It is difficult to imagine the arrangement of modern kitchens without exhaust systems. Combustion products and steam generated during cooking are removed through the ventilation ducts. In addition, such devices purify indoor air and prevent the formation of fat deposits on furniture and household appliances. The editorial staff of Seti.guru will help you figure out what a corrugation for a hood is, how to choose it correctly and carry out the installation yourself.

What is corrugation, and why is it needed for exhaust devices

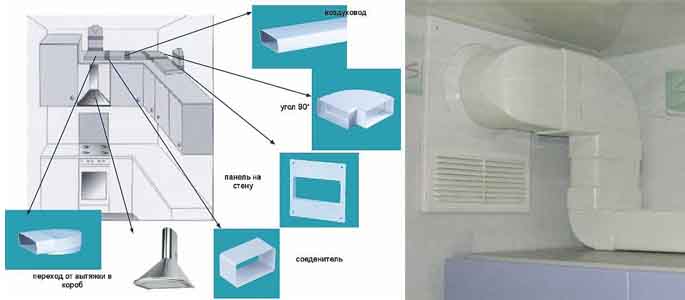

In kitchen exhaust systems, corrugated pipes are used as air ducts through which the products of combustion and evaporation resulting from cooking are evacuated into the ventilation shaft. Devices differ in diameter, length and material from which they are made. Corrugation is made of galvanized and stainless steel, aluminum, as well as various polymers. Products for the removal of exhaust gases have a round or square cross section. It is selected taking into account the shape and size of the hood neck, as well as the ventilation duct itself. Corrugated pipes are also used to remove burnt gases in columns and hinged boilers.

Forced exhaust systems prevent the spread of unpleasant odors that are generated in the kitchen when organic compounds are burned. In addition, there is no need to open windows to check the kitchen, and fat evaporation does not settle on the cladding, furniture and ceiling, so the room is always neat and tidy.

Technical characteristics of corrugated pipes for extraction

When installing an exhaust duct, the determining parameters are the diameter and shape of the exhaust outlet and the size of the building ventilation duct.

The corrugation used for mounting can be rectangular, square or, most often, round. The ventilation corrugation made of metal can be stretched along its length.

When purchasing a cut, it is important to pay attention to the integrity of the packaging and the presence of a description with characteristics. The most popular today are round metal hoses.

The cross-sectional dimensions of such products are unified - 100, 120, 125, 150, 200, 250 and 300 mm. For installation in household ventilation systems, sizes up to 150 mm are used, hoses with a diameter of 200 mm are more often used for gas boilers and water heaters.

Corrugated pipe for exhaust: the advantages and disadvantages of the device

Consider the advantages and disadvantages of corrugated air ducts for hoods. First of all, it should be noted the ease of installation and the ability to bend the structure at a certain angle. In addition, several sections can be connected at the same time using clamps.

The air duct stretches freely and can return to its original state. The flexibility of the design provides some reduction in the noise level during operation of the hood. Due to these properties, corrugated channels are used in rooms with a non-standard layout and in conditions of limited space for arranging ventilation systems.

Please note that the aluminum corrugated duct can be easily divided into sections of the desired length using scissors. In comparison with plastic and metal counterparts, the price of the device is much lower. It should also be noted that the corrugation is resistant to high temperatures. The air duct made of aluminum can withstand up to + 300 ° С, so its ignition is completely excluded.

Table 1. Disadvantages of aluminum ducts

| Lack of device | Description |

| Complexity of cleaning | Since the corrugation has a relief surface, carbon deposits and fat deposits accumulate on it (in comparison with smooth types of air ducts) faster. This makes it difficult to clean the device. |

| High noise level | Compared to exhaust ducts (smooth-walled) made of plastic or steel, the noise level of the aluminum corrugation during operation is significantly higher. |

| Unattractive appearance | Corrugated air ducts, in comparison with plastic ducts, have a less attractive appearance. For this reason, some difficulties arise when decorating the kitchen interior (you need to figure out how to close the corrugation). |

Installation rules and nuances

The ends of the aluminum corrugation are attached to the hood and to the vent.

This procedure requires the purchase of:

- corrugated pipe, the length of which is selected individually, the selection of the diameter is mentioned above;

- clamps made of plastic or metal of the required size, corresponding to the diameter of the corrugation;

- special ventilation grill with a hole for the pipe;

- dowels and screws.

Clamp for tightening the ends of the corrugated pipe.

We attach the corrugated pipe to the wall.

Installation order:

- Before installation, it is necessary to stretch the corrugation as far as possible along its length; this procedure will reduce the noise level produced by the hood during operation.

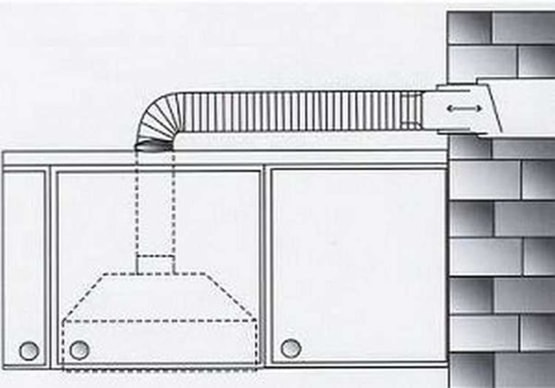

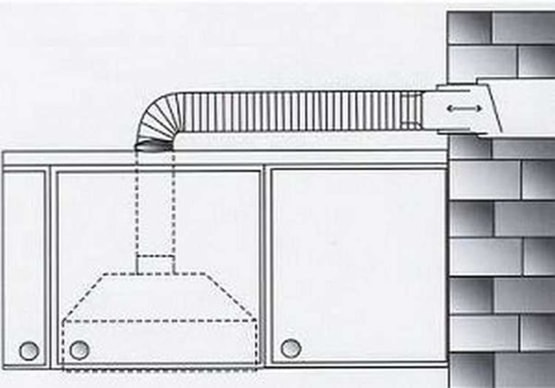

- We are preparing the ventilation duct. It is undesirable to use natural ventilation, it can be blocked by a pipe and function poorly. The best option is to bring the air duct outside, provided that the outer wall is next to the hood. If necessary, we punch a separate ventilation hole, the dimensions of which must correspond to the diameter of the corrugation. For a neat look, the hole can be greased around the edges using a cement-sand mortar.

- We attach a ventilation grill with a hole to the wall (or ceiling) using dowels and self-tapping screws, and seal the entire structure.

- The corrugation is attached to the ventilation hole through the grill, the end of the pipe is put on the sides and fastened with clamps or plastic ties.

- We find a branch pipe on the hood, the dimensions of which correspond to the diameter of the corrugation. We attach the end of the pipe to it with clamps, we seal everything.

The junction of the pipe to the ventilation grill.

Air duct outlet to the outer wall, the non-return valve is indicated by an oblique line.

To bring the ventilation pipe to the street, you must:

- make a hole in the outer wall;

- insert the corrugation and fix its immobility with cement-sand mortar;

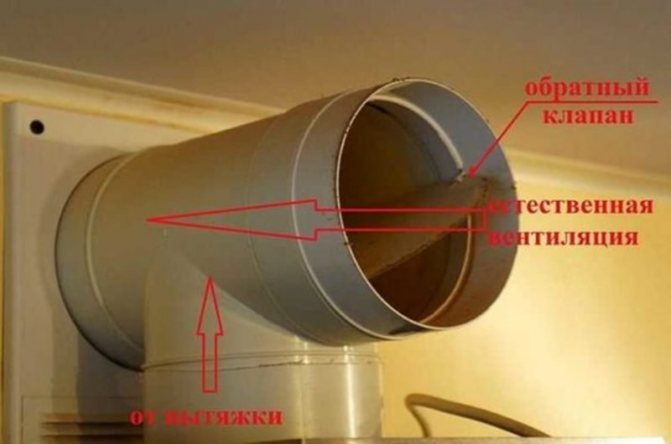

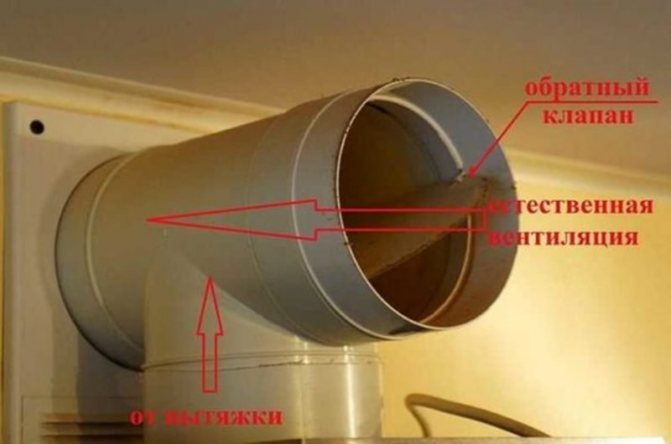

- install an anti-return or non-return valve to protect against air blown in from the street;

- close the outer opening with a grill to protect it from debris and birds and small animals.

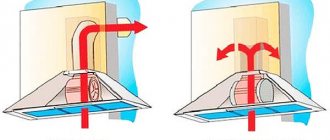

An air check valve is a lightweight plate made of plastic or metal.

The anti-return valve prevents outside air from entering the room. It is also installed in the corrugation connecting the hood to the house ventilation to prevent odors from entering the kitchen from the pipes. When attaching the valve to the pipe at the top and bottom of it, the petals are supported by a small spring. In the inoperative condition of the hood, the design prevents the penetration of air from the outside. When the ventilation equipment is turned on, the air presses the spring, bending the plate forward. A ventilation system without this valve will create problems for the owner of the room, since smells and cold outside will come with the air.

Installed anti-return valve.

Important. If the dimensions of the pipe and the ventilation hole do not match, you can use an adapter.

When using a universal adapter, its extra part is simply cut off.

When installing the corrugation, do not subject it to strong flattening, avoid kinking.

Technical characteristics of corrugated pipe for ventilation

Before purchasing a corrugated pipe for extraction, you should carefully study their technical characteristics and properties. Air ducts for domestic use are flexible and semi-rigid (semi-flexible). The first type of devices withstands bending and tensile deformations well with the possibility of restoring the original state. Using a flexible pipe, you can build an air duct of any configuration and a large number of corners.

The basis of flexible corrugation is a spiral-type wire frame, on which aluminum foil, polymers, or combinations of these materials are stretched.

The main characteristics include:

- device diameter - 100-500 mm,

- resistance to temperatures up to + 100 ° С,

- a bend amount equal to half the diameter.

Flexible air ducts are available with or without thermal insulation. The filler (glass wool, mineral fibers) is used to suppress the noise level in the house during the operation of the hood.

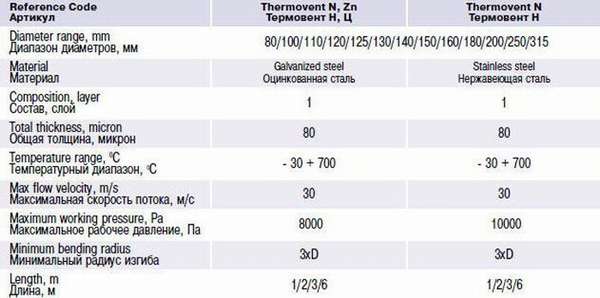

Table 2. Technical characteristics of semi-rigid corrugated pipes

| Device parameter | Picture | Description |

| Material |

| For the manufacture of semi-rigid air ducts, galvanized or stainless steel, as well as aluminum, are used. |

| Permissible bending value of the product |

| This indicator directly depends on the diameter of the duct. It indicates the degree of bending of the product (for example, the bending radius must be at least 0.6 of the corrugation diameter). |

| Internal dimensions of the corrugation (diameter) |

| Air ducts for domestic and industrial use with a diameter of 50-400 mm are widely available on sale. |

| Temperature indicators |

| When choosing corrugated pipes, the temperature indicators of the products should be taken into account. So, stainless steel devices can withstand thermal stress up to + 800 ° C, with a galvanized surface up to 700 mm, aluminum - 250-300 mm. |

Corrugated pipes come in several varieties:

• Aluminum. Pipes made of this material are the most common because they have a relatively low price and good characteristics, which makes them versatile. They are not afraid of high temperatures and fires, they are not very susceptible to corrosion. • Plastic corrugations fit better into the interior of the kitchen. Their surface is well cleaned of plaque and grease. Also, unlike aluminum ones, the plastic hood works almost silently. The only, but rather significant, drawback of plastic pipes is their inability to withstand high temperatures. Therefore, before buying, it is imperative to clarify what maximum possible temperature the plastic corrugation can withstand. Also, with strong heating, plastic corrugations can release toxic substances, which is also far from useful for others. • PVC pipes are used in household and office premises, they have the best sound insulation. • Galvanized corrugations are not sensitive to corrosion, can withstand high temperatures, are strong and reliable, but their price is high, which makes their use impractical.

Used types of corrugation for household hoods

Aluminum corrugated pipe

Kitchen air ducts made of aluminum are the most widespread, since their price is low, and they are universal in use. Most often, users purchase corrugations for hoods of 120 mm and 100 mm (less often - 150 mm). It is quite simple to choose such products, for which it is necessary to take into account the diameter of the inlet channel of the ventilation shaft and the exhaust gas outlet at the hood.

Advice! Corrugated pipe stretches well. So, 0.5 m of the duct can be stretched up to 3 meters in length without losing the properties of rigidity and resistance to high temperatures.This should be taken into account before buying an air duct for the kitchen.

Aluminum products have a long service life and excellent anti-corrosion properties. These devices are fire resistant, so they can be safely used as air ducts passing in furniture sections, decorative boxes, without fear of fire.

Plastic corrugation for ventilation

The purpose of the plastic corrugation for ventilation is the same as that of an aluminum installation - the removal of waste products of combustion and various vapors generated during cooking. Products have a round or square section, and due to their attractive appearance, the air ducts fit perfectly into almost any kitchen interior.

Plastic ducts have excellent throughput, besides, gases are discharged through them into the ventilation shaft almost silently. The smooth surface of the air ducts is effortlessly cleaned, maintaining a beautiful appearance for a long time. The products have one significant drawback - in comparison with their metal counterparts, they cannot withstand high thermal loads. For this reason, before buying a plastic duct, you should ask what the maximum temperature the product can withstand.

Other types of air ducts

There are a large number of types of air ducts that are used as outlet ducts for various communication systems. PVC corrugated pipes are most often used for ventilation in homes and industrial facilities. Most often, products with mineral fillers are used, which provide excellent sound insulation.

Galvanized boxes are also used for installation of ventilation and exhaust systems of complex design. Such material is resistant to chemical reagents, does not corrode and has a long service life. The same applies to analogs made of stainless steel and copper, however, due to the high price for air ducts, it is impractical to manufacture large structures. At home, such products are ideal for arranging hoods, heating systems using solid fuel and gas boilers, requiring the installation of channels that are resistant to high temperatures.

Ceramic air ducts for kitchen hoods are available in round and square sections. These products have the highest thermal stability, since they can freely withstand loads over + 1000 ° C. Ceramic duct manufacturers give their products a 30-year warranty.

How to choose the right corrugation for the hood - our editorial team's recommendations

When choosing air ducts, first of all, you should take into account the dimensions of the corrugation for the hood. The diameter of the product should be 1–2 cm larger than the dimensions of the outlet socket (hole) of the unit. This is necessary in order to reduce the load on the electric motor and the noise level.

For AOGV, it is recommended to develop the design of the exhaust ducts in such a way as to minimize the number of bends. If it is necessary to connect the air duct hoses or turn the duct in a certain direction, use the appropriate fittings. To prevent air from entering the channels, valves of the membrane type or axial analogs with a polymer disc are installed. As for the cross-section of products, it is better to install round pipes, since they provide the most efficient gas outlet.

As for the structures for the kitchen hood, it is worth considering the properties of the materials from which they are made. Flexible metal air ducts are compressed or stretched during installation and can be easily mounted at any angle. They are safe for humans, unlike plastic counterparts, which release toxic substances over time when heated.

Air duct device

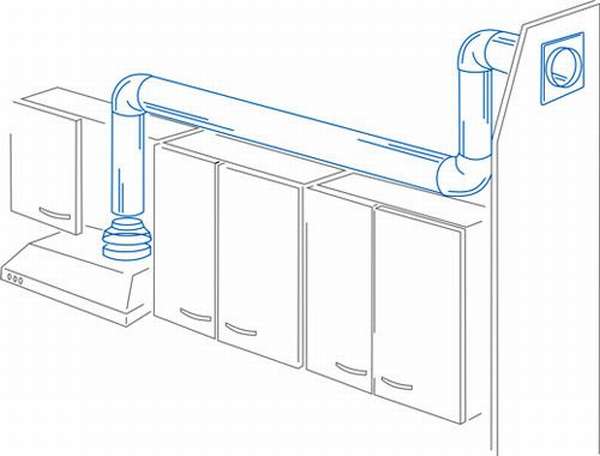

The contaminated air mass is discharged outside through a hole in the wall or a ventilation shaft.

In apartments, it is often necessary to pull the duct to the channel, unlike in private houses

In this case, a long pipe with bends will be required, which partially reduces the level of performance. If the building is being built for a specific layout, then the ventilation outlet during the construction process is immediately installed above the future hob. Therefore, ventilation pipes in a private house are short.

Many people do not like the appearance of the duct, which does not fit into the interior of the updated kitchen. But there is a way out of this situation. Often the air duct is preferred to be installed behind the kitchen cabinets of the upper tier. As an option - painting to match the walls or pasting with washable wallpaper. You can hide the pipe in a decorative plastic box. Such boxes are often equipped with spotlights, and this is additional lighting for the hob. If there are false ceilings in the kitchen, then the box is placed directly under them. In this case, the box will be almost invisible. If it is planned to install a two-level ceiling in the kitchen room, then the chimney for the hood is hidden behind a low level of the structure. There are many installation and decoration options, everyone chooses what is more convenient and easier.

Features of the installation of a corrugated air duct for the hood

Materials and tools used during installation

We will analyze what tools and materials are required to install ventilation corrugated pipes. The first step is to choose the correct air duct itself to connect to the hood. To connect the corrugation to the ventilation duct, you need to purchase a casing with a flange. To fasten it, you will need self-tapping screws and a set of screwdrivers.

To connect the hose sleeve to the grill, you need to purchase metal clamps of the appropriate diameter. In some cases, an external ventilation grill equipped with a non-return valve may be required. To exclude the penetration of air into the channels from the outside, use a silicone sealant. For metal corrugation, aluminum tape may be required.

Advice! Quite often it happens that the air duct openings in different parts of the system can have different sections or diameters. This issue is quite simple to solve, for which you need to buy the appropriate adapters.

Scissors are used to cut the aluminum corrugation for ventilation. Plastic counterparts can be shortened with a hacksaw, choosing the right blade.

Installing the corrugation on the hood: step by step instructions

In this section, we will consider how to install a corrugation on the hood in the kitchen with a detailed description of all stages of installation work. Below is a table with step-by-step instructions and illustrations.

Table 3. Step-by-step installation instructions for corrugated duct

| Stage of work | Picture | Description |

| Development of an exhaust system installation scheme |

| Taking into account the peculiarities of the kitchen, furniture sections and the location of the ventilation shaft, design a plan for the installation of the air duct. This will allow you to calculate the exact number of pipes, fittings, grids, clamps, fasteners. |

| Checking the length of the duct components |

| According to the scheme, prepare the sleeves of the required length for installation. If necessary, shorten the corrugation with scissors, a hacksaw. |

| Installation of a universal reducer on the exhaust outlet |

| Install a universal reducer on the exhaust outlet of the hood. This device will help you to mount corrugated air ducts of various diameters. |

| Corrugation connection with hood |

| Seal the edges of the gearbox with sealant. Install the sleeve, fix the clamp with the screw and screwdriver. |

| Fixing the channel to the wall |

| Fix the plastic (metal) duct to the wall using brackets with clamps.Mount the fasteners at a distance of 1 m from each other along the entire length of the structure. |

| Ventilation grill installation |

| Place the grating on the opening of the ventilation duct. Fix with self-tapping screws. |

| Duct to grille connection |

| Apply sealant to the flare of the grille and put on the neck of the air duct. Secure with a hose clamp. |

| Connecting the hood to the mains |

| Connect the hood to the mains. Check the operation of the exhaust system. |

Video "Features of connecting the hood and air duct":

Installing a ventilation pipe for the hood: practical ↑ tips

The process of installing such a pipe is a connection with its help of a kitchen hood and a ventilation hole in the wall to remove polluted air from the room. And there are several key points in this seemingly simple case.

Firstly, the hood and air duct must not be located on the opposite side of the ventilation duct opening in the wall or ceiling.

Secondly, the trajectory of the pipe laying and its length are important. Ideally, it should not exceed 3 meters. And here the rule applies - the longer the air duct, the lower the efficiency of the hood. In figures, these losses are as follows: for one extra meter of pipe, there is a decrease in efficiency by 10%.

The number of turns of the duct and their angle are also important. If you are installing a plastic structure, then all its bends will be made using L-shaped adapters, respectively, with an angle of 90 degrees. The same value should be adhered to when installing the corrugation.

Correct laying of a plastic pipe using an L-shaped element

It is important! The air duct should not be bent at an acute angle. Otherwise, there is a high risk of problems with air outflow, which will overload the hood.

And here the rule about the loss of efficiency during the operation of the hood is also relevant. Each bend of 90 degrees, if there are more than three, takes 5-10% of the efficiency.

Thirdly, you need to take care of natural ventilation in the room. It will simply not be possible if the air duct completely blocks the opening of the ventilation duct. This can be avoided by installing grilles with a non-return valve.

How it works? This grid has several holes. One of them is large - for connecting a ventilation pipe, and several others are smaller. As soon as you turn off the hood, the check valve opens and the process of natural air movement begins precisely through these holes.

Ventilation grill with openings for extraction and natural ventilation

How to connect the corrugation to each other

The simplest and at the same time reliable way to connect several corrugated sleeves to each other is to use aluminum tape. To obtain a one-piece channel, it is necessary to join the edges of the air ducts, and then fix them with tape.

This material will reliably hold the constituent parts of the duct and prevent depressurization. Also, for connection, adapters are used, on which the sleeves are fixed with clamps (with preliminary application of sealant).

How to hide the corrugation from the hood in the kitchen

Consider how you can hide the chimney in the kitchen. The photo shows one of the options for masking the duct. For these purposes, drywall or plastic boxes are used. In the first case, you need to make a frame from profiles, and then sheathe it with GKL sheets. The plastic structure can be purchased at a hardware store.

Also, the duct can be hidden inside the hinged sections of kitchen cabinets, having previously made holes for the corrugation of the corresponding diameter. If there is enough space between the ceiling and the curtain wall to fit the pipe, it can be routed from above.

Air duct maintenance rules. The need to replace the corrugated pipe for the hood

Smooth-walled plastic pipes are easy to clean, especially if the duct structure consists of several sections of small length and a corrugation diameter of 100 mm (so that a hand can freely pass inside). The sections are disassembled, cleaned of dirt, and then installed in their original place. The situation is more complicated with an aluminum corrugation with a relief surface. Grease, soot, carbon deposits and dirt accumulate in the folds of the structure for a long time. They are very difficult to remove, so it is easier to purchase and install a new corrugated ventilation duct. How to do this, we discussed in detail in the article.

Comparison of rigid duct and flexible corrugation for ventilation

Plastic and aluminum corrugations are very popular with users. Polymer air ducts are more expensive than their metal counterparts, but they look prettier in the kitchen. You should know that plastic does not change its shape, like an aluminum corrugation, therefore, before installation, you need to know the exact dimensions of the future structure. Plastic air ducts are more difficult to install, however, they provide a low noise level of the hood operation. In addition, you can choose a corrugation of almost any color that will ideally match the overall design concept of the kitchen and furniture wall.