In our time, you cannot imagine your life without ventilation systems. They are installed in industrial buildings, offices, educational institutions, shops, apartments. The operation of these systems is inconceivable without the use of exhaust fans of various capacities. A widespread element of apartment ventilation is a kitchen hood. It can have various shapes, sizes, designs.

The amount of purified air in the room will depend on the calculation of the fan power of the kitchen hood.

Exhaust ventilation in the kitchen

But external beauty is not the most important thing. The main task of this device is to rid the kitchen room of odors, burning, soot and grease that appear during cooking. Exhaust ventilation removes fumes from various heating devices. It prevents the appearance of dirty deposits on the ceiling and wall surfaces. This allows cosmetic repairs to be performed much less frequently, which will save you a significant amount of money. It will take less time to carry out general cleaning.

A device capable of passing a certain amount of air through its filters can cope with the task of cleaning the atmosphere in a room. And for this you need to choose a device with a fan of the required power. How to calculate the power of the device?

Varieties of kitchen hoods

The cooker hood is a household appliance that includes an electric motor with filters and fans. First, it is worth mentioning what designs of hoods are.

They are integrated (built-in), they are installed inside the hanging cabinet above the stove. With this design, only the grease filter grate will be visible. But this hood has one drawback. Due to the fact that it is built into the cabinet, it resonates during operation and the noise is amplified.

There are also wall models. They are mounted on the wall above the stove or under the kitchen wall cabinet. There is also such an option as replacing the hanging cabinet itself with a hood.

Island hoods have recently become popular. They are used in kitchens with a non-standard layout and are fixed to the ceiling. The corner model is suitable when you need to install it in the corner of the kitchen. The width of the hood should be no less than the width of the slab, or best of all, greater than the width.

Let's list the operating modes of different hoods:

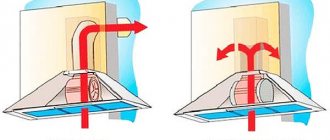

- Exhaust mode. In this case, the air is cleared of fat particles by passing through a grease filter. There are two types of filters, reusable and disposable. Then the air is removed from the room through a special ventilation duct. But this type of hood needs a constant supply of fresh air, and therefore, during its operation, you need to keep the window open. Also, this mode requires mandatory installation of the duct.

- Recirculation mode. In this case, the air is purified from both fat and odor. The air passes not only through the grease filter, but also through the charcoal filter. After which the air returns back to the kitchen. But the carbon filters need to be replaced annually. But not all hoods have this operating mode.

This equipment will purify the air and save the budget on redecorating the kitchen or bathroom furniture (due to high humidity).

Fan power calculation

To calculate the fan power, you need to do the following:

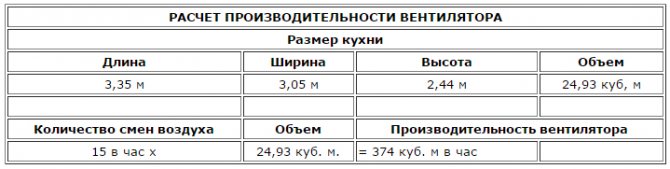

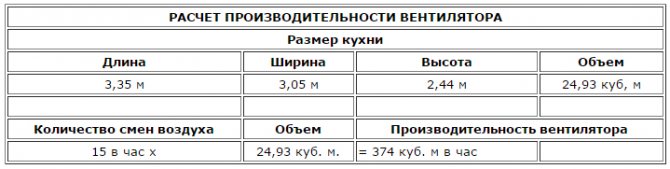

An example of calculating the performance of a kitchen hood fan.

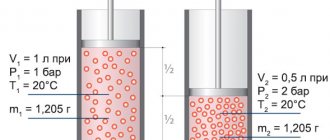

- Using a tape measure, measure the size of the kitchen and determine its volume in meters. To do this, the length must be multiplied by the width and height. The BTI documents indicate the area of the premises.Example: the kitchen area is 10 m². The height from floor to ceiling is 3 m. We multiply the area by the height and get 30 m³. This is the volume of the kitchen.

- Next, the value that characterizes the air exchange is calculated. To do this, you need to multiply the volume of the kitchen by the number of complete air updates per hour. Building codes and regulations (SNiP) provide for an air exchange rate of 10-12. Thus, to calculate the capacity of the exhaust system, you need to multiply 30 m³ by 12. As a result, the figure is 360 m³ / hour. That much air must be renewed every hour.

- To carry out an exchange in such a volume, a fan with a capacity of 400-800 m³ / hour is needed. But standard ventilation ducts are capable of passing only about 180 m³. Therefore, the fan will not help much here.

- In this case, a recirculating exhaust system will help, which passes air through filters and sends it back to the room. Power is also required to overcome the resistance of the filters. Therefore, 40% should be added to the calculated figure. It turns out 560-1120 m³. This should be the capacity of a kitchen hood fan of 30 m³.

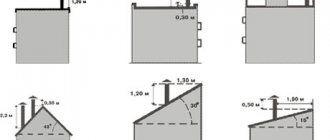

- In some cases, you can do without a ventilation duct. For this, the exhaust fan is installed in a specially equipped opening in the wall, in the ceiling or at the junction of the ceiling and wall. This mounting allows the use of a less powerful fan.

Exhaust power for different rooms.

This is just the simplest calculation of the required power of the exhaust fan. If the kitchen does not have doors, then the volume of the adjacent room must also be taken into account. So, the formula for calculating the fan power for general cases: room width x length x height x exchange rate = desired value. You can calculate the volume of the room without any problems. It is enough to measure the length, width and height and multiply them.

Ventportal

The resistance to the passage of air in a ventilation system is mainly determined by the speed of air movement in this system. As the speed increases, so does the resistance. This phenomenon is called pressure loss. The static pressure generated by the fan causes air movement in the ventilation system, which has a certain resistance. The higher the resistance of such a system, the lower the air flow transported by the fan. Calculation of friction losses for air in air ducts, as well as the resistance of network equipment (filter, silencer, heater, valve, etc.) can be performed using the corresponding tables and diagrams specified in the catalog. The total pressure drop can be calculated by summing the resistance values of all elements of the ventilation system.

Recommended air speed in air ducts:

| A type | Air speed, m / s |

| Main air ducts | 6,0-8,0 |

| Side branches | 4,0-5,0 |

| Distribution ducts | 1,5-2,0 |

| Supply grilles at the ceiling | 1,0-3,0 |

| Exhaust grilles | 1,5-3,0 |

Determination of the speed of air movement in air ducts:

V = L / 3600 * F (m / s)

Where L - air consumption, m3 / h; F - channel cross-sectional area, m2.

Recommendation 1.

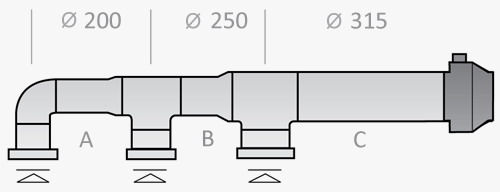

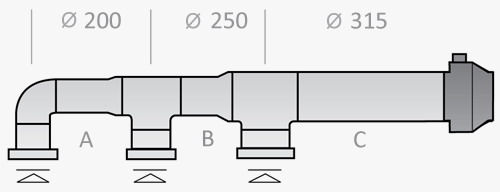

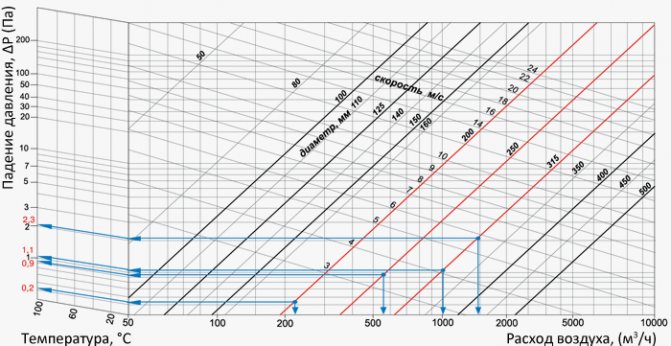

The pressure loss in the duct system can be reduced by increasing the cross-sectional area of the ducts, which provide a relatively uniform air velocity throughout the system. In the image, we see how a relatively uniform air velocity in a duct network can be achieved with minimal pressure loss.

Recommendation 2.

In systems with long duct lengths and a large number of ventilation grilles, it is advisable to place the fan in the middle of the ventilation system. This solution has several advantages. On the one hand, pressure losses are reduced, and on the other hand, smaller air ducts can be used.

An example of calculating a ventilation system:

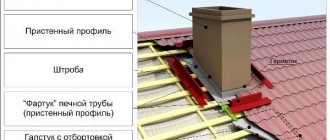

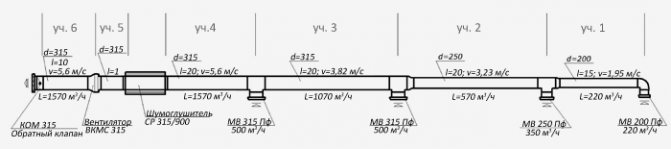

The calculation must begin with drawing up a sketch of the system indicating the locations of the air ducts, ventilation grilles, fans, as well as the lengths of the duct sections between the tees, then determine the air flow at each section of the network.

Let us find out the pressure loss for sections 1-6, using the pressure loss graph in round air ducts, determine the required diameters of the air ducts and the pressure loss in them, provided that it is necessary to ensure the permissible air velocity.

Section 1: the air consumption will be 220 m3 / h. We take the diameter of the duct equal to 200 mm, the speed - 1.95 m / s, the pressure loss will be 0.2 Pa / mx 15 m = 3 Pa (see the diagram for determining the pressure loss in the ducts).

Section 2: we repeat the same calculations, not forgetting that the air flow through this section will already be 220 + 350 = 570 m3 / h. We take the diameter of the air duct equal to 250 mm, the speed - 3.23 m / s. The pressure loss will be 0.9 Pa / mx 20 m = 18 Pa.

Section 3: the air flow through this section will be 1070 m3 / h. We assume the diameter of the duct is 315 mm, the speed is 3.82 m / s. The pressure loss will be 1.1 Pa / mx 20 = 22 Pa.

Section 4: the air flow through this section will be 1570 m3 / h. We take the diameter of the duct equal to 315 mm, the speed - 5.6 m / s. The pressure loss will be 2.3 Pa x 20 = 46 Pa.

Section 5: the air flow through this section will be 1570 m3 / h. We assume the diameter of the duct is 315 mm, the speed is 5.6 m / s. The pressure loss will be 2.3 Pa / mx 1 = 2.3 Pa.

Section 6: the air flow through this section will be 1570 m3 / h. We assume the diameter of the duct is 315 mm, the speed is 5.6 m / s. The pressure loss will be 2.3 Pa x 10 = 23 Pa. The total pressure loss in the air ducts will be 114.3 Pa.

When the calculation of the last section is completed, it is necessary to determine the pressure loss in the network elements: in the CP 315/900 sound attenuator (16 Pa) and in the check valve KOM 315 (22 Pa). We also determine the pressure loss in the taps to the grids (the resistance of the 4 taps in total will be 8 Pa).

Determination of pressure loss at the bends of air ducts

The graph allows you to determine the pressure loss in the bend, based on the value of the bend angle, diameter and air flow rate.

Example... Let us determine the pressure loss for a 90 ° outlet with a diameter of 250 mm at an air flow rate of 500 m3 / h. To do this, we find the intersection of the vertical line corresponding to our air flow rate, with the oblique line characterizing the diameter of 250 mm, and on the vertical line on the left for a 90 ° outlet, we find the value of the pressure loss, which is 2 Pa.

We accept ceiling diffusers of the PF series for installation, the resistance of which, according to the schedule, will be 26 Pa.

Now let's summarize all the pressure loss values for straight sections of air ducts, network elements, bends and grilles. The sought value is 186.3 Pa.

We calculated the system and determined that we need a fan that removes 1570 m3 / h of air at a network resistance of 186.3 Pa. Considering the characteristics required for the operation of the system, we will be satisfied with the fan; the characteristics required for the operation of the system will suit us with the VENTS VKMS 315 fan.

Determination of pressure losses in air ducts.

Determination of pressure loss in the check valve.

Selection of the required fan.

Determination of pressure loss in silencers.

Determination of pressure losses at the bends of air ducts.

Determination of pressure losses in diffusers.

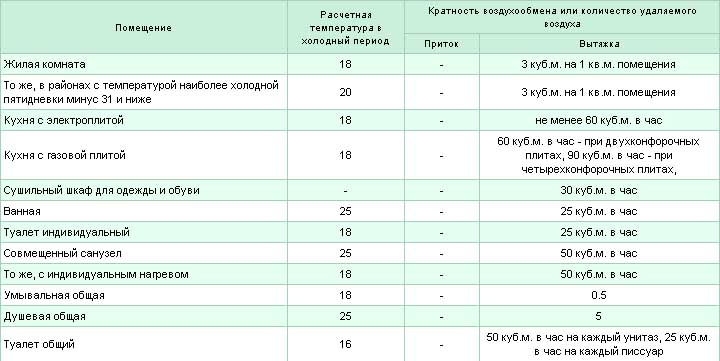

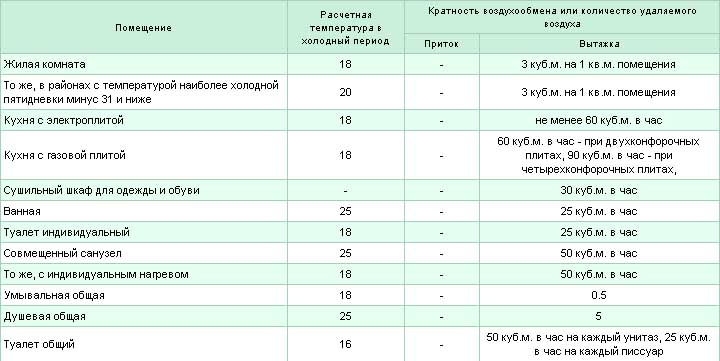

Air change rate

The multiplicity for rooms of different types is determined as follows:

| Room type | Multiplicity |

| Bakery | 20-30 |

| Greenhouse | 25-50 |

| Office | 6-8 |

| Bathroom, shower | 3-8 |

| Barbershop | 10-15 |

| Restaurant, bar | 6-10 |

| Bedroom | 2-4 |

| Lobby | 3-5 |

| Classroom at school | 2-3 |

| Cafeteria | 10-12 |

| Hospital chamber | 4-6 |

| Score | 8-10 |

| Basement | 8-12 |

| Kitchen in a house or apartment | 10-15 |

| Gym | 6-8 |

| Attic space | 3-10 |

| Catering kitchen | 15-20 |

| Pantry | 3-6 |

| Changing room with shower | 15-20 |

| Laundry | 10-15 |

| Toilet in the house, in the apartment | 3-10 |

| Conference hall | 8-12 |

| Living room | 3-6 |

| Billiard room | 6-8 |

| Public toilet | 10-15 |

| Garage | 6-8 |

| Meeting room | 4-8 |

| Utility room | 15-20 |

| Library | 3-4 |

| Dining room | 8-12 |

Table for calculating the minimum performance of the hood relative to the volume of the kitchen.

The highest frequency ratio is chosen for use in rooms with many people, with high humidity and temperature, with a lot of dust and strong odors. In a kitchen with an electric hob, you can choose a lower value, with a gas stove - a larger one. This is due to the fact that the gas, when the stove is on, releases combustion products. The fan, selected taking into account the above data, can be mounted in the wall, window, ceiling of the room.

How to check if the ventilation is working

In old houses, the work of ventilation shafts is often disrupted: over time, they become clogged and cease to perform their functions. Therefore, first you need to check the condition of the ventilation duct. If it is clogged with something, the efficiency of not only natural, but also forced ventilation will decrease.

USEFUL INFORMATION: Advantages of a sensor faucet for water: choosing an electronic mixer

To find out if the ventilation in the bathroom is in working order, simply:

- The windows and the door to the bathroom are slightly opened in the apartment.

- Take gauze, napkin or handkerchief and apply to the opening of the ventilation duct.

- If the air duct works properly, the fabric or paper will stick to the hole by itself. The tighter the handkerchief or napkin is pressed, the better the draft in the shaft. If they do not hold, they fall, then something is wrong with the channel, you need to find out the reason why the ventilation does not work.

Another test can be carried out, it is also very simple and indicative:

- also slightly open the vents and doors;

- light a candle and bring it to the exit of the mine;

- if the light leans towards the hole, then there is a thrust; if it burns without moving, then the air stands still.

Then the experiments should be repeated with the vents and doors closed. If in this case, too, the light deflects or the leaf sticks to the hole, then the traction is good, strong. In this case, it is unlikely that there will be a need to install forced ventilation. If there is no draft, then it will not hurt to install an additional fan.

The main reason for the lack of traction is the clogging of the channel. In this case, it is necessary to clean the mine, if necessary, contact the management company. It happens that residents of the upper floors brick up the ventilation, which also interferes with air circulation. This issue will also have to be resolved through the Criminal Code.