Types of grates

Material

The temperature in the furnace is high enough, which forces the craftsmen to make gratings from special metals:

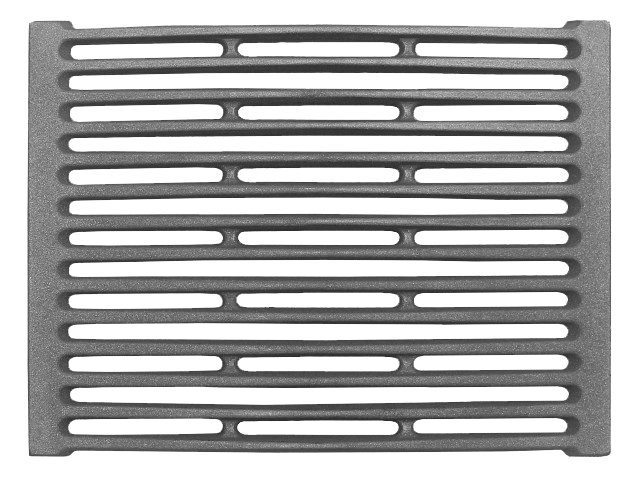

- The most durable is the cast iron grate for the stove.

- There are also steel parts, the most popular of which is antipyretic steel. Such grates do not lend themselves to oxidation and corrosion when burning a flame, and also do not deform. These devices can have different sizes and shapes, the abundance of which provides the possibility of choosing a grate even for a non-standard stove model.

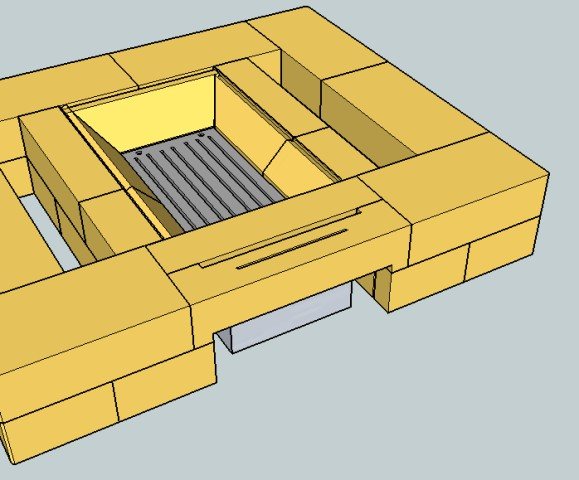

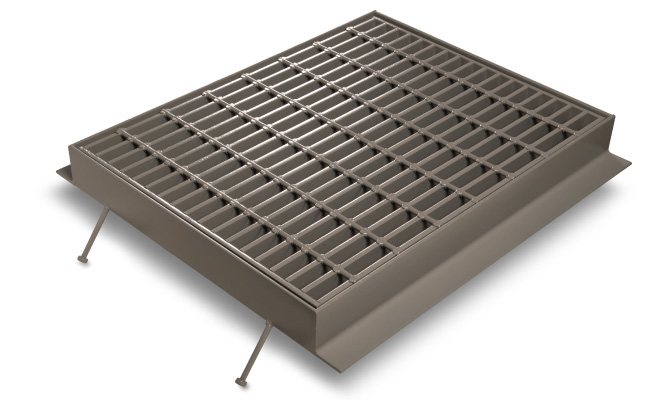

An example of a grate for a furnace

Solid and typesetting

For convenient use, you can choose different designs of grate grates:

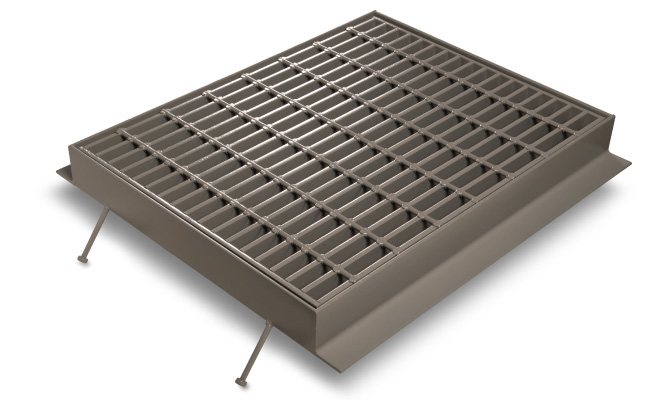

- Whole. have the form of monolithic lattices, they are not decomposed into smaller components. For most manufacturers, the dimensions of the grates for the furnace are standard, focused on the most popular models of furnaces. The choice of sizes of solid parts is large enough. Preference should be given to a particular product taking into account the fuel surface area.

- Inlaid grates. They have a collapsible shape, assembled independently. The number of their components depends on the required area of the device. This guarantees their versatility, because the oven grate can be made in any size, suitable for non-standard ovens.

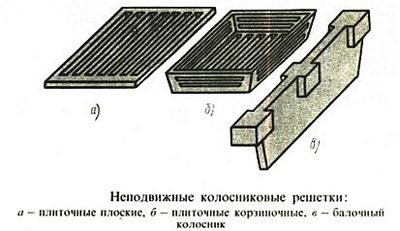

Stationary

Fixed devices - grates that do not move.

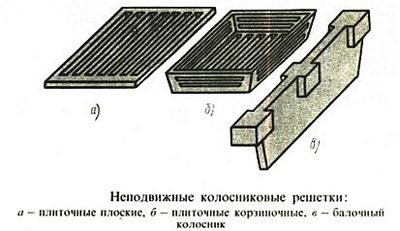

Subspecies of fixed grates:

- tiled flat, the most popular;

- basket, rarely used;

- beam.

Tiled - these are rectangular-shaped parts that are the most popular. They can be used for any model, they are versatile and easy to install. The stores offer a huge selection of grates of this particular type.

Basket grates are not very popular, because they are used for open ovens. In the old days, they were part of the ovens on which food was cooked. Now gas and electric stoves are used for this.

Beam grids visually resemble a construction beam. They are only collected by hand. Consumers like their versatility, the ability to install in any oven.

Movable

Subspecies of movable grates:

- full revolving;

- swinging;

- chain.

Movable furnace grates consist of several parts. These include sections and shaft. Due to the possibility of rotation, the process of cleaning from ash is simplified. Movable gratings are divided into full-revolving and swinging ones: the angle of inclination of the former is 180 degrees, the latter can rotate from 30 degrees. Another type of such grilles is chain. In its design, the elements are connected to each other by chains. The disadvantage of this type of grate is incomplete combustion of wood or coal.

Blown

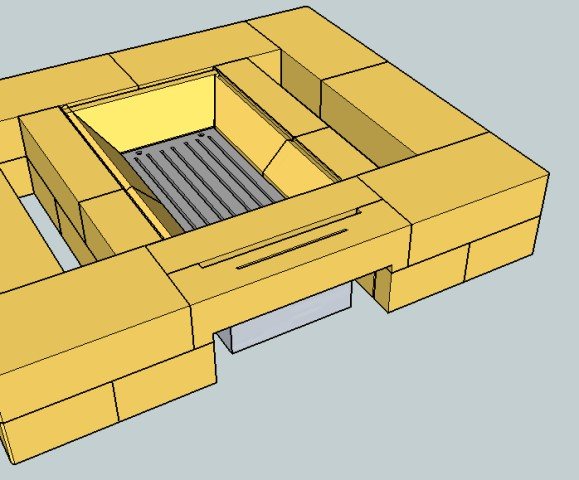

Blown - this is the first air chamber in the oven, usually with a door. Blower chamber spread according to the size of the grate. It can be wider than the grate and overlap by overlapping the rows of side walls to the grate. Through the blower chamber, air enters the firebox through the grate, in addition, it serves to collect ash and other fuel waste.

Blower: 1 - blower chamber; 2 - blower door

Blower door can be of any size, but not larger than the view door. It is convenient to remove ash from the wide blowing chamber through this door, and as for the air, it is enough with the door, even half the size shown.Practice has shown that the best place for the blower door is on the second row of the oven masonry. The door is installed in the blowing window, which is connected to the blowing chamber. When the door is open, air rushes through the window into the blower chamber. The more the door is open, the more air will enter the blower and the better the fuel will burn. Air, especially from below, is needed to keep the fuel burning. Hence the name - blew.

Sometimes the door is used to regulate the draft in the oven: the less the door is open, the less draft. It is not necessary to install a blower door, but it is desirable, because without it it is possible in loosely closing devices, such as latches, a draft. And then the heat will go out into the pipe, and the stove will give less heat to the room.

In the absence of a door, the traction is regulated by a latch. The more the valve is open, the stronger the draft, and with it more air will enter the furnace and the draft will be stronger, which means that the fuel will burn better. If there is no door in the blower window, but there is a view, then the fuel will constantly burn with the same force, but with this force a lot of heat will go into the pipe, which could be absorbed by the brick. Neither draft nor fuel combustion can be controlled by the viewer.

Let's say that the door is a few millimeters smaller than what is shown in the figure. In any case, the seams should be no more than 3-5 mm. For this, the masonry must be carried out from the door to the corner of the oven. The last seam turns out to be thicker than it should be, and such a seam cannot be done. To withstand the thickness of the seams, you need to break off a quarter from a whole brick in the corner of the wall where the door is located. You will get a three-quarter and a quarter. Next, you need to chop off a larger quarter, taking into account the thickness of the seam. It will, as it were, lengthen a whole brick. Instead of a whole brick, you need to put the first three-quarter and the second quarter - it will take the place of a thick seam. The masonry of the upper row above this quarter will be made of a whole brick - it will overlap this quarter. If a thick seam is obtained near the door, then you need to do the same in this place.

If, because of the door, the firebox turns out to be a few millimeters narrower, and the gas ducts are wider, then this will not affect the operation of the furnace. In some regions of the country, stoves are put without a blower at all. In these furnaces, the furnace doors have windows-holes for air intake instead of the blower. In such furnaces, only wood and peat fuel burns, but the wood is buried in ash and forms a lot of embers. When they burn out, the heat goes into the chimney, so the embers have to be pulled out of the firebox and lowered into a bucket of water. Such furnaces are made due to the lack of grates. If they are, then they are installed above the blower chamber.

Dimensions (edit)

Another condition for choosing a grate for the furnace is its length and width. The sizes of grates for the furnace are different, they are due to the type of fuel:

- For light firewood or briquettes, gratings from 140x120 mm to 330x252 mm are sufficient.

- For coal, large parameters are needed: 300x300, 350x300, since this fuel emits a large amount of harmful substances during combustion.

Variety of grate sizes

What are the functions of grate bars for ovens

This element of the stove accessories allows you to achieve high-quality fuel combustion and maintain it while the stove is fired. When one portion of firewood or coal burns out, the ash is poured, and the upper layer of fuel is shifted to the grate, where it is better blown by the air coming from the ash pan and burns more intensely. Thanks to the presence of grates, the task of drying wet fuel is simplified. The efficiency of the furnace depends on the design of the elements, and durability depends on the material from which they are made. It is also important to correctly install the grill so that it fully performs its functions.

The quality of heating the house largely depends on the furnace casting.

Buying Tips

For high-quality combustion, not only the size of the grate is important, but also the weight of the fuel that it can withstand with one laying. The rods should not be deformed and worn out.

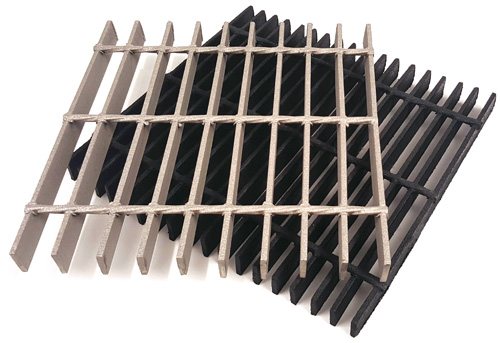

The grate must have a sufficient number of holes - at least 40% of the area of the part itself. If this figure is less, then there will not be enough oxygen to maintain the fire, and ash will remain on the grate and clog the stove.

If the gaps in the grate have a large area, then the remaining fuel will fall from the combustion chamber into the ash pan. Fuel consumption will become uneconomical.

Optimal lattice option

Item for arranging the furnace

Choose the optimal location for the heating stove. To the sample, the stove, installed in the center of the room, will give off heat as efficiently and measuredly as possible. However, such a placement of the oven is not always convenient.

Oven in the middle of the room

In the case of placing the stove structure against the wall (this option is the most popular and often used), cold will go along the floor of the house.

Select in advance the location of the combustion chamber door. Design your stove so that you do not have to carry fuel throughout the room, carrying dirt around the room.

The heating stove is placed against the wall

The best option is to arrange a firebox in a little-attended room.

Recommendations regarding the foundation are standard - an individual concrete base is being set up. You cannot link it to the main foundation.

Calculate the structure of the foundation in such a way that it is able to withstand the load not only of the furnace itself, but also of the smoke exhaust structure, which is also highly recommended to be built of bricks.

What is needed for manufacturing?

It is possible to make a grate with your own hands. What to make a grate into an oven? It is better to use heat-resistant steel as a material, because it is impossible to work with cast iron at home. For the manufacture of the grate, you can use any materials that have heat-resistant characteristics. These can be fittings, angles, steel pipes or strips of metal.

To make grates you will need:

- metal from which the grill will be made,

- steel rods to create partitions;

- ruler, a tool for drawing marks;

- grinder to cut material;

- welding.

Grid design

The size of the grate depends on the fuel to be used in the future. For use in everyday life, designs of two options are recommended - one-piece and composite.

The first option consists of a cast iron grate, which is selected according to the size of the combustion compartment. The second type is assembled from separate elements.

The size of a composite grate is determined in the same way as a solid one, according to the dimensions of the firebox. In addition to the species difference, the devices are also divided according to their functional functions.

The design of the cast-iron grate is of two types: full-revolving and swinging. In the first case, the elements have the ability to rotate horizontally by 180 degrees, which allows ash and slag to be dumped.

This design assumes a groove in the combustion chamber for additional holes. It is extremely difficult to make a full-turn system at home.

In the second design, the elements have lullaby movement elements, the rotation is around at an angle of 30 degrees. This system has the ability to loosen the accumulated slag.

How to make grates for the oven with your own hands?

From reinforcement

It is not difficult to make a grate from fittings yourself. It is enough to choose the desired length of the product and cut the reinforcement with a grinder. It is necessary to determine the number of strips and take into account the ventilation gaps.

When the required amount of material has been prepared, you can start welding the grate with rods.Do-it-yourself grates for a furnace from fittings can be seen in the photo below:

Video instruction:

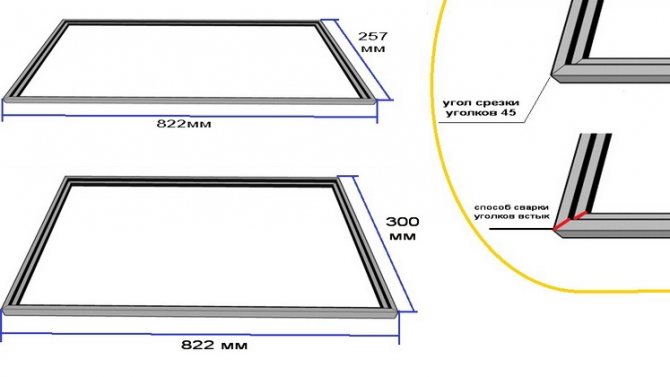

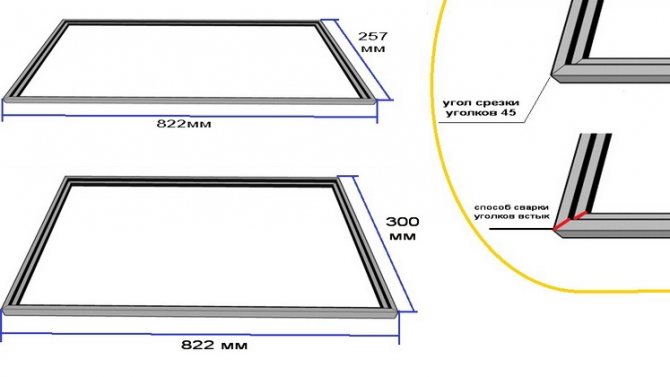

From the corner

It is even easier to make a grate for a furnace with your own hands from a corner than from fittings. To do this, it is enough to weld together two corners of the required dimensions: one side is equal to the width of the product, the second to the length. As a result, you will get a rectangular base of the future part. The lattice can be made from reinforcing rods or thick mesh.

Video instruction:

How to install grate bars in the oven with your own hands?

It is not necessary to call the foreman to install the grate in the oven. You can do this yourself, spending very little time and effort on this process.

Installing a grate in a brick oven has its own characteristics:

- You need to understand that metal tends to expand. Therefore, you need to make gaps of at least half a centimeter along all edges of the product.

- The grate should be placed slightly lower (about one brick) from the firebox door. This will prevent heat from escaping from the oven.

Stage 1

Stage 2

Stage 3

- Do not place the grates too tightly in the oven. This can lead to deformation and cracks when the metal is heated.

- The gap between the grate and the stove is filled with sand. It is important not to use cement admixtures, because the part should not be tightly held.

Does it matter which side of the grate is placed in the oven? Yes, when the bars of the lattice are triangular or any other protruding shape, then the top should be directed downward.

Examples of installation in a brick oven:

Example 2

Example 3

Example 4

Example 5

Firebox

In the firebox, not only fuel burns, chemical substances emitted during fuel combustion - gases, resins - are burned with it. And the water contained in the fuel is converted into dry steam, which determines whether there will be soot drips on the stove. To prevent gases and resins from turning into wet soot that settles in the gas ducts, and the steam to be dry, there must be enough free space in the furnace above the fuel in which lighter fuel particles would burn. Therefore, in heating stoves, in which the firebox is arranged at the full height of the stove, there is almost no soot.

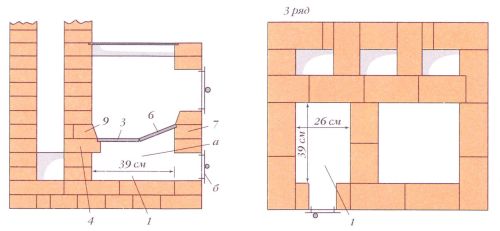

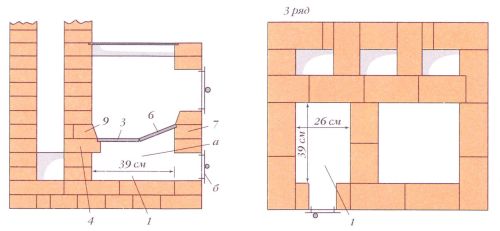

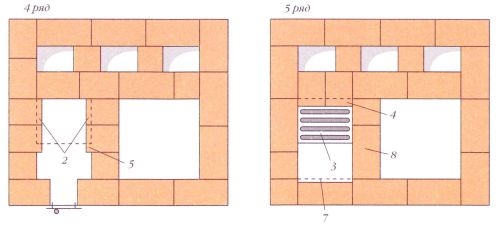

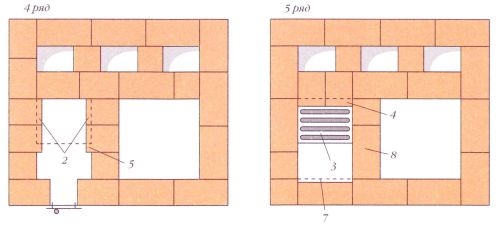

The width of the firebox sometimes reaches 38 cm. In room stoves, the best firebox is 26 cm wide (by the size of the door). Practice shows that if you make a firebox 26 cm wide and 31 cm long with steep side walls, and cut the bevel up to 2 cm at the front and rear walls, then coal (anthracite) in such a firebox burns completely. Coal does not sinter much, therefore a furnace with a more expanded form for coal is worse - in such a furnace, little air enters the walls. A funnel-shaped firebox with a large bevel is good for firewood, brushwood: as it burns, the fuel settles down to the grate. In a firebox with a stove, there must be a space above the fuel formed by two rows of masonry (at least).

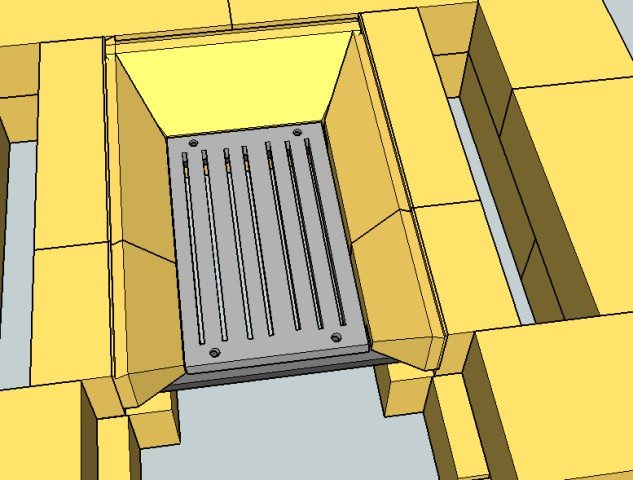

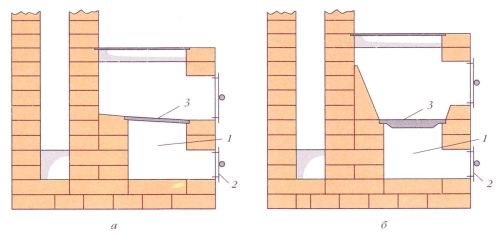

Installation of a grate for fuel: a - wood; b - coal; 1 - blowing chamber; 2 - blower door; 3 - grate

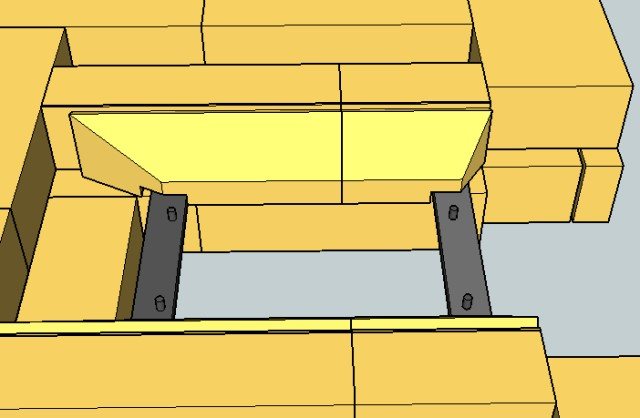

Grate separates the firebox and the blower chamber. For wood fuel, the grate is installed to the rear wall of the stove, slightly raised. Practice shows that raising the bottom for firewood is not necessary, since the rise is formed over time from the growing ash. Under the coal, the grate is laid exactly horizontally one or two rows below the furnace door. It is good to assemble it from piece cast-iron grates across the entire width of the firebox - up to 26 cm. The continuous grate is fragile and therefore breaks down soon. Individual grates are stronger, they are specially produced for heating with coal. Any fuel burns on such grates. Under brown (near Moscow) coal, the grate is installed two rows below the furnace door, so there will be at least three rows of masonry above the blowing window.

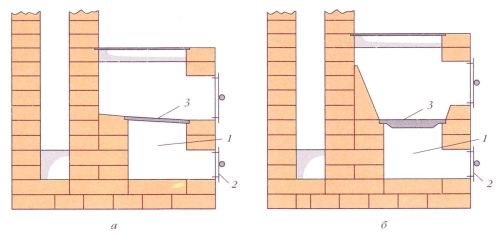

For peat and dung (this is home-made fuel in the form of bricks, which are made from manure and dried on the street), the grate should have slots (holes) no more than 1 cm. In this case, the bottom of the firebox is made of two grates. First you need to try to install the grates dry. If the grate is smaller in size than the blowing chamber 1, then overlaps 2 are made above it, on which the lower grill 3 is placed. Sometimes, due to the small size of the blowing chamber, the grilles have to be installed across it. In this case, if the grilles are narrow, overlaps must be made over the back wall of the ashtray. 4 The dimensions of the overlaps depend on the size of the grate. The second grating 6 is installed obliquely to the lower grating on the remaining free protrusion 5 of the overflow, which is placed at the top in the cut groove in the brick 7. After installing both gratings, the laying of the side walls 8 is continued vertically in relation to the lower rows of the ashlar. For a more complete combustion of fuel, one row 9 is cut above the lower grate (around it).

Installation of a grate for peat fuel: a - blowing chamber; b - blower door

Installation of a grate for peat fuel: a - blowing chamber; b - blower door

I have always set the grates on the grout and pressed them against it in the middle of the grate. He covered the cracks near the grate with the same solution on which he put the stove. The grates were never deformed or bent from the heat, as well as fire doors without asbestos, but only sometimes burned out due to the poor quality of cast iron. And they cannot deform, because during the drying of the oven, when the solution dries, it emits steam. This steam softens the mortar: it becomes soft again, like when laying. The grates expand from the heat, and the soft solution allows them to do this. After firing the furnace, the solution near the grates dries up and contracts along the expanded position of the grates. When the grates cool down, a cobweb-shaped gap forms around them. With the next fires, it will gradually fix itself by dust from ash.

The proposed backfills around the grate are ineffective and are more needed to simplify their replacement with new ones. Ash is better than any backfill: it is compacted in such a way that a scalpel is needed to remove it, so there is no need to complicate your work. The grates are installed shallowly at the top of the hearth so that they can be easily removed during any replacement with new ones. The grates of individual grates can be partially replaced or the hearth completely replaced.

Solid brick grate

Often the firebox is made without a blower, inserting a furnace door with holes if there are no cast-iron grates. Ash wakes up through the grate, and the firewood burns better. The lattice can be made from metal rods by laying them in the masonry. You can also make it from whole bricks. The brick is placed on an edge and a recess is cut out from both sides in it - a gap expanding downward so that ash does not linger.

These articles may also be of interest to you:

- Masonry oven for peat

- Heating furnace masonry

- Triangular oven masonry

- Installing the oven door

Price policy

A quality product cannot have a low cost. High-quality cast iron parts that will last more than one year are expensive. Conversely, lightweight and cheap, made from a mixture of unknown materials, will quickly deteriorate.

Approximate prices for grates for the oven:

| The size | The cost |

| 800x200 mm | 1200-1600 rub. |

| 915x250 mm | 1100-3000 rub. |

| 260x540 mm | 400-500 rub. |

It is better to buy these products in specialized stores. They provide a wide selection of models in different materials and price ranges. The consultants will help you make the right choice based on your preferences, the nature of the fuel, the frequency of operation of the heater.

Output

When choosing a high-quality grate, one should take into account the design features of the stove.The choice of a specific design and lattice components depends on the nature of the fuel. A grate for a cast iron sauna stove will last longer than the same one made of steel or other metals.

Also of great importance is the weight of the fuel itself. Installation of grilles does not require any special knowledge. You can put the grates in the oven correctly on your own; it is enough to take into account only a few nuances. With the right choice of material and installation, they will serve you for a very long time.

Types of cast iron grate

Cast iron grate also comes in several types. The tiled grate has a rectangular pattern installed in the opening of a boiler, stove or fireplace. This type is considered universal in operation. The basket-type grate is ideal for an open hearth used for cooking.

This model is currently practically not used. A beam grating consists of a single or double element, which in its structure resembles a building beam.

Cast iron girder grate is used for the installation of non-standard structures. There is also a movable grill. It got its name due to the fact that its model is able to change the width of the gaps. The movable grate is most often used for long-term operation.