble, carry out all the necessary repair work and adjust the equipment, you will not even need any special tools.

Operation and setup

The boilers are set up during manufacture, at the factory. DAdvanced setup is a small adjustment made during installation and first run.

The working limits of temperature and pressure of gas and working fluids are determined. These actions must be carried out by specialists from the warranty workshop, otherwise the warranty contract will be canceled.

After the first launch, no special actions are required from the owner.... Adjusting the temperature to your liking is done routinely.

It is necessary to invite a master once a year to carry out maintenance.

If a problem occurs, you should immediately invite a technician from the service center.

Download instruction

Download instruction for Daewoo gas boiler.

Boiler DAEWOO

is a functional mini-boiler room, with a capacity of 11 to 47 kW

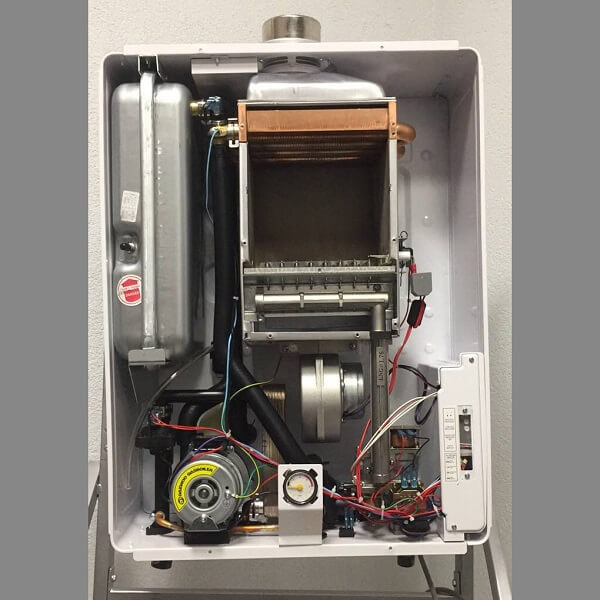

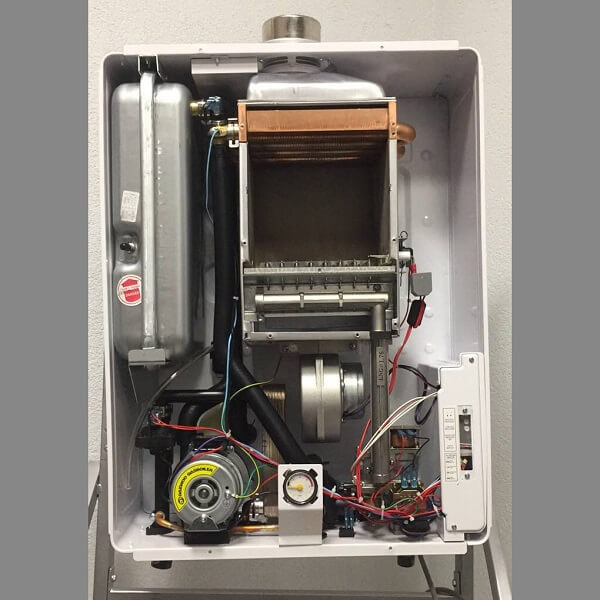

The entire range of boilers has the following main components:

- separate double-circuit heat exchanger: copper for heating, stainless steel plate for hot water supply

- circulation pump with dry rotor and magnetic drive

- trapping magnetic filter

- built-in control unit (motherboard) Japanese, Toshiba

- closed combustion chamber

- Time gas valve (Japan)

- auto-air and relief valves

- temperature, pressure and flame control sensors (infrared)

- three-way valve

- remote control panel with thermostat

- turbofan

- pressure gauge

- flow switch

- expansion tank

Price range

The cost of Daewoo gas boilers is in the conventional range of 34-59 thousand rubles. The price difference depends on the model, power and other factors.

If the region is located far from large settlements, the price of the boiler will increase due to logistics costs. before buying, you should find out in what configuration the equipment is supplied and what needs to be purchased for optimal and safe operation of the boiler.

In addition, you need to take care of concluding a guarantee agreement, which will also cost a certain amount.

IMPORTANT!

Some users do without warranty service, but this approach is only possible for specialists who are able to repair and configure the boiler on their own. For mass users, it is strongly recommended to use the services of warranty workshops.