Types of plaster for facade finishing

Wet facade plaster - the most common way to refine the surface to be treated and protect it from the effects of precipitation and ultraviolet radiation. It is performed on a pre-leveled, cleaned and primed base. A ready-made layer is created not only for decorative, but also for protective purposes, which does not require additional finishing, which has a peculiar texture, as well as a certain color.

The classification of plaster mixes is made according to several principles - structural differences, composition, method of application... There are ready-made solutions immediately suitable for use after mixing and dry mixtures that require dilution with water.

Views by invoice:

- bark beetle;

- pebble;

- lamb (fur coat);

- mosaic.

When applied to the surface of a building, each of the varieties gives a different relief, a certain structure.

Classification by composition:

- mineral;

- silicone;

- acrylic;

- silicate.

Of all the above varieties, mineral plaster for facades is provided by manufacturers in dry form, the rest are ready-made.

According to the methods of application, the mixtures are divided into:

- universal destination;

- mechanized application;

- for manual use.

Universal solutions can be used for both machine and manual application.

Back to content

Textured plaster

Its structure is a decorative and aesthetic parameter. It has no effect on the duration of operation or strength. The implementation of each type of texture is carried out through the use of materials with a certain grain size of the filler. Allocate textures traditional, as well as modern... The former are structured from old, time-tested mixtures, and the latter are innovative in their composition.

They form a relief using different techniques, devices:

- special graters;

- trowels;

- sponges;

- textured rollers.

Surfaces give absolutely any structure you like or apply a bas-relief pattern. There are standard - the most commonly used types of plaster to form the desired texture.

Bark beetle plaster - the most common and has many variations. Traditional methods include vertical, horizontal, circular and cross-cutting. For lovers of a creative approach, you can advise a wave-like texture or your own version.

A relief is formed by grouting the plaster layer with a plastic float. The drawing depends on which direction and with what movements to rub the solution applied to the surface of the building.

Pebble plaster - a universal tool for making a textured pattern for exterior decoration of buildings. The material allows you to make drawings of varying complexity, carved compositions in different colors - "sgraffito", small and large bas-reliefs, traditional - "fur coat", "polka dots". It is a coating densely sprinkled with crumbs with a fraction of 1-3 mm.

The structure is given to the coating with a plastic float by grouting. Special rollers, palette knives, trowels, brushes, a spatula for scratching, smearing, printing patterns and textured elements are used. Various shapes can be drawn on the surface.

Mosaic plaster - a separate variety, which is performed exclusively in the form of a flat, transparent surface.It contains granules of stone chips of natural origin - strong mineral rocks. From an aesthetic point of view - the noblest texture.

It is applied in one layer and rubbed to a state of uniformity. Astringent components - silicone or silicate give lightness and transparency to the coating. It does not need further painting or varnishing.

Lamb plaster or fur coat - the traditional method of shaping texture. It is done by throwing the solution onto the wall and does not require further grouting. For the formation of such a relief, cement-sand, cement-lime mixtures are suitable.

Back to content

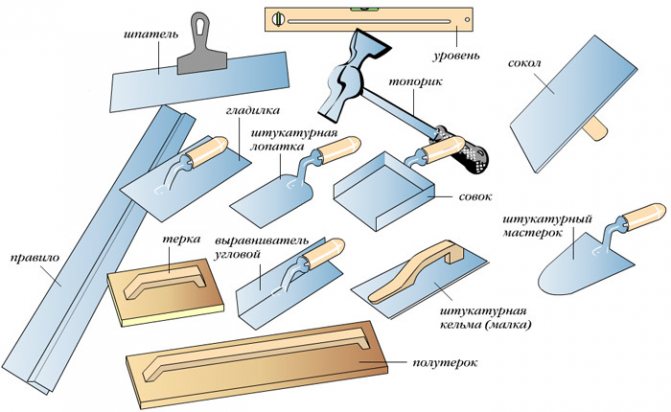

Tool for work

If decorative plaster is used for the walls, then attention must be paid not only to the choice of the mixture, but also to the preparation of tools for work. It all depends on what kind of decoration technology will be chosen. Sometimes it is required to use special templates to apply an unusual pattern.

List of basic tools:

Scheme of applying Venetian plaster using a crumb gun.

- A container in which it will be possible to dilute plaster mixes. It should be deep enough and comfortable so that you can dilute the mixture in it with the help of a construction mixer, getting the proper consistency.

- Trowel for work, graters and half-graters for surface treatment.

- Various spatulas that you may need to apply a pattern and create the required texture. These are simple wide or narrow metal spatulas, serrated, wavy and others. When choosing a spatula, it is important to consider what kind of result is needed.

- Brushes, combs, wide and narrow brushes, baths for solutions.

- A drill that has a special "construction mixer" attachment.

When choosing metal tools, attention should be paid to those made of stainless special steel. Ordinary steel trowels surround rusty spots that can be difficult to remove from the surface.

Features of the composition of building mixtures

The active components of the solution and its high-quality base are the key to successful repairs. Building mixtures facilitate labor and have good technical characteristics. The peculiarity of the use of each of them is due to their composition. There are ready-made plaster solutions, as well as dry ones, which must be diluted with water.

| Type of facade plaster | Release form | Appointment | Structure | Layer thickness | Properties |

| Cement | Dry mix | Execution of textured patterns, drawings | Cement, mineral filler, modifiers | 2-5 mm | Plasticity, wear resistance. |

| Acrylic | Ready solution | Pebble, traditional relief | Acrylic resin, sand filler, modifiers | 3-4 mm | Durability, ease of use, high adhesion to the surface |

| Silicate | Ready mix | Suitable for all types of textures | Silicate binder (liquid glass), modifiers | 4 mm | Water resistance |

| Silicone | Ready solution | Universal | Silicone resin, mineral filler, modifiers, emulsifier | 3-4 mm | High resistance to mechanical damage, high adhesion. Elasticity, antiseptic properties. |

Whatever material you choose, the plaster for the facade, if applied correctly, will create the necessary relief, and will also delight you with a high-quality result.

Back to content

Application

Mass leveling instructions

If the creation of a heat-insulating layer is not expected, the first stage is the preparation of the walls. Remove old, poorly adhering plaster (if any).

If the walls are made of piece materials - bricks, blocks, stone, clean the seams to a depth of 1 cm.

Make expansion joints on the facade in increments of 2.5-3 m.They will increase the adhesion, prevent shedding and cracking of the cladding.

Then dust and moisten the surface of the walls.

The second stage is the preparation of the mixture. Before preparing a solution for plaster, read on the packaging in what proportion the dry composition is mixed, and also pay attention to the production time.

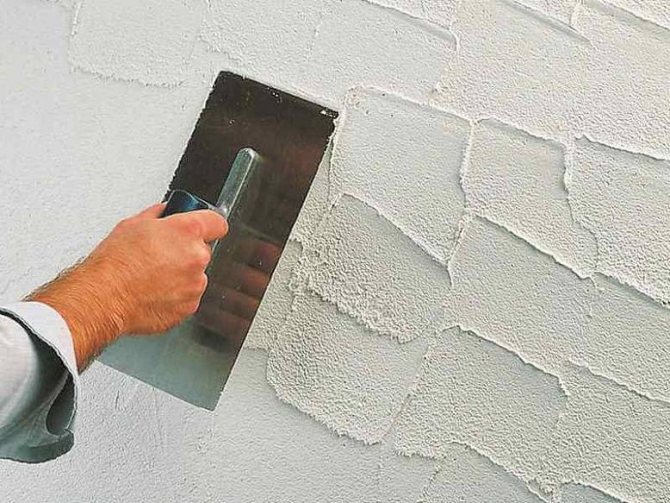

The third stage is directly plastering the walls outside the building by spraying. This operation requires a certain skill, since it is necessary to throw on the surface of the wall exactly the amount of mixture that is required in this area. This should be done with such sharpness and force so that the mass sticks to the wall, and not glass down or splashes to the sides.

Do-it-yourself facade plaster should be applied taking into account several nuances:

- It is impossible to work on freshly erected walls, since when the masonry shrinks, the coating will crack.

- Do not apply plaster-containing mortar directly to concrete walls. The trim may bulge and then fall off the wall. To avoid this, first apply 5 mm lime plaster to the wall.

- Do the grout a few hours after smoothing the mass, when it becomes stiff, but does not have time to fully set.

- The thickness of the layer, which is applied at one time, should not be more than 2 cm.

Note! It is necessary to rub the surface with a wooden or aluminum (with glued foam) float, pressing it with the entire plane to the surface and performing circular movements.

Pros and cons

It cannot be said unequivocally that all types of material have the same advantages or disadvantages - it all depends on the composition, purpose and properties of the plaster, but some features can be distinguished.

Benefits:

- Ecological cleanliness. Thanks to the use of natural, non-toxic ingredients.

- Fire resistance. The coating does not burn and does not contribute to the maintenance of the combustion process.

- Ease of operation. The facade of the building is easy to repair and clean.

- Frost resistance.

- Thermal insulation. Provides heat conservation in the room.

- The work can be carried out manually, as well as without the involvement of specialists.

- Aesthetic beauty.

- Modest weight. The weight of the plaster is very small, so no additional repair work or reinforcement of the foundation is required.

disadvantages

- Low mechanical strength. Low resistance to mechanical stress is possible if no reinforcing mesh was used, the facade plastering technology was not carried out. Then chips and cracks may appear on the surface of the building.

- Labor intensity of installation work. The laboriousness lies in the need for strict adherence to the recommendations for applying the mixture and professionalism. The creation of the texture takes a long period of time.

- The dependence on seasonality forces us to focus on a temperature regime of at least +5 degrees, which limits the time and possibilities for carrying out repair work. If this requirement is not observed, the applied solution will dry for a long time and adhere poorly to the base.

- The material is expensive - the cost of decorative plaster is higher than usual.

Back to content

Tips for choosing a plaster

Finish type is best pick up on your own, focusing on your taste - smooth, textured. The rest of the features you can take into account when choosing a building mixture. Which is better - decide after reading the recommendations for choosing a plaster.

- For high strength a silicone solution is suitable.

- It is advisable for beginners to use ready-made mixtures.

- Interested parties save time can work with a ready-made colored solution.

- Consider what surface the material will be applied to - this is important.

- Use a reinforcing mesh for coating thickness over 50 mm.

Facade decoration with decorative plaster is of the highest quality if silicone mixtures are used. They are immediately ready for work, very plastic, easy to use and easy to paint. At the same time, costs will be minimized.

Back to content

Use of ready-made mixtures

Using textured plaster is a laborious process. You need to navigate in the proportions, features of the application of the material. In order for the repair to be successful, those who do it for the first time are recommended to use not dry mixtures, but ready-made ones:

- they are easier to transport, keep well;

- the complexity of the process is reduced - no need to waste time mixing the solution... There is no need to rush to apply the pasty mass until the end of its viability;

- increased efficiency of consumption - no need to spend money on a primer, protective paint and other additional materials.

What matters is the specific gravity and efficiency of the solution in operation, so do not be alarmed that the finished mixture more expensive, and its mass is less than that of the material in dry form.

Back to content

We select plaster for different surfaces

Each surface interacts in its own way with the building materials used for cladding the outside of the building, so it is necessary to consider which mixture to apply to a particular type of substrate.

| Base material | Type of facade plaster | Features of the |

| OSB board | Acrylic | Requires good elasticity of the coating |

| Wood | Silicate | Needs several coats of priming |

| Brick | Cement, silicone | For medium fraction of filler |

| Aerated concrete | Silicate, silicone | Good adhesion required |

| Insulation | Acrylic | Using reinforcement |

| Rest | Silicate | Depends on coating thickness |

When purchasing material for facade work, consider what is written in the instructions, as well as on the packaging. Check out the technology for applying the mortar, necessary for creating the texture with tools. Select a primer composition and paints and varnishes that are similar in components to the plaster mixture in order to improve the quality of the coating and extend its service life.

After getting acquainted with the types of plaster for facade work, the pros and cons, advice on choosing, the appropriateness of the application. After all this, you can begin to perform textured work, and if you follow the application technique, you can count on a long service life of the coating and its resistance to atmospheric influences.

At what temperature can you plaster outside?

When the outside air temperature reaches below 5 ° C, then already in this case anti-frost additives should be added to the plaster, which allow it to gain strength in frost - ammonia or chlorine water, potash.

In other conditions, it is possible to start preparing the solution and finishing the facade at an ambient temperature of 9 to 25 ° C.

It is not recommended to plaster the facade with a cement-sand mortar if it rained the day before. The surface should be as dry as possible and not show any obvious signs of moisture.