Installation of a new heating system or reconstruction and repair of an old one may require painting the heating radiators:

- When installing new devices that do not have a special coating,

- In case of violation of the integrity of the coating of existing radiators,

- If it is necessary to change the color of the devices due to a change in the design of the room.

This raises the question of what kind of paint is needed for heating radiators of different types and how to apply it correctly.

How to paint a radiator?

Choosing a paintwork

Installing new batteries is costly. Sometimes there is no possibility of installation from the technical side. It is easier to paint the outside of the heating device if it still serves well.

The restoration itself will not cause difficulties, but this does not mean that you can purchase any composition and immediately begin to restore the battery. The paint should also be selected according to certain characteristics, and the radiator itself should be prepared responsibly. If you close your eyes to this point, the new coating will not last long, and soon you will have to refresh the structure again.

An old cast iron battery with climbing paint looks completely unattractive. In addition, the material of its body is oxidized and corroded.

When choosing a composition, experts recommend considering only options designed specifically for heating appliances. However, if there is no such inscription on the label, then you need to analyze the instructions and find information about its heat resistance.

To get a high-quality, reliable and beautiful coating, you need to use paint designed specifically for heating batteries.

Optimum paint properties for radiators:

- Heat resistance. The solution applied to the battery case must hold unchanged at temperatures of 80-90 ° C for a long time, which the manufacturer promises.

- Color preservation. This is a prerequisite, since the restoration of batteries is primarily carried out with the aim of creating aesthetics.

- Adhesion. It is necessary that the paintwork has good adhesion to the surface to be coated. The battery should look attractive as it warms up and cools down.

- Rust protection. The composition must have anti-corrosion properties so that the coating that adheres tightly to the body does not cause its destruction.

- Abrasion resistance. From direct contact with various surrounding objects, things that can be dried on the heater, the paint should not wear off.

- Safety. It is important that the composition is free of substances harmful to humans.

Remember that paint for cast iron batteries, steel and others must comply with all of the above points, and not just individual ones.

Types of compositions

The technical component of the paint is the most important point to pay attention to. However, aesthetic parameters are also not in the last place.

Pros of acrylic compounds

Acrylic compounds belonging to the class of water-based dyes make it possible to kill two birds with one stone. An absolute plus is that it is odorless paint for radiators, quick-drying (about half an hour at room temperature), safe for the human body, characterized by moisture repellency. The composition forms a durable coating that is resistant to mechanical damage.

The aesthetic and technical characteristics of acrylic paints are perfect for heating appliances.

And also an important point - they do not lose their appearance at high temperatures for many years.Within 7-8 years, batteries will not turn yellow, cracks will not go, paint will not peel off.

The whiteness ratio of odorless acrylic paint for heating radiators is 96%, the color comes out quite bright, the surface looks like plastic, with a slight sheen.

Properties of alkyd paints

Alkyd solutions are heat-resistant, so they are also used for painting radiators. They are even stronger than acrylic paints, protect heating devices from corrosion processes, fit perfectly on the surface, and form an even coating.

At the same time, they are not as safe as water-based formulations. The solvent that is included in the composition does not smell very pleasant, it often stays in the room for at least a day. Drying is rather slow, and the characteristic odor may be present in the future.

Such alkyd compositions can only be used in rooms with good ventilation, it is recommended to leave the room while the odor dries and wears off.

Another big disadvantage is that the solutions retain their own color for a short time, and over time they begin to take on a yellow color. When you decide to buy exactly alkyd paint, then choose a composition that forms a glossy finish. In this case, the white battery will last longer, almost 20%, compared to matte or semi-matte solutions.

Other types of paint materials

For painting radiators, compositions are produced based on aluminum and silicate resins, which form a dense and elastic layer on the surface. Cracks do not appear on it, even with temperature drops. Silicate materials have high adhesion, do not require surface priming, and are designed to function at high temperature conditions.

Another variety is hammer, from the class of alkyd compounds. They form a rather interesting, special coating. After painting, the surface does not come out smooth, but as if slightly hammered with a hammer or with an embossing effect.

Hammer compounds perfectly hide the unevenness of cast iron batteries, and this characteristic is very useful for residents using an old heating system.

A big plus of hammer paints in their heterogeneous texture, thanks to which various irregularities, roughness and other imperfections of batteries become invisible. This property is very appreciated when it is required to paint old Soviet-type cast iron radiators, in which the rough surface will not be visible behind a special coating.

Often, silver can be used to restore batteries, which is a mixture of varnish and aluminum powder. It has excellent resistance to high temperatures and can be applied to both primers and old coatings. At the same time, the paint is characterized by a persistent odor, therefore, during its application, the room needs to be well ventilated.

You can buy silverware ready for painting. Alternatively, you can prepare the mixture yourself; for this, parts of aluminum powder are mixed with five parts of varnish.

Aluminum powder is explosive. Therefore, it is very dangerous to prepare the mixture yourself. It is not recommended to start this process if there are flammable objects and small children in the house.

Is it possible to paint a heating radiator

The difficulty here is that the heating devices operate in an alternating heating / cooling mode. This means that the enamel for radiators must be as resistant to temperature changes as possible. It should not be distinguished by a pungent "chemical" odor, which is noticeably enhanced by heating, and the odorless paint for radiators itself should adhere firmly to it, without cracking or forming drips. Therefore, the highest priority should be given to responsible brands and manufacturers.These products have quality certificates that clearly confirm the absence of compounds harmful to human health in the composition of the product.

Painting will return an attractive appearance to the radiator

Preparing radiators for painting

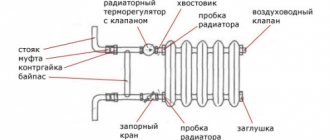

Now let's figure out how to prepare and how to paint cast-iron radiators with our own hands. Preparation is required for quality painting and takes even longer than painting itself.

How do I clean old paint from a battery? Prepare radiators in this way:

- Start with a high-quality surface cleaning before painting. To do this, you need to remove the paint layer, and clean up the places with the emerging corrosion to a metallic sheen. Dust and dirt are removed with a damp cloth, old paint is removed with a spatula and special cleaning solutions.

- Radiators are painted with rinsing solution, which are later covered with a softening film. Then this paint can be easily removed with a spatula, a grinding machine or a metal brush that is put on a drill.

- It is recommended to wear construction gloves on your hands, protect the respiratory tract with a respirator or gauze bandage.

- Then the surface of the radiator is cleaned with sandpaper, degreased with some weak alkali solution.

- An anti-corrosion primer is applied to a high-quality cleaned surface. The solution will also increase the adhesion of the paint to the body of the heating structure. For this, an alkyd-based primer is best suited.

Now you know in general terms how to manually clean old paint from a battery. Remember that the primer must have anti-corrosion properties (information about this can usually be read on the can), otherwise, after a certain time, rust will again make itself felt. On a high-quality cleaned surface, the coloring solution will fall as needed.

To prepare everything qualitatively for painting, you need to remove the old paint from the battery, remove rust, remove dust and dirt.

Currently, the construction market offers a large selection of paint solutions that already contain a primer and a rust converter. Their advantage is that their application to radiators does not require preliminary preparation of the base.

Radiator painting

Preparing the radiator for painting

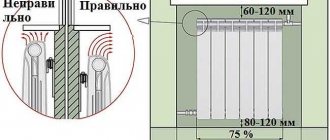

Even if the paint for the radiators is selected correctly, the material is of high quality, but if the painting is done without observing the basic technological requirements, the radiator will not look at a high level. It is especially important to study the technological rules for those who are planning to paint with their own hands for the first time.

First you need to prepare the radiator for painting. To do this, do the following:

- Prepare the radiator for painting. Wash well with a soft cloth, a brush and always with a detergent.

- Degrease. Remove any irregularities from the surface using sandpaper.

- Remove old coating and treat corroded areas with a special compound.

When the radiator is ready, you can start painting. How to paint a radiator is described below. It runs as follows:

- turn off the heating, if it does not work, then dilute the paint so that it can be applied in a thin layer;

- apply paint from top to bottom so that there are no unwanted smudges;

- be sure to paint over all labor-consuming places, where you cannot get a regular brush you need to use a special one for pipes. It has a curved shape;

- it is better to apply two or three thin layers, but before starting to apply the next layer, you need to wait for the first one to dry well.

Sometimes spray cans and rollers are used to paint pipes. They can be used when hard-to-reach places have already been painted over. For convenience, you can remove the radiator from the hinges and paint. If possible.

Important! Even if odorless paint is used for the coating, the windows still need to be opened. All work must be done with gloves.

Painting process

How to paint heating batteries with your own hands with high quality? It is worth saying that the process should be carried out with the heating turned off, otherwise in some areas the paint will dry very quickly, lie unevenly, form smudges that will look unattractive. Of course, you can buy a special dye solution that is used on warm batteries, however, it can lie unevenly if the heating is not turned off.

And yet, if you are not afraid of trouble and are looking for what paint can be used to paint hot radiators, then there is always a choice of solution. You can consider paint for yourself, for example, from Radikor. The coloring solution is applied to structures heated to +60 ° C, dries on hot heaters in less than one hour.

Now radiators are painted in colors that best match the overall interior design of the rooms.

When there is no other possibility, but it is necessary to paint the heating battery during the heating season, then you should at least shut off the supply of warm water yourself or call the housing office with this request. The temperature heating of batteries in this way can be significantly reduced.

You have decided on the dye solution, figured out how to remove the old paint from the radiators, now is the time to start the dyeing process:

- First of all, you should think about the safety of the flooring from dirt and the solution itself. You can put some kind of paper or fabric under the radiators.

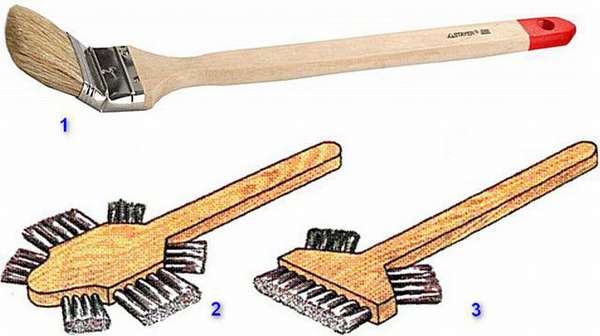

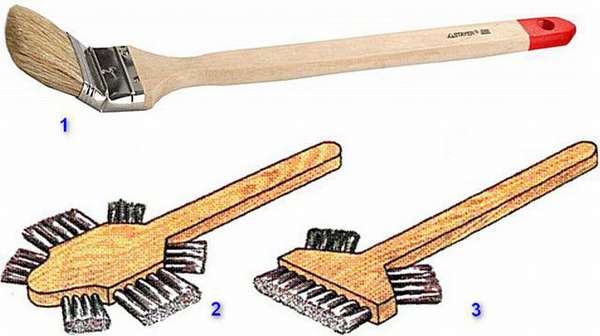

- Then you need to choose small brushes with soft bristles, one is straight, and the other is curved, for painting in hard-to-reach places.

- It is worth starting to paint first the upper part of the radiator, then heading down. Painting is carried out from all sides: initially internal overlap, then external in order to avoid getting hands and clothes getting dirty.

- Two color coats are applied alternately. Remember that two thin coats are better for paint than one thick one. Because only in this case, you can count on a uniform and high-quality coating.

You can also spray or spray the batteries.

When using heat-resistant paint from a spray can, the process will be more convenient and faster, the coloring agent will lie in a thin, smooth layer.

If you decide to use a spray gun for painting, then it is better to remove the heating radiator. This will allow better paint over all areas. Restoration with a spray can be carried out easily and with minimal time costs. As a rule, instructions for using the can is given on the label. The main rule is to perform zigzag movements up and down at a distance of approximately 30 cm from the surface of the body.

How to calculate paint consumption

On the labels, the manufacturer always indicates the average consumption of paintwork per 1 m². Thus, it is not difficult to determine the required amount of enamel when it comes to flat models of radiators. But here, too, one should not forget about painting over the inside of the battery. With cast iron accordion radiators, it is even more difficult.

In this case, technical documentation for heating devices will come to the rescue, usually it indicates the total area of the product. If the registration certificate has not been preserved, special online calculators are used.

Calculation calculator

The online calculator takes into account all the parameters of the upcoming work:

- Battery model.

- The number of sections.

- Paint type.

- The need to paint the pipeline.

- Estimated number of layers.

The program automatically gives the result in kilograms, taking into account the 10% reserve or the total surface area for painting, according to which you yourself the required amount of product.

How to remove old paint

The basic rule for painting used radiators is to remove old paintwork.You can accomplish this task in one of two ways (or in combination):

- Mechanically.

- Using chemical reagents.

For high-quality cleaning and subsequent staining, it is better to remove the battery from the wall.

Mechanical method

Mechanical cleaning involves removing the old paintwork using handy means.

- First, the battery, and, if necessary, the pipe, is cleaned of dust and other contaminants with a damp cloth. For best results, you can use a vacuum cleaner.

- Then the surface is carefully sanded with sandpaper. Rust is completely removed. To speed up the process, a drill with a brush attachment with hard bristles or a grinder is used. To remove paint in hard-to-reach places, you can use a building hair dryer, it heats up the enamel, which is then removed with a scraper.

- Finally, the work surface is again dust-free and degreased.

Mechanical cleaning has a lot of disadvantages:

- Great labor intensity and time expenditures.

- The process is quite dusty.

- There is a high probability of damage to the metal.

On a note! If the paintwork on the radiator shows no signs of wear (swelling, peeling, rusting), but still requires replacement, it may not be removed. To ensure adhesion to fresh enamel, the radiator coating should be lightly sanded.

By chemical means

For chemical cleaning, special preparations and removers are used. They soften the old coating and stimulate its flaking from the metal.

- They need to be applied in a dense, even layer using a brush with natural bristles. The gel form of the drug adheres well to the surface.

- After the time indicated by the manufacturer, the wash is simply removed with a wooden spatula along with the dissolved paint, and the radiator is washed with soapy water.

- The cleaned battery is additionally treated with a corrosion inhibitor and then degreased.

On a note! Some manufacturers produce washes with a corrosion inhibitor already included in the composition. They cost a little more, but significantly reduce the time required to prepare the radiator for painting.

It is important to remember that chemicals are toxic and flammable. Therefore, work should be done in a well-ventilated area away from sources of fire. Personal protective equipment - respirator, gloves and goggles will also be useful.

Should you paint aluminum radiators?

All of the above information with recommendations related to painting radiators made of cast iron, copper, steel. The question arises: how is the painting of aluminum heating batteries carried out? And here is the second question: is it necessary to do this at all? Currently, aluminum devices are painted in factories by professionals with a special powder paint. Home restoration will not provide a reliable, beautiful finish.

In addition, if the battery still has a warranty, then after painting the manufacturer's warranty will not be valid. However, rarely would anyone think of painting a new structure. When the device is damaged during transportation or installation, cracks and chips appear on it, which significantly spoil the appearance. In this case, you can apply auto enamel.

It is worth saying that car enamel fits well and dries quickly only on warm batteries. The drying time at 130 ° C is 20 minutes, and at 20 ° C - two days. It is worth working in a respirator, the room should be well ventilated, paint should be sprayed at a distance of 30 cm from the surface. Do not keep the jet in one place for a long time to avoid smudges.

Radiators made of aluminum or structures made of bimetal, where the outer part of the case is aluminum, it is almost impossible to paint houses yourself.

You can also remove chips and dents from an aluminum battery using automotive putty.To do this, it is necessary to degrease the surface in advance, treat it with a primer. Then apply with a brush the putty of the required color. Do you want to completely change the color of the radiator? It is powerful to paint a radiator over old paint. It is necessary to degrease and prime the surface, apply two layers of paint. You can paint batteries with water-based paint and alkyd paint from a spray bottle.

Why is the paint swelling on the heating radiator?

If bubbles appear on the radiator, this means that in some places there is no adhesion of the coloring material to the body, the film of the solution lags behind the surface and forms a swelling.

Possible reasons:

- an alkyd or oil battery paint was applied to a wet surface;

- moisture has entered through the outer wall;

- the application technique is incorrectly selected;

- for painting, tools that were not suitable for the purpose were used.

How to solve this problem:

- Grind the surface at the place of the bulge, treat it again with a putty, re-grind and repaint with a high-quality dye solution.

- If the imperfections are visible on the entire surface, then it is required to remove the source of moisture (if possible), then clean, prime and repaint the case.

Radiator paints

Technical requirements

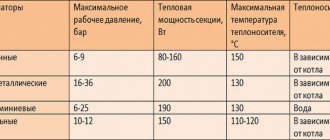

In order for the paint to protect the heating radiator from damage, and also to retain its original appearance for a long time, it must meet the following requirements:

- Intended for painting metal,

- Protect against corrosion,

- Resistant to abrasion and cracking,

- Be heat-resistant (when using water as a heat carrier, maintain a temperature of at least 100 0C).

In addition, it must be non-toxic (without impurities harmful to humans).

Battery painting

Different types of paint

The heating radiator can be painted:

- Enamel. Enamels are inexpensive and have a wide range of colors to your choice, but they do not tolerate high temperatures and reduce the heat transfer of the device. They dry for a long time, smell unpleasant and they can only be painted on a cold radiator.

- Acrylic dyes. They are odorless and dry quickly; they can even be applied to a hot radiator. They do not last long, as they have a low coefficient of adhesion to the painted surface and may crumble over time. After drying, they change color slightly.

- Alkyd paint. Heat-resistant, fits well on the surface, but dries for a long time and smells unpleasant.

- Special paint for radiators. It can withstand any rise in temperature, so it can be used to paint even hot heating elements. Dries quickly, does not reduce the heat transfer of the device and does not turn yellow over time. It is produced in a limited range of colors and is more expensive than other types.

Special heat-resistant enamel

Interesting! The color of paint for radiators can be any - light or dark, suitable for the design of the room. But experience shows that for better heat dissipation, it is better to use dark shades.

How to navigate the range of paints and varnishes

The Russian building materials market is replete with offers for imported and foreign products. However, you cannot go to the supermarket, buy the first compound you come across and cover the heating radiators. For the convenience of selection, modern products have a classification and description of the main parameters. Main division:

- varnishes and paints for outdoor use;

- interior paints (for interior work).

Each coating is designed to handle specific materials. For example, varnish or enamel on wood is not suitable for painting radiators. In addition, any surface is pre-treated with a specialized primer so that the paint does not curl, does not peel, does not darken from reaction with the surface.

The modern market offers many varieties of paints

There are conventional coatings and heat resistant ones. Of course, radiator paint falls into the second category.A can with a heat-resistant coating must indicate the limiting temperature in degrees - 80, 100, 120 or 150. It can be used to process metal products themselves under a coolant, and adjacent surfaces.

Important! Before painting with even the highest quality paint, old pipes and radiators must be prepared in advance - to clean up the places that have begun to turn red, peel and rust. To avoid these troubles later, it is important to choose a specialized heat-resistant paint for the radiator coating.

In a residential area, it is important that after renovation, the smell of paint is non-toxic and quickly disappears with normal ventilation. This is especially important in a room with allergy sufferers or asthmatics. But it is also pleasant for ordinary people when the batteries dry quickly, do not stick, and immediately after repair, you can forget about problems with painting. Therefore, the correct choice of coverage is so important.

Preparing the radiator for painting

Before painting heating devices, they must be prepared accordingly:

- Remove dust, dirt and grease.

- Remove old paint layers. This must be done, since each new layer reduces the heat transfer of heating and lies on top of the previous layers ugly. It can be done:

- mechanically using metal brushes and sandpaper,

- chemically using solvents or fatty acids, observing safety precautions.

- Apply a layer of special anti-corrosion primer.

Attention! The primer should be selected to match the type of paint you choose. In this case, it is better to choose paint and primer from the same manufacturer.

Painting devices from different materials

Heating batteries made of different materials have their own painting characteristics:

- For coloring cast iron, you can use universal enamels. Before painting cast-iron batteries, it is better to turn off the heating. Paint dries faster on hot surfaces and may wrinkle and form uneven spots. If it is impossible to turn off the painting on the radiator is applied in a thinner layer.

- Steel, aluminum and bimetallic batteries are manufactured with an already applied layer of factory powder coating, so painting them at home is quite problematic. Before painting such a radiator, you need to carefully clean it with a grinder. For painting it is better to use alkyd enamel or acrylic (acrylate).

Painting cast iron appliances

Remember! For cleaning non-ferrous metals from old paint layers, it is better to use a mechanical rather than chemical method. Chemical solutions can react undesirably with the radiator surface.

plusteplo.ru

How to paint heating radiators with your own hands

Battery preparation

Removing the old paint coat is only the first preparatory step. In the future, you should adhere to the following recommendations:

- Unevenness and roughness are leveled by metal filler. After it has set, the surface of the battery is again cleaned, dedusted and degreased.

On a note! If you plan to paint with acrylic enamels, it is better to use acetone as a degreaser, and white spirit or gasoline for alkyd compositions.

- The next step will be priming. This also takes into account the type of future coverage. The base of the paintwork and the primer must be of the same type.

- Each coating (putty and primer) is naturally dried at room temperature.

Painting process

Coloring is also carried out at room temperature. In this case, it is advisable to choose the period between the heating seasons (before or after). Only a few types of paints can be applied to a heated battery.

Painting is performed in one of the following ways:

- By hand with a brush or roller.

It is better to choose brushes with soft bristles. This makes the paint smoother and less splashing.Painting the internal elements of a radiator with a regular brush, as a rule, does not give a good result. To ensure 100% painting, special brushes are used, bent at a certain angle, with double-sided bristles, etc. (see photo).

- Using a spray gun or by means of an aerosol can.

Compositions sprayed with a spray gun are pre-diluted by 10 percent with water or solvent (depending on the type of paint).

Whichever method you choose, you need to adhere to the following rules:

- First, the inside of the radiator is painted.

- To avoid smudges, painting is carried out from top to bottom.

- It is better to apply the paint in a thin layer. Then it will dry out better and not flow.

- Coloring is done in 2-3 layers. The next layer is applied only after the previous one has completely dried.

- Do not paint over the air outlet of the automatic air vent. This blocks its work.

Coloring video

Types of paints

It is wrong to think that a radiator for heating can be coated with any paint with a high quality indicator or significant cost. So, before it was often used precisely oil or aluminum paint for heating radiators. Considering them the best suitable option for this device, use was ubiquitous.

It is unacceptable to paint radiators using such substances in these conditions, since their function does not imply protection of the metal surface at high temperatures. Thus, the paint on the radiators quickly fades, cracks and even peels off, requiring re-processing.

Imperfect options were replaced by paints more suitable for thermal elements. The best options are the following types of enamel:

- Alkyd. This composition can be used at temperatures no higher than 150 degrees. When the temperature rises, the color gamut does not change in any way. The paint has an unpleasant odor, which disappears after one week after dyeing. The cost is quite high.

- Acrylic paint for radiators. It is an odorless paint that can withstand approximately 80 degrees. Only white paint is on sale, to which a dye is added. Affordable price and availability of the product often take it to the first place.

- Silicone-aluminum. Long-term use can be up to five years without re-coating. The range of temperature conditions reaches 500 degrees. The elasticity and adaptability of the composition to thermal expansion and contraction make the enamel practically invulnerable. The cost of such a substance is quite high, while an unpleasant odor is observed, which is retained for a long time. Such analogs dry quickly.

- Aluminum with heat-resistant varnish. The people call this paint silver. Used at a maximum temperature of 200 degrees. It should be applied only to a prepared heater and preferably used in non-residential premises. The composition contains many variations of petroleum products, which makes the enamel environmentally friendly. It smells unpleasant and takes a long time. The cost is moderate, the availability is wide.

The advantage of such paints and varnishes in comparison with standard options is obvious. The paint for heating radiators cannot be completely odorless, but there are other positive characteristics.

The above listed compositions are resistant to thermal influences, wear-resistant during operation and do not have a persistent unpleasant odor.

Some useful tips

We paint the heating radiator in the apartment

When choosing a paint, one must take into account the type of room. If the place is public, an office, then cheap materials can be used.When repairs are made in a city apartment, odorless paint is definitely needed, and this is especially important if repair work is planned in the children's room.

Many people use ordinary paint materials for painting pipes, which are designed to work on floors, walls, and ceilings. This is not the best option. They are not suitable for use at high temperatures, therefore they spread quickly and acquire a yellowish tint on the surface.

If you have to choose between glossy and matte paint materials, then you need to take into account the fact that a shiny coating always attracts attention and all the defects, irregularities and other imperfections of the radiator will be visible. The matt light finish will quickly turn gray as dirt builds up in the porous structures.

We paint batteries with our own hands

More often they prefer to choose a paint material for white radiators. This is no longer relevant. Previously, there was not such an abundance of materials as it is now. White radiators look beautiful only in rooms where the walls are made in light colors. It is better to choose the color of the paint to match the color of the walls, the entire room.

Knowing all types of paints, their features and application rules, it remains only to get to work. The main thing is that the work is done in a good mood, and then the repairs carried out will delight you with an aesthetic look for a long time.

What paint is better to choose

The aesthetic appearance of a radiator will largely depend not only on the cost of the chosen paintwork, but also on the compatibility with the material of the radiator itself, as well as on the features of its design. What paint to paint? For primary staining, it is better to use glossy options. It is matte paint for painting heating batteries of a repeated type that is used - its base will hide all the irregularities and imperfections of the radiator.

Consider examples of coloring different types of radiators in accordance with their characteristics:

- Paint for cast-iron heating radiators has many nuances when painting, which relate to irregularities and not quite aesthetic joints, seams. In most cases, even matte paint does not hide all the nuances. The only correct solution would be to use colored paint that repeats the shade of the interior design of the walls. If there is a need to paint the battery exactly in light colors, then the base of the device is pre-filled.

- It is better to paint aluminum and bimetallic radiators with powder paints, but not white. The downside is that processing at home is almost impossible. First, you need special tools. Secondly, in order to perform high-quality staining, special skills are needed.

- Spray paints, that is, paints in spray cans, are the most popular at the present stage. This feature is inherent in the fact that the method of applying the product to the surface is the simplest. The main thing is to cover the wall with some material so that it does not get dirty. It is often necessary to apply at least two coats to level the surface. It is a quick drying option.

It is better to seek the help of a specialist when choosing a paint. The seller will be able to tell you which paint is best correlated with one or another type of radiator. It is necessary to take into account the preferences that relate to the design of the interior design.

Often, several types of paints can be used to create a visual combination in relation to tone or color. It makes no sense to single out any one section of the battery.

The subtleties of the choice of coatings

The choice of paintwork for heating systems should be based on the requirements imposed on them. The following qualities of the protective coating must be taken into account:

| Heat resistance | He has to withstand the effects of high temperatures, reaching over 100 ° C. |

| Non-toxic | During the heating process, no harmful substances should enter the air. |

| Wear resistance | Since all elements of the system become dirty over time, you should choose a paintwork that can withstand the effects of aggressive cleaning agents. |

| Thermal conductivity | The main requirement, therefore, coverage should in no way contribute to a decrease in this indicator. |

As already mentioned, paint intended for painting pipes and heating devices should protect them from damage caused by corrosion. For this reason, it should be of high quality, and its action should be purposeful - i.e. you should choose a coating that is specifically designed for metal. And although its price will be higher, the funds invested in it are able to justify themselves.

Odorless heat-resistant water dispersion enamel for heating radiators

How to choose paint

Radiators and all other elements of the heating system are part of the interior, so their appearance must be impeccable. Therefore, before proceeding with any work, you should familiarize yourself with the proposed assortment that meets the required characteristics.

But the final choice of the consumer depends not only on the properties of the coating, but also on other parameters:

- colors;

- features of application;

- subsequent care of the painted elements.

Consider the most commonly used paintwork materials in this case:

- Acrylic enamels, which include organic solvents, are especially natural... Therefore, during the dyeing process and after drying, a corresponding odor remains. The application of such enamels allows the surfaces to be smooth and glossy.

Odorless acrylic paint for radiators "Rainbow"

- Alkyd enamels presented on the construction market in a wide range of colors are distinguished by increased indicators of thermal and wear resistance.... However, in winter, when the batteries are very hot, such a coating gives off a pungent odor, causing discomfort for the residents of the house.

- The absence of any odors guarantees the application of water-dispersible enamels, while such a coating dries quickly... But only those compositions should be purchased whose purpose is to protect and give a decorative appearance to the radiators. Otherwise, the coating will not provide the required protective properties.

- Convenience and ease of use are provided by aerosol enamels. Their application does not require the use of a brush, which is their main advantage.

Odorless radiator paint for interior use

Characteristics of materials

Despite the huge range of paintwork materials used to cover metal products, special attention should be paid to their characteristics, which can vary significantly.

For example, many manufacturers produce coatings that are capable of performing exclusively decorative or, on the contrary, protective functions:

- The base of acrylic enamels is a synthetic resin that can withstand temperatures of 90 ° C. It is characterized by increased thermal conductivity and does not emit strong odors. After painting with your own hands, the devices acquire a glossy shade.

Eco-friendly odorless enamel for painting heating devices Ecolaque - Alkyd enamels do not emit odors during coloring and do not change color when exposed to high temperatures. Among other things, this material fits perfectly on the surface. If necessary, such enamels can be diluted, for which either turpentine or white spirit is used. However, their content in the enamel should not exceed 5%.

- The ideal option for self-painting would be the use of spray paint. They are intended for coating metal products and can withstand heating up to 650 ° C. And the ease of application and anti-corrosion properties are combined with excellent wear resistance properties, which make heating elements resistant to household chemicals.

- A white semi-matte coating for heating devices, which does not turn yellow over time, is provided by enamel, which is based on glycerophthalic resins. It is able to withstand heating up to 120 ° C and perfectly tolerates the effects of household chemicals.

- Does not contain chemical solvents, dries quickly and provides a semi-glossy shade water-based paint. If necessary, it can be diluted with water; it can be diluted with special pigmented additives to achieve the required shade.

- If the pipes are already painted with paint that can withstand low temperatures, the primer-enamel that can withstand heating up to 200 ° C will increase their heat resistance. Its distinctive feature is that this material can be applied to metal surfaces at temperatures from -25 to 35 ° C.

In the photo - odorless silicone thermal paint for radiators "Tikkurila"

Radiator material and paint application

Various materials are used in the manufacture of heating devices and other elements of the heating system.

Therefore, before purchasing this or that coating, you should familiarize yourself with the features of their composition.

- It is necessary to paint cast iron radiators only with universal compounds. But before starting work, you should turn off the heating and let the system cool down. This requirement is explained by the fact that on a hot surface the enamel dries quickly, forming irregularities.

Advice: if it is impossible to turn off the heating, then the enamel should be applied in a thin layer in a diluted form.

Water-based enamel from TSK TON-M

- Aluminum and bimetal radiators are already painted with a protective compound. Therefore, if there is a need to update their appearance, the protective layer must be removed with a grinder. Alkyd enamels and acrylate are ideal choices for such products.

How to paint batteries

Process instruction:

- At the initial stage, the old coating is removed from the devices, for which improvised tools, for example, a metal brush or sandpaper, can be used.

- Further, the devices are covered with a primer, after which dries, you can proceed to the painting process itself.

Rub the paint thoroughly, avoiding drips

Advice: all work should be carried out exclusively with the heating turned off, applying paint in several layers, which will achieve the best result.

Preparatory work

After the choice of paint for the radiator is made in accordance with the requirements for the composition and functional features of the product, you can proceed to the preparatory stage. It consists of the following actions:

1. First, it is worth treating the surface of the radiator. Secondary painting is usually done, so it is important to accurately assess the condition of the radiator before processing. If at least five layers of paint have already been applied to the battery, then it is better to remove the excess with the help of mechanized cleaning.

2. If the previously applied layers are severely damaged, if the paint is cracked or peeling, it must be completely removed to the very base of the metal. For this, special machines or chemical flushing agents are used. This procedure should be done especially well.

3. In the case when there are no more than three layers, it is enough to process the surface with emery paper. It is worth choosing fine-grained. All streaks and drops that have formed as a result of preliminary staining are preliminarily cut off. It is necessary that the surface is smooth, without the slightest roughness.

4. After sanding, processing is carried out with chemical agents that degrease the surface. This can be done with acetone or solvent. Often this work requires several degrees of processing. Only then is the enamel applied to the surface.

paints and varnishes

30 votes

+

Voice for!

—

Against!

Heating radiators last more than 50 years, but at the same time their outer coating will last much less. The coating can and should be restored. Do it yourself or call a master - it's up to you. The fastest and easiest way to "bring beauty" is to paint the radiators.

In the Loft style, cast iron batteries harmoniously act as an element of the interior. In this case, the paint must be matched to bronze or brass. When choosing a paint, you need to pay attention to its technical and operational characteristics.

When painting, it is worth remembering that some compounds increase (oil paints), and some reduce (paints that contain metal - aluminum, lead) the heat transfer of the radiator.

Content

- Preparing video radiators

- How to choose battery paint?

- Painting radiators video video

Radiator preparation

The most common radiators in Soviet times were cast iron batteries. Probably, the service life of these radiators is equal to the service life of the apartment. But they, like any thing, need care. They are not whimsical in operation, but the appearance needs to be updated.

The preliminary step is to clean the battery from dust residues, previous coatings and rust. Processing must be carried out in several ways:

- mechanical - scrape off dust, paint and rust with a stiff brush with metal bristles and sandpaper, you can use a power tool to facilitate the task;

- chemical - special solvents that soften the paint, and it is also necessary to use a corrosion inhibitor.

After cleaning the surface of the heater, it must be degreased. To do this, you can use a 1% solution of ammonia, soda solution or household detergents.

The surface of a cast-iron battery very often has roughness and chips, which must be primed and leveled with a putty, and then primed again. The metal primer must be from the same manufacturer from which you will be using the paint.

How to choose battery paint?

The main criterion when choosing a paint for heating radiators is its heat resistance. Most modern high-quality materials can withstand temperatures up to +80 ° C. For heating radiators, this parameter should be at least 100 ° C. These paints are specially marked. At the same time, the paint should have greater wear resistance and not release toxic substances when heated.

For painting heating devices, they produce:

- acrylic enamels - made on the basis of polyacrylate. They have a glossy structure and last up to 20 years.

- alkyd enamels - paints based on polyhydric alcohols. They have a wide range of colors. The service life is 3-5 years. The main disadvantage of enamel is solvent fumes, which are toxic and have an unpleasant odor.

- water dispersion paints - developed on a water basis, it is odorless paint for batteries, dries well. It is necessary to use introductory dispersion paints on a mineral basis. The service life of the coating is up to 10 years.

- silicate paints - developed on the basis of a suspension of pigments, hardeners, silicates and water glass. They are highly resistant to heat and wear. Service life up to 20 years.

Each material has its own pros and cons. Which paint for batteries is better is up to you. In residential premises, it is better to use paints, the solvent of which is water, they are completely non-toxic and odorless.

Radiator painting

The optimal time for painting batteries is the time of repairs in the apartment. It is advisable to paint the batteries after the end of the heating season. If you paint during the heating season, you must close the inlet valve or the thermal head of the radiator and wait until it cools down.If you paint a hot battery, the paint will drip in an uneven layer, and wrinkling of the surface film may form due to the excessively rapid drying of the solvent. You can paint hot radiators with special compounds, but they are much more expensive.

Before starting to paint, care must be taken to protect the floor and walls from accidental paint splashes. To do this, use unnecessary paper or cloth. If such material is not found on the farm, it is necessary to purchase construction plastic wrap. If painting is done from a spray can or using a spray gun, it is recommended to cover or move the nearby interior items.

It is necessary to start painting the radiator from hard-to-reach places and various recesses. To do this, use special brushes with a curved handle.

It is worth applying paint in a thin layer, you should adhere to the rule: two thin layers are better than one thick one. It is recommended to apply the next layer on the previous one after the paint has completely dried.

Using the art of decoupage, a cast-iron radiator will turn into a pretty piece of interior decoration of the room. The decoupage technique will allow you to realize the most daring and incredible ideas.

Answering the question - how much does it cost to paint a battery? - the answer will be simple and concise - a little time and desire.

Remember that regular renewal of the protective coating on the radiator prolongs their service life and the service life of the entire heating system as a whole.