When building a house, it is necessary not only to provide for all the loads, but also to protect the structure and especially the foundation from groundwater, which can have a destructive effect. Even at the planning stage, you need to choose which isolation method will be used. Today, protection of the foundation from groundwater can be carried out using mastics based on bitumen or resins, cement mortars, roll or pasting insulation. It is also necessary to think over the device of the drainage system, which will remove moisture around the perimeter of the house.

Waterproofing the foundation will serve as a good protection for it from groundwater, which can thereby have a destructive effect on the structure.

Why protect the foundation from moisture

PVC membrane with convex hemispheres.

Protecting the foundation from moisture is very important. If this is not done, then the basement and subfloor are guaranteed to be damp and cold. The structure of the concrete is porous, somewhat reminiscent of a bathing sponge. The pores are visible even with the naked eye. Because of this, moisture penetrates deep into the material and is difficult to remove from there.

Consequences of moisture accumulation in concrete:

- destruction;

- the appearance of mold;

- lowering the temperature in the room;

- there may be water in the basement.

Izorok fiber insulation is slightly worse than foreign insulation in terms of technical characteristics, but the difference is insignificant.

Most often, Ecover basalt insulation is used to insulate the facade.

When constructing buildings, a lot of attention is paid to protecting the foundation from groundwater. Don't underestimate the cost of a mistake. All work must be performed with high quality, according to the methodology. And also you need to choose the right materials so that their characteristics meet the operational requirements. Interesting article: “Internal and external waterproofing of the basement”.

How does the destruction of the foundation occur?

Freezing of water penetrated into the concrete can cause rupture of the structure

Several main stages can be conditionally defined:

- Destruction of waterproofing protection and ingress of moisture into the pores of concrete.

- Dissolution of mineral salts and solution retention inside the structure.

- Freezing and expansion of the solution at low temperatures.

- Destruction of concrete from the inside under the influence of ice expansion.

- Expansion of cavities, moisture, meanwhile, will fill new volumes of concrete until it reaches the reinforcing cage.

- Destruction of the frame and deformation of the entire foundation. As a result, the likelihood of a house collapse, the appearance of cracks.

Therefore, after preliminary preparation, it is better to protect any foundation even with a cheap roofing material than not to protect it at all. Otherwise, deformation of the supporting structures of the base will begin in a few years.

Foundation protection from the outside

Ideally, moisture protection of the foundation should be applied externally. This is usually done during the construction of a building. If the house has already been built, then outdoor work is possible only after the foundation has been dug around the perimeter.

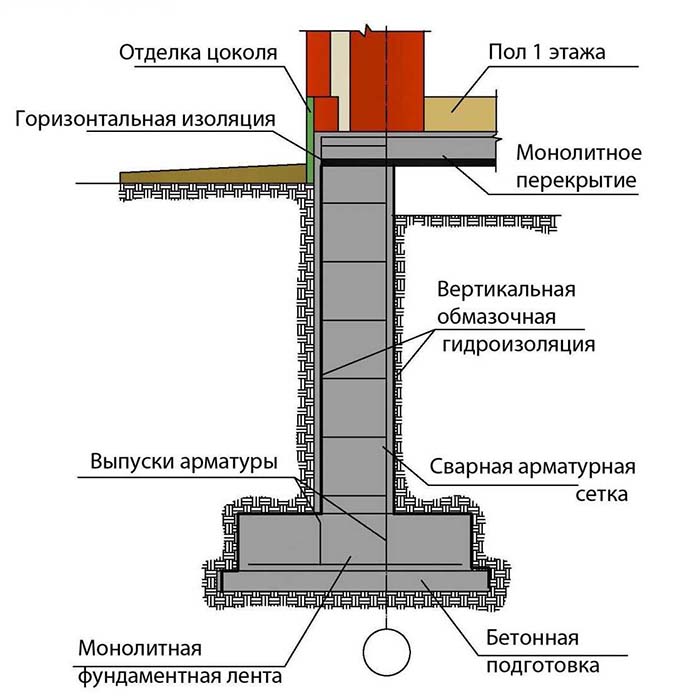

It is imperative to put waterproofing between the foundation and the wall.

Before protecting the foundation from moisture, consider which materials are suitable for outdoor use:

- bituminous rolls;

- polyurea;

- bituminous mastics;

- PVC membranes.

It must be borne in mind that the hydro-barrier will be covered with earth. It contains stones that, under high pressure, can damage the protective layer.The material used must be strong, therefore liquid rubber, acrylic mastics and thin polymer films are not suitable for these purposes.

Bituminous rolls are the most common form of foundation protection against water.

Black bitumen mastic is used as a primer (preparatory layer). It is applied to the work surface with a brush or roller in one layer. Then bitumen rolls are fused onto the mastic. It is a self-adhesive material that becomes sticky after being heated by an open flame. Rolls are laid in at least two layers with overlapping seams.

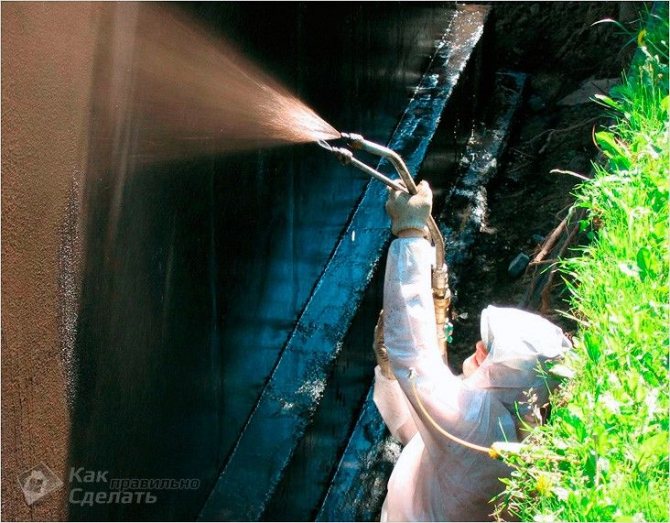

Polyurea is applied by spraying. Beforehand, the working surface must be cleaned of dust. A protective liquid polyurethane compound creates a strong, waterproof film that adheres securely to concrete. It is advisable to apply in several layers.

For installation outside the foundation, do not use thin PVC film. A special PVC membrane with pimples is suitable for these tasks. Hemispherical pads protect from stress and serve to connect the sheets. The waterproofing is attached to the walls of the foundation mechanically (by means of studs).

Horizontal waterproofing

This method of protecting the foundation of a private house is considered the easiest to implement, and therefore the most used.

The main tasks of horizontal waterproofing are:

- Resistance to groundwater if a protective layer is laid under the base of the foundation.

- Protection against wet capillary action, when the waterproofing is laid in the transitions of the foundation walls into the load-bearing walls of the structure itself (private residential building).

This method of waterproofing is used in the construction of almost any structure, regardless of what features the soil has on the site, and what is the total amount of rainwater.

Traditionally, horizontal waterproofing is called a layer created from pieces of roll materials stacked on top of each other several times.

Stages of work

To perform high-quality horizontal waterproofing, you should adhere to the following algorithm of actions:

First you need to prepare the foundation. For this, all surfaces to be treated are cleaned and leveled (if necessary). Then they dry thoroughly.- This is followed by the application of primers, which provide additional protection of the foundation and the maximum possible adhesion of the main waterproofing material to the base.

- At the next stage, the actual application of the waterproofing composition takes place. Most often, roll materials are used that are overlapped. If necessary, the waterproofing sheets or pieces are heated.

- Further, the surfaces are additionally treated with coating materials. And in order for them to provide the proper level of protection, they must be allowed to dry thoroughly. This will take 7 days, at least. Therefore, if the construction time is "burning", it is better not to use this method of waterproofing.

Materials for interior work

How to protect the foundation from destruction if it is not possible to apply waterproofing from the outside? It remains only to apply protection from the inside. All of the above materials do not work for separation. If they are glued to the walls from the inside, then moisture will simply tear off the protective layer over time. In addition, this approach cannot protect concrete from the destructive effects of water. Therefore, the only correct option is to use penetrating waterproofing compounds (impregnations).

Apply penetrating waterproofing to a wet surface.

The bottom line is that the impregnation penetrates the concrete structure and crystallizes there. As a result, all pores become clogged with crystals, making the material waterproof.The crystals are quite fragile, therefore, even with a minimal displacement of the foundation elements, microcracks appear.

Method of applying penetrating waterproofing:

- moisten the wall with water;

- apply a protective composition generously with a brush;

- keep the work surface moist for three days.

If you do not keep the wall moist, then the polymerization of the composition may not be intense enough. As a result, the crystals inside the pores will be smaller, which will negatively affect the waterproofing properties of concrete. Good to know: “Liquid waterproofing materials”.

Oleechnaya waterproofing

Instead of bitumen for arranging horizontal waterproofing of the foundation, today they increasingly use a unique innovative material - TechnoNIKOL sheets. And as a result, the waterproofing is laid in a layer 5 cm thick and consists of multi-layer moisture-proof membranes.

Such membrane sheets are self-adhesive polymer-cement films on a bitumen basis that perfectly protect any brick and reinforced concrete structures, including the foundations of private residential buildings.

It is very easy to apply these membranes to the surface. It is necessary to heat the sheets over a gas burner (very carefully), and then press firmly against the base being processed. Then level the surface with a roller, expelling the trapped air.

Such a material perfectly bridges cracks and fights moisture. However, so far the use of bituminous membranes has not been able to achieve 100% protection of the foundation, as is the case in cases of using bituminous waterproofing. In addition, the new material is not able to reliably close the fine pores of the base.

In addition to bitumen and Technonikol sheets, other materials can be used to waterproof the foundation. The choice is varied today. And each material has its own characteristics, differs in capabilities, pros and cons, as well as in cost.

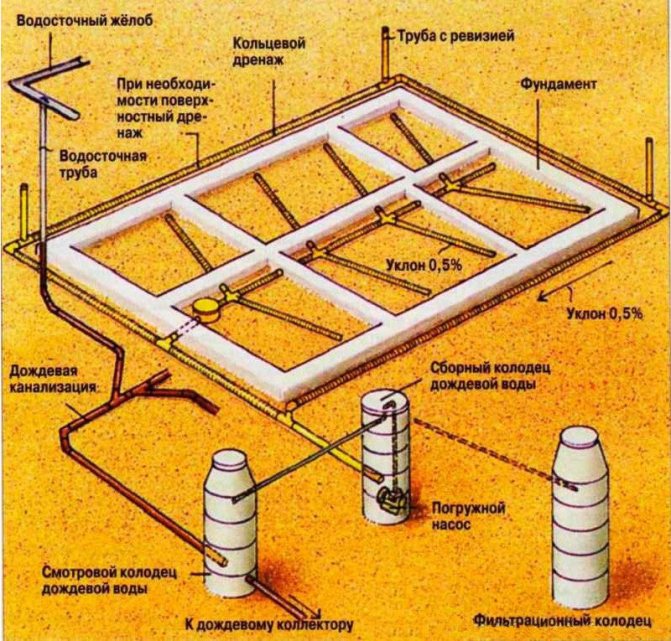

The blind area is the protection of the foundation from rain

The blind area is being built around the perimeter of the house. This is a concrete strip 1-1.5 m wide. The construction of the blind area is carried out according to certain rules:

- there must be a drainage layer;

- insulation is necessary;

- the waterproofing film is laid.

It is advisable to use Polynor sprayed insulation only in small areas, as it is expensive.

Dense basalt insulation Park can be placed even under the screed.

The blind area protects the foundation from rain, and this is the lion's share of all the moisture that affects concrete. The groundwater level is not always high. The blind area is erected when the house is already completely ready. It must be borne in mind that it does not protect the upper part of the foundation (plinth).

What is the best protection of the foundation from moisture

The best way to protect the foundation from moisture is to lay bitumen rolls outside. If for some reason this cannot be done, then it will be optimal to process the concrete from the inside with penetrating compounds, and build a blind area around the perimeter of the house. In addition, during the construction process, waterproofing is mandatory at the junction of the foundation and the wall. Roofing material is usually used. If this layer is not there, then problems with wet walls are guaranteed to you, and it will be very difficult to solve them.

Coating waterproofing

This type of waterproofing can act as the main protective composition or as an auxiliary one when it comes to the foundation. The coating layer is 3-4 mm thick and is applied directly to the surface of the foundation after cleaning, leveling and drying. As for the tools used, you can coat the surfaces:

- polymer solutions;

- bitumen-polymer mastics (cold or hot);

Depending on the composition of a particular preparation, such a waterproofing can be either elastic or rigid. And it is applied and leveled:

- spatula;

- spray;

- or using paint floats.

Stages of applying waterproofing materials

Waterproofing technology for concrete structures

Regardless of the type of waterproofing, there are a number of preliminary measures to prepare the surface for protection from moisture:

- First, the concrete must dry and gain at least half the strength of the brand.

- Then you need to prepare the surface for applying waterproofing.

- It is advisable to dismantle the formwork (if it is removable), then level out all irregularities with plaster, remove adhering dirt and dust, degrease the surface.

- If the foundation already exists, then you should excavate it around the perimeter from the outside, the width of the trench should be at least a meter, so that it is convenient to work there.

- Strengthen the walls of the trench with boards or beams to prevent the earth from shifting.

- Deepen the trench at least 0.5 meters below the base of the foundation so that a drainage system can be equipped.

- Wipe the surface with M-100 or higher grade solution, leave to dry for several days.

Types of mastic for the foundation

The classification is carried out mainly according to the method of application. There are, as a rule, two types: cold and hot mastic. To do waterproofing work with your own hands, it is better to choose cold mixtures. Since, for use, such compositions do not require special equipment.

Classification of mastics

In addition, in addition to some difficulties in the work, hot, assumes the builder has the proper qualifications. Therefore, further, we will consider only the cold method of application.

Foundation mastic is of the following types:

- Bituminous;

- bitumen-rubber;

- bitumen emulsion.

Differences between finely cut and conventional foundation

There are practically no fundamental differences in the installation of insulation of these types of foundations. The only difference is the area of treatment with compositions, the volume of materials, the duration of all work. A shallow strip foundation differs from the usual only in the depth of immersion, but the technology for carrying out the work is one.

It is worth remembering here that the difference in the depth of immersion of the concrete structure means a noticeable difference in the density of the contacts of the monolith and moisture from the soil. The usual type of strip base is lowered to a depth below the freezing limit of the soil. The base is located in more difficult conditions, is affected by changes in the water level, periodic influx of melt moisture, rain.

Therefore, in this case, waterproofing work is carried out using better materials and complex technologies in comparison with the processing of a shallow structure.

What materials should be used

When the question is whether it is necessary to waterproof a strip foundation and what is the best way to protect it, it is necessary to proceed from such factors as the structural features of the base itself and the entire building, the type of soil, operating conditions, etc. There are many materials on the market today and it will not be difficult to choose the most relevant option.

Foundation waterproofing materials:

- Roll (they are also gluing) - produced in the format of films, membranes, bituminous sheets, mounted on a layer of mastic or by heating, landing on glue (already applied to the sheets).

- Coating - bitumen, cold mastics, various compositions for application in liquid form, followed by solidification.

- Penetrating - sprayed or applied with a brush, absorbed into the concrete monolith, followed by crystallization and filling its pores, which makes the concrete resistant to moisture.

- Injection - similar in action to penetrating ones, they are applied by drilling holes in concrete and then distributing the composition under pressure, due to which the monolith is impregnated and strengthened from the inside.

- Painting - liquid polyurethane foam, liquid rubber can be used, which completely solidify after application and create a water-repellent elastic film. They do not last long, but they are applied simply.