In order to create comfortable conditions in the room, it is necessary to prepare for the heating season. Nowadays, there are many options for arranging heating units. For multi-storey buildings, centralized heating is mainly used. In private dwellings, as a rule, various boilers are installed. Installation of a device that uses fuel when heating a room requires an additional device, which is aimed at removing flue gases. Previously, a pipe was installed, which served as a diverting device. Today, more and more new designs appear that significantly improve the operation of the heating system. Often, owners of private buildings install a coaxial chimney, which is more efficient and practical than a conventional chimney.

The uniqueness of the device

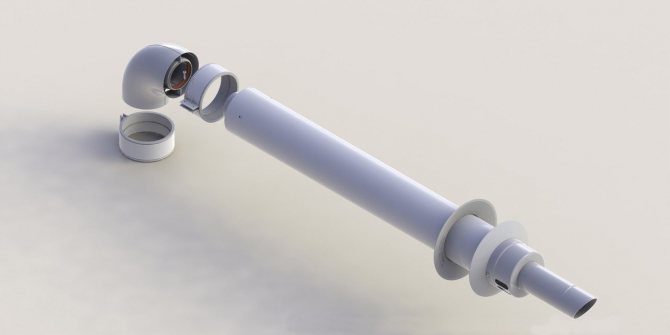

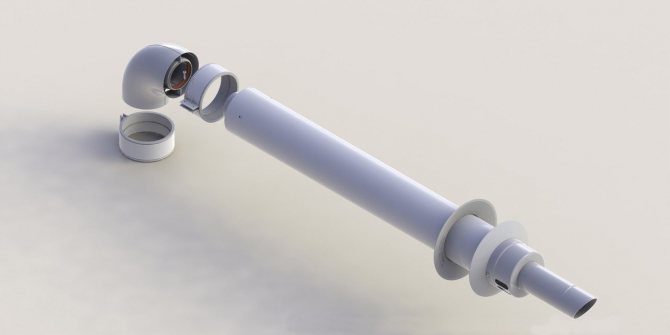

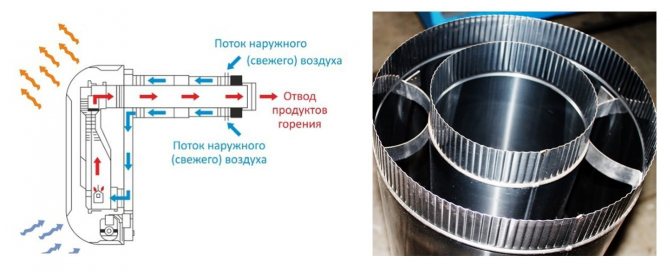

The design of such a device consists of several pipes of different diameters, which are inserted into one another. Hence the name - "coaxial".

In the middle of this device, special bridges are provided that do not allow the elements to come into contact with each other.

The coaxial chimney is installed complete with a gas boiler equipped with a closed combustion chamber.

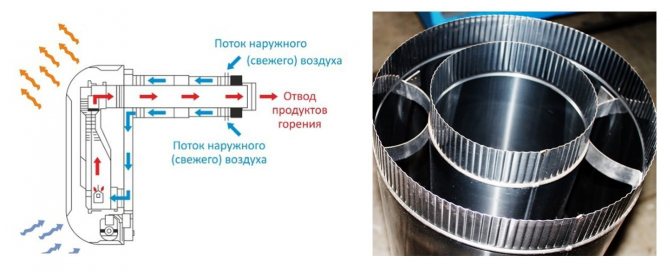

Each of the contours of such a channel has its own task:

- one of them is responsible for flue gas discharge from the combustion chamber of the boiler unit;

- through the second is carried out fresh air supply, which is important for the complete combustion of fuel.

For boilers with a closed firebox, it is necessary to install chimneys with a length of no more than two meters. This is important because the larger the size, the thrust will be poor, therefore, the fuel will not burn completely. This is due to the formation of peculiar eddies that interfere with the exit of the products of the chemical reaction of the oxidation of the substance and the entry of air flows from the outside.

What is a coaxial chimney

The term "coaxial" is used to refer to any structure consisting of two objects located around a common axis. In the case of a coaxial chimney, this is a flue duct consisting of pipes of different cross-sections.

The distance between the pipes is the same along the entire length of the chimney, including bends, bends and other elements. This is achieved through special bridges, which are located along the entire length of the chimney.

Coaxial chimney is made of two pipes with a common central axis, separated by special internal bridges

The principle of operation of a coaxial chimney

The duct between the inner and outer tubes provides a constant supply of fresh air, which is necessary to maintain the combustion processes. The inner pipe is a channel for the removal of flue gases and other combustion products. In fact, the special design of the coaxial pipe allows the chimney to perform two functions at once: removal of harmful substances and supply ventilation.

The flue gases are removed through the inner channel, and fresh air enters the combustion chamber through the annular space.

The main area of application of coaxial chimneys is wall and floor gas boilers with a closed combustion chamber, gas water heaters and convectors. Coaxial chimneys are not used with solid fuel equipment.

Advantages and disadvantages of the coaxial chimney design

Among the advantages of coaxial chimneys are:

- Versatility. The installation of the coaxial pipe is carried out by means of its output through the load-bearing wall, ceiling or roof ceilings. Depending on your needs, you can select the required dimensions of the chimney.

The coaxial chimney can be brought out in the traditional way through the ceilings and the roof, but it is much easier to do this through the load-bearing wall if a boiler with a closed combustion chamber is used

- Environmental friendliness. The higher the efficiency of heating equipment, the better the fuel burns. This, in turn, reduces the concentration of harmful substances and gas released into the atmosphere.

- Increased efficiency. Due to natural heat exchange with the inner pipe, heated air enters the combustion chamber, which significantly increases the efficiency of heating equipment. In this case, fuel consumption becomes noticeably lower.

- Safety. Cold air entering through the outer pipe cools the combustion products discharged through the inner channel. The risk of fire and burnout of the chimney is minimized.

- Easy to install. No special tools or special skills in construction are required to assemble the chimney. The chimney design allows you to quickly install and commission any equipment with a closed combustion chamber.

Despite its many advantages, the design of the coaxial pipe is not without its drawbacks. At temperatures below -15 ° C, the coaxial chimney can get very cold.

This is due to the fact that, in fact, is the advantage of the design in question - cold air is heated due to the temperature of the flue gases leaving outside. The combustion products are very cooled and can condense at the outlet of the chimney, which leads to severe icing on the chimney head.

One of the main advantages of a coaxial chimney turns out to be its main disadvantage - at low temperatures outside, condensation of combustion products occurs and ice freezes on the head of the pipe.

To prevent icing, you should choose special devices designed to work at negative temperatures, as well as more carefully calculate the cross-section of the chimney.

Advantages and disadvantages

As for the advantages of the coaxial design, the following points can be attributed to them:

- Quite high efficiency.

- Small size. When installing a conventional chimney, two pipes are required, and in the case of a coaxial structure, one product is required.

- There is no need for an additional ventilation system.

- Environmental friendliness.

- Staying in a boiler room is absolutely not harmful to human health, since the heating system takes oxygen not from the room, but through canals from the street.

- Economical fuel consumption.

- Due to the constant flow of cold air, the walls cannot become overheated.

The only drawback of the device is as follows: at subzero temperatures, a smaller diameter pipe may freeze over, since the flue gases give off their heat to the inner channel along the way and already have a rather low temperature at the outlet. That is why the formation of condensate accumulations in the pipe is normal. With a decrease in indicators to -15 ° C, a rolled metal product may succumb to severe freezing, which leads to undesirable consequences.

It is believed that coaxial structures are not suitable for the harsh climate of Russian cities. At first, this system was developed for the southern countries. However, many experts agree that pipe freezing is the result of an illiterate design of this system. Whatever the cause, the end effect is the same: the galvanized chamber and burners quickly deteriorate.Repairing such equipment is considered quite expensive.

Most often, such problems are observed precisely in those types of chimneys that are manufactured according to parameters that can significantly increase the efficiency. For this, the diameter of the pipe is made as small as possible, which practically brings the temperature indicators of the flue gases to the dew point.

For southern countries, such values do not affect anything, but in Russia, with the first serious drop in temperature, freezing of the pipe entails a complete installation of the heating system. Manufacturers can only make a helpless gesture, since this device is not tested in such conditions.

Selection of a chimney for a bath

There is no individually designed chimney system for arranging heating in a bathhouse. They select it depending on the type of boiler, the type of fuel and the design characteristics of the room. The arrangement of such chimneys for different stoves is practically the same. Coaxial pipe is usually manufactured made of high quality plastic or aluminum... When purchasing such a system, you must pay attention to the presence of all jumpers, which are designed to prevent the pipes from touching.

It is not recommended to design a coaxial chimney on your own, since many different nuances must be taken into account in the process. Any mistake can lead to undesirable consequences that will be quite expensive.

All recommendations for proper design can be found in the Russian SNiP 2.04.08-87 "Safety rules in the gas industry." Without special skills and knowledge, these requirements will be difficult to understand. For simplicity, you can purchase a turnkey system that includes all the required certifications. By their design, such devices are horizontal and vertical.

Types of coaxial chimneys

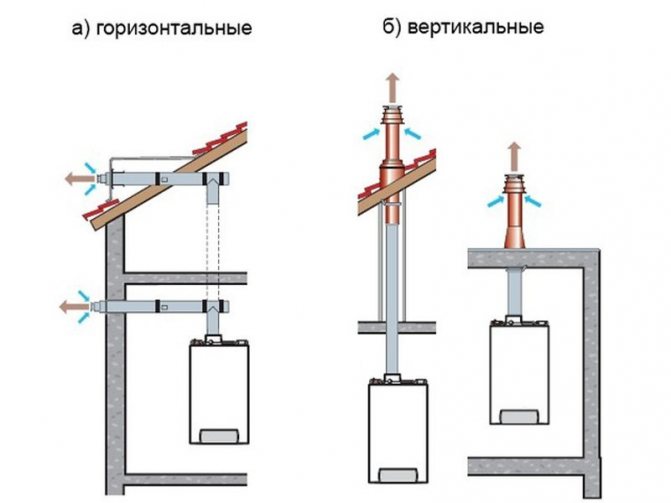

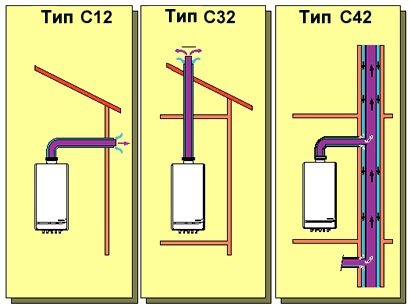

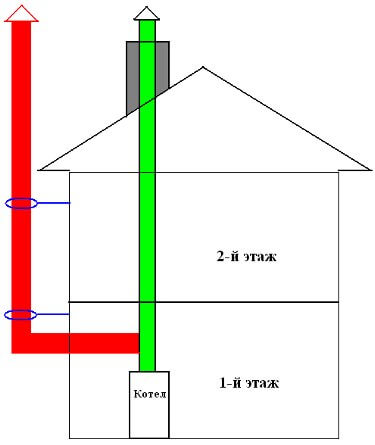

Depending on the method of laying the chimney, coaxial type chimneys are divided into two types:

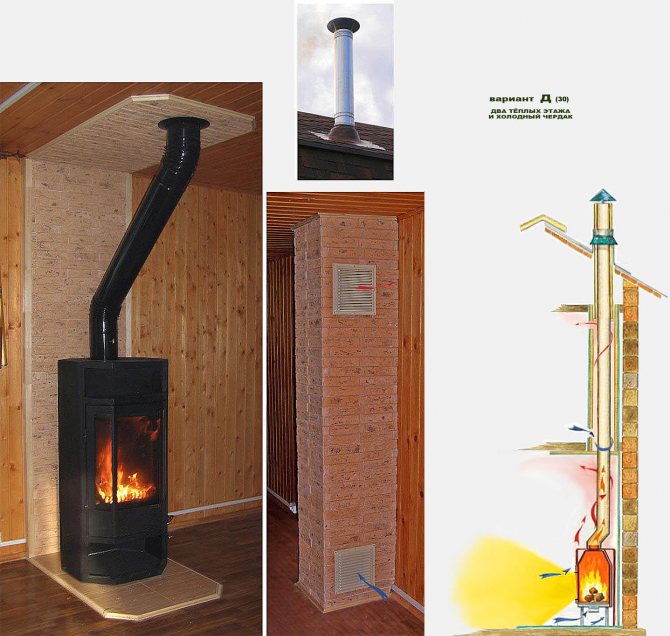

- Vertical - the chimney is located strictly in a vertical position. Gases and combustion products rise from the fuel chamber and are released into the atmosphere above the ridge level. Mainly vertical structures are used in residential buildings and provide a good level of natural draft.

- Horizontal - the main channel of the chimney is represented by a structure located in a horizontal position, which is led out through the load-bearing wall. In this case, the flue gases escape to the outside in the immediate vicinity of the heating equipment. It is more often used in private houses where closed-type heating systems are installed.

A vertically oriented coaxial chimney, despite some advantages, is a more expensive and difficult system to install. The total length of the chimney duct usually exceeds 5 meters, which greatly complicates the process of installation and fixing of the structure.

For the manufacture of a coaxial type chimney, various grades of steel and plastic are used. In accordance with this, several types of chimneys can be distinguished:

- galvanized - the most affordable option for a coaxial chimney. The average service life of the product does not exceed 5–7 years, after which the structure partially rusts or is damaged. The cost of the product depends on the manufacturer and technical parameters, but rarely exceeds 2–2.5 thousand rubles;

- made of plastic and aluminum - a combined option for private use. The inner channel of the chimney is made of aluminum with a thickness of up to 2 mm. The outer tube is made of high-strength, heat-resistant polypropylene. Such chimneys are used only in the private sector for joint work with boilers of small and medium power;

Coaxial chimneys made of galvanized steel are designed for 5-7 years, plastic products will last much longer

- stainless - more reliable and durable chimneys than galvanized ones. They are designed for 10-12 years of use. The cost is almost the same as stainless steel products. In industry and collective systems, chimneys are not used, since "stainless steel" does not withstand a high concentration of chemicals;

- made of high-alloy steel - the strongest and most durable version of the coaxial chimney. High-alloy steel is not afraid of exposure to high temperatures and chemicals contained in flue gases. Average service life is at least 15 years.

A coaxial chimney made of high-alloy steel, unlike "stainless steel", does not deteriorate under the influence of aggressive chemicals contained in combustion products, and serves for at least 15 years

In the line of some manufacturers (Electrolux, Viessmann, Schiedel) there are models of coaxial chimneys with an additional thermal insulation layer. This is a classic design with two channels, which is located in another pipe. The voids between the outer pipes are filled with non-combustible heat-insulating material that prevents freezing and blockage of the air channel.

Video: coaxial pipe for parapet gas boilers

Manufacturers

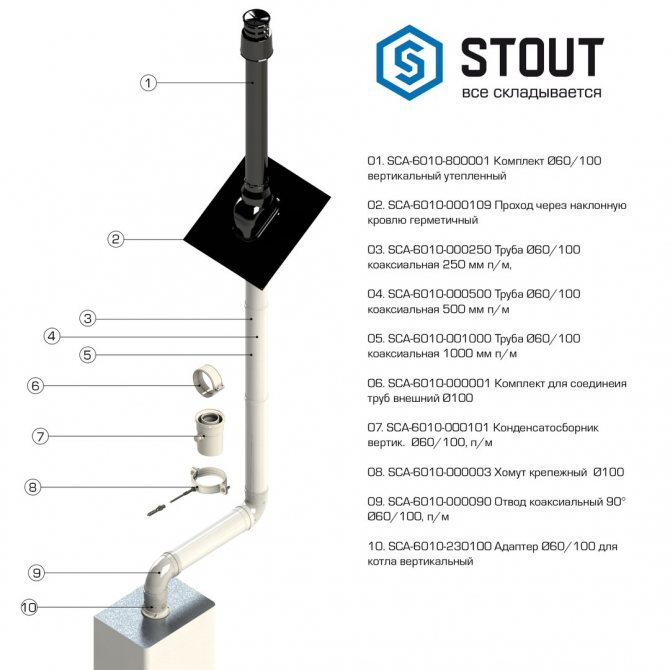

A universal option for most popular gas boilers is the coaxial design of the STOUT brand. All components of the system are ideally matched to each other, easy to install and maintain, adapted for use in our country.

A variety of elements allows you to create absolutely any smoke exhaust system. The manufacturer gives a two-year warranty on all products. The manufacturing process is carried out at the same factories in Italy, where a similar but more expensive product is produced. STOUT is the choice of those who do not overpay for the promoted brand name, but are used to choosing only high quality.

Coaxial chimneys of the company Baxi produced for boilers that run on gaseous fuels. Their construction is made of the highest quality stainless steel.

Company Immergas produces horizontal coaxial flues. It is possible to use such a device for gas boilers, as well as for units operating on liquid fuel.

Firm Buderus is engaged in the manufacture of horizontal chimney systems. Two types of steel are used for their production: galvanized and stainless steel.

Coaxial chimney for gas boilers Hermann It is manufactured in certain sizes: the diameter of the inner pipe is 6 cm, the outer one is 10 cm. Such systems are performed both horizontal and vertical.

Coaxial chimneys of the company Vaillant are manufactured with some design features that allow the device to be used in conjunction with boilers from other companies.

Korean manufacturer Navien manufactures chimneys that can be used with floor-standing or wall-mounted boilers with a capacity not exceeding 75 kW.

Coaxial chimneys of a popular company Viessmann produced in several versions with diameters 6/10 cm, 8 / 12.5 cm, 10/15 cm. By design, they can be both vertical and horizontal.

Firm Protherm manufactures both types of coaxial flues in sizes 6/10 cm and 8 / 12.5 cm.

The design of similar devices of the company Daewoo designed in such a way that the installation can be carried out from either side of the boiler.

Horizontal and vertical chimneys of the company Ariston are made of enamelled steel.

Different chimneys

Important! When calculating how to lead a chimney through a wooden ceiling, it is important to remember that at 200 ⁰C wood charring already begins, and a temperature of 300 ⁰C allows you to maintain a stable burning of firewood in the furnace.This suggests that the main efforts should be directed to lowering the temperature at the junction of the pipe.

Installation specifications

You can use ceramics

- In order to ensure the correct arrangement of a chimney in a wooden house, you do not have to "create a bicycle" - there is practical experience, which at the moment is reflected in the form of regulations in various government documents. You can get the basic installation manual from SNiP 41-01-2003 (heating, ventilation and air conditioning) - it contains basic information that will be taken into account by fire safety representatives during verification.

Sauna oven

- But the constant temperature in the chimney can also depend on the distance of one or another of its sections from the firebox, which is influenced by the design of the heater itself and the design of the chimney system. According to SNiP 41-01-2003, you need to observe certain distances from stoves and pipes to highly flammable objects - in this case, it is wood (walls, partitions, rafters, and so on). So, brick and concrete furnaces or pipes should be at a distance of 130 mm, and metal and ceramics - 250 mm from sawn timber structures.

| Type of equipment | Heating temperature |

| Fireplace or Russian stove (wood) | 350-650⁰C |

| Sauna stove (firewood) | 400-700⁰C |

| Gas generating boilers (firewood) | 160-250⁰C |

| Solid fuel boiler (pellets) | 120-250⁰C |

| Solid fuel boiler (sawdust) | 220-240⁰C |

| A gas boiler | 120-200⁰C |

| Oil-fired boiler | 150-250⁰C |

| Solid fuel boiler (coal) | 500-700⁰C |

Chimney heating table with different heaters

Attention! The same norms apply to fusible heaters such as polystyrene foam, expanded polystyrene and so on. When installing pipes, try to strip the insulation to the specified distance.

Brick pipes

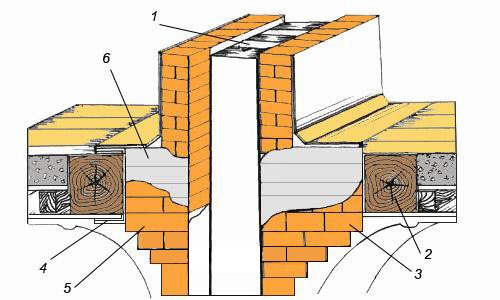

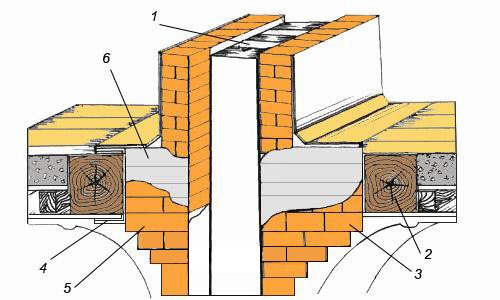

Section at the exit in a multi-storey wooden house: 1 - smoke channel; 2 - floor beam; 3 - cutting into one and a half bricks; 4 - asbestos sheet in 2 layers; 5 - cutting into one brick with insulation; 6 - sheathing

The construction market constantly offers more and more new materials from which pipes for chimneys are made, but, nevertheless, brick always remains the main material for arranging the channel itself, or its insulation.

When the chimney passes through a wooden floor with your own hands, it is important to observe some of the nuances of the masonry - it is laid on a lime or cement-lime mortar right up to the roof.

But for the part that rises above the roof, it is already necessary to use a cement-sand mortar - there the passage temperature drops sharply. The seam on the brickwork should not be wider than 10 mm, otherwise the structure will lose its rigidity and stability, but there is simply no point in strengthening or simply covering the chimney with plaster - it will still crack from temperature changes and collapse.

Such structures are recommended to be erected from a solid single red brick, the average weight of which is 3.45 kg, therefore, the entire masonry will turn out to be very heavy. This indicates that a solid foundation is needed - it should be not only under the stove, but also under the walls of the house, since, starting from the lounger, the entire mass of the smoke channel lies on the ceiling, which, in turn, rests on the walls.

Brickwork as insulation

As a rule, when erecting brickwork, everyone tries to make its front side as flat as possible, but the uneven surface inside the pipe contributes to a very rapid settling and accumulation of soot on the walls, and this already carries a fire hazard.

In addition, a brick or mortar protruding from the inside collapses under the influence of acid condensate, and pieces that have fallen inside block the passage, thereby reducing the channel cross-section, and the thrust becomes worse.

Note.If your brickwork is made as a sleeve, the chimney itself consists of an asbestos-cement or metal pipe, then you can fill the free space with sand-cement mortar or fine-grained concrete (this is called a sleeve - this increases not only the price of the structure, but also its quality). So you will not only strengthen the thermal insulation, but also prevent the premature destruction of asbestos cement.

Slab and wall

Arrangement of thermal insulation in the floor

As you understand, the distance from the chimney to wooden structures according to SNiP 41-01-2003 is given in an open space, but the passage through the ceiling is carried out according to different standards, since in such cases various insulating materials are used that reduce the heat transfer of the chimney.

For example, if two layers of asbestos sheet are used when passing a metal or asbestos-cement pipe through a wooden floor, then the distance of one brick should be maintained here, that is, 250 mm, but if such a heat extinguisher does not exist, then this distance will increase to 380 mm. (See also the article Thermal insulation of wooden floors: features.)

In the photo, brickwork and galvanized sheet are used as thermal insulation.

The requirements for the distance between the chimney and the wall remain exactly the same as for floors, that is, if there is two-layer asbestos insulation, then it must be at least 250 mm, and if there is none, then it increases to 380 mm.

But sometimes such requirements can be waived a little, for example, the distance can be made a few centimeters less near the boiler in the steam room, since it operates periodically, nevertheless, so that the lining does not burn, it is sheathed with galvanized children, as shown in the top photo.

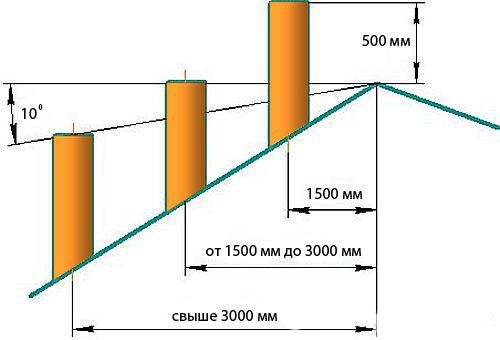

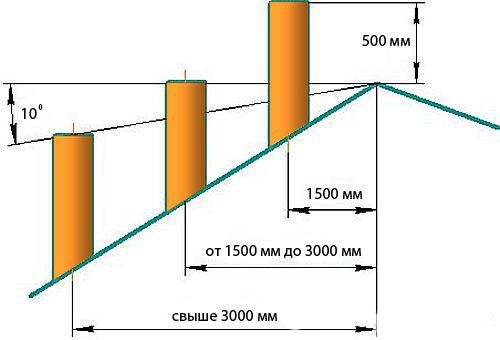

Height requirements

When installing the chimney directly through the ridge, its height to the head must be at least 200 mm. In cases where the pipe is on the side, on a slope, then it must be at least 500 mm higher than the ridge. This will ensure normal traction.

Coaxial chimney

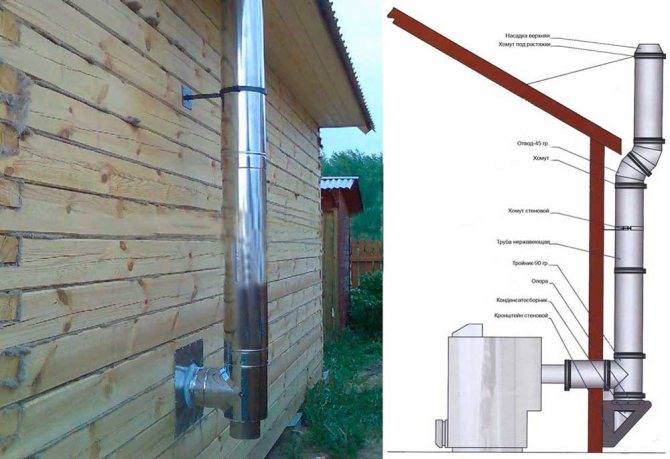

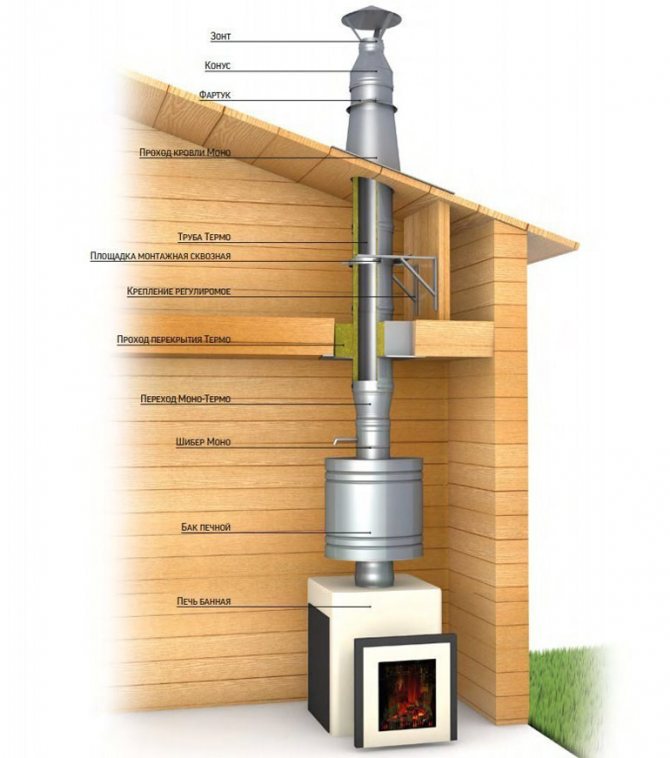

Installation of a coaxial chimney in a wooden house - outside view

When a coaxial chimney is installed in a wooden house, then there are completely different requirements that do not require keeping a distance from flammable objects, since the pipe simply does not heat up. It's all about the device of this device - the gases from the combustion products are discharged to the street, through the inner pipe, and through the sleeve (outer pipe), air from the street enters the boiler, supplying the oxygen necessary for combustion. (See also Attic Flooring with Timber Beams: Features.)

In cases where the gas boiler has forced circulation, the "coaxial" (outlet) is installed only in a horizontal position. With natural circulation, pipes can be installed vertically or with a slope.

Installation requirements

Installation of such a design has its own rules, which should be described in the instructions attached to the equipment. Gas supply services and the Ministry of Emergency Situations can make adjustments and additions.

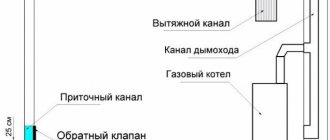

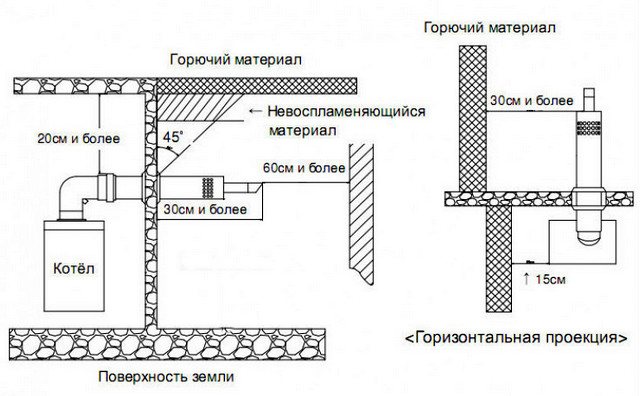

When installing a coaxial chimney, it is important to take into account certain requirements:

- It is necessary to observe the distance from the chimney to the adjacent building, which is calculated taking into account the technical characteristics of the structure and the design features of the chimney itself. In the absence of a deflector, the distance should be approximately 8 m.With this traction amplifier, it is important that the gap from window structures to the pipe is at least 5 m.If the wall is absolutely flat, without doors and windows, the distance can be reduced to 2 m. that SNiP does not say about the requirements for horizontal chimneys, therefore, it remains to follow the instructions from the manufacturer.

- The maximum permissible length of the coaxial pipe must not exceed 5 m.In multi-storey buildings, collective chimneys can be used to lengthen the channel. This problem is also solved by connecting to a common chimney system.

- Attention should be paid to the importance of creating a slope in the duct to allow condensate to escape outside the structure. The slope according to the ground level should be 3 degrees.

- It is important that all elements are connected before the pipe enters the wall.

- The distance to the ceiling structure of the building must be at least 20 cm.

- It is necessary that the outside part of the canal has a length of at least 20 cm.The optimal size is 60 cm.

Requirements for the placement of coaxial flues

So, if you decide to install a coaxial chimney yourself, you need to know some requirements. By the way, the information will be useful for those who are going to call the masters - at least, it will be possible to check whether they comply with the established standards.

- The length of the chimney cannot be unlimited. Manufacturers set and indicate in their passports the maximum length of the coaxial system. As a rule, it never exceeds four (in some cases even less than three) meters. This means that you should calculate in advance the installation location of the boiler. The minimum length is considered to be 1 meter.

- Too many changes in the direction of the coaxial pipe should not be planned. It is recommended that the number of turns do not exceed two. In addition, it is generally accepted that the installation of one bend with a turn of 90 degrees "eats" one permissible meter of the length of the system, a bend at 45 degrees - half a meter.

- During installation, only the parts included in the kit should be used. And the system itself should be suitable for a specific model of a gas boiler. It is strictly forbidden to use third-party components, no matter whether factory or handicraft.

- The use of any adhesives or sealants is strictly prohibited.

- The slope of the horizontal section is made towards the street by 2 ÷ 3 degrees if the chimney is installed on an ordinary gas boiler, towards the boiler at the same angle - if the boiler is condensing or if a condensate collector is installed at the initial section, which was mentioned above.

Docking of pipes at the section of passage through the wall is not allowed. The location of all connectors must allow their visual inspection.

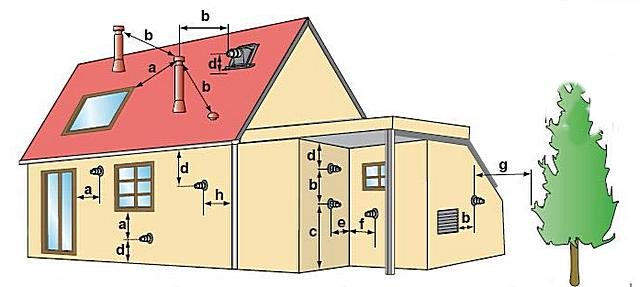

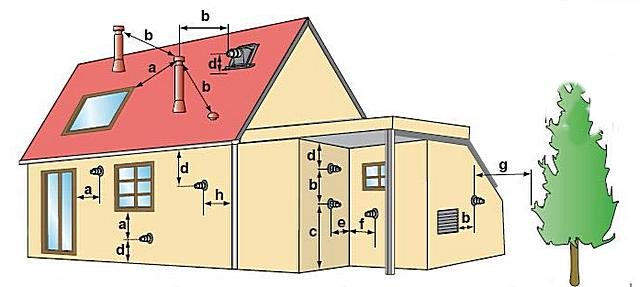

There are a number of requirements for the placement of the coaxial pipe and its head in relation to other building elements and surrounding objects. They can be considered in the following diagram:

Mandatory and recommended parameters for the placement of the head of the coaxial chimney relative to the elements of the building and surrounding objects

a ≥ 400 mm. Required condition. The minimum distance from the axis of the coaxial chimney to any opening object on the facade of the building (window or door). It also applies to the distance from the chimney head with its vertical arrangement to the roof windows.

b ≥ 600 mm. Required condition. The minimum distance from the axis of the chimney to any air intake or exhaust ventilation duct, to the axis of adjacent coaxial or conventional chimneys.

s ≥ 1800 mm. Required condition. The minimum height of the chimney axis above ground level on the side of sidewalks or footpaths. System manufacturers can set their own requirements for this parameter. For example, for some models of boilers and coaxial chimneys, the minimum height is set at 2000 mm. Surface installation is allowed at a height of 150 mm from the sidewalk, provided that a high-quality deflector and protective grill are required.

d ≥ 300 mm. Recommended condition. The minimum height of the chimney axis above ground level on walls that do not border on pedestrian areas.

≥ 1000 mm. Recommended condition.The minimum distance from the axis of the chimney to the adjacent wall of the inner corner of the facade, on which there are opening objects (windows or doors). With a deflector, the distance can be reduced to 150 mm.

f ≥ 150 mm. Recommended condition. The minimum distance from the axis of the chimney to the adjacent wall of the inner corner of the facade, on which there are no opening objects. In both cases (e and f), if the adjacent wall is lined with or lined with combustible material, the minimum distance to it increases to 300 mm.

g ≥ 2000 mm. Recommended condition. The minimum distance from the chimney head to the nearest green space.

h ≥ 100 mm. Recommended condition. The minimum distance from the axis of the chimney to vertical gutters running along the facade and any communication pipes.

No matter how attractive this location of the exit of the coaxial chimney - below ground level, it is strictly prohibited.

It is strictly forbidden to locate the outlet of the coaxial flue below ground level. For example, in an equipped technological pit, collected by a grating.

Several additions to the conditions for installing a coaxial chimney.

A few more requirements:

- Indoors, the pipe should not be closer than 200 mm to the ceiling.

- There must be a distance of at least 150 mm between the boiler (wall-mounted or floor-standing) and the adjacent wall.

- If there is another building opposite the wall, through the finished chimney, there is another structure, then at least 600 mm must be maintained from the head to the wall of this building.

It is impossible to say for sure about the length of the outer section of the coaxial chimney - it can be installed differently, depending on the model. The diagram above shows at least 300 mm. However, there are systems that require half a meter in length, and those in which the head is located almost close to the wall.

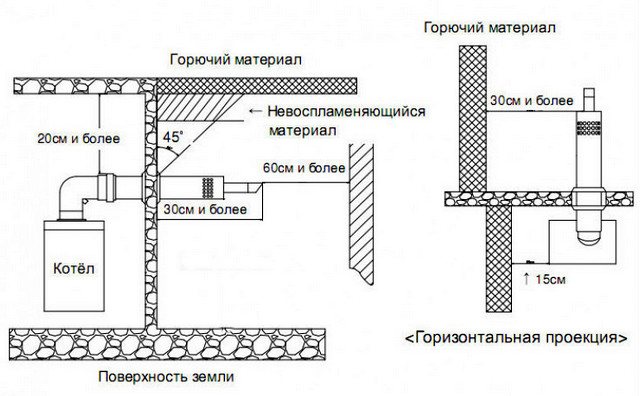

Passing a coaxial device through a wooden wall

In SNiP and fire safety rules, there are no recommendations for the installation of horizontal chimneys. However, there are general requirements, according to which the passage of the pipe through a wooden wall must be carried out with certain cuts. To a greater extent, this condition is met not in order to protect the structure from fire, but to exclude incidents with fire services in the form of fines and instructions.

The passage of a coaxial chimney through a wall made of non-combustible materials

The process of preparing the hole required for the output of the pipe is not particularly difficult. An opening of the required diameter is cut, the slope of which is directed towards the ground. The size of this hole must be equal to the corresponding chimney value. A special extension cord is inserted into the opening made, which fulfills the requirement for the location of the connection to the wall.

It is possible to protect the chimney from icing only by installing additional elements. It is recommended to purchase a special nozzle that will prevent condensate from freezing. This device will also help in case of incorrect design and subsequent installation without the desired slope. The nozzle helps to maintain the temperature inside the pipe at a certain level.

The distance from the gas supply duct to the chimney should be approximately 60 cm.