What if there is nowhere to throw the trash out? Take, for example, a summer cottage or a house in a village. There are no waste bins within a radius of several or even tens of kilometers. How to be? Leave it in place or throw it in a ditch on the way home? Observing a similar picture in the suburbs, we are indignant in our souls.

There is a way out: some of the waste can be burned. But it is dangerous to do this on an open fire. It is better to use a dedicated garbage oven. Various models of Russian and foreign production are sold on the market. It is easy to make a stove, having available materials and skill.

Installation and operation of a waste incinerator

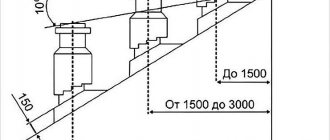

The waste incinerator is installed according to the rules or its own calculated drawings. If the item is from a store, it is better to entrust the installation and adjustment to the service department.

Additional permission for the installation of a household structure at a summer cottage is not required, but no one cancels the instructions and operating rules.

Working with a flame requires caution, because the safety of life, home and the prevention of harm to the environment is more important than the benefits that household incinerators provide.

Afterburning gases in steel furnaces

But now the time has come for steel furnaces and most often people begin to get to know them through the simplest "stoves" and it turned out that the issue of soot deposition has become even more acute. Brick chimneys also did not take root very much. At the beginning, asbestos-cement pipes were used, but it turned out that they could not withstand even half of the heating - they burst. Steel chimneys were used, but it turned out that simple stoves overheat the chimney with temperatures even higher than the temperature in the stoves themselves, and condensates were added to this. The condensate, combining with the oxides of the exhaust gases, forms acids, which in a short time eat up the chimney. The more primitive the stove is, the more the requirements for steel chimneys are. If there is a full-fledged combustion in the furnace, then the temperature of the outgoing gases is lower, and the afterburning of gases does not go in the chimney, and soot is less deposited - here the chimney is already operated in more benign conditions and lives much longer. If someone does not know, then often the chimney is twice as expensive as the average stove. It turns out that when buying a cheap stove, a person will be forced to change the chimney often and there will be no savings - “a miser pays twice”. That is why the requirements for the oven must be high. The stove must fully burn flue gases. In addition to protecting the chimney, full-fledged combustion of flue gases significantly saves fuel, pollutes the environment less, and has less fire hazard (most fires arise precisely from overheating of the chimney). The creation of a bell on a steel furnace with a secondary air supply channel for the afterburning of gases creates all these positive qualities. That is why the Kazachka oven turned out to be the most demanded and desirable for many consumers. The Kazachka stove is a bell-type stove with gas afterburning and three steel steam generators, which made it possible not only to improve its functional properties, but also to significantly relieve the chimney thermally. Moreover, the design features of the built-in steam generator allowed the furnace itself to be made much safer. Next to it, you can not only stand quietly and, even accidentally touch the convector, not get burned. So an integrated approach allows you to create a safe and useful oven with the desired properties. Now there is no need to close the oven with a sarcophagus and put an economizer on the chimneys. The furnace with gas afterburning is the most protected, functional and safe.

Related Videos

The simplest oven is a potbelly stove.

Solid fuel boilers and pyrolysis-type furnaces can be an excellent source of heat, giving full energy independence to an apartment or private house. The above appliances are installed as an additional heating element, helping people save money. After all, everyone knows about the heat loss of the centralized heating circuit, for which the consumer has to pay. Many, using a professional drawing of a long-burning furnace, are trying to build equipment on their own. To what extent will the result obtained justify the hopes of its creator? Is it generally advisable to carry out do-it-yourself pyrolysis ovens?

General advantages and disadvantages

Let's take a look at the advantages and disadvantages of self-incineration in the country.

| Benefits | disadvantages |

| Disposal of solid waste where collection is not organized. | Not all household waste is safe and incinerable. |

| Recycling in an environmentally friendly way. | Strict adherence to fire safety requirements and standards is sometimes difficult. |

| The resulting ash is useful for fertilizing the backyard. | The price for purchased installations starts from fifteen thousand. |

| Receiving additional heat sources for heating water, heating, cooking. | Impossibility of incineration of liquid waste. |

| Extending the life of old things: pipes, barrels, fuel boilers, etc. | The damage caused by the incinerated waste to the atmosphere will have to be reduced by filtering the smoke. |

| Profitability in handicraft production. | Low efficiency. |

The plasma waste incinerator is fast and environmentally friendly. At the same time, at the output, electricity is obtained in an amount sufficient to supply energy to enterprises, recycled products - slags, which are used, for example, in construction.

We advise you to read: The main water pollutants: natural and anthropogenic

Unlike standard incinerators, plasma processing does not emit carbon dioxide or toxic substances into the atmosphere.

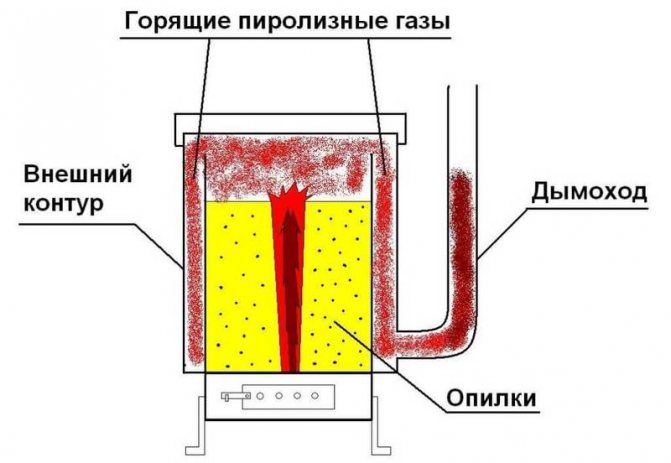

What is a pyrolysis oven

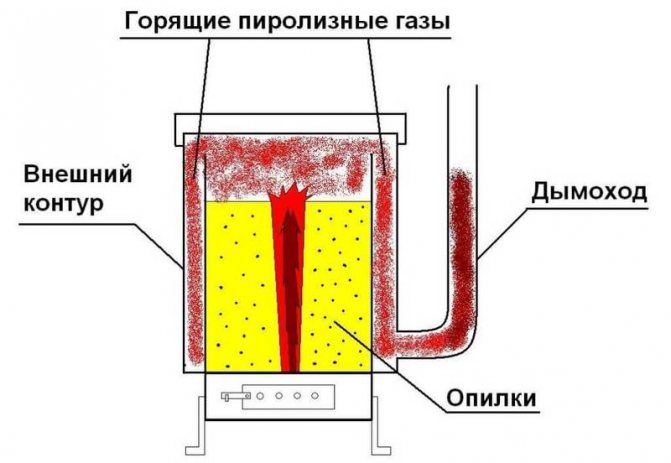

Such a furnace works on the principle of pyrolysis - organic substances during heat treatment in the absence of sufficient oxygen are decomposed into solid residues and gases, which in a conventional furnace go out through the chimney, and in pyrolysis they become the main source of heat. The more the fuel heats up with a minimum amount of oxygen, the greater the percentage of gas evolution goes.

This technology is specially designed for the oil refining industry. Thus, fuel for cars is obtained through the processing of petroleum products. In domestic conditions, the process of pyrolysis for heating living quarters began to be used recently, but many users have already confirmed its effectiveness and efficiency. The difference is the temperature required for processing. Oil products are processed at 800-900 C, while 500 C is sufficient for wood.

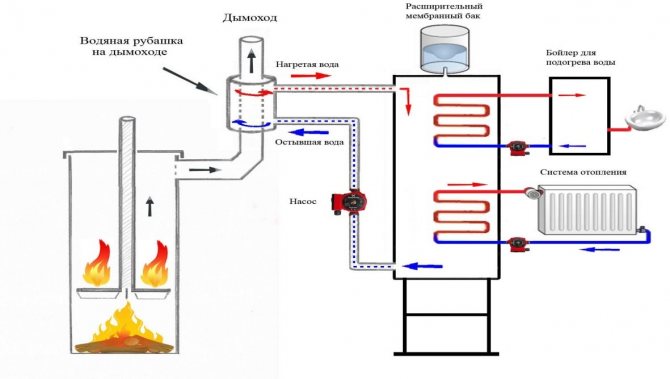

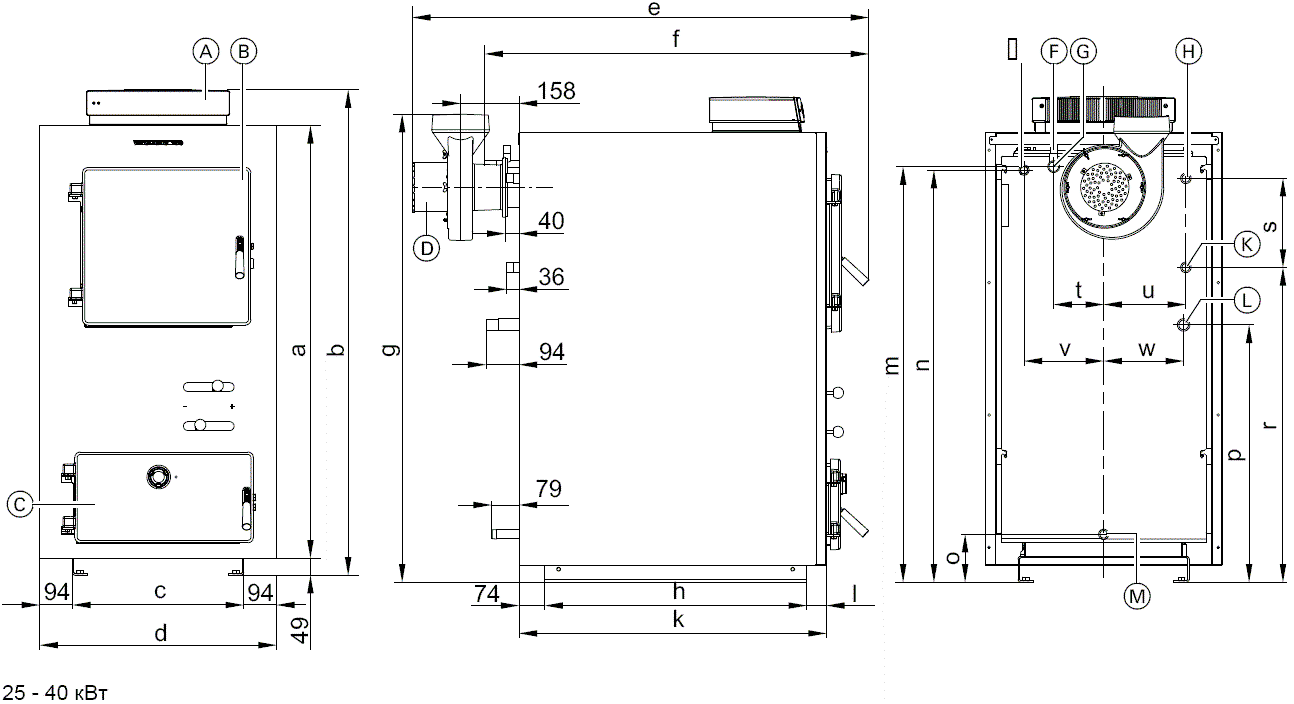

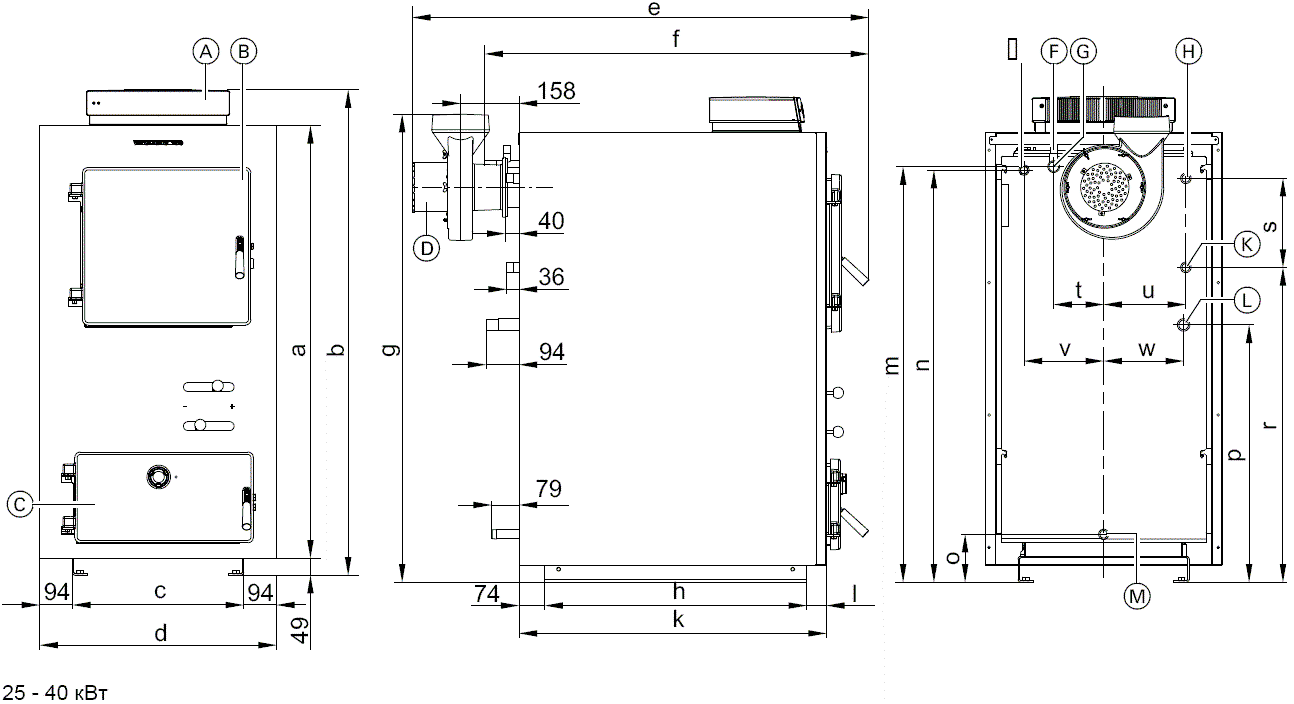

Diagram of connecting the pyrolysis oven to the heating network

The gas extracted from wood fuel has excellent combustibility, and in the process of long-term combustion, it releases enough heat for heating.

Safety regulations

When working with an incinerator, adhere to safety rules, as this is a fire hazardous facility. It should not be located near flammable objects. Do not store flammable materials, dry grass, wood or planks, trees nearby. An accidental spark has dire consequences.

The waste incineration boiler is not placed closer than 50 meters from residential, utility, and other buildings. The proximity of power lines, gas pipelines, other networks and communications is taken into account. For violation of this requirement, there is even an administrative fine of thousands of rubles.

Children, animals must not be allowed near the burning fire, and they must not be left unattended.Place extinguishing media in the immediate vicinity: water, sand, fire extinguisher.

The design, device and principle of operation of a homemade pyrolysis oven

The simplified version of the gas generator device differs from the full-fledged one in the following features:

- The afterburner is located not below, but above, so wood gas enters it by gravity. This is realized as follows: the upper quarter of the internal space of the furnace is separated by a perforated horizontal partition that does not reach the front wall by 20-25% of the length of the furnace. Thus, most of the flue and pyrolysis gases will be deflected forward and we have a front burning stove that is quite easy to control. The lower quarter of the internal space will play the role of an ash pan - it is separated from the firebox by a grate.

- The primary air enters the furnace due to natural draft. For this, there is a hole in the wall of the furnace with an adjustable damper - a blower.

- Air is not supplied to the afterburner separately - it is taken from the firebox.

- The draft is limited by a slide damper installed in the chimney, which has a cut-out of a certain area. When the stove is fired up, this damper opens completely.

An important feature of stoves with such a design is the relatively low temperature in the furnace - provided that wood fuel is used, it is only 550-650 degrees. Due to this, the requirements for the furnace material are significantly reduced - even the furnace can be made of structural steel - without alloying additions - with a thickness of only 4 mm. True, in this case, the stove cannot be fired with coal, since it will quickly burn out (coal burns at a temperature of 800-900 degrees).

What can't be burned?

Only organic waste is subject to incineration. This is garden waste - branches, grass, leaves, etc. It is allowed to burn paper, cardboard, and unusable wooden objects.

When burning, materials made of plastic, polymers, synthetics emit toxic substances that are harmful to human health and the ecology of the environment.

Cannot be burned:

- Painted parts.

- Full-color glossy printing with ink content.

- Chipboards, fiber boards, which used glue and phenols.

Not every oven is suitable for burning paper. It is dangerous to throw aerosol cans, glass, metal objects into fire. Even empty, but under pressure, can explode in fire.

The device and operation of a homemade pyro-oven

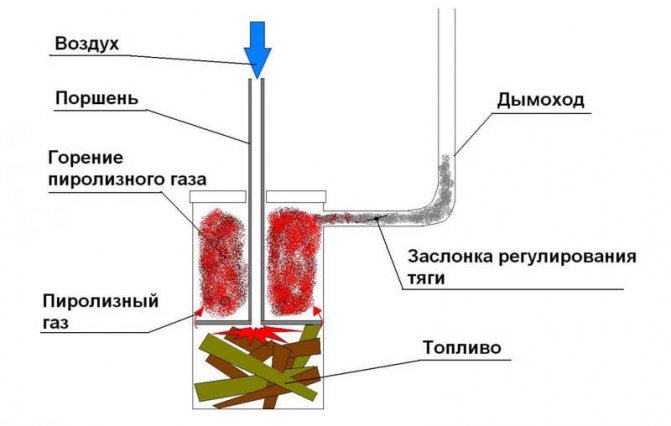

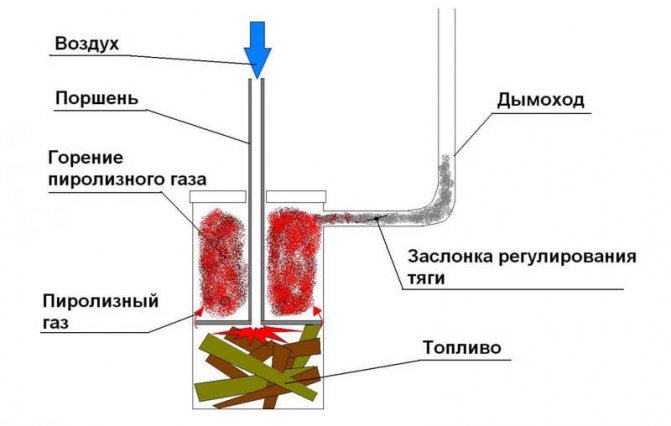

There are no fundamental differences in the operation of pyrolysis furnaces of different designs - the fuel insert smolders in the fuel compartment, with controlled air intake - so that the process does not stop, and no more. Generator gases must go down, since the furnace is structurally higher than the compartment where these gases must accumulate. This arrangement is classic, but in homemade pyro-ovens, the location of the afterburner and the combustion chamber are reversed to reduce the complexity of the assembly.

In order for the pyrolysis gas to escape from the combustion chamber into the channels located in the inner space between the walls of the furnace and the furnace, excess pressure is required. To create this pressure, primary air is fed into the combustion chamber. Secondary air is fed into the compartment where pyrolysis gases are lowered, since they will not burn without air. The air-gas mixture, which is formed as a result of the mixing of pyrolysis gas and secondary air, is a combustible mixture. But the proportion of gas and secondary air must be accurate, otherwise the mixture will not give up all the energy during combustion, and the waste will be in the form of soot. The final stage is the removal of combustion products through the chimney to the street.

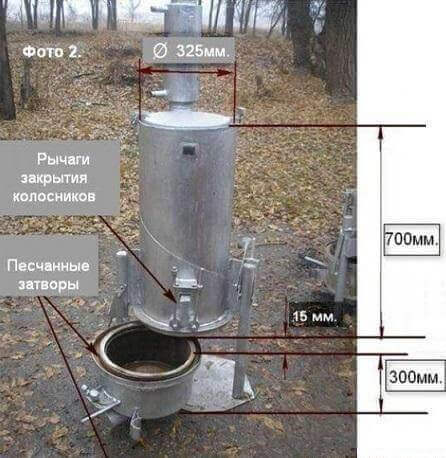

For the manufacture of a pyrolysis stove, it is important that the metal can withstand high temperatures for a long time.The minimum thickness of heat resistant alloy steel is 8 mm. It is possible to make pyro ovens from used gas cylinders, since they are thick-walled, one-piece and fit in size. But the shape of the cylinder determines a slightly different relative position of the furnace and the pyrolysis gas afterburner chamber - the gas burns out in the upper level of the cylinder. Such a redistribution of departments makes it easier to assemble the stove from a cylinder. It is not necessary to locate the afterburner in the upper or lower tier; a lateral arrangement is also possible. The main condition for the pyrolysis process is the decomposition of the fuel and the removal of gas from the solid phase, and the place where the gas will be burned is not so important. As for the smoldering process, it can take place both in the lower level of the fuel insert and in the upper one. ignite the fuel, depending on the location of the compartment - either from the bottom or from the top.

There should be not one, but several channels into which generator gases are removed from the fuel chamber. In the channels, the gas is saturated with oxygen, and the number of channels is assigned depending on the volume of the produced pyrolysis gases. The fuel fill is always of the same volume.

Making a pyrolysis stove from a gas cylinder

- In the inner space of the cylinder, it is required to install partitions to separate the pyrolysis gas combustion chamber, the quantity - according to the selected drawing of the stove. Use sheet steel. The diameter of the cut out circles must match the diameter inside the cylinder. Segments are cut out in circles - less than half of the circle.

- Parts of the partitions are installed inside the cylinder, fastening to the inner surfaces by welding. In the finished structure, the orientation of the baffles must be accurate - all segment cutouts must be exactly offset one above the other, forming a multi-stage coil-chamber. According to this coil, the generator gas will flow in the direction of the chimney, mix with air and burn out with complete heat release.

- In the first compartment-floor of the gas combustion chamber, it is necessary to drill small holes with a diameter of 4-5 mm with a drill for metal.

- The last section of the coil is connected to the branch pipe from which the chimney will go. Weld a branch pipe from the side or top side of the cylinder, to a pre-cut hole.

- The combustion compartment is formed by arranging a rectangular cutout for the door, which is necessary for storing fuel. The door must provide a hermetic closure of the firebox, for this it is necessary that it exactly adjoins the wall of the stove.

- The grate can be made of reinforcing bars, or of sheet steel by drilling holes.

- Holes are drilled under the door of the combustion section through which primary air will be supplied to the chamber.

In this design, the fuel block is ignited from the top, and air penetrates into the smoldering area through the stacked fuel briquettes. The amount of air is insignificant, and the fuel cannot burn with a flame, only a smoldering process is possible. Not only purchased briquettes or granular pellet fuel can be used in pyrolysis stoves. They also use fine coal, sawdust and shavings, finely chopped straw, leaves or stems, preferably after pressing. The main thing is that the fuel has a moisture content of no higher than 20%.

A simplified design of a pyrolysis oven can be done with a cable air distributor or a press. Load such an oven in excess of half the volume. The press is a steel circle, reinforced with parts from the channel. By means of a press, the fuel tab is pressed, not allowing it to flare up. Channels form a constant gap from the walls of the press and from the top of the fuel insert. In the process of reducing the amount of fuel during slow glow combustion, the press is lowered. The channels for the passage of the pyrolysis gas into the combustion area in this embodiment will be formed by the gap between the outer circumference of the press and the wall of the cylinder.Placing fuel in such a structure can provide long-term combustion - up to ten hours, depending on the volume of the fuel compartment received. published

If you have any questions on this topic, ask the specialists and readers of our project here.

P.S. And remember, just by changing your consumption - together we are changing the world! © econet

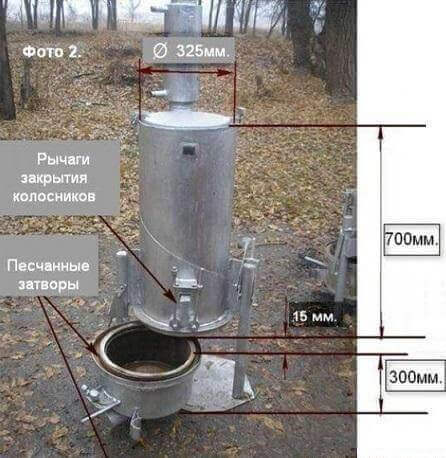

Ready-made incinerators

Waste incinerators in their simplest design are similar to an ordinary metal barrel. The modernized structures are equipped with a chimney, an air blower, a container for fuel intake, filters and other useful functions. Up to water heating or heating. Many parameters of a purchased oven depend on the capabilities of the owner's wallet.

A garbage incinerator is an incinerator with a chimney. The larger the combustion chamber, the faster disposal will take place, and a reliable chimney will save the owners and neighbors from unpleasant annoying smoke.

How the oven works

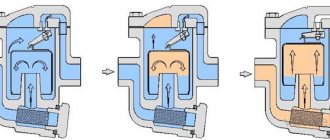

Long-burning pyrolysis ovens are designed according to a special principle. A combustion chamber with a burner is built into the body, where firewood is laid. The main condition for the combustion chamber is tightness. It is designed so that the flow of air inside is minimal. The firebox must have a tight door and a reliable shutter, and a supply and exhaust fan must also be present. After laying and lighting firewood, the combustion chamber is limited in the access of oxygen.

After the wood has charred and released the gas, it rises through a separate air duct into the second combustion chamber, where it mixes with the secondary air in the required proportion and burns. In the process, heat is generated.

The second chamber, as a rule, is combined with an air duct or the beginning of a chimney. Air is supplied by a supply and exhaust fan or a separate fan. If the chimney system is well thought out, then the usual draft with sealed dampers will be enough.

Furnace layout and dimensions

Also, a retort is provided in the body - a rounded part for extracting solid residues of burned-out logs. A feature of the pyrolysis furnace is that the fuel is burned almost completely, with only a small ash residue, which is removed every few days.

Waste incinerator - a complex for the destruction of solid waste

An incinerator, or incinerator, helps to quickly, easily get rid of household waste. Such ovens are in demand among summer residents and villagers.

It is more difficult in the design and operation of an installation for the incineration of hazardous and hazardous waste: medical preparations and used equipment, animal corpses, chemical products.

We advise you to read: List of trucks under the recycling program, program features

The difference between pyrolysis furnaces for burning garbage is that the combustion takes a long time. The principle is based on reducing the oxygen content required to maintain a flame. Therefore, the fuel does not burn, but smolders slowly, releasing pyrolysis gas. Hence their second name is a smokeless waste incinerator.

In the second cycle of operation of such a smokeless furnace, oxygen is already added to completely burn out the fuel.

The principle of operation of the pyrolysis oven

Pyrolysis - technological gas-fired combustion process... As a result of the combustion of solid fuels such as pellets, coal, firewood, peat briquettes, the room is heated. The principle of operation is similar to that of a dry distillation boiler. Pyrolysis is exothermic, and is marked by the ability to heat the incoming air due to the generated heat

The loaded fuel is ignited and the fan will turn on when the door is closed. High temperature conditions (200-800 degrees) and a low oxygen content in the furnace lead to a chemical process - wood decomposes into pyrolysis gas and wood coke.When burning, wood is prone to the formation of methyl alcohol, acetone, vinegar and resin.

The released gas combines with oxygen and goes into the combustion stage. Smoke formed during combustion does not contain harmful carcinogens and other hazardous substances. The burnt fuel releases heat energy, which is used to heat the room. The hot water in the boiler enters the heating system with simultaneous return flow. The coolant is also used as a coolant. This is how a boiler works with a lower chamber.

Homemade constructions

The zealous owners make a garden oven for burning garbage with their own hands in their personal plots. A metal barrel or a large diameter piece of iron pipe will do.

For the base according to the size of the bottom of the future furnace, a recess is dug in the ground, approximately on the bayonet of a shovel. Along the perimeter, they are lined with bricks, a firebox is installed on them. Holes are drilled at the bottom for blowing. It is good if the homemade stove is equipped with a door for adding fuel and collecting the remaining ash.

A lid with a built-in chimney will come in handy. Features, appearance, practicality of such a homemade design depend on the skills of the master, materials and tools.

Metal barrel

It is easier to make a garden waste stove from a two-hundred-liter metal barrel. The thicker its walls, the longer it will serve. For the same reason, it is important that it does not rust.

Old heater

An old sauna stove will serve as a garbage stove in the country. If you love giving things a second life, rather than throwing them away, this option is fine.

What are pyrolysis ovens

On the basis of pyrolysis, quite a variety of designs can work, their construction largely depends on the type of fuel that will be used in the future. Therefore, before planning a structure for your needs, you need to figure out what types of them exist.

Material

- Brick pyrolysis oven

- Metal pyrolysis oven

Purpose and method of use

- Periodic action. The stove is built taking into account the materials that accumulate heat and can give off energy for a long time after the end of the firing process.

- Constant action. The structure is comparatively lightweight and has thin walls, there is no mass storage for heat, and fuel is burned continuously.

Heat transfer method:

- There is a water circuit.

- Heat exchangers for heating air.

- No heat exchangers. Heating will be carried out through thermal radiation and convective heating of the air in contact with the hot surfaces of the device.

Mutual arrangement of cameras and type of thrust:

- The gasification chamber is located at the top, and the pyrolysis gas afterburner is located at the bottom. Such a furnace operates on forced draft, therefore, blowing fans and smoke exhausters are used.

- Furnaces operate on natural draft with the arrangement of chambers, on the contrary, gasification occurs from below, and afterburning - from above.

Furnace components

Oven operation and maintenance

The furnace with partial gas generation is put into operation as follows:

- A portion of fast-burning fuel is placed on the grate - thin branches, chips, pellets or even cardboard. Having fully opened the slide gate and the blower, ignite the fuel and close the firebox door.

- After the fuel turns into coal (you can monitor the combustion through the blower), several dry logs are placed on it. If there is a large block of wood, you do not need to prick it - you can lay it as it is, provided that it fits in the firebox.

- Having closed the door, the furnace is switched to the gas generation mode: the slide gate is completely closed and the blower is covered, adjusting the furnace power with its help.Recall that there is a cutout in the gate, due to which the chimney is not tightly closed.

In pyrolysis ovens, ash is formed in very small quantities, so the owner has to deal with its removal relatively rarely - once every 7-10 days. However, it should be borne in mind that in stoves with partial gas generation, the chimney and firebox very quickly become overgrown with soot. Here it has to be removed relatively often - also about once every 10 days. It is not worth starting the unit too much: soot and tar reduce the lumen of the flue duct, prevent heat transfer to the furnace walls and, with a significant layer thickness, can flare up and cause a fire.

It is not necessary to remove the soot by burning. This venture can also lead to a fire, and, in addition, if the stove is made of ordinary (structural) steel, it can be driven from high temperatures. It is better to simply scrape off the carbon deposits with a spatula, brush or a scraper specially made for this purpose.

The chimney is cleaned through the condensate receiver, after removing the plug from it.