Advantages and disadvantages

Clinker tiles have a number of properties that distinguish them from other finishing materials:

- The durability of the material is a huge advantage. The strength of a tile can be compared to that of clay brick, since in fact it consists of well-fired clay.

- Due to its composition, clinker tiles are considered an environmentally friendly material, fungi do not form on them, they are not exposed to ultraviolet radiation.

- It has a low water absorption rate. This makes the tiles frost-resistant.

- It is very easy to take care of this cladding. A simple wash as it gets dirty is enough without the use of additional agents.

- Assortment of material. There are many clinker tiles in different colors, shapes, patterns and surface reliefs. The front side of the tile is possibly glossy.

- Depending on the type of clinker tiles, it can be used for paving, facing, construction of hydraulic structures.

But clinker tiles also have disadvantages:

- This is a rather fragile material.

- The price of the tiles is above average.

Independent production of facade tiles and fasteners

Can decorative facade tiles be made with their own hands and fastenings for it? Of course yes. In the previous materials on the site, it was already talked about how you can make an artificial stone with your own hands. The technology of production of facade tiles on their own will be about the same.

The technology for the production of tiles for outdoor work will be disclosed in the following materials on the site, but you can familiarize yourself with how the homemade facade tiles with metal fasteners will be mounted right now.

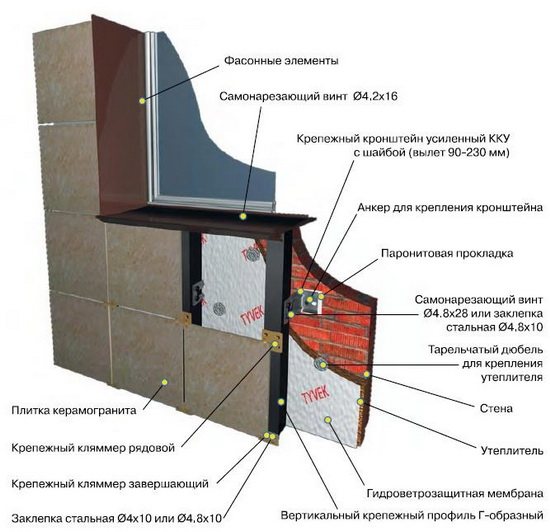

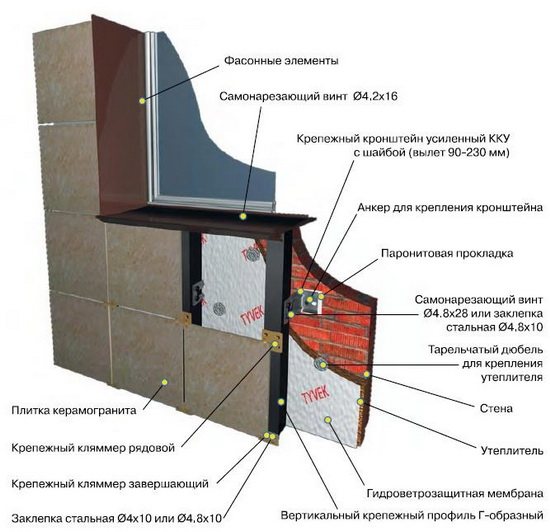

The diagram shows a facade tile with metal fasteners, assembled with insulation, and fixed on the outer wall of the house - this will be the overall "pie" of the wall:

As you can see, it is the clamps that are used, or you can use their homemade likeness, but not the self-tapping screws. Why? Because such a facade tile on self-tapping screws will not be able to stick normally to the wall, even if self-tapping screws with wide hats. The material of the cladding panels itself will not withstand.

See more on this topic on our website:

- Facade tiles for natural materials - brick and stone The range of clinker facade tiles is very wide. Manufacturers offer a wide variety of options for these products. The tile is not inferior in quality to the same brick, although it is much more.

Facade tiles on metal fasteners - what they are and how to mount By their composition, tiles are made of kermogranite, and let's talk about it first of all, almost the same as an ordinary slab. It is made from feldspar.

Correct installation of expanded polystyrene on external walls Due to a number of excellent qualities, extruded expanded polystyrene is readily used in construction or during renovation work. The installation of expanded polystyrene on the walls is not the only purpose for which it serves.

Facade tiles - the correct laying technology Facade tiles are one of the most popular and demanded materials for home decoration. It consists of various sand-cement compositions and can be made completely different.

Insulation and decorative finishing of a brick house In modern construction, walls are still built of bricks. Despite the many positive aspects, a brick house needs additional insulation. Thermal insulation of external brick walls.

Preliminary stages

It is completely pointless to start facing work on an unprepared wall. Some novice home craftsmen naively believe that a layer of ceramic tiles will reliably hide all the "ugliness" of the surface, and the result will be a straight, beautiful wall. They are cruelly mistaken!

What does the preparation process involve?

- It is imperative to get rid of the old wall decoration. It won't, for example, keep the adhesive on the tile on the painted surface. Old wallpapers or even small fragments of them are completely excluded. If previously there was a tile on the wall, then after dismantling it, all flows and drops of frozen glue should be removed.

No old finish should remain on the walls

- The quality of the plaster layer, if any, is necessarily checked. All problematic, crumbling areas are removed immediately. It is necessary to tap the entire area, to identify the places of instability, which must also be removed. And most often it happens that if an exfoliating area is found in one area, then everything else will be pulled from it, that is, the plaster has to be knocked down completely.

Unstable plaster fates are removed without regret. And more often it ends with a complete removal of the old plaster layer.

- In no case is it ignored if traces of their biological damage are found on the walls - mold spots, fungal colonies, etc. Antiseptic priming is carried out on all surfaces without exception, but if this microflora has already settled, then you will have to carry out preliminary "treatment" of the wall with special compounds.

It is completely unacceptable to start finishing in such or similar conditions. We'll first have to deal with the "treatment" of the walls.

- There should be no cracks or cracks on the surfaces. If they are identified, appropriate repair work is carried out to ensure their high-quality termination.

Cracks and crevices must not be left under the finish - all identified defects of this type must be sealed

- The wall should be flat, that is, it should be a plane, not a twisted, collapsed, protruding or concave surface. The tiles can be laid on the aligned walls without any problems. Yes, there are techniques for leveling walls precisely by installing ceramic cladding. But, believe me, not even all experienced craftsmen like to do this, since this task is extremely difficult. And if a newcomer is about to "debut", but there is nothing to even think about. It will be much easier to align - and the finish will definitely turn out to be of high quality.

There are many ways of leveling, and some of them, for example, using moisture-resistant drywall or gypsum fiber boards, are not so difficult and do not take much time.

moisture resistant drywall

- Ceramic tiles are most often installed in rooms with high humidity, so you should also think about reliable waterproofing. To a greater extent, this applies, of course, to the floor, but on the walls it makes sense to provide a waterproof "belt" at least 100 ÷ 200 mm high from the floor along the entire perimeter. In addition, it is advisable to reinforce with waterproofing the sections of passage through the walls of water supply and sewer pipes, the area around water outlets.

Waterproofing wall surfaces - with a belt along the floor and around pipe penetrations.

- Finally, the wall should be carefully primed with a deep penetration compound. This measure will completely remove dust from the surface, eliminate the phenomenon of moisture absorption. That is, the wall material will not take water from the tile glue, allowing it to harden in optimal conditions. The best adhesion performance is achieved. In addition, many primers also have antiseptic qualities, and such a preventive treatment will never be superfluous.

The wall must be primed with a deep penetration compound.

If the absorbent qualities of the material are high, then the primer treatment is performed twice, necessarily waiting for the first layer to dry completely. As a rule, the primer is applied immediately after the completion of the preparatory work. But if, for some reason, there is a significant gap in time between this stage and finishing, it will be advisable to apply the primer again - a day before the installation of the tiles. So a quality result will be guaranteed.

Now the surfaces of the walls can be considered ready for finishing with ceramic tiles.

primer for walls

It is clear that these two issues are closely intertwined. In this publication, we will not analyze design approaches to choosing the interior of a room - we will dwell only on some practical aspects.

Let's make a few remarks at once. Below we will consider not the most difficult way of laying tiles on the wall. It is impossible to grasp with attention and all possible cases. Some points of the work will be deliberately removed from the presentation - simply because these stages are considered in more detail in separate articles of our portal.

But in general, the basic technological techniques will be shown, and a novice home craftsman should form a stable concept of the procedure and rules for tiling the wall with tiles.

Above, it was already mentioned in passing that it is best to start laying tiles on walls not from the very bottom, but from the second row, at whatever height it is located according to the developed scheme. This way you can achieve perfect horizontal rows without really looking back at the evenness of the floor. Well, then, when the flooring is laid, it remains only to precisely fit the tiles of the first row - and everything will turn out very neatly.

This means that at the first stage it is necessary to break through the laying line of the second row, and place some kind of base on it - a support for the tiles.

| Illustration | Brief description of the operations performed |

| It is necessary to implement such a project - for each of the walls a pile is provided with a detailed scheme, which the master will adhere to when laying. The bottom row begins with a whole tile, the top is also whole, but somewhat hidden in height by a stretch ceiling. However, installation will still start from the second row - much easier and more accurate. | |

| If the preparatory work was carried out earlier, and the room was simply "waiting for its turn" for finishing, then it would be useful to perform one more priming of the walls, on which construction dust could have settled, which impairs the adhesion of materials. Normal deep penetration soil is used. It is better to plan the application of the primer one day before the start of the main work. | |

| If priming has already been carried out before, then the composition will not be highly absorbent. And with the help of a roller, this operation can be done very quickly. The next day we start finishing work. | |

| The original view of the bathroom. | |

| As already mentioned, it is best to work (especially in the absence of experience) on flat walls. Everything seems to be fine with this here, but it never hurts to check. Therefore, work begins with control - checking the verticality of the wall. | |

| And the conformity of the plane is checked by applying a long rule. Ideally, it should adhere to the surface along its entire length. But on this wall you can see a gap - there is a slight curvature. This should be noted for yourself - you will have to take a slightly different approach when laying the starting row. If the deviation is no more than 3 ÷ 5 mm, then it is easy to eliminate during finishing. But if the differences are large, it is better to do alignment. | |

| The planes have been checked, the identified areas of small deformations are outlined - you can proceed to skipping the line of the starting, second from the bottom row. Tiles have not yet been laid on the floor in the room, so one cannot vouch for the ideal horizontal floor.Therefore, you need to check and find the highest point - it is from this point that the baseline marking will go. The laser level turns on, which sets a horizontal line in all walls. It is not necessary to place it high - 100 ÷ 150 mm from the floor is enough (optional). | |

| Now with a square, you can walk around the perimeter and check the height of the beam above the floor surface. Measurements - along the corners and along the length of the walls with a step of about one meter. The results can be written in pencil directly on the wall or on the floor. | |

| The point where the minimum height value is obtained is the highest point. From her we will begin to "dance". | |

| You can simply measure the height of the tiles on the wall, but it's easier, so to speak, to simulate the situation. Two cartons are laid on the floor, which imitate the layer of glue under the floor tiles. | |

| We temporarily put floor tiles in a corner. Now from it you can see how the bottom row will rise on the wall. | |

| We put two spacer crosses to imitate the thickness of the seam between the floor and the wall. | |

| Now the tile of the lower row is "in place", and a small line is drawn along its upper edge with a pencil on the wall. | |

| It is at this level that the profile will be attached, which will become a support for laying the second, starting row. | |

| This line needs to be transferred to all walls around the perimeter of the room. The easiest way to do this is with a laser level. | |

| Pencil marks are made on the beam projection ... | |

| ... which are then connected with a solid line using a rule or a long ruler. It doesn't matter if there is no laser level. All of the above6 operations can be done using the water-based one - the accuracy will be no worse. Simply at first, one "base" horizontal line is very accurately marked on the wall with the help of a water level. And then all measurements are made from it, and it is easy to make a parallel transfer of the horizontal line to any section of the wall. But relying on a bubble, even the highest quality and longest level is undesirable, since an error may well run into. It's good for control, but for room-scale layout, you still need something more precise. | |

| The galvanized guide profile, which is usually used for plasterboard systems, is very suitable as a support for the starting row. There are usually holes in it, but if not, they are drilled with a drill, with a diameter of 6 mm, and with a step of about 500 mm in order to prevent sagging. In principle, other materials can be used instead of a profile, for example, a long strip. The main thing is that it is not heavy and perfectly flat. | |

| After installation, the upper edge of the profile must exactly match the marked line. So it is better to call an assistant to control the position during the installation of the fasteners. | |

| The profile is applied exactly along the line, held in this position, and a hole for the dowel-nail is drilled approximately in the center of the wall (6 mm, length up to 35 ÷ 40 mm). Then the dowel-nail is inserted into the hole until it stops and screwed in with a screwdriver to the end (it is better to screw it in so that then there are no problems with dismantling, which happens when driving). | |

| The center is fixed, you can, if necessary, adjust the position of the profile, and then fix it at all other points. | |

| A similar operation is carried out on all other walls. It is clear that the profiles should converge perfectly at the corners, for which it is even better to cut them from the edges at an angle of 45 degrees. During the installation of the profile, regular control is carried out using a level. At this stage, it can be considered complete. |

We suggest that you familiarize yourself with How to make a blind area of concrete around the house

How to lay tiles with your own hands?

Even if you have never had to do anything like this, the amateur has a good chance to put the tiles on the floor or wall with high quality. It is only important to be patient, be careful and consistently carry out all the necessary technological steps.

But first you need to get the right tool:

- hydro or laser level, plumb line;

- square;

- perforator with mixer attachment;

- with a polystyrene foam float for "stretching" the plaster on the surface;

- trowel;

- aluminum rule;

- notched trowel;

- tile cutter;

- with a rubber trowel or a jointing sponge.

Self-laying technology for ceramic and / or tile:

- The first stage is the preparation of the surface for tiling:

- it will be necessary to completely get rid of the old finish, whatever it may be: knock down (observing safety precautions) the previous tile, remove the wallpaper, strip off the paint;

- equip the most even rough base for future laying;

- for walls, using water or laser levels, determine the verticality of the surface, for the floor - all with the same levels, but horizontal;

- The second stage is wall plastering and floor screed with obligatory leveling. And it is better to use cement-based plaster mixes for this purpose on the walls.

- The actual laying of ceramic (tile) tiles.

- And jointing of seams.

Alignment is a mandatory procedure, because without this, the corner of the cladding can simply be "filled up". This means that there will be a large run-up in the seams in width, which looks ugly and bad for the quality of the installation as a whole. The evenness of the corners is checked with a special tool - a square, which is set exactly in the corner, and its ribs should lie tightly along the walls.

How to calculate the number of tiles you need

Calculating the number of tiles required for cladding is quite simple. To do this, you need to measure the width and length of the surface to be faced, whether it be a facade, a staircase or a stove. At the time the measurements are taken, the length is multiplied by the width to give the surface area. The area of the elements located in the calculated surface is subtracted from the taken value, and the area of the required number of tiles is obtained.

Usually the manufacturer himself shows how many tiles are required for facing 1 m2 of surface, and taking into account the tile joints, based on this, it will be very easy to find out how many tiles are needed.

As usual, the tile is attached to the foam

Decorative facade tiles on foam plastic can be fixed in two ways - glued and fixed to the frame.

Let's focus on the wireframe version right away. Polyfoam is a combustible insulation, no matter what the foam manufacturers tell us. If the facade tiles on foam plastic will be attached to the frame with a gap, then there may be a ventilation gap between the outer decorative coating and the insulation.

In the event of a fire, which is possible with such a combination of "foam - ventilation gap", the fire will spread along the ventilation gap, covered with decorative tiles on top. It will be impossible to extinguish such a fire.

The only option when the facade tile on foam plastic can be attached to the frame is the complete adhesion of the tile to the insulation and the possible gluing of the foam plastic - tile connection. In this version, there will be no air flow under the decorative coating along the insulation layer, the occurrence of fire and the maintenance of combustion is impossible.

In the case when a classic wet facade is used, the facade tiles on foam plastic are attached with glue, directly to the plaster reinforcing mesh.

What other materials and tools will be needed

For the purpose of carrying out the work, the following tool is useful:

- grinder, in order to cut the tiles to size;

- a drill with a nozzle for mixing the adhesive mixture;

- containers for mixing glue;

- measuring devices (tape measure, level);

- notched trowel;

- pencil;

- Master OK.

In those cases, at a time when the working surface lacks improvement, in other words, it is too embossed, it will also come in handy:

- shovel,

- buckets,

- usually

- mesh for sifting sand.

Tile adhesive

Gone are the days when tiles were laid exclusively on homemade mortars of sand and cement. Nowadays, a wide range of dry building mixtures for the preparation of tile glue is on sale. Such compositions are distinguished by high adhesion, durability, reliable fixation of ceramics to any prepared surfaces, resistance to moisture and mechanical stress, a fairly quick setting period and complete drying.

Popular brands of tile adhesives

Despite the wide choice, it is still better to give preference to proven brands that guarantee product quality. A few examples are shown in the illustration above.

Of course, you should also take into account the features of the room where the decoration is done. So, if a wall is faced on the street or in an unheated room, then it must be glue for external work. For bathrooms, you should look for a composition with increased moisture resistance - usually this is indicated by an understandable pictogram or in text instructions.

We offer you to familiarize yourself with Buy the best sealant for joints in floors at the best price in the construction online store

Most often, the glue is produced in a gray version, but for some light thin tiles or for marbled finish it is better to pick a white (or light beige) composition.

| Tile size (for rectangular - on the long side), mm | Recommended comb height of a notched trowel, mm | Approximate consumption of adhesive solution, kg / m2 |

| no more than 50 | 3 | 1.9 |

| from 50 to 100 | 4 | 2.5 |

| from 100 to 300 | 6 | 3.8 |

| from 300 to 400 | 8 | 5 |

| from 400 to 500 | 10 | 6.3 |

| over 500 | 12 | 7.6 |

Based on these data, it is quite possible to make preliminary estimates.

The reader can also use the offered online calculator.

Work preceding the laying of tiles

Do-it-yourself tile laying - possible on any basis

With this type of finishing work, the proverb is more relevant than ever: "Measure seven times ...", therefore, special attention is paid to the selection of tools.

To perform the laying of tiles, you need to have the following tools at hand:

- Measuring devices: pencil, crayon, tape measure, level, ruler, rail.

- Master OK.

- Plastic crosses to demarcate seams.

- Masking tape fixing the tiles in the desired position.

- Facing manual work cannot be performed without a spatula. It is identical for both wall material and flooring. This does not apply to a toothed tool (in common parlance - a comb): for floor tiles, the size of the spatula tooth is 10 mm, while for wall cladding material it is 8 mm. In addition to the main one, there is an auxiliary spatula with a width of about 90 mm. It is intended for applying the mixture to the main working tool or for work in hard-to-reach places.

- Nippers for nibbling small pieces of tiles along a predetermined contour.

- A hammer drill or drill with a nozzle for preparing a solution of the desired consistency and a volumetric bucket.

- Cutters - cut holes in tiles. Shaped holes are made using a template previously made of cardboard.

Laying tiles with your own hands - the necessary tools

Important! Carefully carried out preliminary work guarantees a high-quality installation of the tiles.

Great importance is attached to the preparatory stage of laying. Speaking thesis, the following works are performed:

- inspection of floors using a long strip or ruler, identification of irregularities and elimination of roughness, if necessary;

- final adjustment with minimum deviation using a level.

There is another, more expensive way. They use special mortars, pouring which, the leveling of the floor surface is carried out;

- wooden floors before facing are lined with plywood, sheet thickness within 12 mm. This provides the conditions required for laying;

- if necessary, old facing tiles are knocked off or linoleum is removed;

- the cement coating is pre-protected from moisture penetration so that the tiles do not get wet. It is with cement that most builders like to work;

- if necessary, preliminary drying of the surface is carried out. The work itself is carried out in a dry room;

- of no small importance is the structure of the surface of the tile, the presence or absence of a pattern on it. Structurally, you need to imagine what kind of art form on the facing floor area you want to achieve by combining individual tile elements;

Do-it-yourself tile laying - check the markup - the level determines the place of maximum floor deviation and the highest point is located. In it, the layer of adhesive mass will be minimal, but not less than 8mm;

- it should be remembered that the floor is equipped only with the field of repair work with the ceiling and walls. Skirting boards, door frames and jambs are preliminarily removed. The floor is primed;

- if the room “does not fit entirely” the tiles around the perimeter and you have to use pieces of it, you should slightly change the previously made markup, move the boundaries of the laying so that the edges look beautiful. With a small area, it is better to pre-lay both the whole tile and its pieces for a preliminary assessment of the direction of work and the location of each tile in the masonry. Immediately you need to decide on the width of the joints, which significantly affect the consumption of tiles. This calculates the required amount of stacked material. In this case, the planned 10% losses from the battle should be added to the result obtained.

Laying ceramic tiles on the wall - step by step and step by step

An acceptable surface for laying clinker tiles on a wall is considered to be a sufficiently smooth and strong wall. It is not necessary to achieve a perfectly smooth surface. For example, such a roughness, as on a cinder block, does not interfere with installation at all. But a brick wall with deep seams needs to be plastered.

You will have to plaster the wall even if there are falling off elements on it, such as destroyed bricks, dilapidated tiles or plaster. Before plastering, get rid of loose elements: tap the surface, for example with a hammer, and remove the loose fragments.

For plaster, a simple mortar of sifted sand and cement is excellent. Well, the thickness of the plaster layer will depend on the depth of the wall imperfections. Indeed, they are constantly trying to get by with a minimal layer.

Clinker tiles have a lot of weight, therefore it is clear that the perfect floor for laying clinker tiles is a cement base, for example a slab or a cement screed. The screed is useful in cases where the surface is embossed. But do not forget to head that the floor must be free of all kinds of debris and dust before pouring. Otherwise, the tile will not adhere well and will separate from the base over time.

It must be stated that when preparing the floor, pay more attention to the slope. In the case of wall surfaces, this is not too important in principle, but on the floor, especially in rooms with high humidity, this cannot be ignored. Take the bathroom, for example. If you do not pay attention to the slope of the floor, it may turn out that moisture will accumulate in hard-to-reach places. The horizontalness of the floor is a prerequisite.

Opinion of the portal members

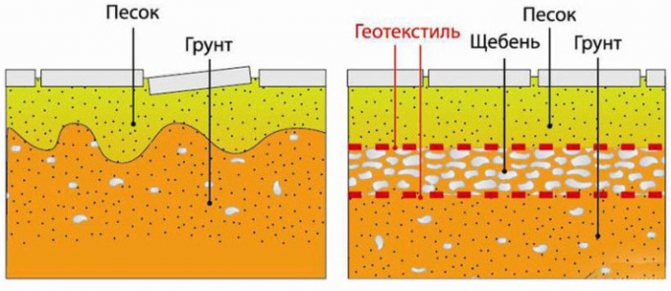

Another active participant in the discussion, Groundworkturf, agrees with the viability of such tracks, but specifies that the geotextile should be dense (from 200 g / m²), with maximum filtering capacity.

Not everyone positively perceived the idea of paving paths without the use of DSP, opinions were expressed that then it would be easier not to prepare the foundation at all, but to lay the tiles directly on the ground. Say, with such a high GWL, the tile will stick tightly, without additional manipulations. But even such attempts among the neighbors did not give a positive result - the clay swells unevenly, over time the paths go away in different directions. And at vwts, it lies flat on the sand, without shifting.

vwts

The path does not rise above ground level - it is flush with the ground, there are no curbs or pegs - the ground holds. Now, ten years later, in several places the soil has risen above the tiles by about 5-10 mm. This does not affect anything, the water does not stand at all - it immediately goes into the sand (which is in the geotextile).

The author's paths are exclusively pedestrian, and there is a tennis table on the site, around which she can withstand the excitement. According to vwts himself, his garden path on clay soil will not withstand the load from the car, but such a task was not set before it. But a decorative, comfortable, durable and durable coating with minimal costs - it turned out.

Selection and preparation of the adhesive mixture

Clinker tiles may be glued to the cement mortar. Sand and cement are useful for this. 4 parts of sand and 1 part of cement are poured into a mixing container. It is very comfortable to measure parts with buckets. For example, if you pour 4 buckets of sand and 1 bucket of cement, then there will be an optimal amount of mortar, which does not have time to harden during the laying of the tiles.

It must be stated that the cement mortar does not provide the maximum long term of the coating, and builders give more preference to special adhesive mixtures containing polyurethane. Such compositions can be produced both in finished and in dry form, and any glue is characterized by a certain degree of frost resistance, hardening and scope of application. The most popular brands of adhesive for clinker tiles are Ceresit CM, RKS, Knauf, Extrabond.

Mixes, which are sold dry, are prepared according to the instructions. But, much more often, the instruction is banal - you need water in a certain proportion and whisper to stir with a construction mixer.

So, we come to the consideration of the technology of laying tiles on the floor. First, it is worth mentioning a few more nuances.

Floor tiles are manufactured with a thickness of 14 to 30 mm. When choosing floor tiles, it is necessary to take into account such an indicator as wear resistance. In accordance with this parameter, clinker tiles are divided into four classes of wear resistance, where class 1 is the least wear-resistant tile, and class 5 is the most wear-resistant tile.

In order to achieve a specific floor design, it is possible to lay clinker tiles in a specific pattern.

- Simple linear masonry is often used - this is a practical option for most rooms.

- Some people like diagonal laying more, and this option is also likely, but keep in mind that in this case there will be a lot of waste.

- Clinker tiles can be laid with bandaging. This option is appropriate in some interior styles, for example, Provence, English style, loft.

- The combination of clinker tiles with mosaics looks presentable.

- Laying clinker tiles in the form of circles looks very interesting, but this method can only be used when finishing a floor of a large area, since otherwise all beauty will be lost, and in dry rooms - with circular laying, rather wide gaps between the tiles are obtained, from which, when hit the grout is washed out.

We suggest that you familiarize yourself with How to sheathe the ceiling of a bath from the inside

Before laying the tiles, you need to process the floor, check the corners of the tiles.If the corner of the tile does not fit into the corner of the room, then you need to move away from the wall and draw an even straight line from corner to corner, applying the rule in order to level the unevenness. This operation is repeated at each wall to obtain an even rectangle of the largest possible size. If this operation is neglected, then it will be necessary to adjust the tile against the wall. But, when using a plinth, this may not be relevant.

When laying diagonally, the markings start from the center of the room.

- Laying begins from a corner that is sufficiently well lit. Initially, you need to lay out a row of whole tiles, check the plane with the rule, correct it, if necessary.

- Apply the adhesive on the floor with a notched trowel in a layer of approximately 8–10 mm. It must be stated that the adhesive mixture can be applied not to the floor, but to the tiles themselves, there is no huge difference.

- Then the tiles are laid and pressed a little in order to remove the cavities. The laid tiles are controlled by the level and, if everything is fine, then the second is laid.

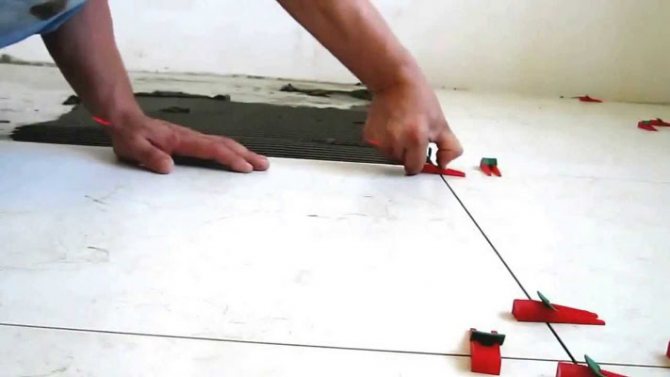

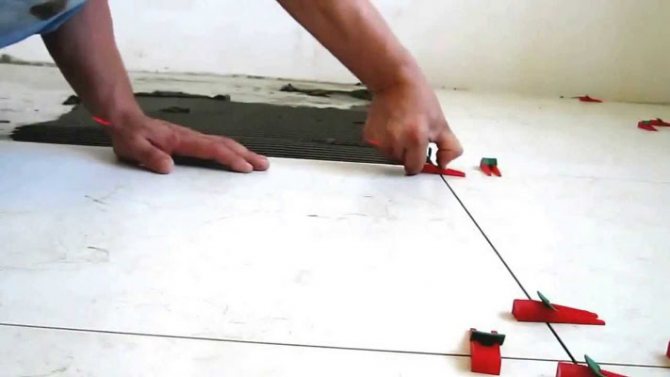

- At the end of the laying of each subsequent tile, dividing crosses of a certain size are inserted into the seams. In this matter, it is better to focus on the advice of manufacturers. In most cases, they advise how thick the crosses should be.

It is more profitable to create laying in rows across the width of the room. be directed to emphasize that if a sufficient laying speed is achieved, then smoothing a row of tiles is possible with a long rule. The rule is applied to the side of the row and pressed slightly until the entire tile moves in one line. In order for alignment, it is necessary that the mixture remains uncured. This means that it is possible to correct the position of the tile within about 15 minutes.

At the end of the installation, the seams are rubbed. For this, special grouting is used. It can be furan based grout, epoxy or cement (cannot be used when grouting joints between glossy tiles, since it works like an abrasive). The application is carried out with a rubber spatula, and after drying is complete, the excess is removed with a wet sponge.

Laying tiles on the floor with your own hands

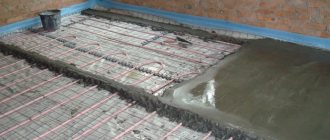

The floor, before laying ceramic tiles on it, will also need to be leveled. Almost by analogy with the walls, but only by the screed method.

With minor irregularities of the floor surface, only self-leveling is needed - a ready-made dry mortar. It will need to be sealed with water and laid out on the floor. And this screed itself will level the surface.

If the irregularities on the floor are serious, there are noticeable differences in level, it will be necessary to level the surface with a screed along the beacons. A solution of a cement-sand mixture.

With a concrete floor, everything is simple and clear, but with a wooden floor, it is more complicated. The fact is that laying tiles on old boards is by no means recommended. It is necessary to lay new ones with a thickness of at least 2.5 cm. In this case, the wooden surface must be cleaned and treated with special impregnations against fungus, water and rot. A waterproofing layer must be laid on top of the tree. You can take roll material, or you can use compounds for spreading on the surface. Next, a reinforcing mesh is placed, and after it concrete is poured. And you will have to wait until the screed hardens.

In general, concrete takes at least 4 weeks to harden (and not dry out). Only special plasticizing additives for solutions can speed up the process.

Once the preparatory steps are completed, you can start laying the tiles. How to install tiles on the floor? Step by step, of course:

- Prepare tile adhesive by kneading the selected dry mixture as written on its packaging. And you need to do exactly as much as you plan to spend, which is called "at a time."

- Apply the correct amount of adhesive to the back of the tile and spread over the entire surface with a special notched trowel.

- Glue the tiles to the floor, starting from the far corner of the room and moving towards the exit. The evenness of the installation is checked in each row. The width of the seams is also controlled.

Regardless of where you had to lay the tiles yourself - on the floor or on the walls, as soon as the process is completed, you need to perform another mandatory finishing operation - jointing. That is, fill the resulting seams with a special composition of a certain shade.

This is done for both practical and decorative purposes. And experts do not recommend saving on a fugue, otherwise the seams will crack.

Seams are joined using a special spatula or a special sponge. The mixture is prepared according to the recipe printed on each package. And after the composition dries, its excess is gently washed off the tile with plain water.

A short video instruction for tiling the floor with tiles:

Clinker cladding

If laying is done indoors, then it must be borne in mind that the walls intended for clinker cladding must be made of durable materials. Materials such as drywall will not support the enormous weight of clinker tiles.

In the event that the laying is carried out on the facade of the building, go to the cladding of the entire perimeter of the basement, and later start laying another surface. Glossy tiles are well suited for the basement, since the dirt from precipitation will be easily washed off from it.

- Before starting work, the walls should be primed.

- The first row, in most cases, is quite laborious, since you have to adjust the dimensions of the tiles to one level, starting from uneven ground. To do this, a horizontal line is made a row higher from the ground and the tiles are trimmed and laid along this line.

- If masonry is selected with an offset, then the second row is shifted to the floor of the tile to the side, so that a semblance of brickwork appears. So at the corners of the building, it is useful to start every second row with laying tiles, cut in half. be directed to emphasize that for a more rapid laying process, it is necessary to lay out the first row strictly according to the level, later one corner, changing the whole and half of the tile. This procedure will allow you to deal with cladding without the distraction of trimming. But, you should not glue the tiles at once on two corners, since it is difficult to calculate what size of the halves will come in handy for the second corner.

- The seams are closed after the glue has dried and the spacers have been removed. A waterproof and frost-resistant grout must be used for the joints.

How to lay tiles in the bathroom with your own hands

Most often, tiles are laid, of course, in bathrooms and toilets. The cladding process is not much different from those described above. The main thing is to choose the right plaster and adhesives. And also correctly calculate the required number of tiles themselves. So as not to buy it later.

There are several tips for laying the material in this particular room:

- trim elements are best placed at the bottom and in the corners;

- it is worth using a horizontal starting rod;

- the lower edge of the tiles in the initial (bottom) row must be installed along this wooden strip;

- check the evenness of the "sides" in the rows with a laser level.

It should be remembered that ceramic or tile, even when laid on a properly prepared surface, dries for several days.

A specialist tells about the secrets of laying tiles:

(57 voice., middle: 5,00 out of 5)

Sound insulation and sound insulation of the floor: theory, materials, technology, schemes

How to remove a stain on the ceiling

Similar posts

Facing steps

For laying on the steps, choose a tile with an abrasive spraying, so that during the icing the steps are not slippery. be directed to take into account the width and height of the step and select the appropriate tile, this will help to avoid unnecessary trimming and speed up the work.

- First of all, the vertical part of the step is faced. A tile is glued to the surface of the vertical side so that its upper part lies in the same plane with the horizontal surface of the step. If necessary, trim the tiles.

- Then the tile is laid on the horizontal surface of the step so that the seams coincide with the seams of the vertical tiles. Care must be taken so that the tile does not protrude forward by more than 2 cm, since such a protrusion will be a good lever when pressure is applied to it. Steps with a huge tile overhang help less.

- Leave the seams empty. If the facing of the porch is carried out, then the width of the seams should be at least 10 mm, since this will reduce the stress on the tiles during frost and prevent destruction. At the end of the complete installation, the seams are sealed with decorative grout. Again, in the case of external cladding, you need to choose a frost-resistant grout.

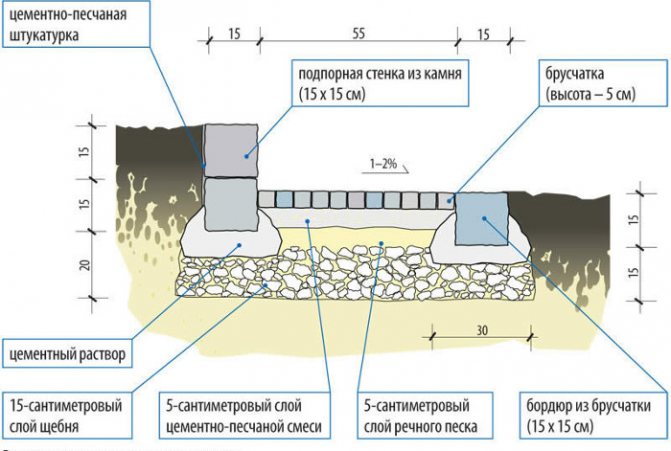

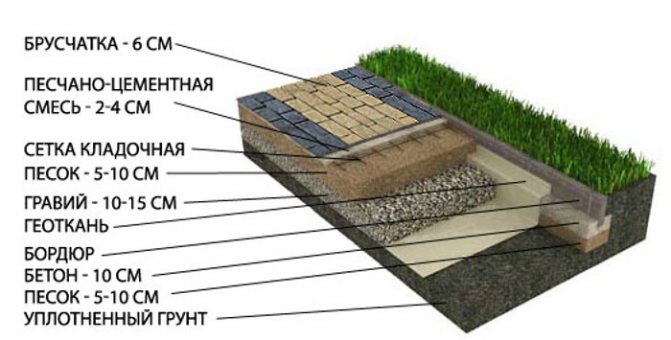

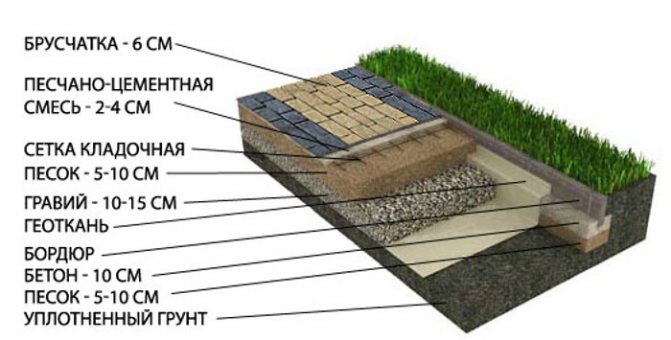

The composition of the pie on soft soils

On soils that are oversaturated with moisture, on loams (a lot of clay and sand), sandy loam (a lot of sand), the composition of the pie for laying paving slabs should not only retain moisture, but also prevent the entire path from sagging. Indeed, in essence, the very base under the tile is a long beam that can bend under load, sinking into soft soil. This can be avoided if geotextiles are laid on the ground before the cake layer.

It must be remembered that geotextiles not only have filtering ability, but have sufficient tensile strength, which will keep the entire layer of the cake from sagging.

The composition of the cake for weak soils looks like this:

- Geotextiles are laid at the bottom of the ditch.

- Then gravel.

- Sand layer.

- Concrete base.

Furnace cladding

There are no big differences in the lining of the stove when compared with the lining of the walls. In addition, it is necessary to use boundary crosses for the seams and perform horizontal rows. In addition, it is directed to leave the seams empty in order to fill them in the future with decorative grout. But it is necessary to take into account the huge temperature differences, based on this, the tiles and glue should be directed to choose heat-resistant ones. A simple cement mortar is not suitable for such a lining.

In order for the stove to look more beautiful, it is possible to start work from the contours of the doors and corners, using tiles with a blacker color in relation to the main cladding. The black color will hide rapidly developing smoke pollution. But when working in such a sequence, you will have to use a grinder quite often, since there will be a large number of trimming elements.

As you can see, clinker tiles can be used for finishing very different surfaces, the main thing is to choose all the materials correctly. If you have any questions, you have the opportunity to ask them on the site.

Fastening facade tiles with self-tapping screws

When the facade tiles are installed on a frame made of wood or metal, or when they are fastened to old wooden walls from a log or bar, self-tapping screws can be used.

Not all facade tiles on self-tapping screws will stick to the wall. For example, it will not be possible to fix porcelain stoneware tiles or ceramic tiles in this way. Other methods are provided for their attachment.

But any light options for decorative coating - plastic or wooden - can be attached in just this way. Self-tapping metal or vinyl facade tiles can be attached directly to the walls of an old wooden house, or you can use a lathing for such an attachment.

If you need to fix heavy tiles - porcelain stoneware or ceramic facade - you will need metal fasteners.

Full-surface wall tiling

The tiling process can vary. Professionals first dilute the glue, then apply it to the walls, trying to ensure that the layer is even.In this case, the solution is applied to the wall at once on nine tiles. Of course, it all depends on the speed of work. The solution should not have time to harden. Therefore, each master, based on his speed, decides for himself which section of the wall to cover with mortar at a time.

After that, the tiles pre-soaked in water are laid on the base, pressing each of them over the entire area. A gap of a couple of millimeters is left between the individual tiles, which will subsequently be filled with grout. To make the seams even, it is convenient to insert plastic "crosses" between individual tiles - they are in every building store.

Wall cladding with tiles ends by rubbing the seams with a special solution (grout) using a rubber spatula. After that, the tiled surface is washed and, if desired, treated with compounds to protect the tile and give it a shine.

Preparatory stage

The preparatory work can, in fact, be divided into two main steps:

- Leveling and priming;

- Layout and layout.

So it is worth talking about each of these steps separately.

Leveling, priming

Having prepared the materials and tools, do not rush to immediately prepare the glue. First you have to get rid of all the excess in the room, remove plumbing, remove old finishing materials.

Achieving a perfectly flat surface is what you need now. To do this, use the level and plumb line, determining the presence of irregularities, drops. Leveling is carried out with a cement-sand mortar if the problems are big. If the irregularities are small, then a regular putty will do.

After waiting for the walls to dry, apply a layer of primer with a roller, and after that you can start coating with waterproofing materials. Now both ready-made formulations and blanks are offered, which can be mixed directly by yourself.

Experts recommend making a double layer of waterproofing, as well as adding special protective compounds against mold and mildew.

Layout and layout

When the alignment is complete, you should think about how exactly your wall tiles will lie on the surface. First row markings play an important role.

- Mark the point in the corner where the first row will be located using the hydro level;

- With the help of a second person, mark out the appropriate dots for all corners. This will draw a straight line.

Having at your disposal the markup, it will be much easier for you to determine the layout, that is, the features of the position of the tiles, borders on the wall. Three main options are currently used:

- A straight seam, where the boards are glued joint to joint.

- The brickwork method.

- Laying with a diamond, that is, diagonally. This option is only suitable for square tiles.

It is not uncommon for techniques to be combined, thereby achieving a unique layout. When the preparatory stage is completed, you can already start the laying process.

Quantity calculation

Stages of laying tiles on the wall.

In order to buy the required amount of material, it is worth making calculations. First you need to calculate the area of the walls. Also, when calculating, it is very important to take into account the moment that the tile can be cut. Therefore, it is worth taking a tile with a small margin (suddenly something breaks during cutting).

As for the calculation of the adhesive solution, you can find out the required amount by reading the recommendations on the package. With proper preparation and use of the adhesive, a small amount of the substance will go away.

The tiles in the bathroom should be laid on a flat, treated surface. If the walls are uneven, they must be removed. For this, the surface can be leveled with plaster or plasterboard sheets. When leveling with plaster, beacons must be installed on the surface.

If gypsum board is used, then it is very important that it is moisture resistant. After the walls are leveled, they must be covered with antiseptic solutions to prevent the formation of mold and mildew. Only a flat surface will ensure a high-quality tile installation.

There are a large number of tile options.

Dismantling old tiles

You will have to remove the old cladding on the walls with a hammer and a chisel (chisel). It's simple: we split the tiles with a hammer, pry them off with a chisel and tear them off the surface. During work, it is recommended to protect your eyes from splinters and construction dust with special construction goggles. We clean off the remnants of the solution or glue.

Next, you need to inspect the walls and decide if they need repair. If the plaster has a large number of flaws, then they need to be putty. And to make the surface of the walls even more reliable, it is impregnated with CT17. As a result, the surface of the walls in the bathroom will be ideal for subsequent tiling.