Calculation of heating a private house

Arrangement of housing with a heating system is the main component of creating comfortable temperature conditions in the house for living in it.

There are many elements in the piping of the thermal circuit, so it is important to pay attention to each of them. It is equally important to correctly calculate the heating of a private house, on which the efficiency of the heating unit, as well as its efficiency, largely depends. And how to calculate the heating system according to all the rules, you will learn from this article

And how to calculate the heating system according to all the rules, you will learn from this article.

- What is the heating unit made of?

- Heating element selection

- Determination of boiler output

- Calculation of the number and volume of heat exchangers

- What determines the number of radiators

- Formula and calculation example

- Pipeline heating system

- Installation of heating devices

We calculate the volume of the heating system using the formula

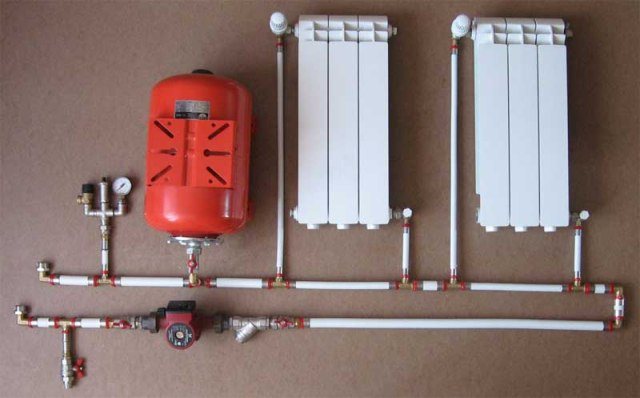

Before proceeding with the installation of a circulation pump or expansion tank, it is imperative to calculate the volume of the heating system and, of course, calculate the circulation pump for the heating system. To get the correct result, it is necessary to add up the volumes of all elements of the heating structure, namely the boiler, radiators and pipelines.

The formula for calculating the capacity of the heating system and its elements looks like this:

V = (VS x E): d, where

V - means the volume of the expansion tank; VS - the volume of the heating system, the calculation for which is done taking into account the boiler, pipeline, batteries and heat exchanger; E is the coefficient of expansion of the hot coolant; d - an indicator of the efficiency of the tank, which is planned to be installed in the heating structure.

Heating devices

How to calculate heating in a private house for individual rooms and select heating devices corresponding to this power?

The very method of calculating the heat demand for a separate room is completely identical to the one given above.

For example, for a room of 12 m2 with two windows in the house we have described, the calculation will look like this:

- The volume of the room is 12 * 3.5 = 42 m3.

- The basic thermal power will be 42 * 60 = 2520 watts.

- Two windows will add another 200 to it.2520 + 200 = 2720.

- The regional coefficient will double the heat demand. 2720 * 2 = 5440 watts.

How to convert the resulting value into the number of radiator sections? How to choose the number and type of heating convectors?

Manufacturers always indicate the heat output for convectors, plate radiators, etc. in the accompanying documentation.

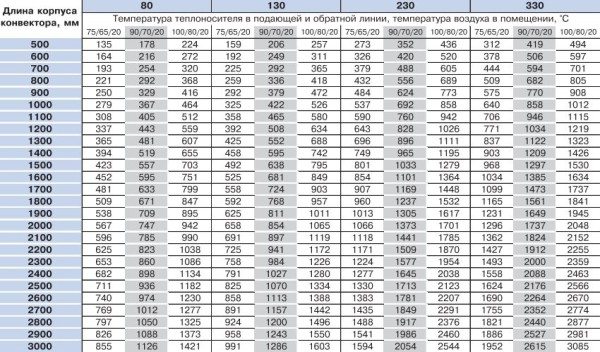

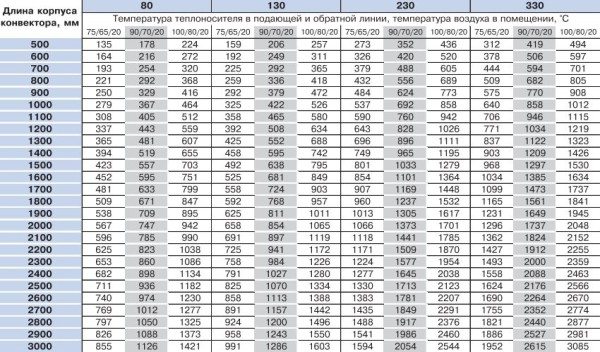

Power table for VarmannMiniKon convectors.

- For sectional radiators, the necessary information can usually be found on the websites of dealers and manufacturers. There you can often find a calculator for converting kilowatts in the section.

- Finally, if you use sectional radiators of unknown origin, with their standard size of 500 millimeters along the axes of the nipples, you can focus on the following averaged values:

Thermal power per section, watts

In an autonomous heating system with its moderate and predictable parameters of the coolant, aluminum radiators are most often used. Their reasonable price is very pleasantly combined with a decent appearance and high heat dissipation.

In our case, aluminum sections with a capacity of 200 watts will require 5440/200 = 27 (rounded off).

Placing so many sections in one room is not a trivial task.

As always, there are a couple of subtleties.

- With a lateral connection of a multi-section radiator, the temperature of the last sections is much lower than the first; accordingly, the heat flux from the heater falls. A simple instruction will help to solve the problem: connect the radiators according to the "bottom-down" scheme.

- Manufacturers indicate the heat output for a delta of temperatures between the coolant and the room at 70 degrees (for example, 90 / 20C). When it decreases, the heat flux will fall.

A special case

Often, homemade steel registers are used as heating devices in private houses.

Please note: they attract not only by their low cost, but also by their exceptional tensile strength, which is very useful when connecting a house to a heating main. In an autonomous heating system, their attractiveness is nullified by their unassuming appearance and low heat transfer per unit volume of the heater

Let's face it - not the height of aesthetics.

Nevertheless: how to estimate the thermal power of a register of a known size?

For a single horizontal round pipe, it is calculated by the formula of the form Q = Pi * Dн * L * k * Dt, in which:

- Q is the heat flow;

- Pi - number "pi", taken equal to 3.1415;

- Dн - outer diameter of the pipe in meters;

- L is its length (also in meters);

- k - coefficient of thermal conductivity, which is taken equal to 11.63 W / m2 * C;

- Dt is the delta temperature, the difference between the coolant and the air in the room.

In a multisection horizontal register, the heat transfer of all sections, except for the first one, is multiplied by 0.9, since they give off heat to the upward flow of air heated by the first section.

In a multi-section register, the lower section gives off the most heat.

Let's calculate the heat transfer of a four-section register with a section diameter of 159 mm and a length of 2.5 meters at a coolant temperature of 80 C and an air temperature in the room of 18 C.

- The heat transfer of the first section is 3.1415 * 0.159 * 2.5 * 11.63 * (80-18) = 900 watts.

- The heat transfer of each of the other three sections is 900 * 0.9 = 810 watts.

- The total thermal power of the heater is 900+ (810 * 3) = 3330 watts.

Heating system liquid volume calculator

Pipes of various diameters can be used in the heating system, especially in collector circuits. Therefore, the volume of liquid is calculated using the following formula:

S (cross-sectional area of the pipe) * L (pipe length) = V (volume)

The volume of water in the heating system can also be calculated as the sum of its components:

V (heating system) =V(radiators) +V(pipes) +V(boiler) +V(expansion tank)

Taken together, these data allow you to calculate most of the volume of the heating system. However, in addition to pipes, there are other components in the heating system. To calculate the volume of the heating system, including all important components of the heating supply, use our online calculator for the volume of the heating system.

Calculating with a calculator is very easy. It is necessary to enter in the table some parameters regarding the type of radiators, the diameter and length of the pipes, the volume of water in the collector, etc. Then you need to click on the "Calculate" button and the program will give you the exact volume of your heating system.

You can check the calculator using the above formulas.

An example of calculating the volume of water in the heating system:

An approximate calculation is made based on the ratio of 15 liters of water per 1 kW of boiler power. For example, the power of the boiler is 4 kW, then the volume of the system is 4 kW * 15 liters = 60 liters.

Choice of coolant

Most often, water is used as a working fluid for heating systems. However, antifreeze can be an effective alternative solution. Such a liquid does not freeze when the ambient temperature drops to a critical mark for water. Despite the obvious advantages, the price of antifreeze is quite high.Therefore, it is used mainly for heating buildings of insignificant area.

Filling heating systems with water requires preliminary preparation of such a coolant. The liquid must be filtered to remove dissolved mineral salts. For this, specialized chemicals that are commercially available can be used. Moreover, all air must be removed from the water in the heating system. Otherwise, the efficiency of space heating may decrease.

Calculation of the volume of radiators and heating batteries

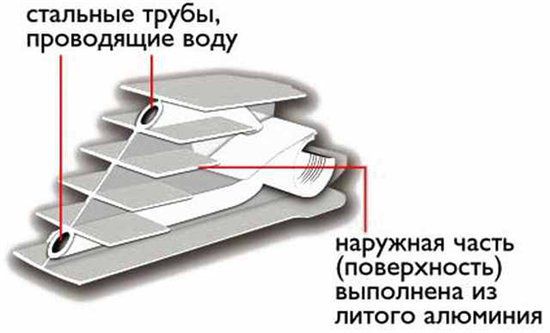

Sectional bimetal heating radiator

To perform an accurate calculation, you need to know the volume of water in the heating radiator. This indicator directly depends on the design of the component, as well as its geometric parameters.

As well as when calculating the volume of a heating boiler, the liquid does not fill the entire volume of the radiator or battery. For this, the structure has special channels through which the coolant flows. The correct calculation of the volume of water in the heating radiator can be performed only after obtaining the following device parameters:

- Center-to-center distance between direct and return pipelines to the battery. It can be 300, 350 or 500 mm;

- Manufacturing material. In cast iron models, the hot water filling is much greater than in bimetallic or aluminum;

- The number of sections in the battery.

It is best to find out the exact volume of water in the heating radiator from the technical data sheet. But if this is not possible, you can take into account the approximate values. The greater the center-to-center distance of the battery, the larger the volume of the coolant will fit in it.

| Center distance | Cast iron batteries, volume l. | Aluminum and bimetallic radiators, volume l. |

| 300 | 1,2 | 0,27 |

| 350 | 0,3 | |

| 500 | 1,5 | 0,36 |

To calculate the total volume of water in a heating system with metal panel radiators, you should find out their type. Their capacity depends on the number of heating planes - from 1 to 2:

- For 1 type of battery, for every 10 cm, there is 0.25 of the volume of the coolant;

- For type 2, this indicator increases to 0.5 liters per 10 cm.

The result obtained must be multiplied by the number of sections or the total length of the radiator (metal).

To correctly calculate the volume of a heating heating system with designer radiators of a non-standard shape, the above method cannot be used. Their volume can only be found out from the manufacturer or his official representative.

Calculating the volume of water in the heating system with an online calculator

Each heating system has a number of significant characteristics - nominal thermal power, fuel consumption and the volume of the coolant. Calculation of the volume of water in the heating system requires an integrated and scrupulous approach. So, you can find out which boiler, what power to choose, determine the volume of the expansion tank and the required amount of liquid to fill the system.

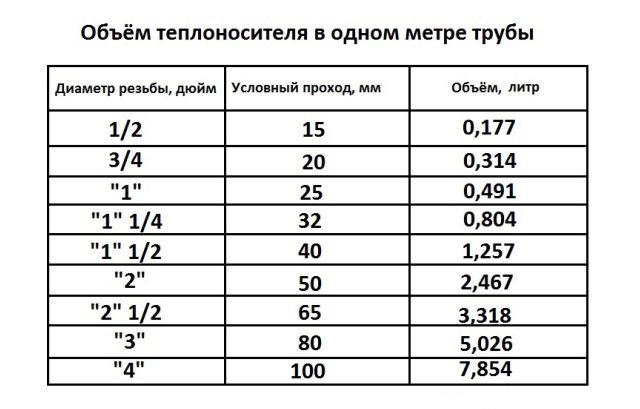

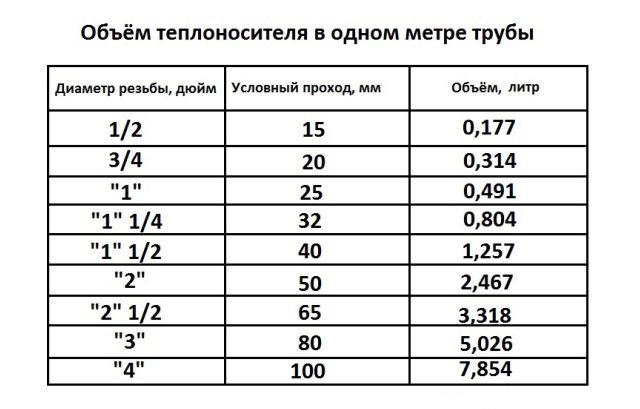

A significant part of the liquid is located in pipelines, which occupy the largest part in the heat supply scheme.

Therefore, to calculate the volume of water, you need to know the characteristics of the pipes, and the most important of them is the diameter, which determines the capacity of the liquid in the line.

If the calculations are made incorrectly, then the system will not work efficiently, the room will not warm up at the proper level. An online calculator will help to make the correct calculation of volumes for the heating system.

Heating system liquid volume calculator

Pipes of various diameters can be used in the heating system, especially in collector circuits. Therefore, the volume of liquid is calculated using the following formula:

The volume of water in the heating system can also be calculated as the sum of its components:

Taken together, these data allow you to calculate most of the volume of the heating system. However, in addition to pipes, there are other components in the heating system.To calculate the volume of the heating system, including all important components of the heating supply, use our online calculator for the volume of the heating system.

Advice

Calculating with a calculator is very easy. It is necessary to enter in the table some parameters regarding the type of radiators, the diameter and length of the pipes, the volume of water in the collector, etc. Then you need to click on the "Calculate" button and the program will give you the exact volume of your heating system.

You can check the calculator using the above formulas.

An example of calculating the volume of water in the heating system:

The values of the volumes of various components

Radiator water volume:

- aluminum radiator - 1 section - 0.450 liters

- bimetallic radiator - 1 section - 0.250 liters

- new cast iron battery 1 section - 1,000 liters

- old cast iron battery 1 section - 1,700 liters.

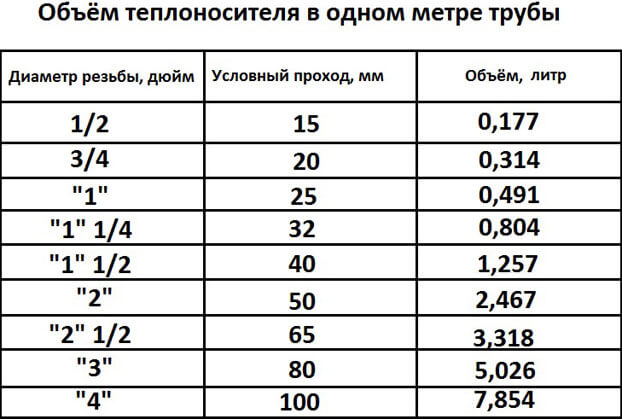

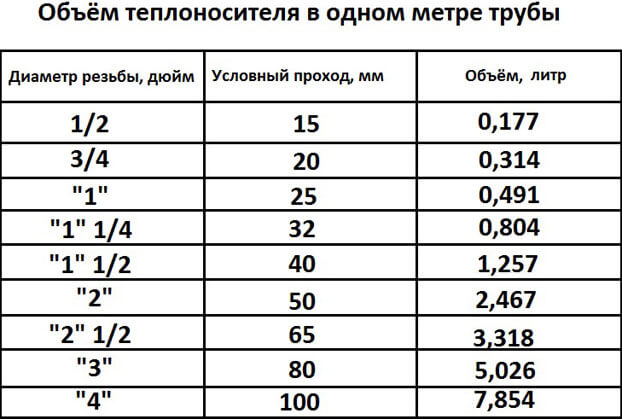

The volume of water in 1 running meter of the pipe:

- ø15 (G ½ ") - 0.177 liters

- ø20 (G ¾ ") - 0.310 liters

- ø25 (G 1.0 ″) - 0.490 liters

- ø32 (G 1¼ ") - 0.800 liters

- ø15 (G 1½ ") - 1.250 liters

- ø15 (G 2.0 ″) - 1.960 liters.

To calculate the entire volume of liquid in the heating system, you also need to add the volume of the coolant in the boiler. These data are indicated in the accompanying passport of the device, or take approximate parameters:

- floor boiler - 40 liters of water;

- wall-mounted boiler - 3 liters of water.

The choice of a boiler directly depends on the volume of liquid in the heat supply system of the room.

The main types of coolants

There are four main types of fluid used to fill heating systems:

- Water is the simplest and most affordable heat carrier that can be used in any heating systems. Together with polypropylene pipes that prevent evaporation, water becomes an almost eternal heat carrier.

- Antifreeze - this coolant will cost more than water, and is used in systems of irregularly heated rooms.

- Alcohol-based heat transfer fluids are an expensive option for filling a heating system. A high-quality alcohol-containing liquid contains from 60% alcohol, about 30% water and about 10% of the volume are other additives. Such mixtures have excellent antifreeze properties, but are flammable.

- Oil - is used as a heat carrier only in special boilers, but it is practically not used in heating systems, since the operation of such a system is very expensive. Also, the oil heats up for a very long time (warming up to at least 120 ° C is required), which is technologically very dangerous, while such a liquid cools down for a very long time, maintaining a high temperature in the room.

In conclusion, it should be said that if the heating system is being modernized, pipes or batteries are installed, then it is necessary to recalculate its total volume, according to the new characteristics of all elements of the system.

How to calculate consumption

The value is the amount of heating medium in kilogramswhich is spent per second... It is used to transfer temperature to a room through radiators. To calculate, you need to know the boiler consumption, which is consumed to heat one liter of water.

Formula:

G = N / Qwhere:

- N - boiler power, Tue

- Q - warmth, J / kg.

The value is converted in kg / hour, multiplying by 3600.

Formula for calculating the required volume of liquid

Re-filling of pipes is required after repair or rebuilding of piping. To do this, find the amount of water required by the system.

Usually it is enough to collect passport data and add them. But you can also find it manually. For this consider the length and section of the pipes.

The numbers are multiplied and added to the batteries. Volume of sections the radiator is:

- Aluminum, steel or alloy - 0.45 l.

- Cast iron - 1.45 l.

And there is also a formula by which you can roughly determine the total amount of water in the piping:

V = N * VkWwhere:

- N - boiler power, Tue

- VkW- the volume, which is enough to transfer one kilowatt of heat, dm3.

This allows you to calculate only an approximate number, therefore it is better to check the documents.

For a complete picture, you also need to calculate the volume of water held by the other components of the piping: an expansion tank, a pump, etc.

Attention! Especially important tank: is he compensates for pressure, which rises due to the expansion of the liquid when heated.

First of all, you need to decide on the substance used:

- water has an expansion coefficient 4%;

- ethylene glycol — 4,5%;

- other liquids are used less frequently, so look for data in a look-up table.

Formula for calculation:

V = (Vs * E) / Dwhere:

- E Is the coefficient of expansion of the liquid indicated above.

- Vs - the estimated consumption of the entire strapping, m3.

- D - the efficiency of the tank, indicated in the passport of the device.

Having found these values, they need to be summed up. Usually it turns out four indicators of volume: pipes, radiators, heater and tank.

Using the data obtained, you can create a heating system and fill it with water. The filling process depends on the scheme:

- "By gravity" performed from the highest point of the pipeline: insert a funnel and let the liquid in. This is done slowly, evenly. Beforehand, the tap is opened at the bottom, and the container is substituted. This helps to avoid the formation of air pockets. Applies if there is no forced current.

- Forced - requires a pump. Anyone will do, although it is better to use a circulating one, which is then used in heating. During the process, you need to take readings of the pressure gauge to avoid pressure build-up. And also be sure to open the air valves, which helps with the release of gas.

How to calculate the minimum flow rate of the coolant

Calculated in the same way as fluid costs per hour for space heating.

It is found in between heating seasons as a number that depends on hot water supply. Exists two formulasused in the calculations.

If the system no forced DHW circulation, or it is disabled due to the frequency of work, then the calculation is performed taking into account the average consumption:

Gmin = $ * Qgav / [(Tp - Tob3) * C]where:

Qgav - the average value of the heat transmitted by the system per hour of work in the non-heating season, J.

$ - coefficient of change in water consumption in summer and winter. It is taken accordingly equal 0.8 or 1.0.

Tp - the temperature in the flow.

Tob3 - in the return line with parallel connection of the heater.

C - heat capacity of water, taken equal to 10-3, J / ° C.

The temperatures are taken to be equal respectively 70 and 30 degrees Celsius.

If there compulsory DHW circulation or taking into account water heating at night:

Gmin = Qtsg / [(Tp - Tob6) * C], Where:

Qtsg - heat consumption for heating the liquid, J.

The value of this indicator is taken equal to (Ktp * Qgsr) / (1 + Ktp), Where Ktp Is the coefficient of heat loss by pipes, and Qgav - average indicator of power consumption for water at one o'clock.

Tp - supply temperature.

Tob6 - return flow measured after the boiler circulating liquid through the system. It is equal to five plus the minimum allowable at the point of draw-off.

Experts take the numerical value of the coefficient Ktpfrom the following table:

| Types of DHW systems | Loss of water by the coolant | |

| Including heating networks | Without them | |

| With insulated risers | 0,15 | 0,1 |

| Insulated and towel dryers | 0,25 | 0,2 |

| Without insulation, but with dryers | 0,35 | 0,3 |

Important! The calculation of the minimum flow rate can be found in more detail in building codes 2.04.01-85.

Antifreeze parameters and types of coolants

The basis for the production of antifreeze is ethylene glycol or propylene glycol. In their pure form, these substances are very aggressive media, but additional additives make antifreeze suitable for use in heating systems.The degree of anticorrosion resistance, service life and, accordingly, the final cost depend on the additives introduced.

The main task of the additives is to protect against corrosion. Having a low thermal conductivity, the rust layer becomes a heat insulator. Its particles contribute to the clogging of the channels, disable the circulation pumps, and lead to leaks and damage in the heating system.

Moreover, the narrowing of the inner diameter of the pipeline entails hydrodynamic resistance, due to which the speed of the coolant decreases, and energy consumption increases.

Antifreeze has a wide temperature range (from -70 ° C to + 110 ° C), but by changing the proportions of water and concentrate, a liquid with a different freezing point can be obtained. This allows you to use intermittent heating and only turn on space heating when needed. As a rule, antifreeze is offered in two types: with a freezing point of no more than -30 ° C and no more than -65 ° C.

In industrial refrigeration and air conditioning systems, as well as in technical systems with no special environmental requirements, antifreeze based on ethylene glycol with anti-corrosion additives is used. This is due to the toxicity of the solutions. For their use, expansion tanks of a closed type are required; use in double-circuit boilers is not allowed.

A solution based on propylene glycol obtained other possibilities of application. It is an environmentally friendly and safe composition that is used in food, perfumery and residential buildings. Wherever it is required to prevent the possibility of toxic substances entering the soil and groundwater.

The next type is triethylene glycol, which is used at high temperature conditions (up to 180 ° C), but its parameters are not widely used.

Coolant requirements

You need to immediately understand that there is no ideal coolant. Those types of coolants that exist today can perform their functions only in a certain temperature range. If you go beyond this range, then the characteristics of the quality of the coolant can change dramatically.

The heat carrier for heating must have such properties that will allow for a certain unit of time to transfer as much heat as possible. The viscosity of the coolant largely determines what effect it will have on the pumping of the coolant throughout the heating system for a specific time interval. The higher the viscosity of the coolant, the better characteristics it has.

Physical properties of coolants

The coolant should not have a corrosive effect on the material from which pipes or heating devices are made.

If this condition is not met, then the choice of materials will become more limited. In addition to the above properties, the coolant must also have lubricating properties. The choice of materials that are used for the construction of various mechanisms and circulation pumps depends on these characteristics.

In addition, the coolant must be safe based on such characteristics as: ignition temperature, release of toxic substances, flash of vapors. Also, the coolant should not be too expensive, studying the reviews, you can understand that even if the system works efficiently, it will not justify itself from a financial point of view.

A video about how the system is filled with coolant and how the coolant is replaced in the heating system can be viewed below.

Calculation of water consumption for heating Heating system

»Heating calculations

The heating design includes a boiler, a connection system, air supply, thermostats, manifolds, fasteners, an expansion tank, batteries, pressure-increasing pumps, pipes.

Any factor is definitely important. Therefore, the choice of installation parts must be done correctly.On the open tab, we will try to help you choose the necessary installation parts for your apartment.

The heating installation of the mansion includes important devices.

Page 1

The estimated flow rate of network water, kg / h, to determine the diameters of pipes in water heating networks with high-quality regulation of heat supply should be determined separately for heating, ventilation and hot water supply according to the formulas:

for heating

(40)

maximum

(41)

in closed heating systems

average hourly, with a parallel circuit for connecting water heaters

(42)

maximum, with a parallel circuit for connecting water heaters

(43)

average hourly, with two-stage connection schemes for water heaters

(44)

maximum, with two-stage connection schemes for water heaters

(45)

Important

In formulas (38 - 45), the calculated heat fluxes are given in W, the heat capacity c is taken equal. These formulas are calculated in stages for temperatures.

The total estimated consumption of network water, kg / h, in two-pipe heating networks in open and closed heat supply systems with high-quality regulation of heat supply should be determined by the formula:

(46)

Coefficient k3, taking into account the share of the average hourly water consumption for hot water supply when regulating the heating load, should be taken according to table No. 2.

Table 2. Coefficient values

r-Radius of a circle equal to half the diameter, m

Q-flow rate of water m 3 / s

D-Internal pipe diameter, m

V-speed of the coolant flow, m / s

Resistance to the movement of the coolant.

Any coolant moving inside the pipe strives to stop its movement. The force that is applied to stop the movement of the coolant is the resistance force.

This resistance is called pressure loss. That is, the moving heat carrier through a pipe of a certain length loses pressure.

The head is measured in meters or in pressures (Pa). For convenience, it is necessary to use meters in the calculations.

Sorry, but I'm used to specifying head loss in meters. 10 meters of water column create 0.1 MPa.

In order to better understand the meaning of this material, I recommend following the solution of the problem.

Objective 1.

In a pipe with an inner diameter of 12 mm, water flows at a speed of 1 m / s. Find the expense.

Decision:

You must use the above formulas:

Examples of calculations

Specific examples, which interested visitors should familiarize themselves with, will provide significant assistance in understanding the principles of calculations and the sequence of actions when performing calculations.

Calculation of the volume of the required coolant

For a country house for temporary residence, you need to calculate the volume of purchased propylene glycol - a coolant that does not solidify at temperatures down to -30 ° C. The heating system consists of a 60 liter jacketed stove, four aluminum radiators of 8 sections each and 90 meters of PN25 pipe (20 x 3.4).

Pipes of the PN25 20 x 3.4 standard are most often used to organize a small heating circuit with a series connection of radiators. Its inner diameter is 13.2 mm.

The volume of liquid in the pipe must be calculated in liters. To do this, take the decimeter as the unit of measurement. The formulas for the transition from standard lengths are as follows: 1 m = 10 dm and 1 mm = 0.01 dm.

The volume of the boiler jacket is known. V1 = 60 HP

The passport of the Elegance EL 500 aluminum radiator indicates that the volume of one section is 0.36 liters. Then V2 = 4 x 8 x 0.36 = 11.5 liters.

Let's calculate the total volume of pipes. Their inner diameter d = 20 - 2 x 3.4 = 13.2 mm = 0.132 dm. Length l = 90 m = 900 dm. Hence:

V3 = π x l x d2 / 4 = 3.1415926 x 900 x 0.132 x 0.132 / 4 = 12.3 dm3 = 12.3 l.

Thus, the total volume can now be found:

V = V1 + V2 + V3 = 60 + 11.5 + 12.3 = 83.8 liters.

The percentage of the amount of liquid in the pipes in relation to the entire system is only 15%. But if the length of the communications is large or if the “water heat-insulated floor” system is used, then the contribution of pipes to the total volume increases significantly.

In industrial and agricultural facilities, home-made heating radiators are often installed, arranged according to the type of registers. Knowing the dimensions of the pipes, you can calculate their volume

Calculating the volume of a homemade radiator from pipes

Let's figure out how to calculate a classic homemade heating radiator from four horizontal pipes 2 m long.First you need to find the cross-sectional area. You can measure the outer diameter from the end of the product.

Let it be 114 mm. Using the table of standard parameters of steel pipes, we find the wall thickness typical for this size - 4.5 mm.

Let's calculate the inner diameter:

d = 114 - 2 x 4.5 = 105 mm.

Determine the cross-sectional area:

S = π x d2 / 4 = 8659 mm2.

The total length of all fragments is 8 m (8000 mm). Let's find the volume:

V = l x S = 8000 x 8659 = 69272000 mm3.

The volume of the vertical connecting pipes can be calculated in the same way. But this value can be neglected, since it will be less than 0.1% of the total volume of the heating radiator.

The resulting value is not informative, so let's convert it to liters. Since 1 dm = 100 mm, then 1 dm3 = 100 x 100 x 100 = 1,000,000 = 106 mm3.

Therefore, V = 69272000/106 = 69.3 dm3 = 69.3 l.

Large radiators or heating systems (which are installed, for example, on farms) require significant amounts of coolant.

Therefore, since it will be necessary to calculate the volume of pipes in m3, then all dimensions, before substituting them into the formula, will have to be immediately converted into meters.

Calculation of the required length of PP pipes

You can get the value of the fragment length using an ordinary ruler or tape measure. Minor bends and sagging of polymer pipes can be neglected, as they will not lead to a serious final error.

With such a curvature of polymer pipes, their length will be much greater (by 10-15%) than the length of the section along which they are laid

To be accurate, it is much more important to correctly determine the beginning and end of the fragment:

- When connecting a pipe to a riser, you need to measure the length from the beginning of the horizontal fragment. It is not necessary to grab the adjoining part of the riser, as this will lead to double counting of the same volume.

- At the entrance to the battery, you need to measure the length up to its tubes by gripping the taps. They are not taken into account when determining the volume of the radiator according to its passport data.

- At the entrance to the boiler, it is necessary to measure from the jacket, taking into account the length of the outgoing pipes.

Roundings can be measured in a simplified way - assume that they are at right angles. This method is permissible, since their total contribution to the length of the pipes is insignificant.

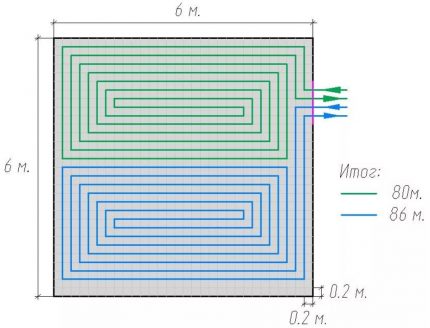

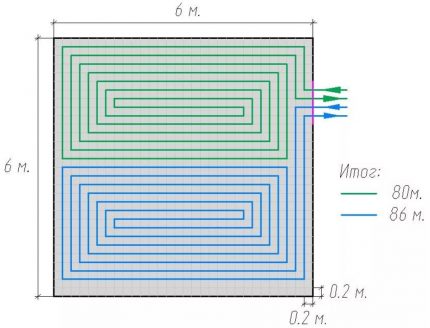

If there is a layout for the heated floor, you can calculate the length of the tubes with the coolant according to the plan with the application of a scale grid on it

The volume of the underfloor heating is calculated by the footage of installed pipes.

If there is no data on the length or a diagram, but the pitch between the tubes is known, then the calculation can be carried out using the following approximate formula (regardless of the method of laying):

l = (n - k) * (m - k) / k

Here:

- n is the length of the heated floor section;

- m is the width of the heated floor area;

- k is the step between the tubes;

- l is the total length of the tubes.

Despite the small cross-section of pipes that are used for a water-heated floor, their total length leads to a significant volume of the contained coolant.

So, to provide a system similar to the one in the above figure (length - 160 m, outer diameter - 20 mm), 26 liters of fluid will be needed.

Obtaining the result by an experimental method

- In practice, problematic situations arise when the hydraulic system has a complex structure or some of its fragments are laid in a hidden way. In this case, it becomes impossible to determine the geometry of its parts and calculate the total volume. Then the only way out is to conduct an experiment.

Using a collector and laying pipes under a screed is an advanced method for secretly supplying hot water to heating radiators. It is impossible to accurately calculate the length of communications in the absence of a plan

It is necessary to drain all the liquid, take a measuring container (for example, a bucket) and fill the system to the desired level. Filling takes place through the highest point: an open-type expansion tank or an upper drain valve. In this case, all other valves must be open to avoid the formation of air pockets.If the movement of water along the circuit is carried out by a pump, then you need to give it an hour or two to work without heating the coolant. This will help flush out any residual air pockets. After that, you need to add fluid to the circuit again.

This method can also be used for individual parts of the heating circuit, for example, underfloor heating.To do this, you need to disconnect it from the system and “spill” it in the same way.

Advantages and disadvantages of water

The undoubted advantage of water is the highest heat capacity among other liquids. It requires a significant amount of energy to heat it, but at the same time it allows you to transfer a considerable amount of heat during cooling. As the calculation shows, when 1 liter of water is heated to a temperature of 95 ° C and cooled to 70 ° C, 25 kcal of heat will be released (1 calorie is the amount of heat required to heat 1 g of water per 1 ° C).

Water leakage during depressurization of the heating system will not have a negative impact on health and well-being. And in order to restore the initial volume of the coolant in the system, it is enough to add the missing amount of water to the expansion tank.

The disadvantages include freezing of water. After starting the system, constant monitoring of its smooth operation is required. If it becomes necessary to leave for a long time or for some reason the supply of electricity or gas is interrupted, then you will have to drain the coolant from the heating system. Otherwise, at low temperatures, freezing, the water will expand and the system will rupture.

The next drawback is the ability to cause corrosion in the internal components of the heating system. Water that is not properly prepared can contain increased levels of salts and minerals. When heated, this contributes to the appearance of precipitation and the build-up of scale on the walls of the elements. All this leads to a decrease in the internal volume of the system and a decrease in heat transfer.

To avoid this disadvantage or to minimize it, they resort to purifying and softening water, introducing special additives into its composition, or using other methods.

Boiling is the simplest and most familiar way to everyone. During processing, a significant part of the impurities will be deposited in the form of scale at the bottom of the container.

Using a chemical method, a certain amount of slaked lime or soda ash is added to the water, which will lead to the formation of a sludge. After the end of the chemical reaction, the precipitate is removed by filtration of water.

There are fewer impurities in rain or melt water, but for heating systems, the best option would be distilled water, in which these impurities are completely absent.

If there is no desire to deal with the shortcomings, then you should think about an alternative solution.

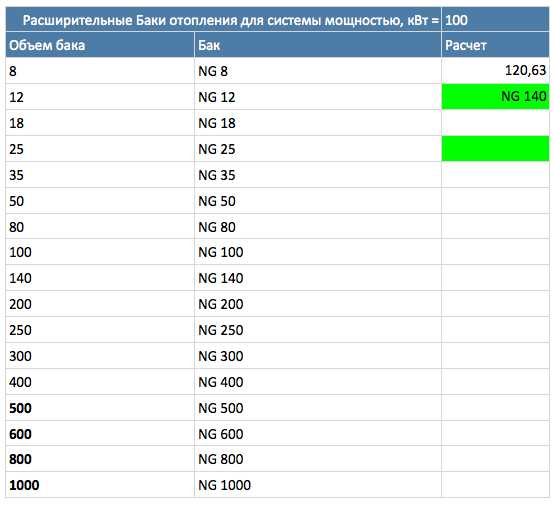

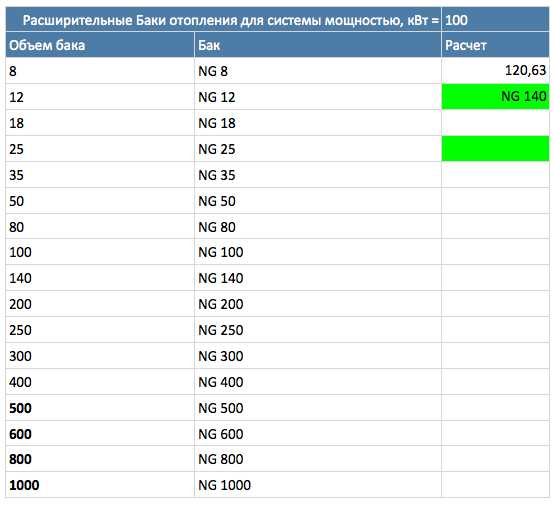

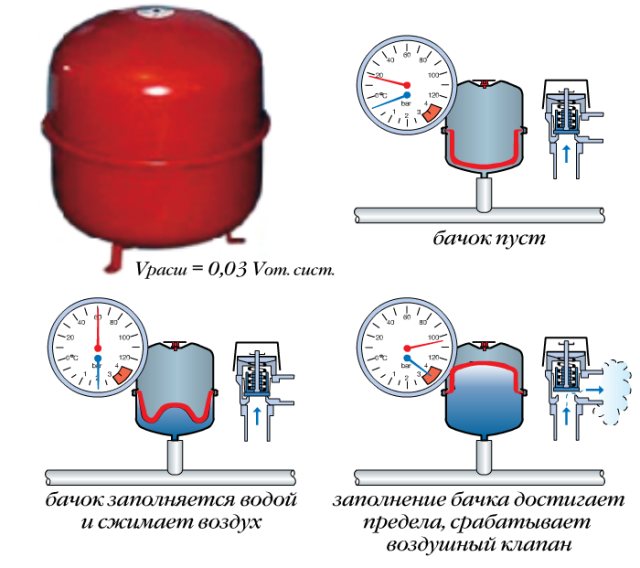

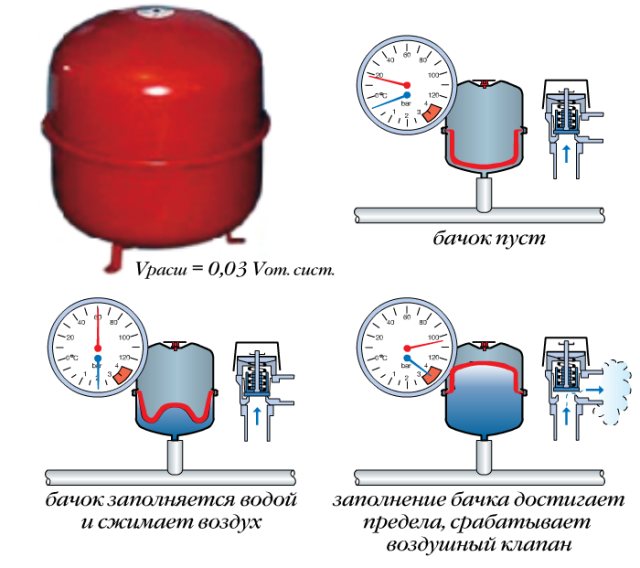

Expansion tank

And in this case, there are two calculation methods - simple and accurate.

Simple circuit

A simple calculation is utterly simple: the volume of the expansion tank is taken equal to 1/10 of the volume of the coolant in the circuit.

Where to get the value of the volume of the coolant?

Here are a couple of the simplest solutions:

- Fill the circuit with water, bleed air, and then drain all the water through a vent into any measuring container.

- In addition, the rough volume of a balanced system can be calculated at the rate of 15 liters of coolant per kilowatt of boiler power. So, in the case of a 45 kW boiler, the system will have approximately 45 * 15 = 675 liters of coolant.

Therefore, in this case, a reasonable minimum would be an expansion tank for the heating system of 80 liters (rounded up to the standard value).

Standard volumes of expansion tanks.

Exact scheme

More precisely, you can calculate the volume of the expansion tank with your own hands using the formula V = (Vt x E) / D, in which:

- V is the desired value in liters.

- Vt is the total volume of the coolant.

- E is the coefficient of expansion of the coolant.

- D is the efficiency factor of the expansion tank.

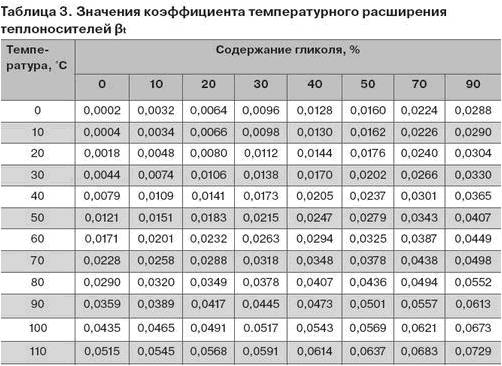

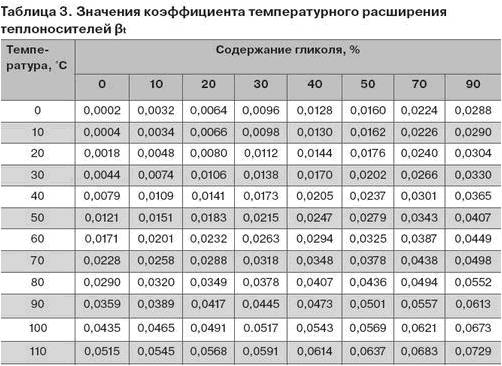

The expansion coefficient of water and poor water-glycol mixtures can be taken from the following table (when heated from an initial temperature of +10 C):

And here are the coefficients for coolants with a high glycol content.

The tank efficiency factor can be calculated using the formula D = (Pv - Ps) / (Pv + 1), in which:

Pv - maximum pressure in the circuit (pressure relief valve).

Hint: usually it is taken equal to 2.5 kgf / cm2.

Ps - static pressure of the circuit (it is also the pressure of the tank charging). It is calculated as 1/10 of the difference in meters between the level of the tank location and the top point of the circuit (an excess pressure of 1 kgf / cm2 raises the water column by 10 meters). A pressure equal to Ps is generated in the tank air chamber before filling the system.

Let's calculate the tank requirements for the following conditions as an example:

- The difference in height between the tank and the top point of the contour is 5 meters.

- The power of the heating boiler in the house is 36 kW.

- The maximum water heating is 80 degrees (from 10 to 90C).

- The efficiency factor of the tank will be (2.5-0.5) / (2.5 + 1) = 0.57.

Instead of calculating the coefficient, you can take it from the table.

- The volume of the coolant at the rate of 15 liters per kilowatt is 15 * 36 = 540 liters.

- The expansion coefficient of water when heated to 80 degrees is 3.58%, or 0.0358.

- Thus, the minimum tank volume is (540 * 0.0358) / 0.57 = 34 liters.

Calculation of an expansion tank for a closed type of heating

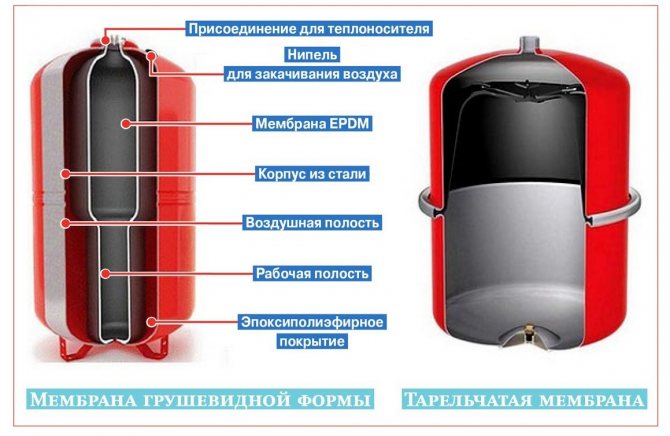

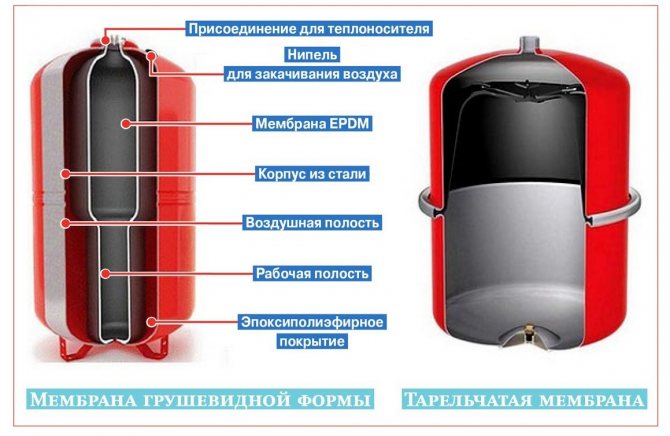

Special containers are used to compensate for the increase in the coolant with increasing temperature. A membrane tank is installed in a closed heating system.

Diaphragm tank for closed system

Below are the features of a typical design with the purpose of typical functional components:

- a flexible sealed partition divides the working volume into two parts;

- one - through a pipe connected to the heat supply line;

- air is pumped into the other under the required pressure;

- corrosion-resistant materials are used to create the body;

- fixation in the horizontal position of large models is provided by the stand.

The diaphragm expansion tank is installed in any place convenient for users. Ensure easy access for service. Using the built-in fitting with a valve, add (bleed) air, creating the required pressure.

The calculation of the expansion tank for a closed heating system begins with determining the amount of liquid in the system. The most accurate data can be obtained at the filling stage. A sequential addition of the capacities of pipelines, radiators, and other components is also used.

To calculate the total volume of the coolant quickly, specialized specialists often use approximate proportions.

Below are the values (in liters) per 1 kW of boiler power when connecting different types of equipment:

- steel convectors (6-8);

- aluminum, cast iron radiators (10-11);

- warm floor (16-18).

If a combination of different heating devices is used for heating a private house, take 15 l / 1 kW. With a gas boiler power of 7.5 kW, the following calculation result will be obtained: 7.5 * 15 = 112.5 liters.

The suitable size of the expansion vessel for closed heating depends on several parameters:

- the total volume of the water supply system and connected devices;

- type of coolant;

- maximum pressure;

- temperature conditions.

When the heating system is filled with water, the volume increases by 4% as the temperature rises from 0 C to +95 C. To prevent freezing in winter, the coolant is supplemented with ethylene glycol.

This mixture expands 10% more than the example discussed above (4.4%). Similar corrections are made when installing refrigeration.

The summary table shows the expansion coefficients of the water (mixture).

This data will help you make an accurate selection of the expansion tank:

| Ethylene glycol concentration in% | Heat carrier temperature, ° С | ||||

| 0 | 20 | 60 | 80 | 100 | |

| 0 | 0,00013 | 0,00177 | 0,0171 | 0,0290 | 0,0434 |

| 20 | 0,0064 | 0,008 | 0,0232 | 0,0349 | 0,0491 |

| 40 | 0,0128 | 0,0144 | 0,0294 | 0,0407 | 0,0543 |

The calculation of the expansion tank for heating (O) is performed according to the formula O = (Os x Kr) / E, where:

- OS is the total volume of functional components;

- Кр - correction factor (from the table for a certain composition of the coolant);

- E is the efficiency of the tank.

The last position is calculated as follows E = (Ds-DB) / (Ds + 1), where D is the pressure:

- Дс - maximum in the hot water supply system (standard for private houses is 2-3 atm);

- DB - compensating, which is taken equal to static (0.1 atm for each meter of the building height).

Correct calculation of the coolant in the heating system

According to the totality of features, ordinary water is the undisputed leader among heat carriers. It is best to use distilled water, although boiled or chemically treated water is also suitable - to precipitate salts and oxygen dissolved in water.

However, if there is a possibility that the temperature in a room with a heating system will drop below zero for a while, then water will not work as a heat carrier. If it freezes, then with an increase in volume, there is a high probability of irreversible damage to the heating system. In such cases, antifreeze-based coolant is used.

How to calculate the volume of an expansion tank for an open heating system

In an open system, experts advise installing the tank at the highest point. This solution, together with expansion compensation, will provide air removal without additional devices. Of course, the room must be heated. If you decide to use the free space under the roof, you will need appropriate insulation.

In this case, an exact calculation of the expansion tank of the heating system is not required. To prevent emergencies, a branch pipe built into the wall of the tank at a certain level is connected to the sewer.

Circulation pump

For us, two parameters are important: the head created by the pump and its performance.

The photo shows a pump in the heating circuit.

With pressure, everything is not simple, but very simple: the contour of any length reasonable for a private house will require a pressure of no more than the minimum 2 meters for budget devices.

Reference: a drop of 2 meters makes the heating system of a 40-apartment building circulate.

The simplest way to select the capacity is to multiply the volume of the coolant in the system by 3: the circuit must be turned around three times per hour. So, in a system with a volume of 540 liters, a pump with a capacity of 1.5 m3 / h (with rounding) is sufficient.

A more accurate calculation is performed using the formula G = Q / (1.163 * Dt), in which:

- G - productivity in cubic meters per hour.

- Q is the power of the boiler or the section of the circuit where circulation is to be ensured, in kilowatts.

- 1.163 is a coefficient tied to the average heat capacity of water.

- Dt is the delta of temperatures between the supply and return of the circuit.

Hint: for an autonomous system, the standard parameters are 70/50 C.

With the notorious boiler thermal power of 36 kW and a temperature delta of 20 C, the pump performance should be 36 / (1.163 * 20) = 1.55 m3 / h.

Sometimes the capacity is indicated in liters per minute. It's easy to recount.

The critical stage: calculating the capacity of the expansion tank

In order to have a clear idea of the displacement of the entire heat system, you need to know how much water is placed in the boiler heat exchanger.

You can take the average. So, on average, a wall-mounted heating boiler contains 3-6 liters of water, a floor or parapet boiler - 10-30 liters.

Now you can calculate the capacity of the expansion tank, which performs an important function. It compensates for the excess pressure that occurs when the heat carrier expands during heating.

Depending on the type of heating system, tanks are:

For small rooms, the open type is suitable, but in large two-story cottages, closed expansion joints (membrane) are increasingly being installed.

If the capacity of the tank is less than required, the valve will release pressure too often. In this case, you have to change it, or put an additional tank in parallel.

For the formula for calculating the capacity of the expansion tank, the following indicators are needed:

- V (c) is the volume of the coolant in the system;

- K is the coefficient of expansion of water (a value of 1.04 is taken, in terms of the expansion of water at 4%);

- D is the expansion efficiency of the reservoir, which is calculated by the formula: (Pmax - Pb) / (Pmax + 1) = D, where Pmax is the maximum allowable pressure in the system, and Pb is the pre-pumping pressure of the expansion joint air chamber (parameters are specified in the documentation for the reservoir );

- V (b) - capacity of the expansion tank.

So, (V (c) x K) / D = V (b)

If you take into account the required volume of coolant when installing the heating system, then you can forget about cold pipes and radiators. Calculations are performed both empirically and using tables and indicators that are given in the documentation for the structural elements of the system.

The volumes of the coolant will be needed for scheduled or emergency repairs.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear on the heater, as well as significant energy consumption.

The required amount of coolant is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

The calculation of the power of the heating unit allows you to determine the indicator of the boiler capacity. To do this, it is enough to take as a basis the ratio at which 1 kW of thermal energy is sufficient to effectively heat 10 m2 of living space. This ratio is valid in the presence of ceilings, the height of which is no more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the amount of equipment in the passport data.

Therefore, if the correct power calculation is performed, problems with determining the required volume will not arise.

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross-section of the pipeline according to the formula - S = π × R2, where:

- S - cross section;

- π - constant constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the value of the cross-sectional area of the pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

It is possible to determine what capacity the expansion tank should have, having data on the coefficient of thermal expansion of the coolant. For water, this figure is 0.034 when heated to 85 ° C.

When performing the calculation, it is enough to use the formula: V-tank = (V system × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-system - the total volume of liquid in the remaining elements of the heating system;

- K is the expansion coefficient;

- D - the efficiency of the expansion tank (indicated in the technical documentation).

Currently, there is a wide variety of individual types of radiators for heating systems. Apart from functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first calculate their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the technical data sheet of the product. In the absence of such information, you can navigate according to the averaged parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 liters per section;

- aluminum - 0.4 liters per section.

The following example will help you understand how to calculate the value correctly. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make a calculation: 5 × 6 × 0.4 = 12 liters.

As you can see, the calculation of the heating capacity is reduced to calculating the total value of the four above elements.

Not everyone is able to determine the required capacity of the working fluid in the system with mathematical precision. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, the system is filled by about 90%, after which the operability is checked. Then the accumulated air is released and the filling is continued.

During the operation of the heating system, a natural decline in the level of the coolant occurs as a result of convection processes. In this case, there is a loss of power and boiler performance. This implies the need for a reserve tank with a working fluid, from where it will be possible to track the loss of the coolant and, if necessary, replenish it.

Calculation of the volume of the heat accumulator

In some heating systems, auxiliary elements are installed, which can also be partially filled with coolant. The most capacious of them is the heat accumulator.

The problem in calculating the total volume of water in the heating system with this component is the configuration of the heat exchanger. In fact, the heat accumulator is not filled with hot water from the system - it is used to heat it from the liquid in it. For a correct calculation, you need to know the design of the internal pipeline. Alas, manufacturers do not always indicate this parameter. Therefore, you can use an approximate calculation methodology.

Before installing the heat accumulator, its internal pipeline is filled with water. Its amount is calculated independently and taken into account when calculating the total heating volume.

If the heating system is modernized, new radiators or pipes are installed, an additional recalculation of its total volume must be performed. To do this, you can take the characteristics of new devices and calculate their capacity using the methods described above.

As an example, you can familiarize yourself with the method for calculating the expansion tank:

Expansion tank calculation

are performed to determine its volume, the minimum diameter of the connecting pipeline, the initial pressure of the gas space and the initial operating pressure in the heating system.

The method for calculating expansion tanks is complex and routine, but in general it is possible to establish such a relationship between the volume of the tank and the parameters affecting it:

- The larger the capacity of the heating system, the larger the volume of the expansion tank.

- The higher the maximum water temperature in the heating system, the larger the tank volume.

- The higher the maximum permissible pressure in the heating system, the smaller the volume.

- The lower the height from the installation site of the expansion tank to the top point of the heating system, the smaller the tank volume.

Since expansion tanks in the heating system are necessary not only to compensate for the changing volume of water, but also to replenish minor leaks of the coolant - a certain amount of water is provided in the expansion tank, the so-called operational volume. In the above calculation algorithm, the operational volume of water is 3% of the capacity of the heating system.

Selection of heat meters

The selection of a heat meter is carried out based on the technical conditions of the heat supply organization and the requirements of regulatory documents. As a rule, the requirements apply to:

- accounting scheme

- the composition of the metering unit

- measurement errors

- the composition and depth of the archive

- dynamic range of the flow sensor

- availability of data acquisition and transmission devices

For commercial calculations, only certified heat energy meters registered in the State Register of Measuring Instruments are allowed. In Ukraine, it is forbidden to use heat energy meters for commercial calculations, flow sensors of which have a dynamic range of less than 1:10.