Firewood is the classic and most common solid fuel option. When wood is burned, thermal energy is generated, which is used to heat various rooms. The combustion efficiency depends entirely on the combustion temperature of the wood, but it, in turn, depends on the type of wood, their humidity and combustion conditions. Each type of wood can be used for different purposes and tasks. Some are used for cooking on a grill or stove, others for heating the space (in a fireplace or stove).

Burning wood: the main stages

Combustion is an isothermal phenomenon, in other words, a reaction in which heat is released. Each wood species has its own heat efficiency. To measure the temperature of burning wood in the stove, a special thermometer is used - a pyrometer. All other devices and thermometers are not suitable for this purpose, no matter how much you try.

The combustion temperature can also be determined by the color of the flame of the rock used. If the rock ignites with a dark red flame, then this is a low-temperature combustion. A white flame indicates a high combustion temperature. But the most optimal flame should still be yellow. Usually dry birch burns with such a flame.

The whole process of burning a tree consists of several important stages that are interconnected.

Wood burning stages:

- Warming up. At a temperature of 120 - 150 degrees, the wood becomes charred, as a result coal is formed, which then ignites itself.

- Combustion of flue gases. Further heating can lead to thermal decomposition and gases flare up, covering the entire zone. At the same time, the tree burns with a light yellow flame.

- Ignition. Its temperature is 450 - 620 degrees. A good amount of thrust is required for successful ignition.

- Combustion. It consists of two phases: the process of smoldering and burning with a flame. A fire burns as long as certain conditions are created and maintained for it: as long as there is unburned fuel itself, oxygen continues to flow and the required temperature is maintained.

- Attenuation. If at least one of the conditions is not met, the combustion process stops and the fire goes out.

The best quality firewood is solid deciduous wood, they have high thermal conductivity and have a long burning time. These species include oak, beech, birch, acacia. Beech also has a pleasant aroma and is used for smoking. But if you light a pear, apple or cherry in the house, then their pleasant smell will fill the entire room. The ability of birch firewood to burn up even when freshly cut is very high, therefore they are the most profitable and demanded fuel.

Burns like a match

Briefly about the structure of the match. It consists of a stick and a head. Sticks are made of wood, cardboard and paraffin-impregnated cotton tow. The tree is chosen soft species - poplar, pine, aspen. Raw materials for sticks are called matchsticks. To avoid smoldering straws, the sticks are impregnated with phosphoric acid. Russian factories make aspen straw.

The head of a match is simple in shape, but complex in chemical composition. The dark brown head of the match contains seven components: oxidizing agents - Berthollet's salt and potassium dichromate; glass dust, red lead, sulfur, bone glue, zinc white.

- poplar - 468;

- aspen - 612;

- pine - 624.

The fire temperature of a match is equal to the ignition temperature of wood.Therefore, the white flash of the sulfur head is replaced by the yellow-orange tongue of the match.

If you look closely at a burning match, then three zones of flame appear. The bottom one is cold blue. The average is one and a half times warmer. The top is the hot zone.

Burning temperature of wood: factors contributing to the process

Every owner of a private house where there is a stove or fireplace knows that their efficiency will also depend on the thermal conductivity of firewood. Another important indicator is also responsible for the quality of burning firewood. This indicator is the burning temperature of the wood. It is different for each tree species. The more the degrees increase, the faster the heating system will heat up, but the water in the pipes or brickwork will keep the heat longer.

There are different types of coal, in which more or less ash content is present. There are also differences in different types of wood. For example, they differ in the temperature that is released during combustion and in the composition of the products remaining after the combustion of firewood.

In order to choose high-quality and solid wood, you need to know some important factors that are responsible for the best wood burning. These factors will determine not only the quality of the fire, but also the temperature of the flame and the combustion process itself.

Factors that contribute to the combustion process:

- Wood grade;

- Wood moisture;

- The amount of air entering the firebox.

Also, wood species differ: density, structure, as well as the composition of resins and its quantity. All these factors directly affect the thermal conductivity, the nature of the flame, the temperature of ignition and combustion of various rocks. For example: poplar lights up with a high and very bright flame, but its maximum combustion temperature can be only 500 degrees Celsius, and this is not at all enough for heating. But during the combustion of such species as beech, ash or hornbeam, a temperature of more than 1000 degrees is released, which contributes to excellent heating.

Temperature characteristics.

Often, when choosing a polymer material, taking into account its thermal behavior is more important than evaluating strength characteristics. The operating temperature of a plastic product affects the values of breaking stresses, deformability, modulus of elasticity, hardness, impact strength and other properties that significantly adjust consumer characteristics. Often this adjustment is not in favor of the polymer material.

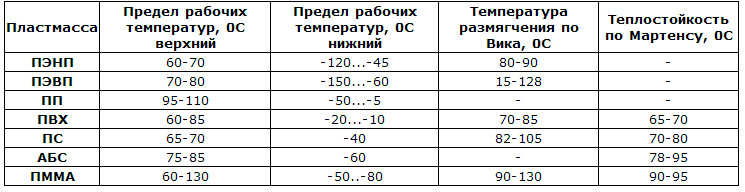

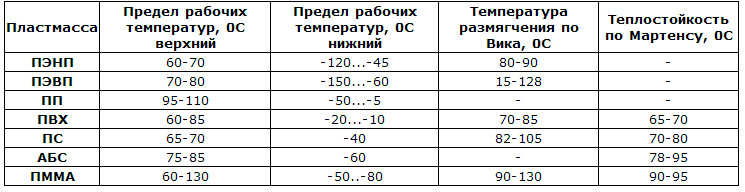

Table "Temperature characteristics of general-purpose thermoplastics".

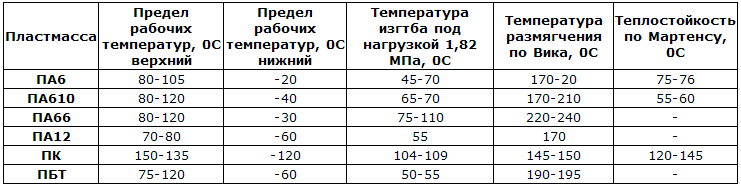

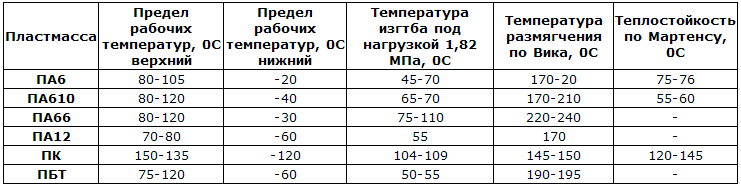

Table "Temperature characteristics of structural thermoplastics".

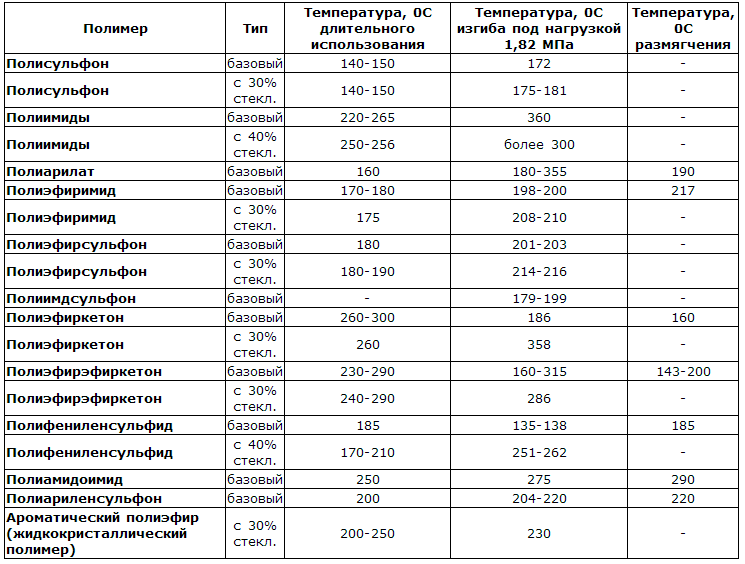

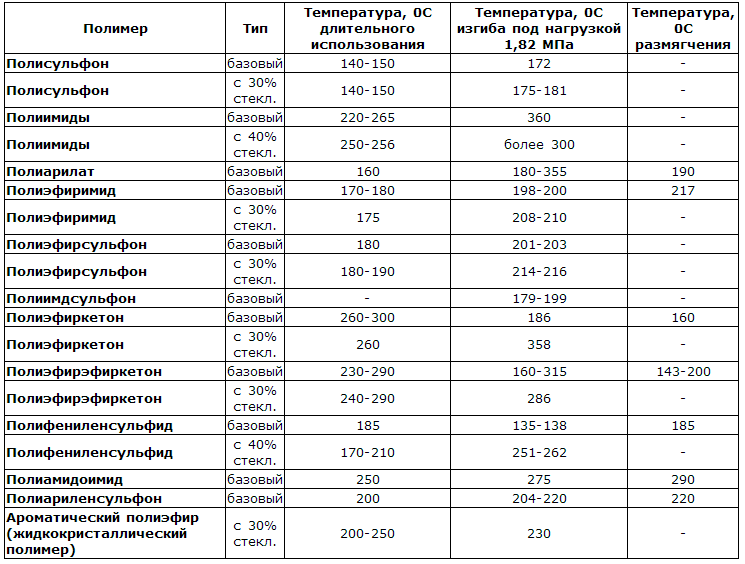

Table "Temperature characteristics of thermoplastics with increased heat resistance".

Firewood heating performance: table of main species

Considering different types of wood, in the end, you can notice some differences: some of them burn very brightly and perfectly, while there is a strong warmth, while others just barely smolder, leaving almost no heat behind. The point here is not at all in their dryness or moisture, but in their structure and composition, as well as the structure of the tree.

However, it is worth paying attention to the fact that a wet tree ignites and burns very badly, while a large amount of ash remains, which has a bad effect on the chimney, they become heavily clogged.

The highest heat output is found in oak, beech, birch, larch or hornbeam, but these species are the most unprofitable and expensive. Therefore, they are used very rarely, and then in the form of shavings or sawdust. The lowest heat transfer is in poplar, alder and aspen. There is a table showing the main rocks and their heat output.

Table of some of the main rocks and their heat transfer:

- Ash, beech - 87%;

- Hornbeam - 85%;

- Oak - 75, 70%;

- Larch - 72%;

- Birch - 68%;

- Fir - 63%;

- Linden - 55%;

- Pine - 52%;

- Aspen - 51%;

- Poplar - 39%.

Conifers have a low burning temperature, so it is better to use them for lighting an open fire (fire). However, pine wood catches fire very quickly and is capable of smoldering for a long time, since it contains a huge amount of resins, so this species is able to retain heat for a long time. But nevertheless, it is better not to use coniferous species for heating, since when it burns, a lot of flue gases are formed, which settle in the form of soot on the chimney and it must be cleaned, since it quickly clogs up.

Constructive protective measures

Fire-retardant measures in relation to most wooden houses and other buildings are provided with appropriate design solutions, as well as due to their treatment with special chemical reagents (fire retardants).

The protection of this type is realized by increasing the mass of individual elements, with the exception of pointed edges and strongly protruding parts ("sharp edges"), using wood elements devoid of voids.

Heat-resistant insulation materials are also used, fire protection of the surfaces of wooden structures with special coatings. Protective coatings are used in the form of asbestos-cement (gypsum) sheet blanks and plaster up to 1.5 centimeters thick.

In addition, in order to reduce the flammability index, the design deliberately reduces the number of structures with parallel wood elements and voids between them.

Additional measures to counter the spread of fire require compliance with the norms for the formation of fire breaks.

To this can be added the breakdown of buildings with special partitions and the corresponding arrangement of wall openings (windows and doors) and fire-resistant roofs. All these measures make it possible to strengthen the structure in terms of its ability to resist the spread of fire.

Complete and incomplete combustion: what is released when wood burns

Not only wood can burn, but also its products (chipboard, fiberboard, MDF), as well as metal. However, the combustion temperature is different for all products. For example: the combustion temperature of steel is 2000 degrees, aluminum foil - 350, and wood starts to ignite already at 120 - 150.

Burning wood eventually produces smoke, where the solid is soot. The entire composition of combustion products depends entirely on the constituents of the tree. Wood is mainly composed of the most important constituents: hydrogen, nitrogen, oxygen and carbon.

If 1 kg of wood is burned, then the products of combustion in a gaseous state will be released somewhere between 7.5 and 8.0 cubic meters. In the future, they are no longer capable of burning, except for carbon monoxide.

Wood combustion products:

- Nitrogen;

- Carbon monoxide;

- Carbon dioxide;

- Water vapor;

- Sulphur dioxide.

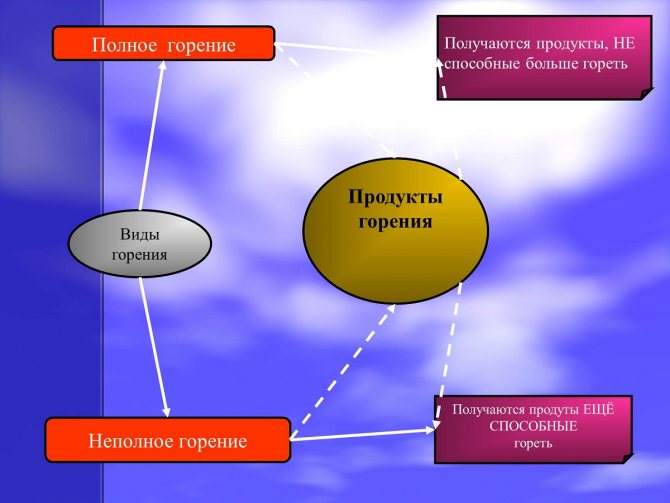

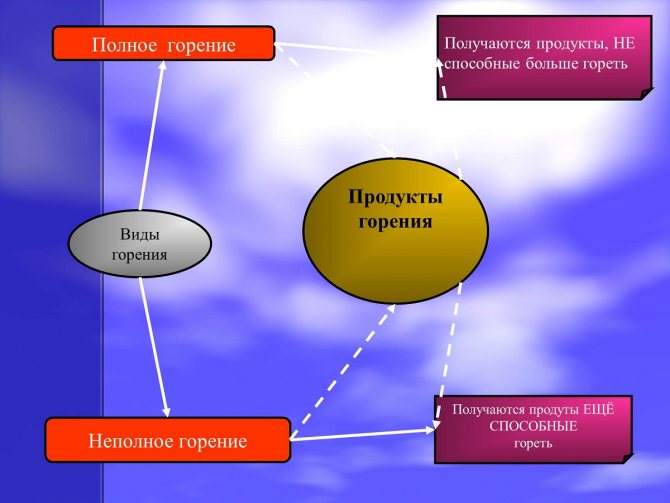

Burning in character can be complete or incomplete. But both of them occur with the formation of smoke. In case of incomplete combustion, some combustion products can still burn later (soot, carbon monoxide, hydrocarbons). But if there was complete combustion, then the products that were formed in the future are not capable of burning (sulfur and carbon dioxide gases, water vapor).

Exploring fire in our own kitchen

Gas stoves run on two types of fuel:

- Main natural gas methane.

- Propane-butane liquefied mixture from cylinders and gas tanks.

The chemical composition of the fuel determines the temperature of the gas stove fire. Methane, burning, forms a fire with a capacity of 900 degrees at the highest point.

Burning a liquefied mixture gives heat up to 1950 °.

An attentive observer will note the uneven coloring of the tongues of the gas stove burner. Inside the fiery torch, there is a division into three zones:

- Dark area located near the burner: there is no combustion here due to lack of oxygen, and the zone temperature is 350 °.

- A bright area lying in the center of the torch: the burning gas heats up to 700 °, but the fuel does not burn completely due to the lack of an oxidizer.

- Semi-transparent upper section: reaches 900 ° C and full combustion of the gas.

The figures for the temperature zones of the flame torch are given for methane.

The average temperature of burning wood (video)

Combustion is a complex process where heat is generated as a result. Today the most relevant fuel is wood. The combustion process itself will depend on its quality. Firewood should be chosen, preferably hardwoods, absolutely dry with high heat transfer, then the heating efficiency will increase.

Comments (1)

-1 Anya 02.02.2018 21:05 I think those people who heat their houses with wood know what the combustion temperature is and know which wood burns longer. There are rocks that burn in just a few hours, and some burn for hours.

Quote

Refresh comment list RSS feed of comments for this post