The foundation for the stove Modern stoves for the baths are distinguished by high performance and compact dimensions, but they are far from always installed in baths and cottages. After all, many owners of such structures wish to have ancient stoves made of baked bricks and tiled.

After all, such an oven will not only provide an optimal temperature regime in the room and create a sufficient amount of steam, but also has a high performance. But the mass of the furnace from the brick is large, as are the dimensions, so you cannot do without a special foundation.

The foundation for the stove was not made in ancient times, because the material of the stove was often made of wood, less often made of clay, so it was enough to strengthen the floor of the building. Now stoves are built from bricks, revetted and decorated with decors.

They can make a barbecue compartment, provide a fireplace, create a completely homely atmosphere in the house. In addition, such a stove is capable of heating large areas if you correctly think over the ventilation and heating system, and make the fireplace open and protected.

When do you need a foundation?

As mentioned above, the installation of structures should be accompanied by the construction of a foundation in the form of a foundation, with the exception of structures whose weight does not exceed 200 kilograms, in all other cases it is necessary.

Even lightweight brick structures need a good foundation, due to the constant movement of the soil and the general shrinkage of the house. And it's not even worth talking about massive, heavy, brick stoves - without a high-quality foundation, correctly designed, they cannot withstand the conditions of the modern climate.

The foundation for a metal stove in a bath

The foundation for a brick oven is not difficult to make, you first need to immediately find out the total weight of the structure and then make the correct calculations. Bath the foundation for the stove is made taking into account the humid environment. So here it will be necessary to make the foundation 20% deeper and to carry out good waterproofing.

The depth, width, as well as the length of the base directly depend on the dimensions of the structure and weight.

We make a calculation

- These figures already include the weight of the mortar, which is used to seal vertical and horizontal joints and the brick itself. If the furnace structure does not weigh more than seven hundred and fifty kilograms, then you do not have to necessarily engage in the construction of a separate foundation. Usually the construction of such small stoves will require no more than two hundred bricks. As a base for them, I take a sheet of asbestos, which is mounted on a clay mortar, and a sheet of simple metal is placed on top.

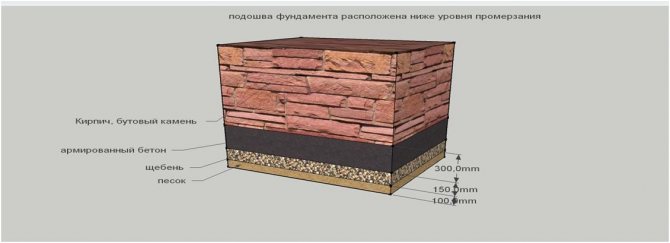

- The foundation for the oven with your own hands should be below the freezing mark. It is worth saying that in different areas this level is different. By doing this, it will be possible to avoid the influence of the seasonal movement of the soil on the final structure, because under it there will be a high-quality foundation, erected by an artificial method.

A brick oven will not stand without a foundation, it must be done reliably and thoroughly.

There are steps to follow:

- Work should begin with a pit; after its appearance, it is worthwhile to carefully level the base and lay a layer of crushed stone and sand.

- After tamping, a sole is arranged, and not only crushed stone is used, but also broken brick. Then the entire sole must be filled with a liquid cement mixture;

- It's time to start laying rubble stones or solid bricks, because in this masonry it is solid material that is used, hollow material cannot be used.All rows must be even and this is checked using a building level. Also, air should not be allowed in the masonry;

- Do not forget also about the need for suture dressing. The outer row is placed on the cement mortar under the scapula, and the inner row is put in place. Immediately it is necessary to align the upper plane, we do this simply with a solution. As a result, the surface should be absolutely horizontal, therefore, during all work, you need to use the rule with a level;

- In order to prevent groundwater from getting into the brick stove, it is necessary to lay a double layer of roofing material, which will perform waterproofing functions;

- After that, several more rows of brick are laid out to the very floor. At this stage, the foundation device can be considered complete. It is left for a while so that it reaches maximum strength and dries up. Then, work is carried out related to the laying of the stove.

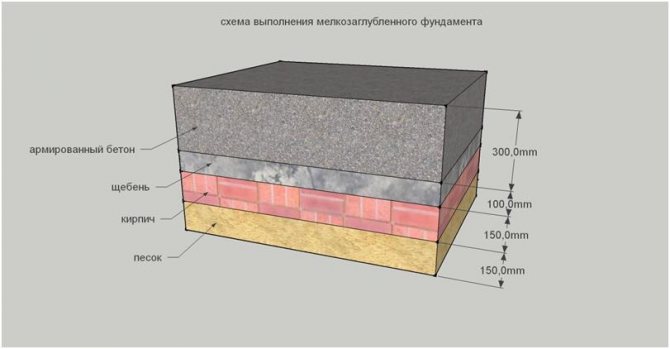

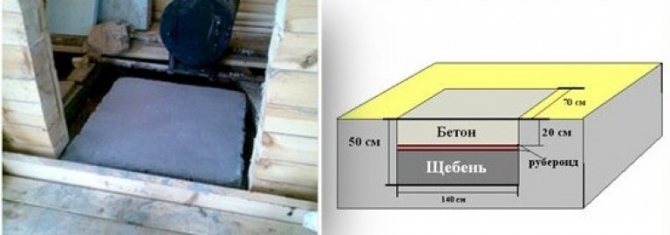

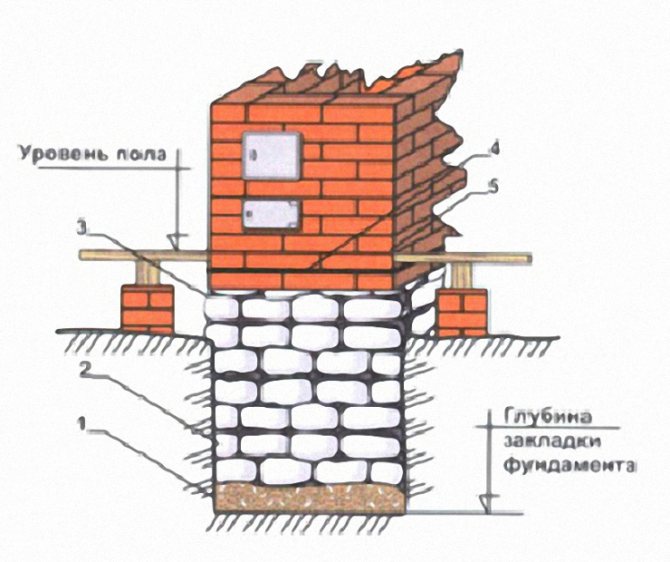

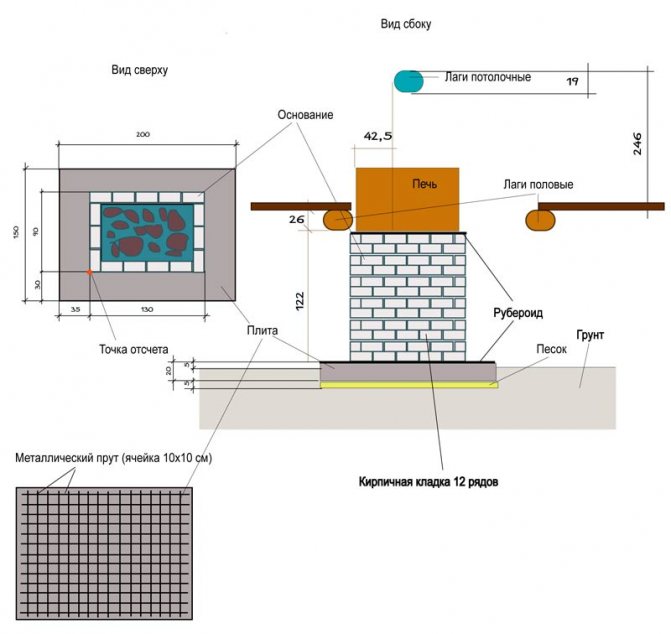

Construction involves high-quality performance of work and the diagram of the device looks like this:

- Crushed stone sole;

- Underground masonry, or rather, part of it;

- Cut from above;

- Waterproofing layer;

- Stove masonry.

Strip foundation

The foundation for a brick oven is not at all difficult to make. And with his own hands, it will be done with high quality.

Strip foundation diagram

So:

- First of all, you need to mark the plane. Only the dimensions should be made larger than the net size. If cladding is to be done, then the size of the material must also be taken into account;

- We dig a trench, its depth is chosen at least 50 cm.

- Now we are backfilling with sand. It is best to wet it immediately, it should shrink;

- Now so, if this is a foundation for a stove in a bath, then it will have to be reinforced. This will give the required stiffness. We cook a lattice from reinforcement and place it in a trench;

- After that, gravel is poured. Any stone from the site can be successfully applied here. Then we do the ramming

- We prepare a cement mortar, but only a liquid one. After pouring, we should not have any voids;

- Fill after that we ram again. With us, the solution must pass into all voids;

- We are waiting for complete drying and put waterproofing. For this, you can use any roofing material.

The foundation for the stove in the house is also made mainly of tape. After all, it is reliable and it does not take much time to make it.

If you have decided to create just such an option for the foundation for the firebox, this will reduce the amount of work with the ground and significantly save the materials spent. This construction is perfect for wet soil.

Columnar foundation diagram

- Moreover, in addition to the construction of the pillars themselves at several angles, it is necessary to carry out the installation of the base, which is placed on these supports. Its functions can be performed by any reinforced concrete slab or frame, which is welded from several steel profiles.

- Do not forget that the dimensions of such a plate should be larger than the oven itself, which makes the entire structure more stable and reliable.

- Piles or pillars, which act as supports for foundation slabs, prevent possible seasonal soil movement, which can occur when heaving loamy and clayey soils during severe freezing.

All work is done in the following order:

- Using a drill, we make cylindrical holes that go to the desired depth, their diameter will be about twenty centimeters;

- At the bottom of the pits, a layer of rubble is poured, whose thickness should not be more than ten to fifteen centimeters. The material is rammed in the most careful way;

- Roofing pipes are inserted into the drilled holes, which are formwork;

- Pour a mixture of concrete;

- The concrete pillars must be left to dry (this can take about ten days);

- After this time has passed, you can safely proceed to the installation of a reinforced concrete slab;

- Waterproofing is performed on the upper edge of the foundation.For these purposes, you can take roofing material, which is lubricated with hot bitumen and laid in several layers.

If the characteristics of the soil make it possible to use a shallowly buried foundation, then the slab should be laid in a small trench on the previously poured crushed stone. The installation of piles in this situation will not be so important, which will help reduce the costs required for the foundation for a brick oven.

According to building codes, pouring a foundation for a brickwork stove is required if the load on the floor exceeds the permissible values. It is possible to determine the need for additional strengthening of the base after relatively simple calculations.

We offer you to familiarize yourself with the Stove for a bath with a built-in heat exchanger

The production of the foundation is envisaged in the early stages of designing a residential building or bathhouse, even before the construction of the walls. During preparation, the depth is calculated, the type and material of the base is selected.

Calculations are based on the actual load experienced by the substructure under the weight of the masonry. The mass of one cubic meter of laid bricks, including the mortar required for laying, is 1350 kg.

According to SNiP, the maximum possible load on the floor, which does not require additional strengthening of the foundation, is 750 kg. More weight leads to the need for additional measures aimed at strengthening the bearing surface.

A light brick oven without a foundation takes no more than 200 pieces. stone. The total weight of the structure varies from 600 to 750 kg. If a stove is installed from more than 200 pieces. brick, you will need to make a correct, suitable foundation, taking into account:

- Weight and load on the base.

- Financial expenses.

- The depth of soil freezing, atmospheric and weather conditions.

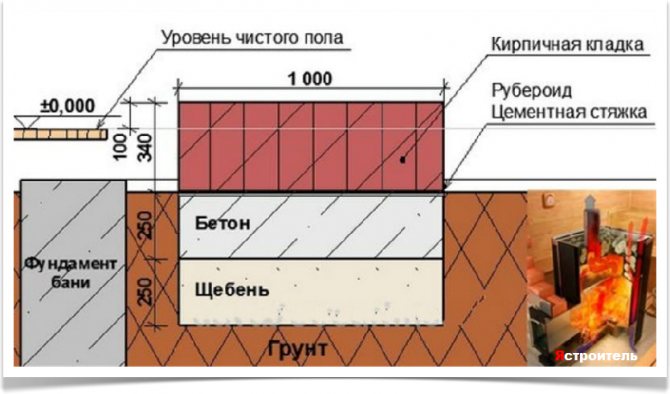

The thickness of the foundation is made in proportion to the load on the foundation. For a light stove, it is enough to pour a concrete cushion 10-15 cm thick. Complex brick structures require the manufacture of a foundation base.

If it becomes obvious that the construction of a foundation for a brick oven is required, it is necessary to correctly select the option to strengthen the base. The following solutions to the issue are widespread:

- Bored and screw piles.

- Brick pillars.

- Reinforced concrete slabs and strip foundations.

- Reinforcement of wooden floors and load-bearing structures.

When choosing a suitable option, take into account the design features of the furnace, the period of work, financial costs.

Pile foundations

One of the economical options for making a foundation is the use of bored or screw piles. The device allows you to do without extensive excavation and concrete work, and at the same time ensures the strength of the base for installing the furnace.

Pile or needle foundations are made quickly, which reduces the time of work in half, compared to concreting:

- Bored piles - for installation, a hole is drilled in the ground with a drill in order to achieve a solid ground. If there is no such possibility due to the peculiarities of the soil, they deepen below the freezing level. After drilling a hole, at the very bottom, a hole is expanded with a special drill, making a "skirt". A metal frame is installed to prevent soil shedding. The dug hole is poured with concrete with the obligatory reinforcement of the bored pile. The columns are tied together with reinforcement. A concrete pad or tape is poured from above.

- Screw piles - the structure of the pile-screw foundation is the same as the bored analogue, only special metal rods are used as supports. In shape, the drills resemble a threaded screw with a large pitch. For installation, the piles are screwed into the ground. Twisted piles are cut to one level. The metal elements are left in the ground, the inner cavity is filled with concrete.A concrete pad is poured from above with the obligatory strapping of screw piles to each other.

Screw and bored piles have approximately the same load resistance. The existing SNiP allow the use of a needle foundation in the construction of a residential building. Therefore, pile screw and bored foundations are successfully used for brick ovens.

Work markup

After choosing a place for the structure, you need to carry out detailed calculations for the object.

Concrete foundation

To build the foundation for the furnace you will need:

Cement.

- Coarse sand without inclusions. The ideal option would be to use mountain sand, but sea and river sand are also suitable. We have already considered the methods of cleaning sand from impurities on the pages of our Internet resource.

- Formwork material.

- Crushed stone.

- Roofing material or dense polyethylene.

Instruments:

- Solution trough

- Shovels: bayonet, shovel

- Building level

- Hammer, nails, hacksaw for formwork construction

- Construction stapler

Do I need to go deeper

You can start building the foundation for the stove. Many people may wonder whether it is necessary to go deep into the ground when the foundation is being built with their own hands under the stove. Our answer is obligatory. Sometimes there is an option in which the foundation is arranged with a shallow depth. Only the upper vegetation layer is removed and after the installation of the formwork, the foundation is poured. This is completely wrong way. The slab of the foundation, arranged in this way, will constantly experience loads, especially in the winter. The motivation for the economical consumption of building materials when constructing such a foundation is not justified by anything. The deepening must be carried out to a depth below the freezing level in your area. You can use a shallow foundation in the bathhouse under the stove, but with the obligatory installation of piles under the main foundation slab.

3298747c3106dbca1d54e8cc0871aa17.jpe

Pit construction - basic parameters

Digging a pit

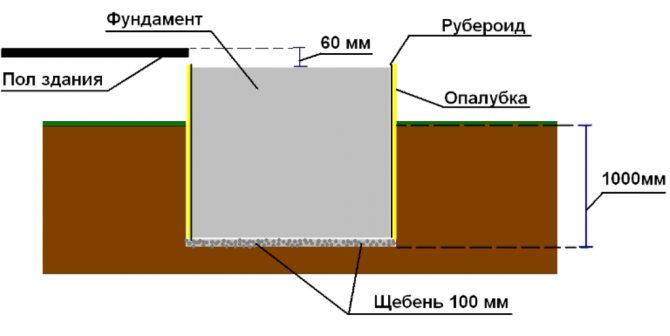

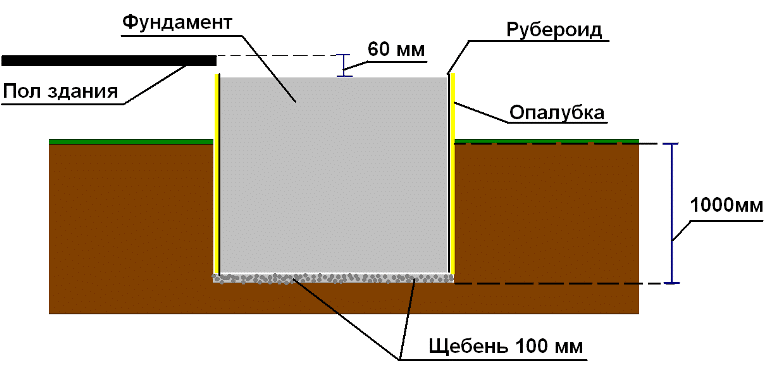

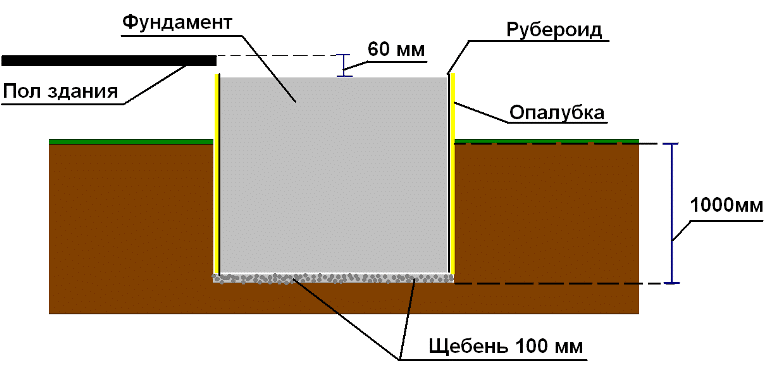

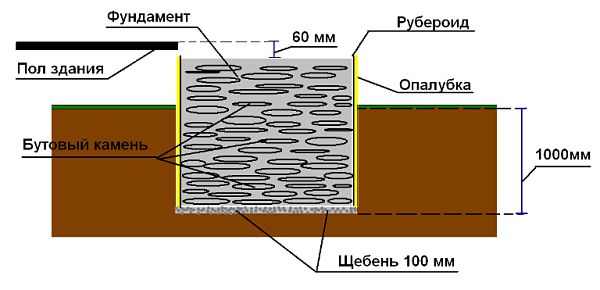

For dry, sandy soils, 500 - 600 mm is enough. But on heaving soils, this depth should not be less than 1000 mm. We repeat - this is the correct foundation.

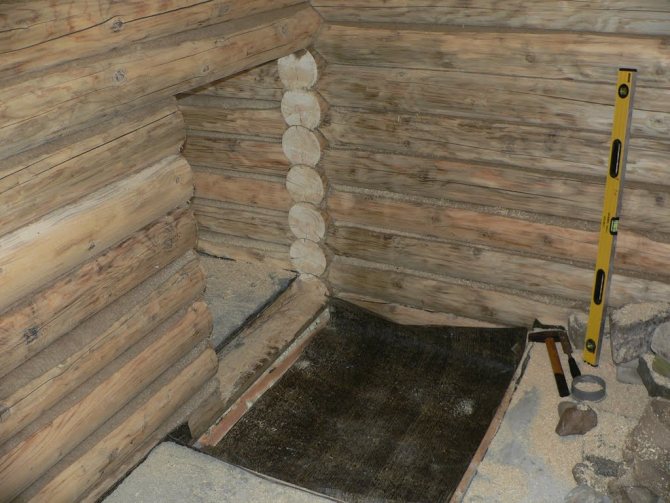

Correct laying of the foundation

We dig a foundation pit according to the markings. The size of the pit must allow the installation of the formwork. But if the soil on your site is dense enough and the edges do not crumble, you can do without it. In any case, it all depends on the specific location and soil. When the formwork is installed, a layer of crushed stone 100 mm thick is poured onto the bottom of the pit. Crushed stone must be leveled. After that, it is necessary to compact the crushed stone with a manual rammer.

Waterproofing and filling

For waterproofing the foundation, a layer of roofing material is attached to the inner side of the formwork using a construction stapler. You can start pouring

It is important to know that the upper level of the foundation should be 60 - 70 mm lower than the main floor of the building. We prepare the solution in the following proportions:

- Cement 1 part

- Sand 3 parts

- Crushed stone 5 parts

Solution

- First, a dry mixture of cement, sand and crushed stone is prepared. You can use mortar for laying the stove.

- After shoveling and obtaining a homogeneous mass, water is gradually added until a solution of the consistency of thick sour cream is formed. The solution can be poured.

Furnace foundation height

There are three options:

- below floor level;

- on the same level;

- above.

Questions can only arise about why the base of the stove should be made below the final level of the floor. The answer has two parts:

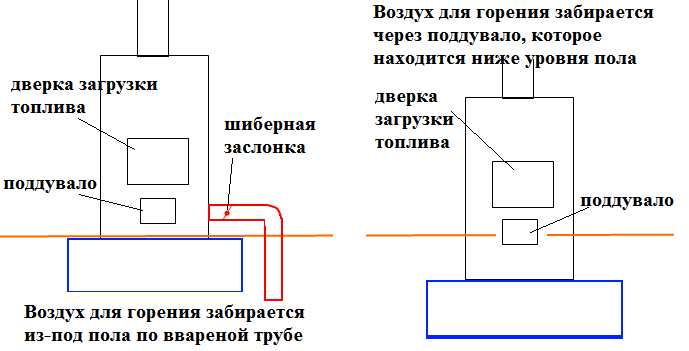

- So that combustion air is taken from the underground. Then the stove, if there is a desire, can be heated from the steam room, and not from the rest room or the dressing room: oxygen in the room is not burned out, as it "stretches" from the underground. Only in the foundation should there be ventilation holes to ensure the flow of air.

- To keep the floor warm. Despite the increased circulation in the subfloor, the floors warm up quickly with this arrangement of the stove. Then there will be no problems with the cold floor, be it wooden or concrete.

How to supply combustion air from the underfloor

Also, as a bonus, with this arrangement, there is no problem with drying the floor. Only this is true only with properly made drainage and waterproofing of the floor.

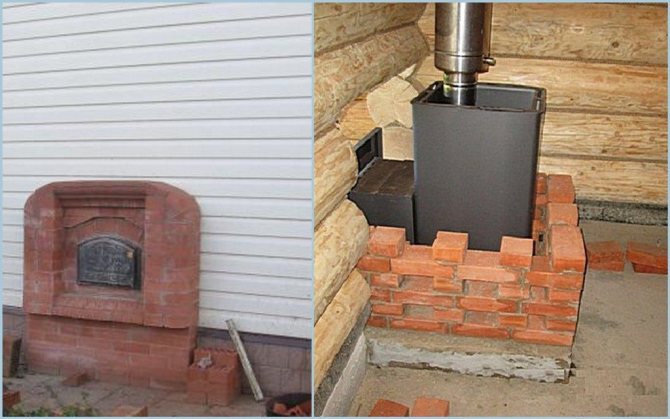

Everything will work if the blower is below the level of the finished floor. If the foundation is made at the same level with the floor or higher, and the air intake must be organized from the underground, the metal stove is modernized (in the photo, the option on the right). A thick-walled metal pipe with a gate is welded into the sidewall.

A more detailed image of the oven limiter

In the same way - by welding the pipe - problems with the combustion of an already installed furnace are solved. Problems arise from lack of oxygen. And it is provoked by current technologies: to reduce heat loss and heating costs, we make houses and saunas - thermoses. If you forget to make ventilation or make it insufficiently effective, then the stove burns badly.

Here, however, there is an option that does not require changes to the furnace: the pipe coming from the ventilation hole in the foundation is taken out in the area of the blower. Sometimes it is enough to bring it under the boards, sometimes it is necessary to bring it flush with the floor or slightly higher. Not the best and most aesthetic option, but the stove will burn normally.

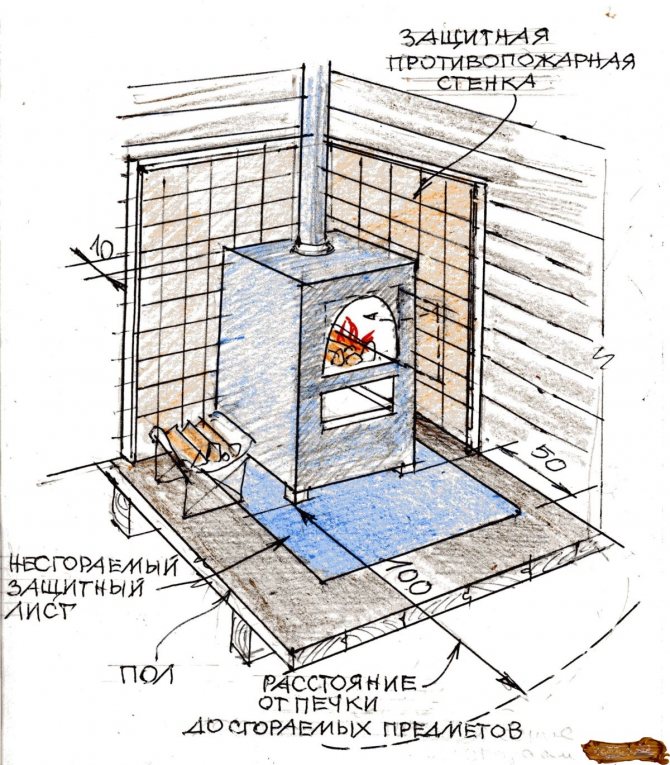

Please note that if the foundation of the stove is close to the base of the bath (house), it is necessary to make them incoherent. This means that they should not touch each other. There should be a gap of at least 5 mm between them for an iron stove and 50 cm for a brick one. In the case of an iron stove, the gap can be filled with a layer of heat insulator (basalt cardboard).

What is required to complete the foundation?

Work markup

- The approximate size of the furnace structure is drawn on the ground, while the foundation should be 15-20 cm higher.

- Marking is carried out and pegs are installed to limit the size of the pit.

- A hole is pulled out to a depth of 100 cm.

- The bottom is covered with sand by 10-15 cm, after which it is covered with gravel by 30 cm.

- Water is poured and the mixture is tamped tightly.

Based on the results of the calculations, it is possible to determine whether a foundation is needed for a stove in the house. The fact is that a furnace up to 750 kg can be built without a foundation. It is enough to lay a sheet of asbestos on a clay mortar and cover it with a sheet of roofing iron.

A massive brick stove in a bath must have a solid base, the bottom of which is below the freezing level of the soil. Such a foundation will reduce the influence of seasonal soil movement on the furnace structure. Before making a foundation for a stove in a house, you should find out the depth of soil freezing in a certain area, taking data from reference books.

Basic rules for laying the foundation

Whatever version of the foundation for the furnace you choose, and whatever size you decide to implement, there are a number of basic rules that you should not ignore:

The foundation for the stove must be made independent, in no way connected with the foundation of the whole house. Why? The fact is that during operation, the house may shrink slightly. When lowering, he should not pull the stove with him, as this can lead to its deformation, deterioration of traction and violation of technical properties.

The foundation for the furnace is separated from the general

In some cases, you can partially combine two bases by connecting them with one wall.

- If both foundations (for the house and for the stove) are located close to each other, sand backfill with a thickness of 50 mm must be made between them.

- If the foundation for the common house is tape, then the base for the furnace should in no case come into contact with this foundation with the walls.

- When choosing a place for a stove and, accordingly, a foundation, one should not only rely on wishes, but also on factors such as: the location of doors, windows and roof beams. The location of the chimney should be taken into account so that the pipe does not fall into the ceilings and beams during the construction of the stove.

- When calculating the size and depth of the foundation, be sure to take into account the severity of the floors and the weight of the stove together with the chimney.

The dimensions of the foundation are influenced not only by the dimensions of the furnace, but also by the density of the soil on which it is being erected. The main load in the stove is usually created by the chimney, therefore, when designing the stove, it is necessary to carry it closer to the center of the base. This will help to avoid asymmetric loading and premature, incorrect shrinkage of the oven.

Sometimes, when designing a very large and massive stove with a stone chimney, stove-makers make a separate base for the chimney.

Also, the choice of foundation depends on the material of the furnace. For a metal structure and a stone one, it will be different in depth, the entire mass of a brick oven is at least 400-500 kg, while a metal oven weighs about 150 kg.

How to calculate the weight of a stone oven

In principle, for a small metal stove, you can separately and not equip the foundation, especially if it is being built in a house that stands on a tiled monolithic base.

The density of the soil and the degree of its freezing play an important role in determining the size of the foundation. The climate in Russia is accompanied by rather severe winters practically throughout its entire territory. Therefore, the foundation for the furnace should be laid to the entire depth of soil freezing.

The type of soil is also of great importance.

Soil types

It is of three types:

- clay;

- sandy loam;

- loam.

In places where a large number of rivers, reservoirs, lakes prevail, as a rule, sedimentary types of soil are found. Here, it is better to entrust the construction of the foundation for the furnace and the house to professionals, so the calculations of the point of passage of the waters should be carried out.

In Central Russia, a very common type of soil is loam, which is a mixture of sand and clay. It is clay that predominates in it, therefore such soil is less plastic.

Loam

Erection of a foundation on such soil is usually associated with hassle and additional problems, since in a dry state the loam is crumbly, with the onset of frost it begins to "heave", and with a large amount of sediment it becomes viscous.

Clay soil

Therefore, in this case, the depth of laying the foundation for the furnace must be made above the freezing point.

But in forest areas, on the contrary, it is necessary to lay the foundation for the furnace below the freezing point of the soil and to equip the base on a sand cushion 60-90 cm thick.

One of the most reliable types of soil for building a foundation is gravel and rocky, but, unfortunately, sometimes you have to build a house and a stove on an unstable one. Competent construction of a reliable foundation will help neutralize this fact.

Rules for performing calculations of the foundation for the furnace

If the total weight of the heating system exceeds 750 kilograms, then a high-quality foundation will require a strong and durable foundation, with a deep type of foundation made of rubble or concrete stone. With a lower weight of the structure, a base made of roofing iron, asbestos sheets and even ordinary wood may be suitable.

When making calculations for the foundation of a brick stove, take into account the type of soil on the site. On soft, swampy and easily sinking wet ground, the foundation should have a height of at least 150 centimeters, while on dry ground, the foundation may have a depth of only 70 centimeters.

1350 * 0.8 = 1080kg

We add 70 kg and we get the total weight of the heating system - 1150 kg. Since our soil is quite hard, but the furnace has a large mass, we will install a foundation with a depth of 1 meter - this will be enough for long-term stability.

If the foundation for a brick stove is laid before the walls are erected, then before installing it, you need to determine where the heating system will be installed - it will not be possible to change the decisions, so think before starting the construction of the base where exactly you will have the stove.

Construction of a wooden foundation

Experts do not recommend building a wooden foundation for a stove, but if you are interested in familiarizing yourself with the technology of its construction, then you should read the information provided below.

At the first stage, wooden poles are prepared and processed, which provides for their antiseptic or firing. This will extend the period of their use, since soil moisture will affect the surface of the products. Next, the site is marked and cleaned, holes are dug, the diameter of which is 1.5 times the diameter of the prepared supports, and then a sand cushion is set up.

This base does not do without waterproofing, after laying the layer of which the pillars are installed. To increase the load bearing area, such pillars should be placed on a concrete slab or crosspiece. The next step will be backfilling, leveling the supports horizontally and waterproofing the ends of the posts.

It is quite easy to build such a foundation for a stove with your own hands, however, the labor and time costs will be more impressive. This is also due to the fact that the wooden foundation will have to be additionally protected from moisture, as well as the increased influence of temperatures from the oven.

Options for foundations for a brick oven

Pile foundations

The foundation of the columnar type is made in the same way as the bored one, with the difference that the pillars are made of bricks. Almost any rubble karmic stone is suitable for work.

During the execution of work, some nuances are taken into account:

- Brick used for the foundation - the base is laid out of a material that is moisture resistance, strength and the ability to withstand frost without losing strength characteristics.

- Material selection criteria - it is better to lay out the base from solid ceramic bricks. A material with defects is suitable: chips, inclusions, etc. It is impossible to make a foundation of silicate bricks. Silicate brick quickly picks up moisture, cracks, mold and mildew. Over time, the columns begin to sag and become unable to withstand further stress.

- The distance between the columns - as a rule, the supports are placed at the corners of the future design of the furnace and with a step every meter from each other.

It is better to use ceramic bricks for the foundation. Used brick will do. During masonry, a sand-cement mortar is used with the addition of fine and medium crushed stone.

Concrete base for a brick oven, withstands the maximum load. Most often, a strip foundation is made. In some cases, a ready-made reinforced concrete slab is laid as a base.

Each of the options has its own characteristics:

- The foundation of concrete blocks is characterized by quick installation and the ability to withstand high loads. In buildings where reinforced concrete slabs are installed as interfloor partitions, the furnace can be installed on the second floor, of course, if the rest of the technical characteristics of the house allow it. Lack of concrete goods, the need to use special loading equipment and the impossibility of independent work.

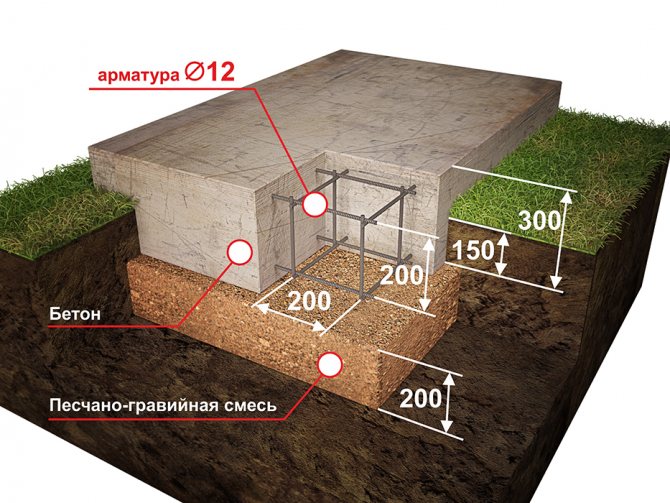

- The strip foundation is the grade of the concrete mixture used M 400. Before pouring, trenches are dug out and the formwork is installed. The lowest point of the strip foundation should be below the freezing level. Gravel filling is made at the bottom of the dug trench. At the lowest point of the future foundation, a "tooth" or "skirt" is made, expanding the base of the pit at an angle of 45 °.A knitted reinforcing cage is laid in the ditch. The thickness and step of the reinforcement, respectively, 1 / 10-15cm. After the manufacture of the metal reinforcement cage, the base is poured with a concrete mixture.

The strip foundation is suitable for large Dutch and Russian ovens with a weight load of over 1400 kg. For maximum strength, a layered cake is made. Compaction of crushed stone with sand is done. Experienced craftsmen water each layer abundantly with water to increase the density.

In a wooden bathhouse or a residential building, a timber foundation is used. The wooden base is not very suitable for installing a brick oven. But, if there are no other options and subject to fire safety rules, you can fulfill the minimum conditions that make it possible to install lightweight furnace equipment weighing up to 750 kg.

For installation, the following conditions are met:

- Strengthen the wooden floor - sew a QSB board on top of the boards. Lags are reinforced with a metal corner 3-4 mm thick.

- They protect the wood from heat and moisture - an insulating material is laid on top of the wooden floors, a steel sheet is laid on top.

To put a massive brick structure in a wooden house, the floors at the installation site are dismantled, a concrete base is poured, or screw and bored piles are used.

Speaking about what kind of foundation is needed for the furnace, three main options are considered:

- rubble concrete;

- solid concrete;

- support-pile foundation.

The classic foundation for the furnace is erected from cement-based rubble, or from concrete. The base itself should be 50-100mm larger than the area of the furnace itself along the entire perimeter. In terms of height, the foundation should be the same as the foundation of the bathhouse itself or a wooden house.

Roofing material or 2 layers of roofing roofing for waterproofing is laid on the finished base, bricks are laid out on the insulation and outlets are prepared from metal corners, from which fire-prevention cuts are obtained.

Nuances of construction

The first nuance is that the foundation for the furnace is not associated with the main foundation of the building. In addition, if they are close enough, then a sand cushion with a width of about half a meter is necessarily laid between them.

The second nuance: in no case should the old foundation be re-concreted, since during further installation, shrinkage will occur on the entire structure of the furnace, cracks will go and many other problems will arise.

The most classic foundation for a stove is erected with a solid slab. The depth of the base depends on the following factors:

- ground water level;

- type of soil;

- depth of soil freezing.

To avoid surprises in the future, before starting the construction of the foundation, it is worth conducting geological exploration of the entire site, its cost fluctuates around $ 50. Thus, you can get accurate data on the level of groundwater, type of soil, depth of soil freezing. This data will help you determine exactly what depth of the foundation should be chosen.

Depth calculation example:

- sandy and dry soils - 80cm;

- heaving - below the freezing zone, at least 1 meter;

- the weight of a brick kiln is calculated by the formula: 1350xV = P, V is the volume of the masonry.

If mistakes were made in the design and construction, then the following problems may emerge in the future:

- through cracks on the furnace and its foundation;

- destruction and collapse of masonry (brick oven);

- violation of the integrity of the chimney;

- subsidence of the base, the stove will be lopsided.

The biggest problem is that such blunders cannot be repaired normally. The situation will worsen and the furnace will collapse.

After the depth of the future foundation for the stove has been determined, its dimensions, it is necessary to choose the right place where the stove will stand. This directly affects the location and outlet of the chimney. An unsuccessfully chosen place in the future will create a bunch of problems with bypassing the supporting structures and lengthening the chimney pipe, and its output to the street.

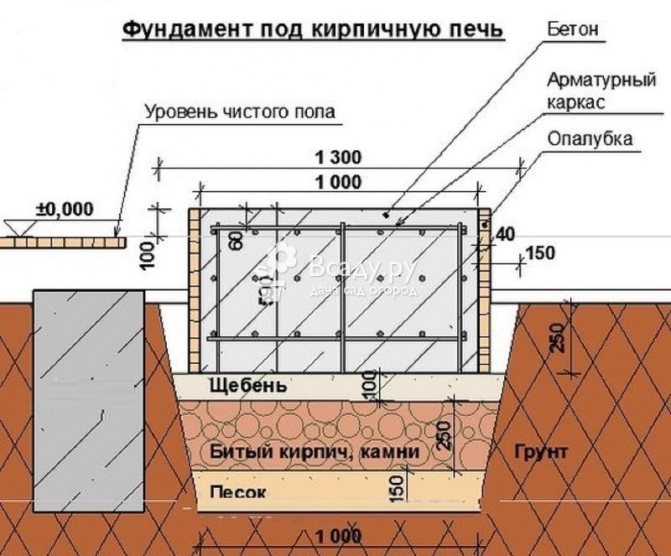

- The first steps are carried out similarly to the previous method: a pit is pulled out, formwork is installed and waterproofed with polyethylene (or roofing material).

Diagram of a concrete foundation

- Next, it is necessary to compact the bottom of the pit well and fill the bottom with a rubble layer (the diameter of large stones should exceed 16 cm).

- We pour a layer of crushed stone of the middle fraction by 10 cm, level it.

- We fill in the cement mortar for 10-15 and take a technological break for several days until the mixture hardens well.

An example of a concrete foundation - We repeat the layer of crushed stone of the middle fraction, and then fill the solution again, filling it almost to the end, not reaching the level of the finished floor by 8 cm.

- We level the mortar and check the evenness of the coating with a building level. We make a technological break for several days. We cover the foundation with a layer of polyethylene.

- Thus, we get a solid foundation, consisting of four layers.

- Remove the upper part of the formwork with a hammer.

Removing the formwork

- We bring the foundation to the level of the finished floor using two rows of red baked bricks.

- Depending on which brick you took, immediately calculate its height and do not bring the concrete mix to exactly 2 brick heights. The top row of bricks must be exactly the same as the finished floor.

The foundation for a Russian stove can be made with your own hands, observing a certain sequence of actions:

- First, they dig a pit, adhering to the size of the foundation for the furnace. The bottom of the pit is leveled and compacted.

- A layer of sand and gravel is poured, watered and tamped.

- Next, arrange a pillow of broken brick or crushed stone, level it and fill it with liquid cement mortar.

- The next step in building a foundation for a stove with your own hands will be laying a solid brick or rubble stone. In the process of laying, they control the evenness of the rows and make the obligatory dressing of the seams. After laying the last row, check the horizontalness of the upper part using a building level. If necessary, level the surface with a layer of cement mortar.

- Roofing material is laid on a flat cement surface in two layers. This waterproofing material will prevent the penetration of groundwater into the brickwork of the sauna stove.

- A few more rows of bricks should be placed on the roofing material so that the structure reaches the floor level. In this form, the foundation for the stove is left to dry and gain the necessary strength.

Construction stages

Pit for a sauna stove

The procedure for arranging a monolithic foundation for a stove in a bath does not differ from the general sequence of actions for the construction of a typical base. It includes the following steps:

- pit preparation;

- arrangement of formwork;

- pouring concrete mixture.

The construction works of various foundations differ in some details.

Under a brick oven

Step-by-step instructions for building a foundation for a brick oven:

- The trench is marked and the soil is selected to a depth of at least one meter.

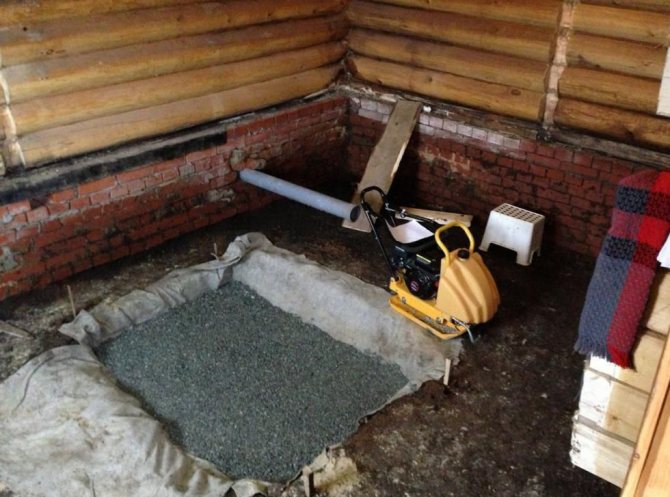

- Crushed stone is poured into it, which is then carefully rammed.

- The bulk layer of the pillow is calculated for a thickness of 30 cm.

- A pre-prepared concrete mixture is poured.

Under a metal oven

The concrete slab must be installed strictly horizontally

A foundation for a metal stove in a bath is required only in cases where the weight of the structure exceeds 150 kg. Its use allows the oven to be installed strictly horizontally and to guarantee its constant position. The slightest deviations lead to deformation of structural elements and deterioration of its characteristics.

The order of operations for the construction of the foundation for the stove:

- Marking is made and a small trench is pulled out (no more than 0.5 meters deep).

- Crushed stone is poured in a thin layer, which is immediately compacted.

- A concrete mixture is poured in the same proportions.

Similar to the first case, waterproofing is done, the finishing layer of which is leveled.

Pile foundation

Arrangement of the pile foundation takes time, but the structure is durable

The procedure for arranging a support-pile foundation for brick ovens is somewhat different, since in this case a different technology is used. It consists in the construction of a series of pillars or pile supports, on which a frame is subsequently placed under the furnace structure.

Sequence of working steps:

- On the prepared site, markings are made corresponding to the dimensions of the furnace with an overlap of 10 cm on each side.

- With a bayonet shovel, about 20 cm of soil is removed, after which pegs are driven along the perimeter with a certain step, between which the string is pulled.

- At the intersection of individual threads, marks are made, along which holes are then drilled about 50 cm deep and 20 cm in diameter.

- Formwork is made from wooden planks in the form of pits, and then installed in them.

- The bottom is closed with a 15 cm thick layer of sand, which is then carefully compacted.

Upon completion of these procedures, gravel is poured on top and filled with clean water, after which a reinforcing frame is knitted from a reinforcing wire with a diameter of 0.8 mm. Piles are installed in its center, the function of which is performed by asbestos pipes of appropriate length.

At the final stage of work, the entire structure placed in the pit is poured with concrete, the shrinkage and drying of which takes about 2 weeks. After that, they proceed to pouring the platform for the furnace, resting on the finished piles. It also takes about 2-3 weeks to dry.

Concrete foundation

Natural stone with cement mortar is the most durable foundation material

Step-by-step instructions for building a rubble foundation for a stove:

- A trench is marked for pouring the base, the size of which is chosen 10 cm larger than the dimensions of the furnace, taking into account a small margin for formwork.

- A pit is pulled out along the markings, at the bottom of which a pillow is made of selected rubble 15 cm thick.

- The formed layer is carefully rammed, after which several large rubble stones are placed on the very bottom (their diameter should not exceed 15 cm).

- Crushed stone is poured on top, filling the voids between the stones.

- A cement-sand mortar is poured into the trench to the depth of the layer, in the manufacture of which the classic ratio of 1 to 3 is used. For its preparation, cement of the M400 grade or higher is best suited.

After a day, another layer of stones is laid on top of the frozen mass, which are also filled with the same concrete composition. This procedure is repeated until the entire trench is filled with the rubble. After that, a building level is taken and with its help the resulting surface is checked for evenness. The detected irregularities are eliminated with the help of a liquid cement-sand composition. Then the base is covered with plastic wrap and left to dry completely (at least 2 weeks).

Tools and materials for the construction of the foundation

The first thing to do before starting construction work is to stock up on the necessary set of tools.

Work will have to be carried out not only excavation, but also carpentry, so prepare the following tools:

- Bayonet shovel (needed to dig out the main pit).

- Shovel (it is convenient to prepare a sand-cement mortar).

- A hammer.

- Hacksaw or saw.

- Sieve for sifting cement (mesh size 1 * 1 mm).

- Sieve for sifting sand (mesh size 2 * 2 mm).

- A bucket for water (for preparing a cement-sand mortar).

- A metal trough in which we will prepare the solution.

- Building level.

- Roulette and pencil.

- Stapler.

- Concrete mixer.

Of the materials you will need:

- Boards (for the manufacture of formwork).

- Polyethylene (for formwork waterproofing).

- Sand.

- Cement.

- Gravel.

- Reinforcing mesh or rods.

Installation of pile foundation supports in the house

The solution to the question of how to make the foundation for the stove implies the following actions:

- With the help of a manual or mechanical drill, wells with a diameter of no more than 20 cm are made in the ground.

- Crushed stone is poured at the bottom of each well and carefully tamped, the layer thickness can be 10-15 cm.

- Tubes are made of sheets of roofing material and inserted into the wells. It turns out a kind of formwork.

- A concrete solution is poured into each tube and the resulting pillars are left to dry. In most cases, the supports dry out in 10-12 days.

- After that, the installation of the base of the stove is carried out.

- Do not forget about waterproofing such a foundation. To do this, you can use sheets of roofing material folded in half and smeared with molten bitumen.

The slab should not be laid tightly on the ground, the gap left will ensure free shrinkage of the foundation.

If the foundation is being erected on stable ground, then the base plate can be laid on a compacted crushed stone cushion. To do this, they first make a small depression in the ground and cover it with rubble. In this case, the cost of arranging the foundation for the furnace is significantly reduced.

What should be considered?

So, all questions regarding the foundation for the furnace need to be resolved only after it becomes known what it should be:

- classic brick;

- steel;

- cast iron.

And whether it will be wood, gas or electric is a secondary issue. Its weight plays a very important role here. It is from this indicator that it is necessary to build on when building a bath.

The question of the basis for a metal or cast iron stove is much easier to solve. Here it will be enough to make a reliable floor. For example, concrete it, and then lay the tiles on top. Then you can safely put on almost any metal stove. As for brick heating units, their weight can vary greatly, ranging from 500-600 kg, and ending with several tons.

The foundation for the oven is needed for several reasons:

- huge pressure;

- the possibility of bath settling;

- unstable soil.

If a brick oven is laid out directly on the floor, it will lead to tragic consequences. Even if the floor is reliably concreted, and its layer is from 15 to 20 cm, then this will increase the load on the foundation of the entire bath. As a result of uneven loading, especially when the stove is not built in the center of the bath, the whole structure will be distorted.

Concrete

The classic base for the furnace is a concrete slab, which is made by pouring cement-crushed stone mortar into a deep pit.

Scheme and device

The diagram shows the base that we calculated above for a stove weighing 1150 kilograms.

To install a high-quality concrete foundation, a certain list of materials is required:

- Cement;

- Coarse sand;

- Formwork boards;

- Crushed stone;

- Waterproofing, in the role of which roofing material or plastic film is excellent.

Also, to install a concrete foundation for a brick oven with your own hands, you need the following tools:

- A container for preparing a solution or a concrete mixer;

- Bayonet and shovels;

- Measuring tools: tape measure, corner, level;

- For the manufacture of formwork: hammer, hacksaw, nails;

- Construction stapler for waterproofing installation;

- For laying the base, a manual rammer.

Solution preparation

The base for the furnace must be strong, so the concrete solution is prepared in the following proportions: 1 part of cement, 3 parts of sand, 5 parts of crushed stone. Such a consistency will be able to withstand a large oven mass for a long time.

- It does not matter what kind of brick base is installed under the stove or concrete, it is initially necessary to dig a pit for it. The depth of the pit depends on several factors: the mass of the stove, the type of soil, the presence of groundwater.The width and length of the pit must correspond to the dimensions of the heating system and additionally have a certain margin of distance for the formwork. In order not to accidentally make a mistake, it is recommended that you first prepare a drawing of the future concrete base.

- After that, the formwork is installed, according to the dimensions corresponding to the final values of the dimensions of the structure, according to the drawing and diagram, which should have been prepared in advance. Sometimes formwork is not needed - if the soil is very hard and does not collapse from external influences on it.

- After the formwork is ready, the waterproofing is laid, it is attached to the formwork using a stapler.

- Pieces of brick are poured into the resulting hole, or large stones - this is necessary so that the resulting concrete slab under the stove does not sag and is well adhered to the ground, as shown in the photo below:

- Then concrete mortar is poured so that the base rises 6 centimeters above the floor. When pouring, carefully measure its evenness using a building level and level it to perfect condition.

- If it is possible to overlay the ground part of the foundation with a brick or rubble concrete stone, this can be done in this way:

Before starting the installation of the heating system, the foundation for the stove must dry for about 10 days, spray the concrete surface with plain water for the first week.

For a light oven

For the oven, assembled with sheet steel, which weighs no more than 150 kg, a separate foundation is also required. To do this, a pit is dug to a depth of 0.5 meters. Its length and width will directly depend on the size of the oven. After that, crushed stone is poured onto the bottom with a layer of 30 cm and compacted well.

Then a solution of cement of medium density is prepared. For this, 4 parts of sand, 1 part of cement and water are taken. This mixture is poured into crushed stone in the pit and left in this form for a day to solidify. In this way, the sole of the foundation is created.

After this time, in order to create waterproofing, roofing material is laid on the surface of the dried cement in two layers.

Next, concrete is prepared for pouring. Take 2.5 parts of sand, 4 parts of fine gravel, 1 part of cement and water. The pit is poured with the ready-made mortar to the required foundation height. And finally, using a level, the foundation surface is leveled to a horizontal state.

The kiln foundation is the most important structure in the entire structure. If it is made using high-quality materials and in compliance with all the rules, then it can last long enough on any soil, without creating unnecessary trouble for any design of heating equipment