One of the most popular models in the Baxi line is the Baxi Eco Four 24 gas boiler. The equipment can be with a closed or open combustion chamber. The power of the unit is 24 kW. The name indicates the letter "F" if the gas boiler has a closed combustion chamber and forced smoke removal. In apartments, turbocharged boilers from Baxi are most often used. Consider the structure of the expansion tank, breakdowns, pressure drop and how to fill the Baxi expansion tank with air.

Heat carrier in the heating system

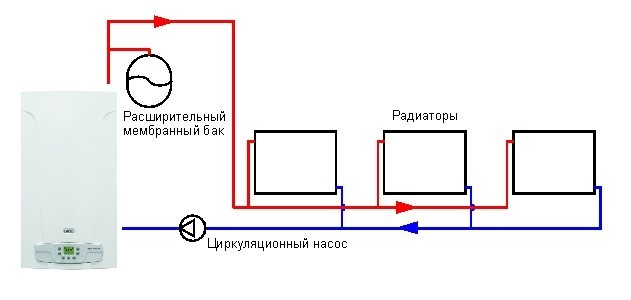

When installing a heating system, different options can be used. The most optimal is a closed heating system, in which the movement of the heat carrier is carried out using a circulation pump. In the primary heat exchanger, antifreeze is heated by a gas burner, and with the help of a pump it is pumped through a system of radiators, thus transferring heat to the room.

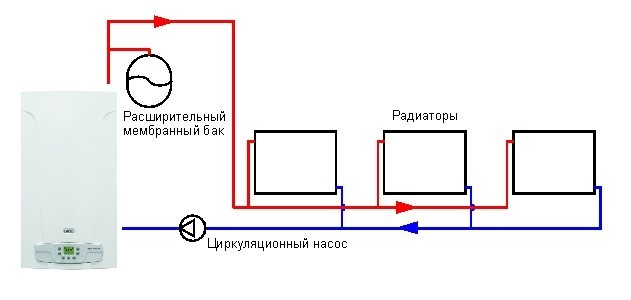

The heating system must be filled with water for proper circulation. When heated, the liquid begins to expand, so the increase in volume must be compensated. In connection with this, expansion tanks are installed in the heating system.

In this scheme, the gas boiler is only a heater. In the Baxi Eco Four, a circulation pump and an expansion tank are already built-in, so such equipment can be easily installed in small apartments.

Baxi expansion tank device

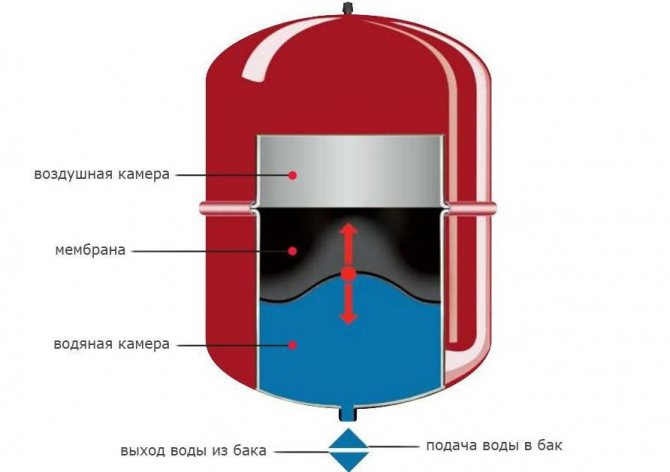

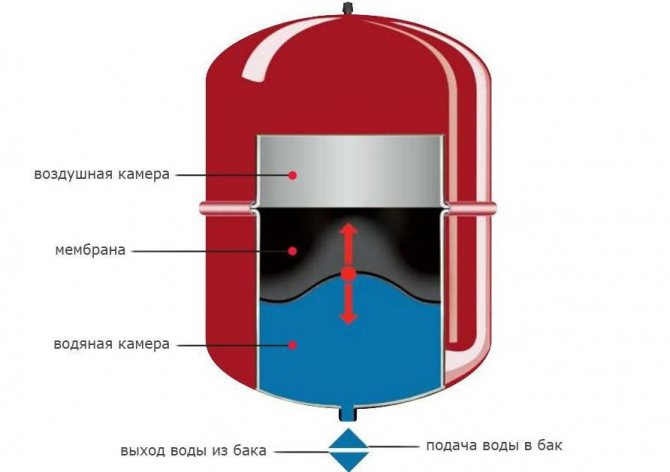

In the Baxi Eco Four 24 gas boiler, the expansion tank is located on the rear wall of the equipment and is a round red container. The built-in expansion tank has a volume of 6 liters and is divided into 2 parts by means of a membrane. Part 1 is pumped with air, and the second is connected to the heating system. When the system is heated, the volume of liquid increases and the resistance of the membrane is overcome, then the free volume of the tank is filled. After cooling, the membrane returns to the opposite position and pushes the liquid into the heating system. Consequently, the operating pressure remains unchanged.

The structure and location of the expansion tank BAXI

The baxi eco four 24 expansion tank is a round red tank located on the back of the boiler. The built-in expansion tank of the baxi with a volume of 6 liters is divided into two parts by an elastic membrane, one part is connected to the heating system, the other is pumped with air. Therefore, when the heating system heats up, the increasing volume of liquid overcomes the resistance of the membrane and fills the released volume of the tank, and when it cools down, the membrane tends to move to its original position and pushes the liquid back into the heating system. Thus, the pressure in the heating system during operation remains practically unchanged.

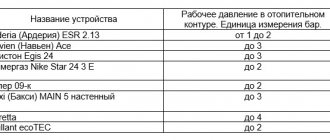

What is the normal pressure in the expansion tank of a Baxi double-circuit boiler

The instructions indicate the approximate pressure in the expansion tank - 0.5 bar. But this value is not entirely correct, since the pressure in the circuit should be 20% higher at room temperature of the heat carrier.

Many systems recommend filling pressures between 1.2 and 1.5 bar. Thus, the required pressure in the air cavity of the tank must be between 0.8 and 1 bar. Trained technicians generally recommend setting the expansion vessel pressure to 1 bar.

Setting indicators in a new expansion tank before starting the system

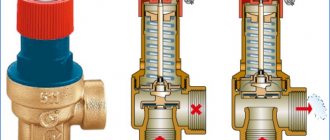

The diaphragm type tank is separated by a membrane.One of the halves is under pressure, air or nitrogen is pumped into it. You can clarify this parameter by looking at the documents for the tank. The pre (factory) pressure will not necessarily be optimal for the operation of the circuit. This parameter can be easily reconfigured. Manufacturers have foreseen this by leaving a spool in the body of its "air" part, with which it is possible to regulate the air pressure.

It should be borne in mind that all manometers show only excess pressure. That is, if in calculations it is necessary to use the concept of absolute pressure, then one atmosphere (bar) must always be added to the readings of the pressure gauge.

The initial pressure in the expansion tank is set 0.2 atm higher than the coolant pressure in the cold system, which is equal to the static pressure of the circuit. This head is defined as the distance in height between the top point of the contour and the middle of the expansion tank. For example, if the height of the heating system is 8 m (2 floors), then the statistical head will be equal to:

∆P = 0.8 atm (10 m = 1 atm), then the pressure in the membrane tank is calculated as follows:

∆P + 0.2 = 0.8 + 0.2 = 1.0 atm (bar).

Below are the consequences of an erroneous pressure setting:

Advice! The initial air pressure was adjusted correctly, but the safety valves of the heating system continue to operate. The volume of the expansion vessel may have been chosen too small. To avoid this, it is recommended to install a tank with a volume of at least 10% of the total volume of the coolant.

Why an expansion tank in a wall-mounted boiler Baxi

The gas boiler Baxi Eco Four 24 has a built-in expansion tank with a volume of 6 liters. Based on the total volume of the system, you can find out if an expansion tank is needed.

It is not difficult to make a calculation, since the filling volume of the radiators and the boiler is in the characteristics. If the diameter and total length are known, then the filling volume of the pipelines can be calculated.

If the water is heated to 80 degrees, then the volume will increase by about 5%. Thus, it is necessary to have an expansion tank with a volume of 8% of the total volume of the system when filled with water, as well as 12% when using antifreeze as a heat carrier. The built-in expansion tank will be enough for a heating system with a volume of no more than 75 liters when using water, and when using antifreeze - up to 50 liters.

These values are approximate. When choosing the volume of the expansion tank, calculations should be made for a specific system or follow the advice of the manufacturer.

In many cases, the built-in tank in Baxi gas boilers is sufficient. If necessary, an additional tank is selected when designing the system.

How to fill the expansion tank of a Baxi gas boiler with air

The expansion vessel may only be filled with air when the boiler is empty.

To do this, you need to perform the following actions:

- Close the heating system taps.

- Drain off the water through the drain cock.

- Pump up the tank to the required pressure.

- Close the drain cock.

- Feed the heating system through the make-up tap.

- Open the taps on the circuit.

In order to carry out maintenance, it is required to install a valve on the air cavity of the expansion tank. The valve is a common automotive nipple, so you can pump the tank of a Baxi gas boiler using a tire pump (electric or manual). The electric pump is convenient as it has a pressure gauge to monitor the pressure. You can pump up the system with a hand pump and check the pressure with a car pressure gauge. If the need arises, then you can play off the excess.

How to adjust the pressure in the expansion vessel?

The expansion tank has a spool mounted in the nipple for pumping or venting air. It is located on the side opposite to the connection point for the coolant. The tank nipple is very similar to the car nipple, so you can add pressure using a conventional auto pressure gauge pump. This can be done as follows:

- turn off the unit and wait about 8 minutes until the flow of the coolant completely stops;

- close the shut-off valves of the pipeline where the container is located and drain the water; at the tank built into the boiler, the supply and return are closed;

- open the nipple and connect the pump hose to it;

- pump air up to 1.5 atm and wait until all the liquid is poured from the container, then release oxygen;

- close the shut-off valves and pump up the pressure to the required pressure with a pump;

- remove the pump, put the cap on the nipple and close the drain connection;

- open the shut-off taps and draw water into the heating system;

- check the correct pressure in the tank.

When the unit reaches the operating parameters, the pressure gauge needle should not jump, but gain indicators smoothly.

The car pump pressure gauge is in MPa, not in bars. To find out how much MPa should be collected, it is taken as a basis that 1 Bar = 1 atm = 0.1 MPa.

Broken expansion tanks

The gas boiler must be serviced annually. Checking the pressure is included in the list of works. If you carry out all the checks in a timely manner, then no problems should arise. But if you do not carry out maintenance, there may be some problems:

- The expansion tank was not serviced and there is no pressure in it, the circuit pressure has a maximum permissible value. After the system cools down, the volume of liquid begins to decrease, and the decrease in pressure is not compensated by anything, therefore, the boiler stops working. Such a problem often arises due to the long operation of the gas boiler in the DHW mode or during a power outage.

- The pressure in the air chamber decreases, and with each make-up of the gas boiler, the tank is filled with water and eventually stops working. In addition, the membrane is pressed against the wall of the air part of the tank and can be damaged by the valve spool. In such a situation, you will have to replace the expansion tank.

- For no particular reason, some owners of gas boilers make make-up. For example, when using hot water, the pressure on the pressure gauge decreases and the boiler stops working by mistake. Since thermal expansion is not compensated for, the next time the heat carrier heats up, the excess pressure is relieved by means of a safety valve. Some people divert the discharge, and do not pay attention to this situation. But frequent replenishment of untreated water can lead to malfunction of the heat exchanger.

Expansion tanks for gas boilers: device and pressure regulation

Heating equipment is always designed for a certain pressure and head in the system. Gas boilers are no exception to this rule. Expansion tanks for gas boilers help them maintain the stability of the parameters.

The question of how these tanks should operate normally is associated either with operational irregularities or with the need for maintenance. The main purpose of using the cistern is to eliminate the expansion effect of the heating water. It becomes more and more, but the volume of pipes, radiators and storage tanks is finite. In closed heating circuits, filling is mandatory to 100%, and this means that the excess mass of the coolant must be dumped somewhere. The tank becomes a suitable place.

If suddenly there is no way out, the liquid will certainly find a way along which the excess will escape. This is usually the location of the safety valves, but it is more of an emergency equipment. Even if they work exactly as expected, you will have to eliminate the spilled water, re-fill (top up) the system. Installing the cisterns in advance helps prevent this from happening. And even with a boiling coolant, keep everything in perfect order.

Expansion tanks are tightly closed vessels, which are divided into two fragments using rubber membranes. This is not a simple rubber, as it must withstand significant heat, while remaining flexible and not losing strength.

Important: the pressure must be determined inside the air cavity entering the empty container, strictly at a temperature of 20 degrees. It is equal to the static pressure of the heating system filled to the limit. This condition makes it possible to achieve an equilibrium state of the membrane and compensate for the pressure exerted by the coolant.

That is, by the time of start-up, the tank will be completely empty, and its entire volume can be used to correct the thermal expansion of water or antifreeze. If the gas boiler sensor detects that the pressure in the heating system has dropped to 0.7 bar or less, it gives a command to turn off the heater. And the average value for normal operation is 1.2 bar. Since moving from a non-equilibrium position to an equilibrium one, the membrane can raise the pressure even more, its initial level for an empty tank is taken to be 0.3 bar (on average) higher than the standard for the heating system.

Conclusion: with a closed heating circuit with a gas boiler, the pressure should be from 0.8 to 1 bar; the parameters of any system deviating from the standards are calculated individually, taking into account:

- the estimated volume of water or antifreeze;

- Tank efficiency;

- its required value;

- starting pressure.

The tanks on Baxi double-circuit boilers, as follows from the instructions, must operate at a pressure of 0.5 bar. However, in reality, this indicator is minimal, and the same pressure of 0.8 - 1 bar allows to guarantee the normal functioning of the device. The built-in expander with a capacity of 6 liters works stably with heating systems with a capacity of 75 liters (on water). Or 50 liters (with antifreeze).

Whether it is necessary to use an additional expansion tank, or if the standard equipment is enough, only specialists decide at the time of project preparation.

It is very important to check the actual pressure in the expansion tanks. Hand-held pressure gauges are almost always used for this purpose, since most air chambers are equipped with standard nipples, like car or bicycle tires. The problem may arise if the boiler is wall-mounted. Compensating devices are most often located on its back wall, and it can be difficult to use them. The solution is to use a compact mobile pressure gauge.

As soon as a deviation of the indicator downward is detected, air should be properly pumped. Leaving everything as it is, you may encounter emergency boiler stops. It is even difficult to say whether this outcome is worse or the release of excess fluid.Every gas boiler manufacturer advises consumers to measure the pressure in the tank annually. There will be no harm, of course, if you do it twice as often.

It must be remembered that pumping is carried out only when the tank is completely empty; for this, the water must be drained from the boiler. The easiest way is to use a bicycle pump while monitoring the result through a hand-held pressure gauge.

The sequence of actions is as follows:

- the heating system taps are twisted;

- water is drained from the boiler;

- the tank is pumped to the desired pressure;

- the drain valve is closed;

- the heating circuit is saturated to the required level through the provided tap;

- the taps connecting the tank with the heating are opening.

It is not always possible to pump the expansion tank to the required number of atmospheres. People who strictly monitor the serviceability of equipment rarely encounter problems, of course. But carelessness or an irresponsible approach can present a number of troubles. Often, the pressure gradually decreases, and after a series of feeds to the boiler, the tank fails. It even goes so far that the membrane from being pressed against the wall is deformed by the spool.

In this case, repair is impossible, the expander can only be replaced completely. It also happens otherwise: the pressure in the heating circuit is at the maximum permissible level, and the tank was not serviced and remained without pressure. As soon as the heating system stops and begins to cool down, the liquid will be compressed, the pressure change will be impossible to correct. As a result, the boiler gets into an "accident". Problems of this kind can be triggered by prolonged use of the hot water heater or power outages.

Another likely scenario is that new water has to be supplied systematically and for no apparent reason. For example, the hot water circuit is working, and the pressure gauge shows a drop in pressure, the boiler stops working. Since the thermal expansion is not compensated for, the heating of the coolant leads to the discharge of its excess by the safety valves. If you do not notice this situation in time, you can face serious troubles. Therefore, it is required to pay maximum attention to the condition of the expansion tank, to regularly measure the pressure inside it.

The expander helps to absorb water hammer created by air locks and abrupt closing of the valve. The tanks will be able to perform this function if they are placed on the return flow of the coolant directly in front of the boiler. Do not assume that the factory set pressure will be ideal for practical needs. It is readjusted by a slide valve.

Important: when measuring the pressure in the expander, any pressure gauge registers only an excess value; to obtain an absolute figure, add 1 bar.

The pumped-over tank does not work well, since the air will push the coolant out. If everything is configured correctly, but the fuses continue to discharge water periodically, the problem is most likely in the unnecessarily small volume of the expander. Therefore, it is worth choosing tanks that hold 10% of the total coolant circulating in the system, or even more. Since the tank does not provide fittings for pressure gauges, they must be connected to the nipple. It is located on the side opposite to the contour filling the coolant.

Since car and bicycle pressure gauges measure pressure in MPa, you need to compare their readings with the pressure in the heating system (expressed in bar or kgf / sq. Cm). One bar equates to 100 kPa. When using a car meter, it is recommended to wait 10 minutes after turning off the boiler so that the circulation stops. When the tank is built into the boiler itself, it is supposed to shut off not only the shut-off valves, but also the supply of the coolant, and its return. By following these recommendations, you can significantly simplify your life.

For information on how to check the serviceability of the expansion tank, see the next video.

www.stroy-podskazka.ru

Pressure drop in the gas boiler Baxi when hot water is turned on

Often the pressure drops when hot water is turned on in a Baxi gas boiler. This problem occurs due to the low pressure of the expansion vessel. This is due to the fact that when the equipment is switched to the water heating mode, the circulation pump starts pumping liquid in a small circle through the secondary heat exchanger. At this time, the heating circuit stops heating, and the heat carrier cools down, the volume decreases and in the absence of compensating pressure in the tank, the heating system pressure drops and the e10 error appears on the boiler.

But with such a problem, the heat exchanger may be broken. In addition, water can enter the DHW system from the heating circuit. In order to carry out the check, it is required to stop the supply of cold water to the gas boiler and open the disassembly valve. If water comes out of the tap, then this is the heat carrier from the heating circuit and the heat exchanger must be replaced.

It should be remembered about the timely maintenance of the gas boiler, as it helps to avoid serious breakdowns, therefore, the service life of the entire heating system increases.