Pros and cons of welding

This method produces a strong, leak-proof connection. Its advantages also include:

- there is no weighting of the system with additional parts;

- automation of the process;

- for welding, there is no need to specially level the cut edge;

- suitable for systems of non-standard section elements: square. rectangular, oval. The connection of non-circular steel pipes on the thread is not possible.

Welding work is usually performed by a specialist and requires special equipment. Residual stresses arising at the joints can lead to depressurization of the seams under mechanical stress, vibrations. When repairs are required, the welded parts can only be cut off. It is technologically difficult to weld different metals (steel / cast iron), and it is impossible to weld different materials (steel / PVC). It is impossible to weld steel pipes with copper, aluminum.

Working with a welding machine

Types of threadless connection with Gebo fitting

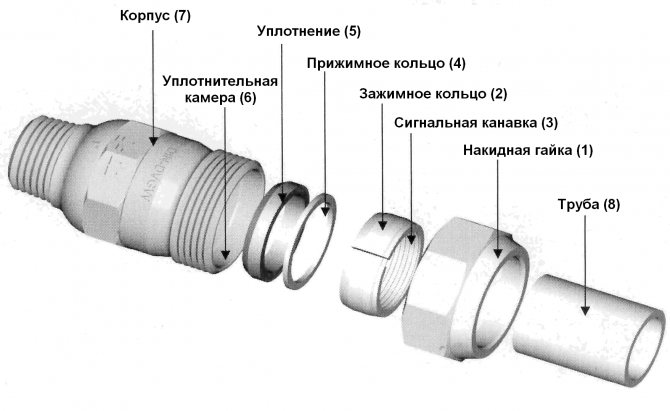

The youngest and most popular threadless coupling is the Gebo compression fitting.

This type of connection can be of two types: one-sided and two-sided. In the first case, on the adapter, one part is made with a thread, and the other is a compression one, this is suitable, for example, when connecting a flexible hose or meter to a pipe.

The Gebo double-sided coupling has compression rings on both sides. There are several more varieties of these fittings: in the form of a coupling and in the form of a tee, that is, it can be used simultaneously as a connecting element and an adapter.

Pros and cons of a fitting connection

A fitting connection provides a number of advantages without changing the requirements for tightness of joints:

- all docking points are easy, quick to change;

- you can make changes to the system yourself by changing the type of fitting;

- if the pipeline breaks down, the fittings can be reused;

- no expensive special equipment is required;

- pipes made of different materials can be connected.

The disadvantages are the impossibility of connecting the cuts with the angular section, the weighting of the system with additional elements. Such a connection will serve for a long time with strict adherence to the installation technology.

Plumbing or heating

Metal pipes in the water supply and heating system (how to carry out in a private house is written here) have one unpleasant feature - threaded and welded connection points, after several years (15-20), become completely unusable.

At the same time, the condition of the pipe itself is still quite satisfactory, but the drives are so corroded that during the next heating season they can easily break, with all the ensuing consequences.

There is only one way out - to completely replace the unreliable site.

For replacement, you can use a piece of pipe made of metal or polypropylene. The main feature is that we will use a threadless connection. For this, compression threadless fittings are used.

What do you know about electrofusion couplings? They are used for joining pipes in hard-to-reach places when laying and repairing water lines. Read how to use them in a helpful article.

About the manufacture of countertops from artificial stone for the bathroom is written on this page.

In everyday life, they are all often called GEBO. (gebo), but it is also not correct how to call all SUVs jeeps, and all copiers - copiers.

Simply, GEBO was the first, which began to produce similar compression fittings, and over time, the name stuck.

Today, such devices are produced by many companies, and on the market you can find both more expensive and high-quality ones, as well as cheaper ones.

This technology can be easily applied when laying a system from scratch., but, it found especially wide application, namely, during repair work.

Such fittings can be used everywhere., where the temperature does not exceed plus 90 degrees, which means that they are suitable for both hot water (read about a heated outdoor jacuzzi pool here) and for a heating system.

There is no need for threading and welding, which greatly reduces time and costs.

Welding technology

Welding works are carried out using welding machines. Additionally, transformers (rectifiers) and a set of electrodes are used in electric welding. It is imperative to carry out work only in protective equipment.

In all types of welding, pipe sections are pre-prepared for the seams to be welded: clean, cut off the flange, degrease, remove rust, paint.

Further, the process depends on the welding method:

- The gas method involves the use of a welding wire, with which the seam is filled in one pass. In order to immediately get a high-quality result, you must have special training. If, for technological reasons, the external seam does not provide the necessary tightness, an internal one is performed in front of it. Optimal for pipes with wall thickness up to 4 mm;

- The electric arc method requires alignment, installation in tacks of pipeline elements. This is because the work is done in parts. The seam is formed layer by layer. For each stage, a larger diameter electrode is taken. The method is used for thick-walled pipes;

- Welding in a protective environment is the most efficient way. A mixture of gases acts as a protection: argon, oxygen, carbon dioxide. The seam is neat and durable.

After welding in any way, the seam is cleaned of slag deposits, its tightness is checked. Welded joints are durable and aesthetically pleasing.

Weld

Flange connection

Flanges are thick discs with a center hole equal to the pipe diameter and side holes for bolting. Flanges are installed in areas that have to be revised from time to time:

- when inserting removable plugs, the flange is welded to them at the factory;

- for the installation of metering devices (water meters, heat meters);

- installation of shut-off valves (various gate valves, taps).

Flange connection of metal pipes

A detachable threadless connection of metal pipes is formed by tightly fitting the discs onto the edges of the pipes. When the plates are pulled together, a rubber O-ring creates a sealed butt joint that can withstand high pressure. The seal between the flanges on the water pipes is changed when leaks appear. When transporting hot or ammoniacal media (sewage) every three to five years.

Couplings and their installation

In the threadless method, compression iron, metal-plastic, steel couplings, Gebo crimp couplings are used.

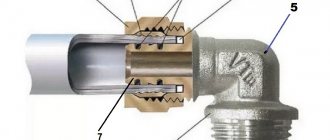

Compression couplings have an O-ring, union nut. They do not provide complete reliability of fastening: with mechanical force, the pipe can be pulled out of the coupling. They are installed either as a temporary option during the repair phase, or where no external impact is expected.

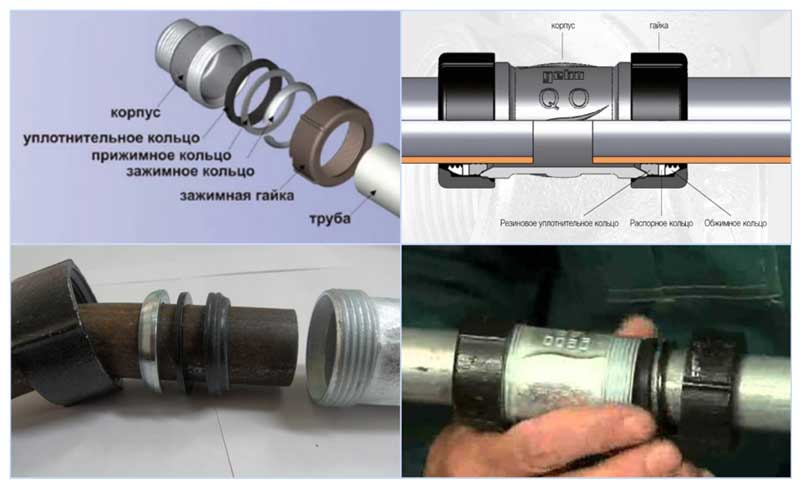

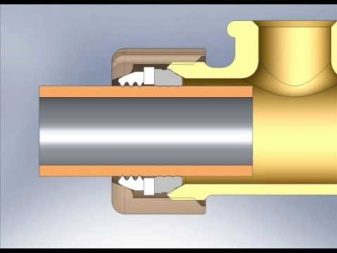

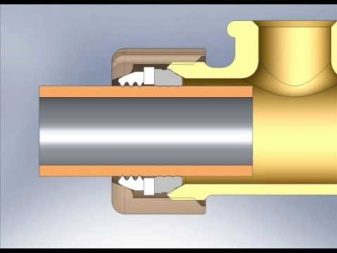

Gebo crimp couplings have three rings:

- clamping;

- sealing;

- clamping.

All elements are housed in a metal case, and together with a clamping nut, they form a common device Such a coupling is effective when connecting steel structures with plastic, PVC pipelines.Scope of application: water pipelines, sewerage and gas systems where the pressure does not exceed 0.4 MPa. The positive aspects of using the Gebo clutch include:

- versatility of use;

- does not undergo elastic deformation;

- the declared warranty period of use is more than 10 years;

- a deviation of 30 does not affect the quality of the connection;

- there is no internal stress;

- there is no metal fatigue.

Original Gebo couplings are sold necessarily with a passport.

Coupling connection

Methods for joining metal pipes without welding

Not all metals weld well, sometimes the quality of the seams is poor. Threaded joints are not tight enough, screw threads on metal deteriorate over time.

Non-welded technological connections. The devices are used on high-pressure gas pipelines, when transporting heated media. Installation of seals does not require preliminary preparation of joints, cutting edges. It is enough to clean the ends of dirt and dust.

Methods for connecting metal pipes without welding:

- Clamp screed. A sealed, tight-fitting pad is used to eliminate leaks. Repairs can be done quickly.

- Flanged. The tightness of the plates is adjusted by bolt fasteners, the tightness is ensured by a rubber gasket.

- Installation of a repair and assembly clip. The joint is securely fixed in a small metal case.

- Using the Gebo clutch. The compression fitting is suitable for repeated use.

- Fastening fittings without threads. A permanent sealed connection of high strength is formed.

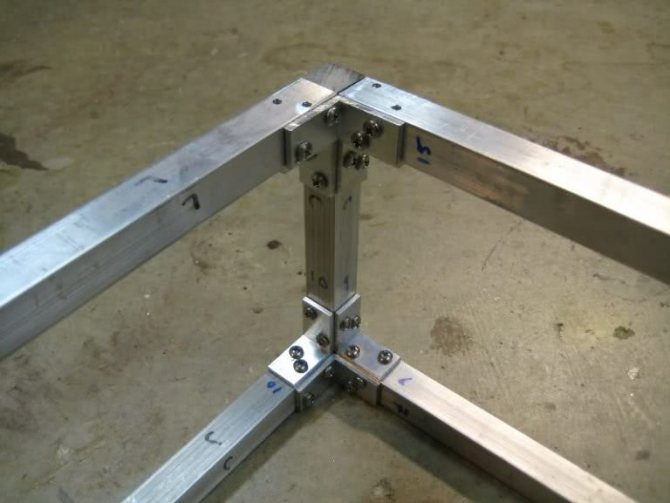

- Crab systems. Used for profile rental.

For threadless connections, no special electrical or gas equipment is required, an assembly tool is sufficient. No technical training is required to install the device.

Press fittings

Steel pipe press fitting is a type of compression fitting. They allow you to create a completely permanent connection. This property is considered a disadvantage, because it is impossible to reuse them. In case of leakage, such fasteners must be replaced.

As for the crimp structures, they do not have this drawback. The main disadvantage of crimp and press fittings is the not very high reliability of the connection. For these reasons, such parts often need to be tightened during operation.

The main area of application is construction and repair work, where it is necessary to dock pipe-rolling materials with an external volume not higher than 6 cm.

Convenient and inexpensive crimping parts have almost no drawbacks, and during operation they do not create additional problems.

Compression fittings

Steel pipe fittings are versatile fittings. They can be used multiple times. They make it possible to bend the pipeline in any direction.

It is possible to join steel pipes using these parts without the use of welding and threading. At the same time, the tightness of the connection is at a high level.

They are made from materials that are distinguished by their durability and wear resistance. At the same time, there is a great opportunity to choose different configurations of structures.

Such mechanisms are equipped with one or two rings. The principle of operation is based on the use of a polymer seal. This material contracts under the influence of external pressure. At the same time, it tightly wraps around the outer part of the pipe, which is inserted into it. The result is a high-tightness connection.

Compression (crimp) fittings for steel pipes do not need to be installed with special tools. Installing them is quick and easy.

Video

But, these mechanisms have a significant drawback. They have low resistance to mechanical stress.Shock and vibration can cause leakage.

IMPORTANT! Before using compression (compression) fittings again without loss of tightness and strength, it is recommended to change the O-ring and rubber gasket.