Home / Solid fuel boilers

Back to

Published: 09.03.

Reading time: 6 minutes

0

163

Fuel pellets are pellets of artificial origin obtained by pressing. The raw material for them is woodworking and agricultural waste. The vast majority of household automatic pellet boilers are designed to use wood pellets.

This ensures efficient operation of sources with the least amount of maintenance and low emissions of harmful substances into the environment. Since 2010, in the EU countries, the production of fuel pellets is determined by the EN 14961-2 standard under which the designs of heating boilers have been modified.

- 1 Device

- 2 The principle of operation of automatic pellet boilers 2.1 Pellet feeding

- 2.2 Ignition and combustion

- 2.3 Ash removal

Pellets and their effectiveness as solid fuels

Pellets - Cylindrical granules compressed under high pressure resulting from the processing of agricultural waste (husk of seeds of cereals, hay or straw) and woodworking (sawdust, chips, shavings or bark). Peat and coal pellets are less popular.

This is how different types of pellets look like.

Calorific value index (specific heat of combustion) of pellets is 17.2-19.5 mJ / kg = 4.7-5.4 kW / h, which is much higher than, for example, wood, pure peat and even fuel briquettes. Burning 2 tons of pellets gives the same amount of energy as 960 cubic meters of gas, 1000 liters of diesel fuel or 3.2 tons of wood.

In Russia, the production of pellets of the "Premium" and "Standard" grades is permitted, which have an insignificant ash content of 0.4–1% and 1.5–3%, respectively.

reference... Contrary to popular belief, pellets are produced without the addition of synthetic substances: and although there are standards that allow chemistry in the composition, most of the pellets do not contain binders or improvers, and gluing occurs due to lignin released when heated.

The disadvantages include, perhaps, storage conditions - they cannot be left simply under a canopy, but must be stored in a closed room or container.

The principle of operation of automatic pellet boilers

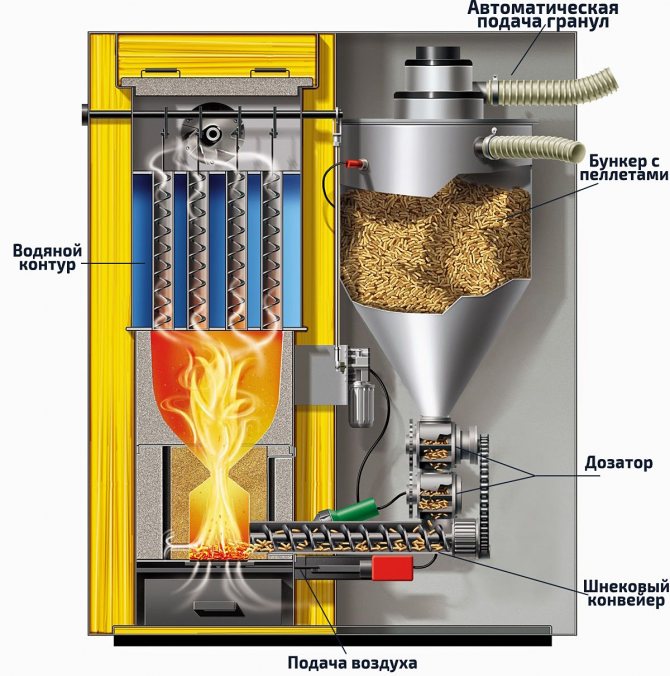

Pellet boiler Hoval in section.

An automatic pellet boiler is a steel or cast iron heating unit, which, from a structural point of view, is the same solid fuel boiler, but with the possibility of complete automation of the work process, i.e. it can function with minimal human intervention.

The principle of operation of a pellet boiler consists in the sequential interaction of 3 separate systems (storage bins, a mechanism for transporting pellets to the combustion chamber and the burner itself), combined into a single device by the ABU attachment - a hardware control unit.

Accordingly, the process of equipment operation includes 3 stages:

- Supply of pellets from the bunker or from the fuel storage to the combustion chamber.

- Ignition, reaching the required temperature and maintaining combustion.

- Regular cleaning, including removal of ash and carbon deposits from the elements of the device.

From the storage, the pellets are delivered to the boiler hopper. The dispenser supplies the required amount of pellets to the combustion chamber. The pellets ignited by the burner heat up the water circuit.

In general, automatic pellet boilers designed for domestic use are very easy to maintain.The main thing is to initially correctly configure the appropriate operating mode, so that later you can turn on and off the heating with one button and simply monitor the number of granules.

Pellet feeding system

The organization of the automatic pellet feeding system directly depends on many factors (design features of the heat generator model, the availability of free space in the room, financial capabilities, as well as other personal preferences) and can be carried out in several ways:

- bulk (spontaneous) - pellets fall into the burner under their own weight, which can only be realized from the built-in hopper;

- pneumatic (vacuum) - feeding is carried out using a powerful pump that can suck pellets even from another room (up to 30 meters);

- auger (worm) - the intake of granules is carried out by means of a gear-screw mechanism, which assumes a portioned supply of new batches;

- conveyor (conveyor) - the fuel is delivered according to a standard (> 45 °) or steeply inclined (<45 °) "endless" belt with blades.

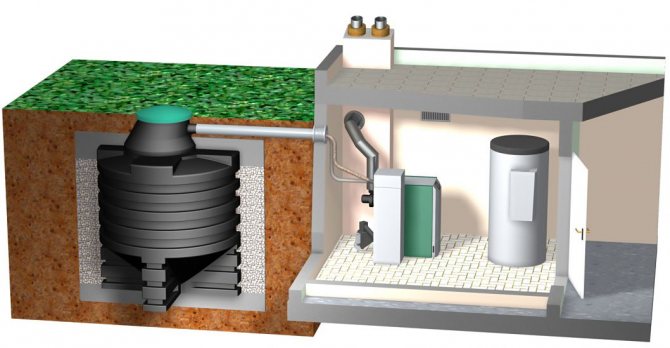

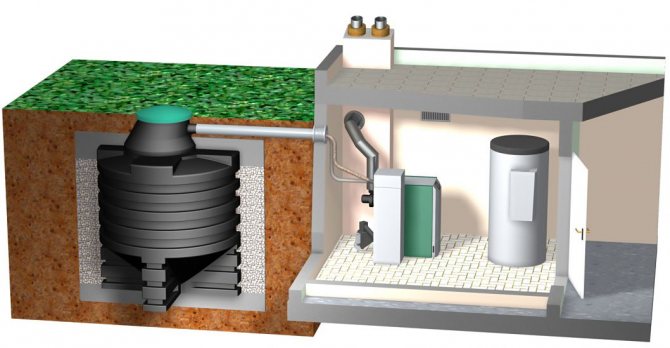

An example of organizing the supply of granules in a vacuum way from a street bunker.

In addition, for greater ease of installation, the above options can be subjected to various modifications, as well as combined with each other.

One loading of pellets can be enough for a rather long period - from 2-4 days to 1-3 months, up to the entire heating season (depending on the volume of the built-in or separate hopper). At this time, the ABU controller itself assesses the situation and ensures the uninterrupted operation of the heat generator.

Ignition and combustion maintenance

After pressing the start button, the electric ignition system is activated:

- The glow plug (or heating element) ignites the fuel, the flame sensor turns on.

- The fan blows in air and creates a stable combustion flame.

- The photosensor detects the presence of a flame, the glow plug turns off.

- The boiler goes into heating mode, pellets are regularly fed to the burner.

- When the temperature reaches 60–70 ° C, the maintenance mode is activated.

- The volume of incoming air and the pellet feed rate are reduced.

- When the temperature drops (sudden cold snap), heating starts again.

- Periodically, the burner will turn on / off in the specified mode.

The fully automated pellet boiler is also equipped with a temperature limiter and a coolant overheating sensor. When the supply of a new batch of fuel to the burner is interrupted, the system goes into the afterburning mode - the fan burns out the residues at full speed for 5-10 minutes.

The work can be stopped by manually pressing the "Stop" button or (in case of any error) by a program command of the device. Modern GSM modules make life even easier: they synchronize with mobile gadgets and immediately notify of emergency shutdown, end of pellets, etc.

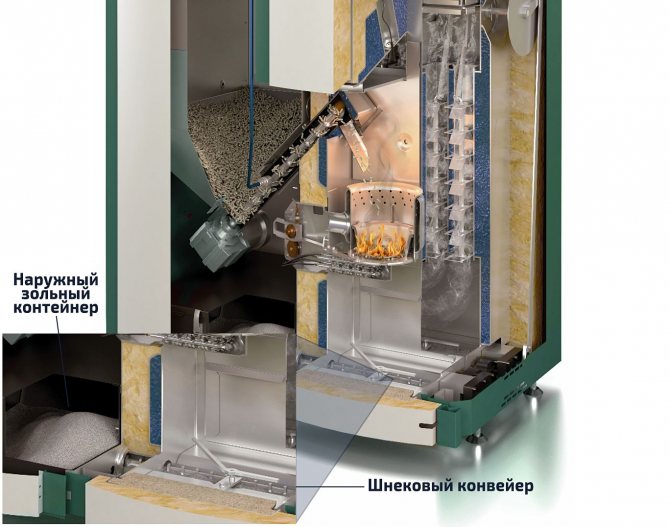

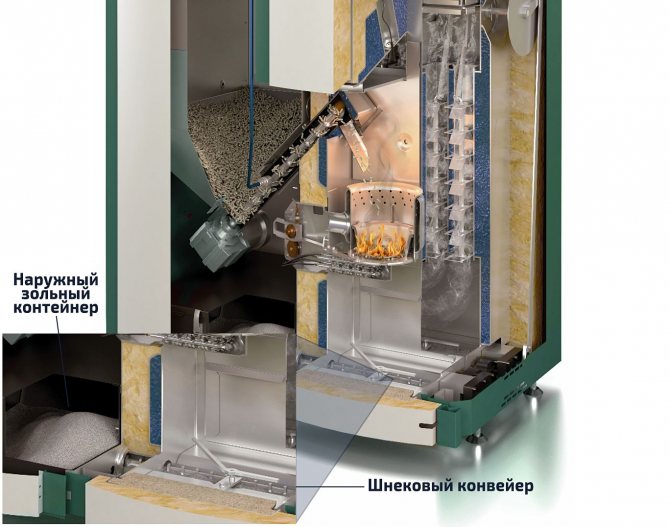

Ash and carbon deposits removal

The frequency of maintenance of heating equipment, i.e. removal of carbon deposits and ash remaining from the combustion of pellets, depends on the degree of its equipment:

- model without automatic cleaning - once every 3–10 days;

- self-cleaning model - once every 4-6 weeks

That is, the built-in self-cleaning system does not completely eliminate the need for manual cleaning, but only allows you to significantly reduce its frequency.

Boiler unit with automatic cleaning system.

Automatic ash removal goes through the transportation of burnt-out residues to a large outer container using a screw conveyor. When agitated, the ash is compacted, which saves space in the ash pan. The drive of this mechanism can work both from the controller of the boiler itself, and autonomously.

Automatic removal of carbon deposits from the burner is carried out at the expense of knives - moving parts of the grate. In fact, they simply cut off the carbonized tar particles and send them to the ash box.When it is filled, the consumer is given a signal about the need for cleaning.

How pellet boilers work

A pellet boiler is equipment that runs on a special type of solid fuel - pellets. Pellets are granules that are made by pressing waste from wood processing. The device is designed to provide the room with hot water supply. Models are available that have different powers from 15 kW to 100 kW.

Among the advantages of pellet boilers, it is worth noting economy and efficiency.

There are 3 options for this equipment:

- The first is designed to organize work exclusively on pellets;

- The second provides an opportunity to use firewood or briquettes, but only as a reserve, since the work will last no more than 2-3 hours;

- The third one is combined and is capable of working not only on pellets, but also on wood with coal, since the design includes several combustion chambers.

The boilers are made of sheet steel. It includes several mechanisms at once, for example, a boiler with special pellet burners, a conveyor that will feed pellets into the combustion chamber and a bunker that stores fuel.

The work happens in this way:

- Pellets, which are loaded into the tank by means of the auger, are sent to the firebox. Combustion takes place there.

- The heat generated during combustion heats up the heat carrier. He, in turn, carries it around the room, which is heated.

Basically, all devices are equipped with an automatic type control, it creates fuel regulation and maintains the temperature that was set by the coolant. The operation is very simple. The pellets are placed in the boiler once for 3 to 14 days. It depends on how much the container has. In addition, the boiler needs regular cleaning of the burning channels and cleaning of the ash drawer. The service life of such an installation varies from 10 to 50 years, depending on the class.

Reviews of household automatic pellet boilers: advantages and disadvantages

Feedback from the owners of automatic pellet boilers suggests that this technique has both strengths and weaknesses, or rather, nuances:

| Benefits | disadvantages |

| autonomy - equipment with a GSM-module can be left unattended for weeks | the cost - the price of even the most modest options is 100-120 thousand rubles. |

| universallyst - most models also work on wood chips, husks and sawdust | energodependentlyst - without access to the network, a backup generator is required for operation |

| convenience - self-cleaning and auto-feeding minimizes manual maintenance | service - many foreign firms simply do not have a representative office in Russia |

| safety - the body does not heat up, which is especially important for children and animals | pellet consumption - often real figures differ from theoretical calculations |

| purity - there are no traces of exploitation in the room, i.e. soot, dust and smoke | fuel price - the cost of pellets exceeds the cost of firewood or coal |

reference... An unexpected increase in the consumption of pellets is often associated with the inadequate quality of the product itself: if they contain impurities or their moisture content is more than 10–12%, then in order to maintain a given mode, it becomes necessary to compensate for the loss of heat capacity by quantity.

What to look for when choosing a boiler unit

The coefficient of performance (COP) is the most important point worth paying attention to, since it is he who shows the efficiency of the heater. Usually, manufacturers indicate an efficiency of 85–98%, but in reality it depends on the correct setting, the quality of the granules and the design features.

Main characteristics of automatic pellet boilers:

| Burner type | |

| retort (meat grinder) - "omnivorous" vertical burner, but the use of less heat-intensive fuel reduces efficiency | stocker (flare) - horizontally directed burner, efficient, but demanding on fuel quality |

| Heat exchanger material | |

| steel - durable, but (with a thickness of up to 6-8 mm) material subject to burnout | cast iron - durable, but fragile material if misused |

| Control system | |

| built-in controller - a control unit located on the boiler controls the processes of loading pellets and heating | full automation - options for supply, ignition, heating, self-cleaning, thermal and photosensor, timer and protection system |

| Maximum power | |

| The boiler power required for heating a house is calculated individually, but in any case, it is recommended to buy the device with a small margin - 10-20% | |

| Heating circuit | |

| single-circuit - intended only for heating the very space of the house | double-circuit - allows you to heat water for sanitary and domestic needs |

reference... If there are several heated systems, for example, radiators, water supply and underfloor heating, or it is necessary to create climatic zones, then it is better to purchase double-circuit equipment with additional automation that allows you to control several temperature modes at the same time.

It is also worth paying attention to equipping the boiler with a device for swirling fuel gases: thanks to it, part of the heat does not go into the chimney, but is transferred to the heating system as much as possible, which increases efficiency, and it also prevents ash formation, because pellets are almost completely burned out.

How to choose a room thermostat for a heating boiler and save up to 30% every month

Pellet boiler: working principle

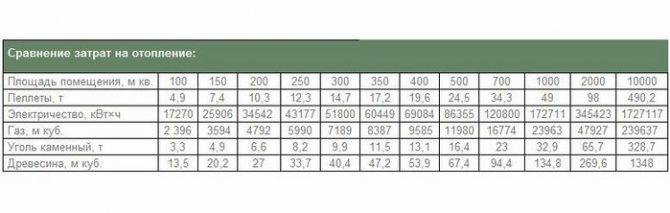

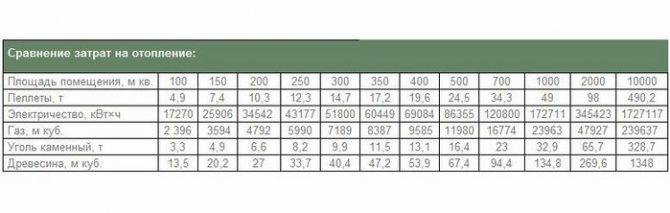

Figure 3. Comparative table of fuel consumption of different types.

Pellet heating is the safest, environmentally friendly hi-tech technology, which allows you to automate the operation of the boiler house completely, in contrast to the use of coal and firewood. The pellet boiler consists of 3 mechanisms, which are combined into a single functional device: as a rule, this is a boiler with a special burner in which fuel is burned, a hopper in which a supply of pellets is stored, and a mechanism that feeds pellets into the combustion chamber.

The basis of this type of heating system is a pellet boiler. The pellet boiler has the following principle of operation: wood pellets are poured into the hopper and from there are fed, as required, into the boiler furnace using a special auger controlled by automation. The more heat we need, the greater the consumption of the pellets. When the room temperature reaches the required level, the auger stops and the pellets stop entering the oven, saving fuel consumption. Hopper capacity varies. There are silos that can be loaded with pellets for a whole year, season, month, week, or just for a few days. It is advisable to use a pellet boiler in conjunction with an additional, reserve boiler.

The best known manufacturers and models: characteristics and prices

When choosing a pellet boiler with automatic feeding, you need to focus not only on the technical characteristics, but also on the manufacturer, since not everyone will be able to ensure the timely delivery of replacement parts, as well as provide a specialist for installation, adjustment and warranty service.

Therefore, in order not to be left without heating at the wrong time, it is better to choose a proven model from a company with extensive experience in this field.

ZOTA Pellet-15S

Wear-resistant pellet boiler of Russian production, supporting different types of fuel (pellets, firewood, briquettes). It is designed for use in harsh winter conditions that imported solid fuel boilers cannot withstand.

Those. parameters: power - 15 kW, bunker volume - 296 l, efficiency - 90%.

average cost: 150,000-170,000 rubles as standard.

Manufacturing firm: TPK KrasnoyarskEnergoKomplekt, Russia.

FACI 15

A compact boiler with a twin-screw feed system provides high combustion efficiency for almost any crushed biofuel. It is equipped with an "anti-slag" type cast iron retort burner, which allows to reduce the ash content of even low-quality pellets.

Those. parameters: power - 15 kW, bunker volume - 352 l, efficiency - 92%.

average cost: 130,000-150,000 rubles as standard.

Manufacturing firm: LLC FACI-RUS (FACI Caldaie), Russia-Italy.

Teplodar Kupper OK-9 with APG 25 burner

Universal boiler equipped with an APG 25 pellet burner, also suitable for conventional solid fuels, including wood and coal. The simple combined design is easy to modify, if desired, you can switch to a gas burner.

Those. parameters: power - 9 kW, bunker volume - 200 l, efficiency - 68–95%.

average cost: 80,000-110,000 rubles with a torch burner.

Manufacturing firm: OOO Teplodar, Russia.

Biopellet P-15

A boiler with an original, but well thought-out design, which is easy to assemble and maintain, even by an untrained specialist. It is unpretentious in the quality of the pellets, it can be heated with both white and gray varieties without the risk of stopping the burner due to contamination.

Those. parameters: power - 15 kW, bunker volume - 200 l, efficiency - 92%.

average cost: 160,000-180,000 rubles as standard.

Manufacturing firm: OOO Dozatech, Russia.

START-50-GR

A powerful domestic-assembled boiler with a bunker of impressive dimensions and imported components (automation and burner). It is known for its high reliability and durability, thanks to its cast iron parts (burner, boiler door, grate) and a durable 6 mm thick steel heat exchanger.

Those. parameters: power - 50 kW, bunker volume - 400 l, efficiency - 95%.

average cost: 230,000-250,000 rubles as standard.

Manufacturing firm: LLC Heating boilers "START", Russia.

Calculating the minimum required power

The easiest way to calculate the required boiler power (N) - according to the formula:

N= S × W oud/10

- , where S is the heated area of the house, taking into account all residential and utility rooms;

- W beats - the power required for heating 10 m2 (in accordance with the climate).

In central Russia, a medium-heated room with a ceiling height of 2.5–2.7 m and an area of 10 m2 can be fully heated with a power of 1.1 kW.

Thus, the minimum required power of a pellet boiler for heating a house 10 × 15 m will be calculated using the formula 150 m2 × 1.1 kW / 10 = 16.5 kW.

Standards and requirements for installation

Installation of long-burning boilers with automatic pellet loading is carried out taking into account the existing fire safety rules (PPB):

- placement in a separate room - a boiler room (basement or annex);

- covering the floor in the room with the boiler exclusively from non-combustible material;

- a room without high humidity, equipped with a ventilation system;

- the minimum distance from the boiler to the pellet storage place is at least 1 m;

- fireproof partition between the external fuel storage and the boiler;

- organization of the chimney in accordance with the building codes of the joint venture and SNiP.

Despite the fact that before installing the pellet boiler, you do not need to contact any regulatory authorities (for approval and examination), as practice shows, it is rather difficult to independently install and connect weather-dependent equipment, therefore it is better to entrust these matters to professionals.

Screw feed

The screw feed was historically the first and for a long time it was the only option for automating an external warehouse.

Horizontal auger and wooden slopes. The auger in the external warehouse is both a turner and a feeder.

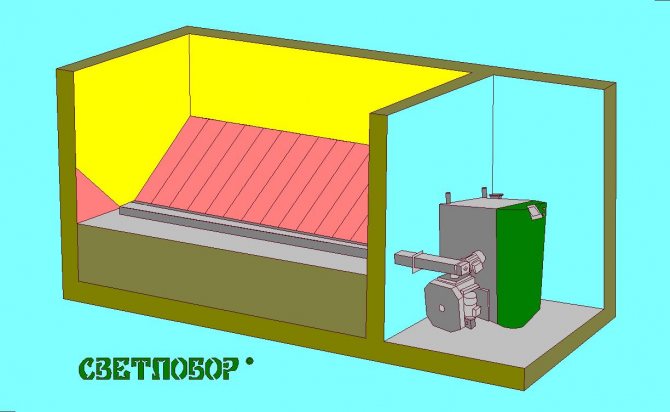

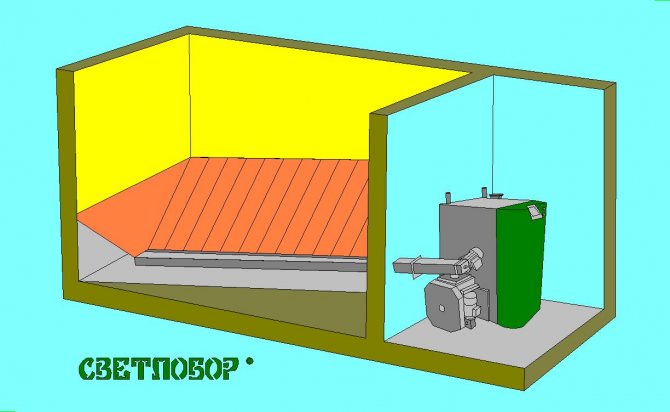

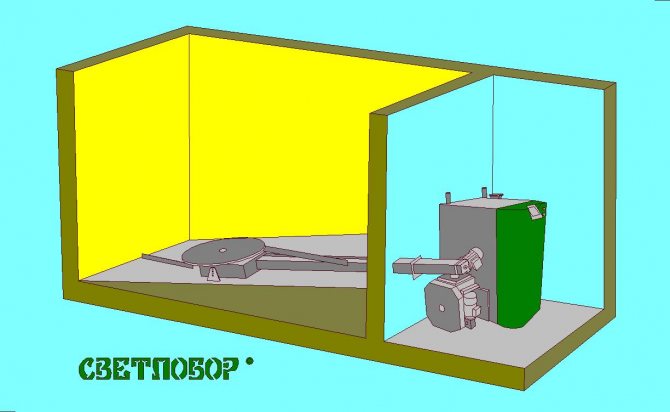

The figure shows a good layout of the warehouse directly behind the boiler. Due to the peculiarity of the layout of the Svetlobor boiler, the boiler is directly pushed against the wall and occupies a minimum area. The external warehouse is raised by 700 mm relative to the floor level in the boiler room.The volume loss of the warehouse reaches 30%. The main advantage is simplicity. The scheme is effective for long and narrow rooms in plan. For example, LxW 4000x2500 mm.

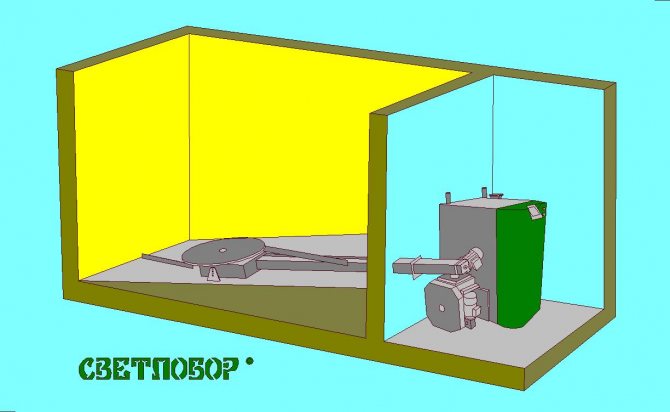

Inclined auger and wooden slopes. The auger in the external warehouse is both a turner and a feeder.

The volume loss of the warehouse does not exceed 20%. The scheme is effective for long and narrow rooms in plan. For example, LxW 4000x2500 mm.

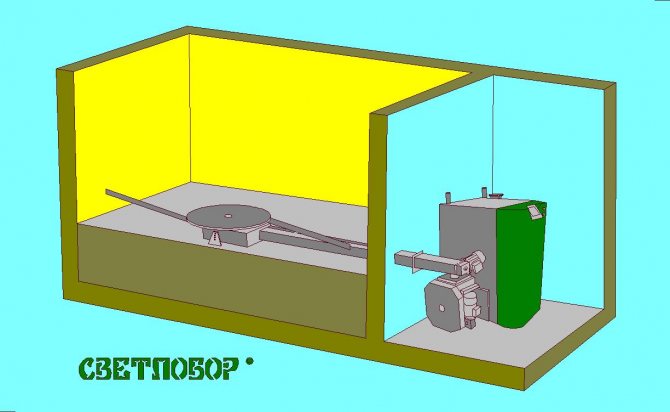

Leaf spring agitator with a screw drive. The auger drives the spring agitator disc. Two springs (flat springs) are fixed on the disk. When the warehouse is full, the springs are pressed against the disc during rotation and do not create additional resistance. As the warehouse is emptied, the springs straighten and rake the pellets to the auger. Maximum agitator diameter 3000 mm.

The external warehouse is raised by 700 mm relative to the floor level in the boiler room. The volume loss of the warehouse is about 15%. The scheme is effective for square rooms. For example, 3000x3000 mm.

It can be used for feeding pellets and chips.

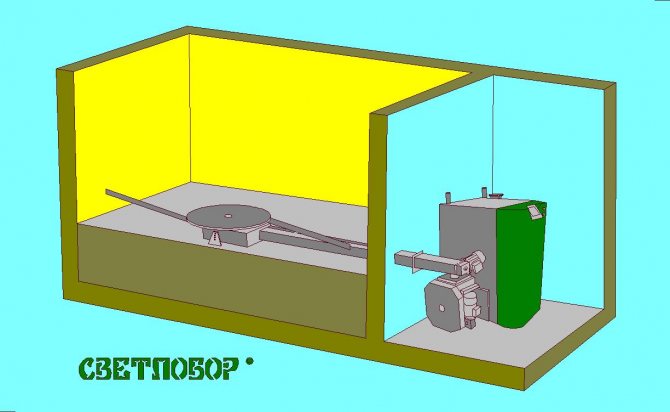

Inclined leaf spring agitator with auger drive. The auger drives the spring agitator disc. Two springs (flat springs) are fixed on the disk. When the warehouse is full, the springs are pressed against the disc during rotation and do not create additional resistance. As the warehouse is emptied, the springs straighten and rake the pellets to the auger. Maximum agitator diameter 3000 mm. An inclined ramp is usually made of wood.

Loss of the volume of the warehouse premises about 6%. The scheme is effective for square rooms. For example, 3000x3000 mm.

It can be used for feeding pellets and chips.

Modification of boilers Svetlobor, when using a screw feed, is distinguished by the replacement of the vacuum feed hopper with a special receiving device with a hinged assembly.

Of course, the entire fire safety system based on the bronze rotary airlock is retained.

The price of the boiler for modification with screw and vacuum feeding is the same, see the price list.

How much fuel will be needed for the heating season?

Pellet consumption (M x) for a limited period of time is calculated by the formula:

M x= X /fuel heat capacity

, where X is the heat loss during the heating season, determined by the formula:

X = S × D × 24 × 0.9 × 70

- , where S is the heated area of the house, taking into account all residential and utility rooms;

- D is the duration of the heating season;

- 24 - the number of hours of boiler operation per day;

- 0.7 - coefficient of boiler operation;

- 70 - average heat loss per hour (for a typical residential building).

For the calculation, you can take a house of 150 m2 from the previous example. If you heat it for about 6 months (175 days) a year, then the heat loss will be X = 150 × 175 × 24 × 0.7 × 70 = 30870 kW for the entire season or 177 kW per day. Accordingly, the consumption of pellets for the same period will be equal to M1 = 30870/5 = 6174 kg (season) and M2 = 177/5 = 36 kg (day).

Heating costs per month are calculated by multiplying the average daily consumption of pellets by the number of days and the price of pellets per 1 kg, i.e. 36 × 30 × 8.5 = 9180 rubles.

Fuel consumption, efficiency calculation

To assess the heat loss at home, there are many different methods that allow you to calculate the fuel consumption for heating it. But the point is that these methods are based on the use of SNiP and other regulations, but in practice the situation is different. If we take as a basis a dwelling with an area of 100 m², which is insulated in accordance with SNiP standards, then its energy loss under conditions of a minimum outside temperature usually does not exceed 100 W per 1 m² per hour. Thus, to compensate for energy losses, we need a heat source that produces 10 kW of thermal energy. This indicator does not depend on the heating system, but solely on the structure of the building. Suppose the heating season lasts 5 months (150 days).

During the heating season, temperature drops occur, there are both cold and warm periods. Therefore, we will take into account one more condition: the average energy loss of the room during the heating season will be half of the maximum - 5 kW / h.Therefore, for one day you will need 5 * 24 = 120 kW. Thus, for the heating season, our premises need: Q = 24 * 5 * 150 = 18000 kW. Burning 1 kg of pellets gives 5 kW. Fuel consumption for one day will be: 120/5 = 24 kg of pellets. This figure changes depending on weather conditions, house insulation, etc.

On average, for a 25 kW boiler, the consumption of pellets can be as follows:

- at an external temperature of -30 ° C - about 60 kg;

- at -20 ° C - about 40-50 kg;

- at -5 ° C - about 30 kg;

- at 0 ° C - about 22 kg;

- at + 5 ° С - about 18 kg.

However, to get an answer to the question about the efficiency and cost reduction of the heating process, it is better to compare the fuel consumption of different types. With information about the required heat, a simple table can be used to obtain the required data. (Fig. 3. Comparative table of fuel consumption of different types.).

When calculating, the height of the room was taken as 3 m, heat loss - 80 W / m², temperature 22 ° С. It is believed that when switching from diesel heating to pellet heating, the boiler will pay off in more than 1 year.

You can check whether the pellet boiler is working effectively by measuring the temperature of the gases at the outlet. The temperature in the range of 120-150 ° C is considered normal.

If it exceeds 160 ° C, then something is wrong with the boiler.

Price

The cost of pellet boilers with automatic fuel supply:

| Model name | power, kWt | Average price, rub. |

| ZOTA Pellet-15 S | 15 | 153 000 |

| FACI 15 | 15 | 146 000 |

| Kupper OK-9 + APG 25 | 9 | 101 000 |

| Biopellet P-15 | 15 | 171 000 |

| START-50-GR | 50 | 242 000 |

| ACV ECO Comfort 25 | 25 | 217 000 |

| Kiturami KRP-20 A | 30 | 236 000 |

Where to buy a pellet boiler with automatic feeding?

In Moscow

- Hermes, st. Bulatnikovskaya 20, office 17 from 9:00 to 18:00, tel. +7 (495) 384-19-66;

- Pechi-fireplaces, st. Jubilee 4-A from 9:00 to 18:00, tel. +7 (495) 215–56–94.

In St. Petersburg

- TechnoDom, 57 Stachek ave. from 10:00 to 19:00, tel. +7 (812) 671–00–88;

- TeploTorg, st. Anchor 10 from 9:30 to 18:00, tel. +7 (812) 612-40-02.

And in conclusion: an automatic pellet boiler, despite the fact that it is, of course, easier to maintain than many other options (for example, coal, wood, pyrolysis), still requires attention - both in terms of cleaning and the plan of the purchased fuel. These factors should be considered before buying.

Pellet boilers

The best option

A fully stocked boiler is a very expensive piece of equipment. Its cost starts from 100 thousand rubles, and for large objects it can cost more than a million. At the same time, making the installation yourself can also be too difficult.

In such a situation, the best solution would be to purchase a set: an automatic burner with a pellet tank and a feeding system. Such a kit can cost from 17 to 81 thousand rubles. and is intended for installation on a solid fuel stove already in the house (even a brick stove with a water jacket will do).

- No need to digest heating.

- Installation may take less than an hour.

- In the future, the pellet burner will not interfere with heating with the usual fuel - wood, coal or electricity.

- Cheaper than a full-fledged boiler, easier than a homemade version.

The installation method may differ, depending on the type and size of the boiler, but the essence of the work is to fix the burner instead of the door, or directly in the ash pan door:

- If the dimensions of the door do not match the burner, remove it and fit a metal adapter plate with a suitable hole.

- The hopper is assembled and installed next to the boiler.

- Then the auger is installed, and a flexible corrugation is connected to the burner.

- The control unit is connected (to the auger).

- A temperature sensor is connected from the heating pipes to the control unit.

- The unit is powered from the mains and settings are made.

Conclusion

It makes sense to install pellet boilers if pellets are available for heating. This type of fuel is easy to store - they do not smell, do not stain, do not explode, and do not generate dust. Pellets are safe - they do not emit as much harmful substances and slag during combustion as in the case of coal.

Modification of the finished boiler with a pellet installation will make the heating process simpler and more environmentally friendly. It will be necessary to load pellets into the bunker every three days (larger bins are filled every two weeks).

Despite the fact that during the construction of a private house, the owner has almost complete freedom in design, there are some premises that must necessarily comply with the SNIP standards. The boiler room is such a room. What are the requirements for a boiler room in a private house, you can find out on our website.

Whether it is worth heating a home with an induction boiler, read in this material. And also how to make the unit yourself.