A fireplace is a fairly old, but still relevant piece of furniture. Once it was used as a device for heating and cooking, but recently it can combine decorative functions.

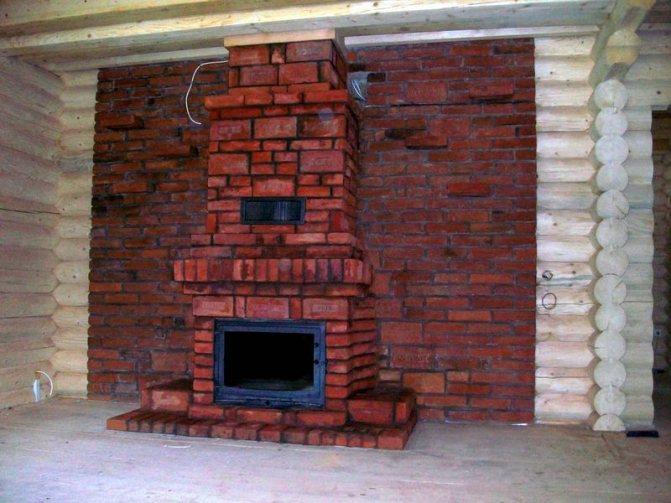

The fireplace has a lot of weight, therefore it needs a separate base. The foundation for the structure can be made using various technologies, but installation in a wooden house has special rules and requirements.

A fireplace that performs only decorative functions does not need a separate foundation. An obligatory foundation is required only for a full-fledged structure, the hearth of which will be used on a regular basis.

Safety engineering

First of all, it is necessary to choose a suitable place that meets the fire safety conditions.

The fireplace is a source of open flames and embers can ignite with a slight draft. Therefore, it is not recommended to place it opposite windows and doors.

There are a number of rules that should be followed:

It is prohibited:

- Place the fireplace on a floor covering, as it is usually heavy and can push through the floor slab.

- Install a large fireplace in a small room of a wooden house, with a total area of less than 11 m2. It burns oxygen and dries out the air, thereby harming the house and deforming the connection of logs and planks.

Features of the

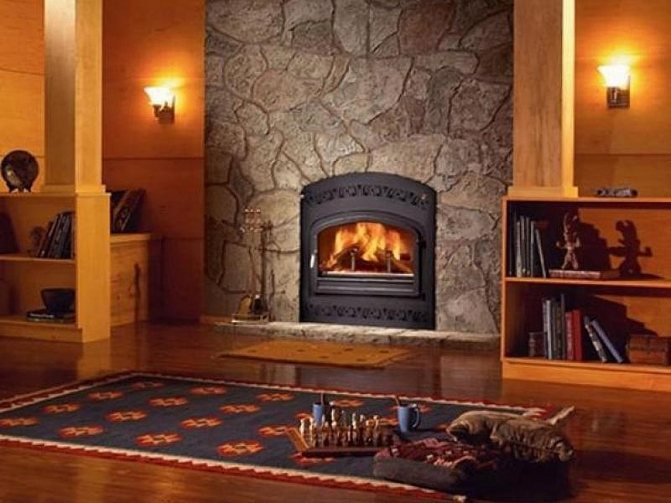

The design can be used for its intended purpose or act as a portal for an artificial focus

A concrete fireplace can easily cope with the function of heating a room due to high-quality heat removal - the high thermal conductivity of the material allows energy to penetrate into the air and heat it. However, the same quality is the reason for the rapid cooling of the fireplace.

Laconic performance for indoor and outdoor use

For the most simple fireplace to make, concrete blocks or rings are used. Such products allow you to quickly erect a structure without having certain skills. Concrete is a durable material that is resistant to temperature extremes and humidity, which is why it is used to make outdoor fireplaces in country houses.

Concrete fireplace on the street

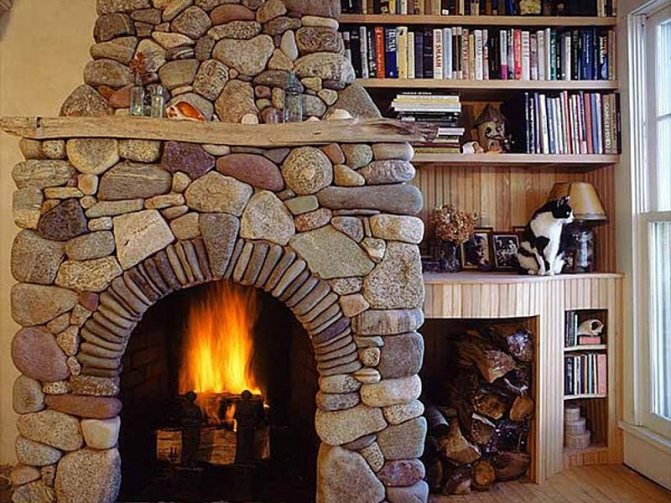

Natural stone looks beautiful in the manufacture of fireplaces, but its price is quite high, and the construction process is complicated. Concrete product, on the contrary, can be done by hand - instructions will be given below.

Construction technology

When choosing a foundation project for a fireplace, it is worth considering the following data:

- the mass of the fireplace, its dimensions;

- soil characteristics (soil type);

- earthworks.

Considering that the fireplace is heavy and large, its foundation is poured regardless of the base of the house. The distance between the walls of the bases, that is, the gap, must be 50 mm. The gap is filled with a mixture of crushed stone and sand.

It is important to follow this technology, since each foundation has its own specific gravity and its own shrinkage time.

On clay soil, the foundation gradually subsides and deformation occurs, which leads to its destruction. Therefore, it is necessary to build a foundation on a sandy base, then the soil is compacted under the influence of the gravity of the structure.

It is advisable that the main foundation is 20 cm below the freezing of the soil, since movements and swelling are possible in the winter months.

What is a brazier fireplace?

Today, outdoor barbecue fireplaces are considered more popular.Braziers familiar to us are losing their relevance, they are being replaced by barbecue fireplaces. A brazier-fireplace with your own hands makes it possible to organize a barbecue with pleasure in any weather, because, in addition to the firebox and woodpile, it has a roof at its disposal.

Summer cottages are the best place for spending the weekend in the fresh air, cooking fragrant kebabs in your own. The barbecue has many advantages, including fire safety, no smoke, the ability to ignite in any weather conditions. In addition, the brazier-fireplace will successfully fit into the landscape design of the summer cottage, creating a kitchen corner under the open sky. This is an undeniable advantage over friends and guests.

The brazier fireplace is a multifunctional complex that makes it possible not only to cook food, but also to warm the room in which it is located, and contemplate the sight of fire.

A garden fireplace in appearance and principle of operation does not differ from a room fireplace. It is installed directly in the pavilion or outdoors. It is based on a rectangular frame, skewers over it and fuel. The forms of the grill-fireplace can be very diverse: in the form of a rock, castle or column. Brazier fireplace can have a hearth with a grill, sink, oven, cooking oven, tandoor, smokehouse, cauldron for water.

Outdoor brazier fireplaces are of two types:

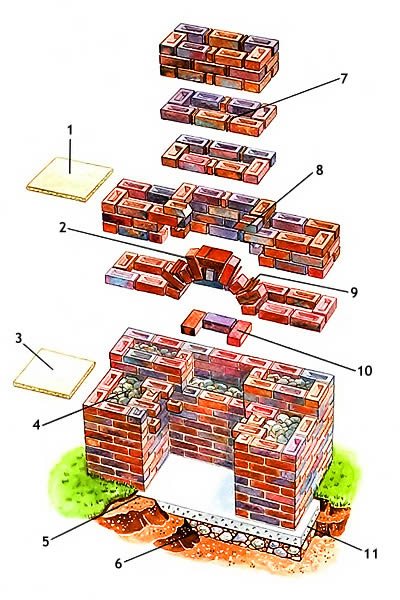

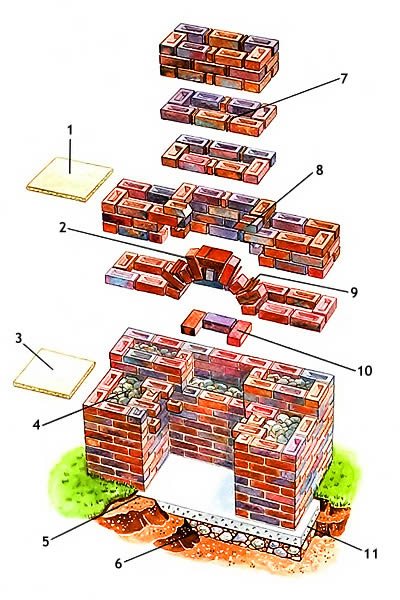

Barbecue masonry scheme: 1, 3 - Concrete slab, 2 - Arch, 4 - Voids, 5 - Foundation, 6 - Crushed stone, 7 - Pieces of bricks and tiles, 8 - chopped bricks, 9 - Pieces of tiles, 10 - Chimney framing, 11 - Concrete.

- Wall-mounted barbecues no more than 1.5 m high in the form of a triangle, square, semicircle. The fire will not go out even in inclement weather. As a rule, it is built in a covered terrace, the chimney is led out through the roof of a residential building.

- Free-standing barbecues in the form of a cylinder with a pipe and a conical vault.

The construction of a fireplace must be carefully planned. It is necessary to decide not only on the appearance, size and design of the future fireplace, but also it is important to choose the right location and provide a hanging structure. Today, to simplify the construction of a barbecue fireplace as much as possible, you can purchase special items such as a grate, fasteners, a charcoal tray, etc.

Depending on the skill, desires, creative ideas and financial capabilities, there are several ways to make brazier-fireplaces with your own hands. For the construction of outdoor barbecues, refractory and facing bricks, concrete blocks, natural and decorative stones are used. It is distinguished from a room fireplace by the simplicity of the chimneys and the absence of a damper in the smoke channel, since the purpose of the barbecue fireplace is not to heat the building, but to cook food. The grill fireplace is equipped with an open firebox, in which there is a grate for skewers, pots.

Back to the table of contents

Foundation for light fireplaces

To evenly distribute the load, it is necessary to dig a pit with an ideal horizontal plane and the desired dimensions.

When mixing the concrete mixture, it is necessary to maintain the following proportions: 1: 2: 3, where 1 part of cement (m-500), 2 parts of sand, 3 parts of crushed stone. The amount of water for filling the mixture is poured at the discretion of the master.

The ready-mixed concrete is poured onto the bottom of the pit 15 cm thick.

A stone (river, hard sandstone or even old broken concrete) is laid in this mixture. It is undesirable to use broken brick, since it consists of clay, and this is a fragile material for filling the foundation for a fireplace, it can crack.

A concrete mixture is poured over the stone.

For the above-ground part of the foundation, a formwork of the required size is installed, its sides must be strictly vertical.Further, the pouring continues in layers to the desired height, the base horizon is checked with the building level.

Explanation: floor level (1), brickwork (2), shut-off waterproofing (3), mortar screed (4), fraction (5), foundation pit (6).

Brick BBQ fireplaces

Before starting work, you need to prepare tools and materials.

Namely

:

- Brick red;

- Fireclay brick;

- Dampers;

- Firebox doors;

- Grate;

- BBQ grates;

- Clay;

- Cement;

- Sand;

- Armature;

- Metal sheet;

- Boards;

- Tar;

- Plumb lines and level;

- Hammer;

- Saw;

- Bulgarian.

What do you need to prepare before building a BBQ oven? In addition, a mortar should be prepared before laying. It can be: a home-made mixture of clay and river sand or a ready-made mixture (it has a different composition, for different temperature conditions).

Next is the calculation of the required number of bricks for the construction of a barbecue fireplace. Before starting construction, you must purchase the required number of bricks. Calculations are made according to the finished detailed drawing of the future design of the fireplace.

In addition, about 300 more bricks will be required if it is planned to install a brick chimney for the stove and a brick table used as a barbecue.

Now we need to create a construction order. For example, if the fireplace will consist of 30 rows, you need to draw each row separately and mark on each brick laying pattern. This will make it easier to understand while working and will help determine the right number of bricks. After completing the preparatory work, you need to decide on the installation site where the brazier will be installed.

He is selected taking into account the following criteria

:

- The fireplace should be located at a remote distance from summer cottages;

- Do not install a fireplace near wooden buildings and trees;

- The barbecue fireplace must be installed so that there are no problems with the water and electrical supply;

- There should be free space nearby for installing the gazebo.

Now we start laying the foundation. We start with the markup. When calculating the size of the foundation, it is necessary to take into account the presence of a gazebo. We dig a pit about 50 centimeters deep, fill it with a mixture of gravel and sand at a level with the ground, tamp it and create a wooden formwork. We mount the reinforcement and fill it with concrete, then tamp it again so as not to leave voids. Finally, so that the foundation does not crack, we cover it with burlap. After complete drying, we dismantle the formwork.

The next stage is the installation of walls for a modern fireplace. We coat the walls with tar. Then we put two layers of roofing material and prepare a mortar for laying bricks. We lay out the first and second row of bricks with columns. At approximately the level of the 7th and 10th rows, we install a metal plate.

We install a sheet of metal in the groove. Starting with the 15th row of bricks, we create a vault, having previously built a template from wood.

We cut out a sheet of plywood, choosing the right size. Mark the curvature and make an arc using a jigsaw from a pair of boards. Then we nail the plywood sheets along the curved side of the board and insert a third between the two boards, fastening them together. We install the resulting structure between the walls, and lay bricks on top of the mortar.

When building a BBQ fireplace insert, refractory bricks should be used. Somewhere from the eighteenth row of bricks, you need to start laying out the chimney. Each next row is gradually narrowed, each subsequent row should be less than the previous half, and so on until the twenty-eighth row. If the material needs to be saved, then the pipe can be made of metal, in which case the smoke will go up.

Additional tips and tricks

Before placing a concrete fireplace at home or in the garden, it is important to familiarize yourself with the basic requirements for its installation.

As a ready-made solution, you can take care not only of the appearance of the oven itself, but also of the surrounding space. For this, the garden or any other area must be properly ennobled. If this is a garden, you need to level the surface, plant flowers or beautiful lawn grass. If you are planning to spend your evenings by the outdoor fireplace, it is important to ensure that you have the necessary outdoor furniture. It can be both simple chairs and small benches, armchairs, sofas, hanging cocoons, a hammock. For added convenience, you can prepare the floor surface and veneer it with materials such as stone, concrete or ceramic tiles.

To make an outdoor fireplace even more functional and useful, you can equip it with a special grate on which you can cook food. You can also additionally design a barbecue rack, equip the oven with a hob for one or more burners, and an oven. This will allow you to cook food right on the street and not take up more free space in the house.

Grids and racks of the combined type are especially convenient to use, the height of which can be varied manually. Thus, the grate can be closer or farther from the fire burning in the furnace, and you, in turn, can shape the speed and intensity of frying / baking food.

As an alternative and spectacular option, you can equip the outdoor oven with a grate, which is fixed on special chains located on both sides. Such a design will be in harmony with both classic and modern, and with more complex styles (loft, country, Provence).

Finishing

The appearance of the concrete walls is rather inconspicuous, so such a fireplace definitely needs cladding. The heat capacity of concrete is high, so not all materials can be used. Even if you pick up refractory ceramic plates, they can burst, since it will not be possible to escape from the phenomenon of thermal expansion.

Good to know: How to properly insulate a fireplace, why you need thermal insulation

The most practical and attractive option would be brick lining of the fireplace. Remember that the foundation has a larger area than the fireplace itself. This surplus is intended for brickwork. You can use ordinary cement slurry, since the temperature in this zone is not as high as in the furnace zone.

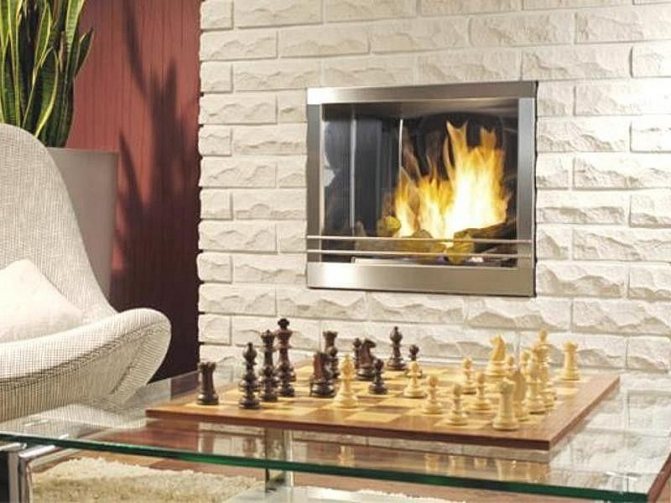

High-tech living room

There is no special theory for stacking rows. A beginner master can also cope with this process. If there is no initial experience, then it is recommended to lay out the row without mortar. This will help you navigate which brick should be trimmed and by what amount. Do not forget about the strapping, each new row should be offset from the previous one by half a brick.

You can try to decorate the fireplace using other materials, such as tiles. But at the joints you will have to insert a wooden wedge and screw a screw with a large head into it. This hat will hold four tiles. This manipulation is repeated for all angles.

Brazier fireplace with your own hands made of bricks

The most common material for a barbecue fireplace is a facing brick from the outside and a heat-resistant refractory brick in places of contact with fire. This material perfectly retains heat, is resistant to temperature extremes, and makes it possible to build any shape.

Required materials for the construction of a brick brazier fireplace:

- facing and refractory bricks;

- concrete solution (cement, sand, water);

- edged and unedged board;

- fittings;

- roofing material;

- metal pipe with a diameter of about 15 cm;

- metal sink;

- mixer;

- rubber hose;

- countertop;

- lattice;

- coal box.

Required tools:

- building level;

- putty knife;

- grinding machine;

- drill;

- a hammer;

- trowel;

- drill for concrete;

- container for solution.

If the construction of a barbecue is carried out not only for the sake of frying a kebab, then a sink and a cutting table are additionally equipped. Given the size of the building, fire safety rules, you can start construction.

Stages of building a brick brazier fireplace with your own hands:

First of all, you need to build a foundation, for this:

- we clean the site of the planned structure, remove nearby tree branches and mark the boundaries of the future fireplace;

- we dig out the soil around the perimeter of the building (plus 5 cm) with a depth of about 80 cm (depending on the freezing point);

- we lay a pillow of sand, slag or gravel at the bottom and tamp it carefully,

- we construct the formwork;

- we reinforce the bottom of the fireplace;

- fill with concrete.

After three days (preferably three weeks), a waterproofing layer (roofing material) must be laid on the concrete screed to prevent it from getting wet from the ground.

Next, the walls of the barbecue are erected in half a brick (do not forget to leave openings) to a height of 80 cm (60 cm in the case of an arched opening). We align each row with a building level. It is important that the grill for the grill is at a comfortable level.

We lay a metal corner on the last brick row in order to indicate a rectangular opening.

We spread the brick wall around the perimeter to the end (90 cm), while on the last row we leave a ledge outward for the countertop. When planning the arrangement of the sink, you must in advance leave an opening in the half-brick for the drainpipe.

We prepare the base for the countertop and the firebox. To do this, on a step made in a brick row, you need to lay boards, pour concrete mortar.

We lay out the firebox in 2 rows so that a facing brick is laid on the outside, and heat-resistant on the inside. We get an opening of the furnace in 9 rows with a width and depth of 70 and 60 cm, respectively. We report an additional couple of rows of bricks.

We install the pipe to a height of 12 brick rows, first reducing the dimensions of the furnace (side walls - by ¼, front and rear - by ½ brick).

A month after the final setting of the concrete screed, the finished brazier fireplace can be used. In the case of planning to cook a large amount of food, it is necessary to equip several chimney turns in order to heat water in pre-installed cast iron hot water boilers. For long-term operation of the fireplace, it is necessary to provide protection against precipitation. A sophisticated version of the barbecue fireplace includes a base for storing firewood, for burning firewood, followed by frying barbecue, smoking meat and fish products, a smoke collector for collecting smoke and steam, a chimney for removing combustion products, a fuel compartment, a combustion chamber for installing skewers, lattice, bowler hat.

Back to the table of contents