Furnaces for long burning bricks with wood are becoming quite popular devices in suburban areas and in private houses. Such designs can significantly increase the efficiency of the heating structure, which leads to the possibility of saving on fuel. Long-burning brick ovens have a simple design, which allows you to build them yourself. A long-burning boiler based on a brick oven is also able to solve the problem of heating a house, and is used in the arrangement of a Russian bath.

Long burning brick stove capable of heating a house or a bath. It has a simple design, so it is quite easy to build it yourself.

Advantages and disadvantages of long burning wood burning stoves

Choosing between a brick stove for a house with wood and long-burning equipment, most opt for the latter type, since it has a number of undeniable advantages. Of the positive aspects, it should be highlighted:

- Compactness and light weight.

- Possibility of installation of equipment without preliminary filling of the foundation.

- High efficiency. Depending on the design, it can reach 85%.

- Possibility of long-term operation (at least 10 hours) at one filling.

- Low consumption and the ability to add firewood during combustion.

- Long service life, reaching half a century.

- No requirement for the room in which the installation work is carried out.

- Wide range of models.

- Possibility to change the location of equipment installation.

- Fuel availability. Firewood, if necessary, can be replaced with another solid fuel.

A large assortment will allow you to choose the right option for any interior

The disadvantages of long-burning wood-fired heating stoves. should be attributed:

- Work exclusively on solid fuels.

- Increased complexity of commissioning.

- Requirements for the design features of the chimney. The presence of bends due to the small traction is unacceptable.

- There is a high probability of condensate formation in the chimney, requiring timely removal or additional design decisions.

- Increased requirements for care.

The possibility of using solid fuels of various types

Advice! To extend the service life of a long burning wood heating stove, you should carry out preventive maintenance work every week.

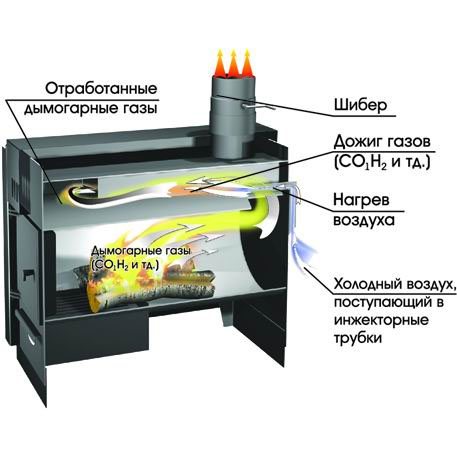

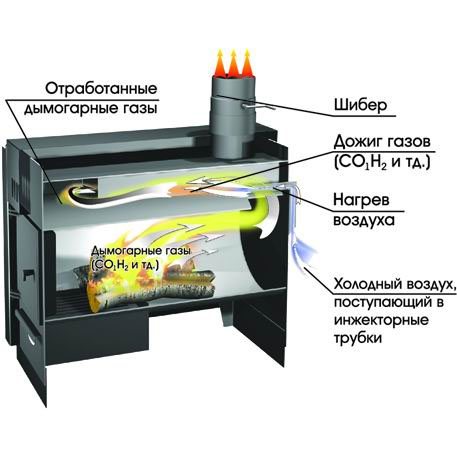

Pyrolysis combustion as a source of savings

To visually verify the effectiveness of pyrolysis - just light an ordinary wooden match. If you hold it upside down, it will burn out much faster than in the opposite position. Moreover, if you measure the released heat, it turns out that in the second case there was more of it. The reason is pyrolysis combustion.

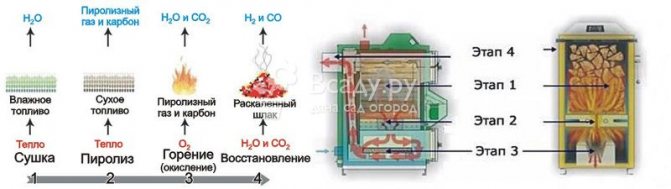

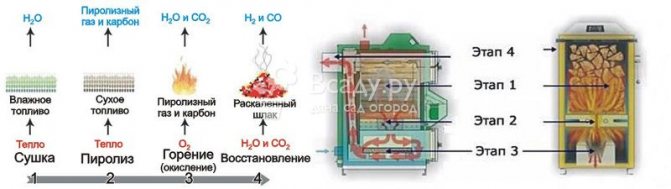

Wood is composed of complex carbohydrates, where the main components are carbon and hydrogen. Pyrolysis is the decomposition of the initial fuel under the action of high temperature into CO and HO under conditions of metered air supply (stage 1), and the subsequent reaction to harmless CO2 and H2O (stage 2).

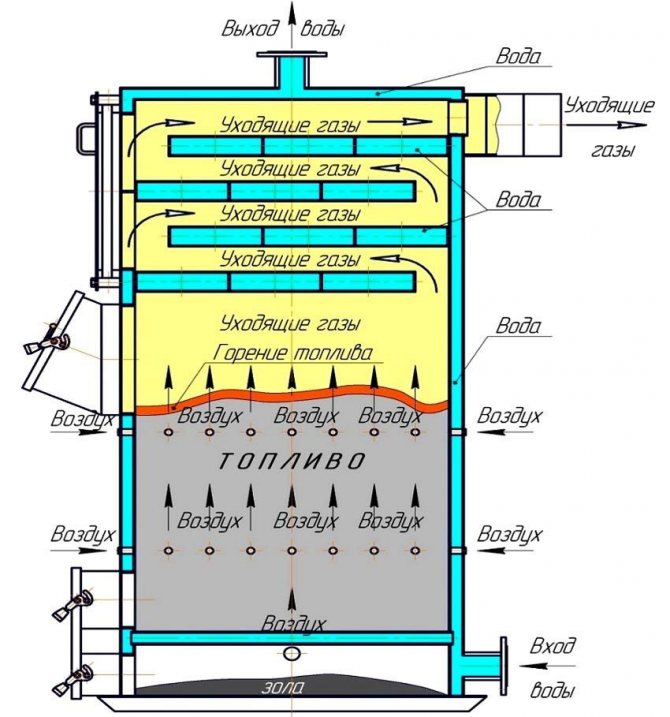

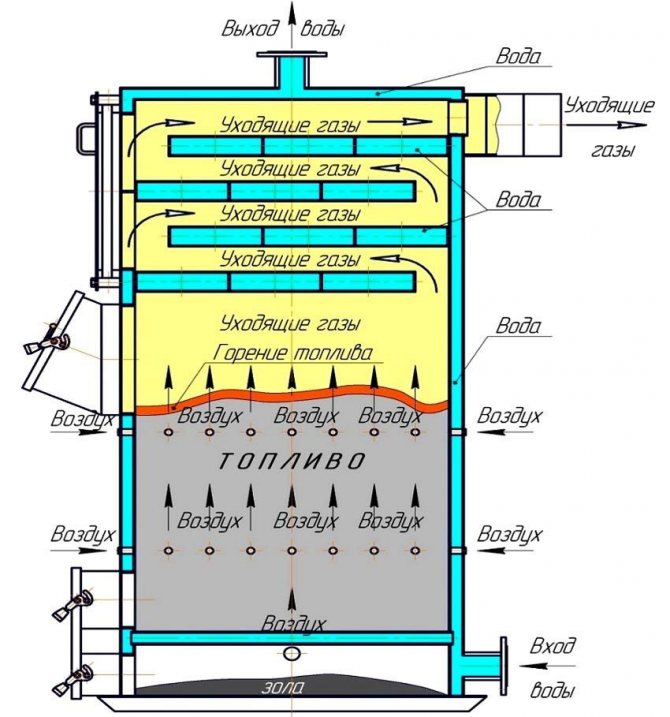

Pyrolysis processes in a long-burning wood-burning stove

Design of long burning furnaces

When choosing a wood stove for giving long burning, special attention should be paid to its design features. Controlling the air supply will reduce the intensity of the combustion process. There are three ways to achieve this effect. By:

- top burning;

- bottom burning;

- pyrolysis of firewood.

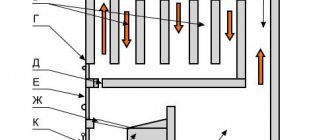

Most often, these furnaces have top burning. This design allows you to create conditions under which the firewood smolders from top to bottom, gradually sinking to the base of the firebox. To limit the combustion area, the air supply is carried out in a limited volume and strictly from the top. Due to the lack of convection, oxygen burns out with wood preservation.

Top combustion furnace design

The combustion chamber has the shape of a tall glass with a square or circular cross section. Firewood is laid as tightly as possible up to a certain mark. A small pile of brushwood or liquid intended for starting a fire is used for arson. At the first moment of time, when the dampers are fully open, the wood of the stove is heated. After the start of active burning of wood, the access of oxygen is cut off so that the fire goes out and the process of slow smoldering begins.

In devices with low combustion, air is supplied from the bottom of the chamber and in a metered amount. As a result, it is possible to partially implement the pyrolysis method of fuel combustion. At the initial stage, the wood is not only warmed up, but also dried. This contributes to an increase in heat transfer with the release of combustible gas, which is then additionally combusted in a separate upper chamber. It can also be plugged so that oxygen is displaced without burning out the fuel plug.

Bottom combustion furnace design

In pyrolysis boilers, the maximum energy is selected from the fuel. Thanks to the use of the bottom combustion mode and the active use of the emitted pyrolysis gas. As a result, the temperature stays at a high temperature for a long time, which is below the spontaneous combustion point, or, in the absence of oxygen, begins to decompose into pyrolysis gas, ash and other substances. Due to the fact that the resulting flammable mass will be hotter and lighter than air, it will begin to accumulate in the upper part of the combustion chamber. With constant gas supply of gas to the additional chamber. After setting fire, the released heat is transferred by the walls of the furnace, heat exchanger or convector.

Wood fired pyrolysis boiler

Features of fireplace stoves

Along with conventional wood-burning stoves, wood-burning fireplaces are in demand for giving a long burning. It is a unique design that is highly energy efficient and traditional in appearance. Such heating stoves are in demand in cases where there is no way to think over another way of heating the room. A wood-burning stove can be installed even in an open field, where there is no light and heating systems. In addition, such stoves look harmonious in any interior, creating an atmosphere of warmth, comfort and kindness in it. The long-burning fireplace stove for summer cottages has a number of features:

- The body is made of a material that heats up quickly and keeps the room warm for a long time.

- High level of efficiency compared to open hearth fireplaces.

- Thanks to the closed firebox, high fire safety is ensured, coals do not fall out of it, and smoke does not enter the room.

- Fireplace doors are made of refractory bricks, which is the key to rapid heating and long-term preservation of heat in the room.

- Fireproof glass makes it possible to convey all the beauty of a burning flame.

The principle of operation of long-burning furnaces

Due to their operational features, such heating devices are sometimes called gas-generating devices. Long burning furnace operation consists of two stages. At the first stage, active combustion of fuel takes place, followed by smoldering under conditions of limited oxygen access. In the second stage, the exhaust gas is burnt. This generates most of the heat.

The first step is to melt the oven. A small amount of firewood is laid.The inlet flap is opened, designed to ensure the access of a sufficient volume of oxygen, and the outlet, which supports the combustion process. At this stage, the oven begins to actively warm up. The temperature in the furnace reaches the required value. After that, a large stack of firewood is added. The inlet flap is closed to restrict oxygen access. As a result, the wood inside the firebox does not burn, but smolders slowly.

The principle of operation of the oven

At the second stage, the warmed-up wood begins to emit gas, which, having risen into the upper chamber, burns out entirely. By closing the outlet flap on the chimney, you can achieve the greatest efficiency from the heating system.

Attention! Thanks to the implemented principle of operation, it is possible to ensure continuous heat production for 6 - 10 hours.

Main technical characteristics of long burning wood burning stoves

When choosing a long-burning stove for a summer residence, you should pay attention to the main technical characteristics:

- the capacity of the purchased equipment;

- firebox material;

- the weight of the product, which largely depends on the material used in the manufacture of the furnace. Cast iron have more weight and longer service life. For a wooden house, it is better to purchase a steel model, the weight of which is half that;

- functional purpose. For heating, you can choose a conventional model. Otherwise, fireplace stoves or heating and cooking models deserve attention.

The heating and cooking model must have sufficient power

Heaters design

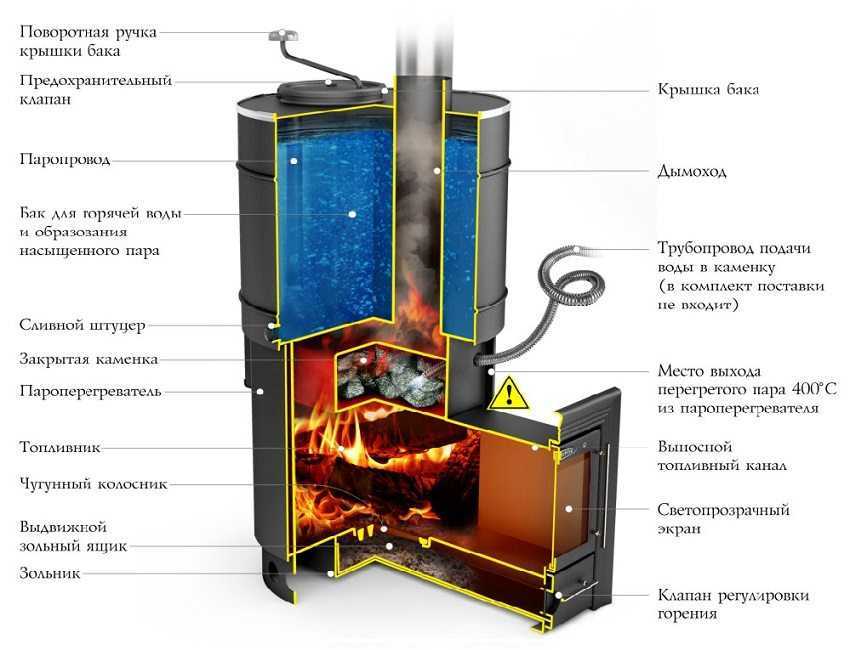

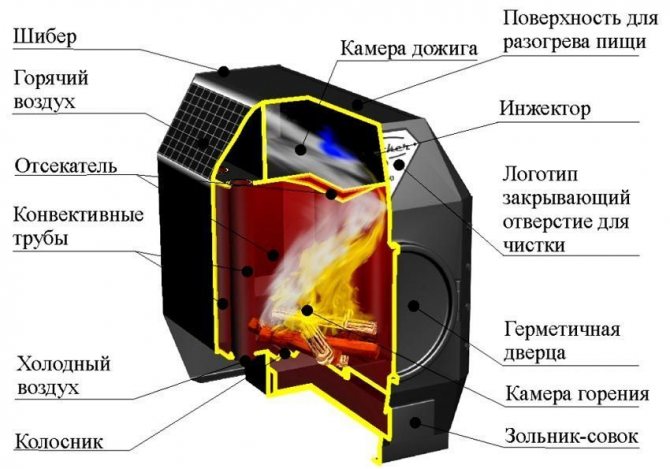

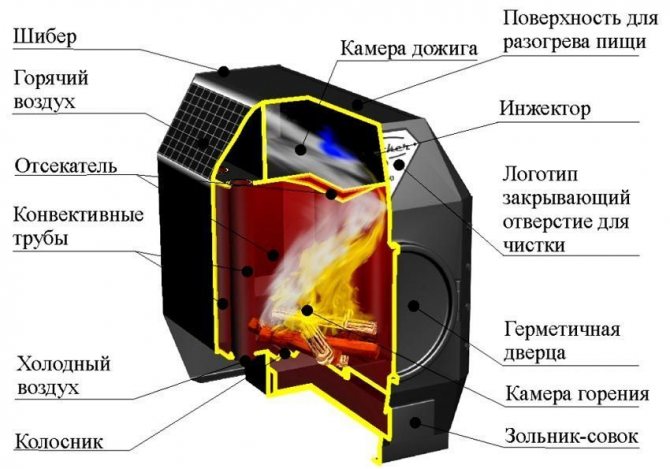

The scheme of the pyrolysis furnace

Long burning stoves have a similar design, regardless of the model. Among the main elements:

- Furnace chamber. Firewood is stacked in it.

- Primary air supply channel. Required to support wood smoldering.

- Secondary combustion chamber.

- Partition between the combustion chamber and the place of gas afterburning.

- Branch pipe. It is used for chimney installation.

- Furnace door with heat-resistant glass. They are transparent, so through them you can look at the fire and control the combustion process.

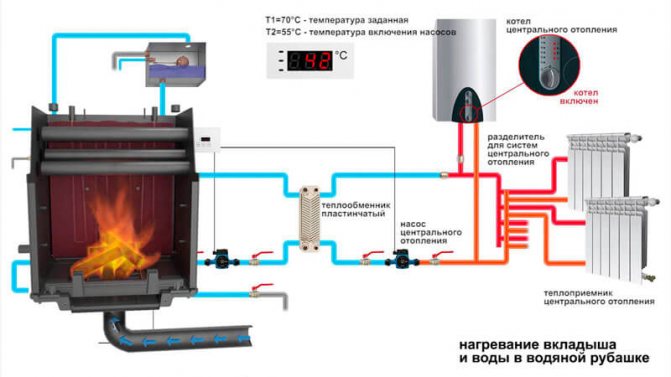

Furnace design with a water circuit:

- Firebox.

- Water jacket. Placed around the combustion chamber.

- Grate. It is necessary for the primary extraction of heat during smoldering.

- Firebox door.

- Ash door for periodic cleaning.

- A valve that regulates the supply of primary air to the combustion chamber.

- Gate valve for supplying secondary air to the gas afterburner.

- Ash pan.

- A branch pipe for installing a chimney pipe.

- Flange for connecting the heating system return pipe.

- Flange for the coolant supply pipe.

- Body with a layer of thermal insulation. Not available on all models.

- Additional heat exchanger. Also, not in every type of long burning stoves.

- Channels, cavities of the internal circuit with a coolant.

Models for heating with a water circuit have a more complex design. This is due to the additional function of heating and supplying water to the heating system.

How to choose a long burning wood stove?

When starting to choose a wood-burning stove for heating a house with long burning, you should first of all pay attention to the power of the offered equipment. It should be sufficient to maintain a comfortable indoor environment. For the calculation, it can be roughly assumed that for heating each 10 squares, 1 kW of generated heat energy will be required. The calculated value should be rounded to the nearest.

The volume of the firebox must be sufficient to accommodate a stack of firewood

You should not buy a stove with a significant power reserve. Due to the lack of automation, it will be impossible to reduce the room temperature to an optimal level. In addition, the increase in capacity will increase the cost of subsequent maintenance.

Further, in the selection process, it is worth comparing the volume of the combustion chamber.This determines the amount of firewood that can be put into the stove in one tab and, consequently, the duration of the combustion process.

If you decide to purchase a wood-fired fireplace for your home, then you should pay attention to the design features of the model you are interested in. To prevent soot from constantly settling on the front glass during operation, thereby impairing the visibility of the flame, appropriate measures must be taken.

The constructive solution deserves special attention

The metal of the body and the shape of the furnace itself deserve special attention. It is advisable to purchase equipment with thick walls (more than 3 mm) in order to ensure a long period of equipment operation. Round products have the best aerodynamic performance.

The body itself should have a horizontal orientation (recumbent) with several internal baffles. The convection casing will protect the people in the room from infrared radiation when the oven is very hot and will give aesthetics to the installed equipment.

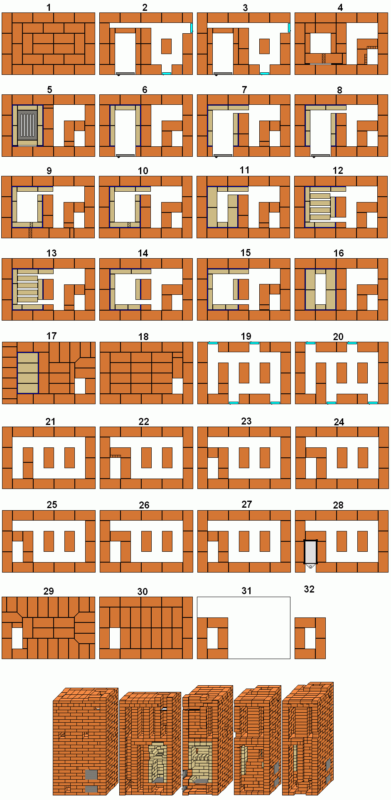

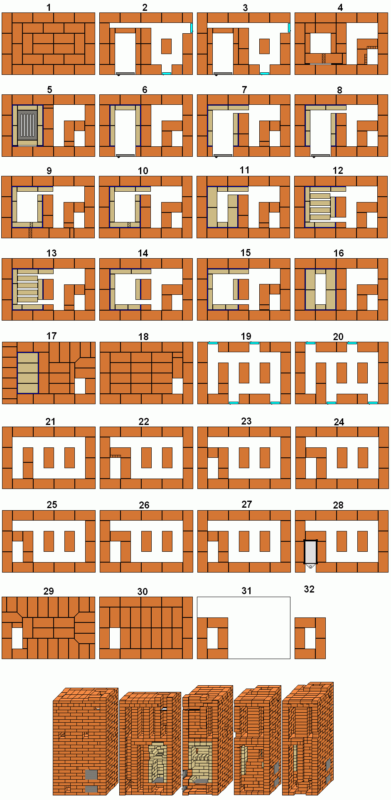

Furnace masonry

The masonry is made of red-hot bricks, and the firebox and internal partitions are laid out with heat-resistant, ceramic material (fireclay bricks).

For a reliable design, it is imperative to follow the order. The evenness and accuracy of the first and subsequent rows are measured with a plumb line and a level ruler. The bricks are placed on a sandy clay mortar. After laying the fuel chamber, the seams are fired to check the quality of the mortar and the masonry itself.

The fuel chamber door, dampers and dampers are installed last when the last row of masonry is laid. All these elements must be hermetically sealed, therefore, before installation, asbestos gaskets are laid between the brickwork and the metal. The use of silicone additives is allowed.

For the construction of a chimney, it is advisable to use composite elements - they will increase the operational life and facilitate maintenance. Inside the finished brick blocks, there is a ceramic pipe, finished with insulation. The instructions for installing a composite chimney are different for each manufacturer and is included in the delivery set.

How to improve the efficiency of a long burning wood stove?

There are situations when it is required to increase the interval between the next loadings of firewood into the furnace firebox. To do this, you can perform a number of measures that will improve heat transfer and will contribute to more economical fuel consumption. Can:

- Intensify heat transfer from the furnace surface by forced air supply. To do this, it is enough to put a small fan near the stove, which can activate the movement of air masses in the room. If the room is small, you can use a cooler from the power supply.

- Install a water heat exchanger on the flue pipe. Such a device will take heat from the exhaust gases and transfer them through the water to the inside of the room.

- Use dry fuel only. The use of damp wood will lead to the formation of a dense deposit on the walls of the fuel, impairing heat dissipation.

- Add a small amount of fuel briquettes with the wood. Due to its high heat transfer, such fuel will be able to compensate for the lack of heat.

The fuel to be loaded must be dry

Some installation guidelines

The installation of a long-burning furnace does not cause any particular difficulties. For a correct installation, it is enough to follow simple rules:

- Use a refractory sheet as a "backing" for the oven. It is important that the edges of the sheet extend beyond the oven, creating a "rug" in front of the firebox.

- Do not install the structure close to walls. The optimal distance between the oven and the wall is about 20 cm... this will provide an even flow of air and prevent the surface of the walls from heating up.

- To ensure sufficient draft force and prevent blockages in the chimney, its cross-section must be not less than 15 cm.

- The installation of the chimney must be carried out while maintaining access to it. It is best to make a collapsible chimney - this will make it easier to clean the chimney.

- The chimney is best mounted against the movement of gases. This will protect the floor from the ingress of condensation that settles on the walls of the pipe.

Furnace types

Currently, you can buy a long-burning wood-burning stove of various capacities and with a variety of designs. Individual models are manufactured with additional functions:

- a hob that can be used for cooking;

- in the form of a fireplace, if you want to add exclusivity to the decorated interior. Finnish stoves for home heating look especially advantageous in this case.

Appearance is very important

Long burning wood stoves fireplaces for summer cottages

Related article: Today, many have come to a consensus that fireplace stove for giving long burning, this is the most efficient and safest heating method. In the article we will talk about the advantages of devices, their types, consider popular models, average prices, how to choose the right one.

Modern models are easy to use. They are economical. They are distinguished by a long service life. They are easy to ignite and quickly warm up the room. Some stoves, fireplaces for giving wood burning long burning are universal: they are equipped with hobs.

Fireplace stoves are compact mobile devices that do not create problems during operation. Ash can be removed from the firebox directly during operation. The stylish appearance of the equipment allows you to transform any interior.

Their main disadvantage is the uneven heat distribution due to the design features of the equipment. The temperature near the ceiling is always higher than near the floor. As a result, smoke, heated to a sufficiently high temperature, condenses to form soot on the inner surface of the pipe. If the stove is used continuously, the chimney should be cleaned every six months.

Stove-fireplace - a stylish solution for the interior

Wood burning boilers

The basis of the operation of such heating equipment is based on the principle of smoldering firewood in conditions of a limited supply of oxygen. Such boilers do not need a constant supply of firewood. Depending on the technical characteristics of a particular model, one bookmark can be enough for a period of 3 to 12 hours. At the same time, instead of firewood, another type of solid fuel can be used. Due to the special design for heating the room, it is not required to connect the heating equipment to other communications.

The disadvantages of long-burning boilers include the high cost of equipment and low heat transfer of firewood, which does not exceed 89%. In addition, constant human intervention is required to ensure the boiler operability. Such equipment does not allow you to adjust the temperature.

Long burning solid fuel boiler

Wood burning stoves for home heating with a hob

Furnaces equipped with a flat iron surface can be used not only for heating the room, but also for cooking. Such products are reliable, durable, and economical. They are able to harmoniously fit into the kitchen environment: manufacturers offer products with various designs.

Such equipment does not pose any problems during transportation. Easy to assemble. However, during the installation process, you should carefully follow the rules. To achieve optimum results, use the correct fuel quality when operating the device.However, the lack of adjustment options does not allow to reduce the degree of heating of the metal surface in most models. Some units are equipped with an additional flap, which helps to reduce the temperature.

Long burning oven with hob

Construction of a furnace from a metal barrel

If the decision regarding the construction of a homemade stove is made, you must first prepare all the necessary material, namely:

- a metal barrel with a volume of 200 liters (it must be made of stainless steel, cast iron or steel);

- two steel pipes of different lengths;

- Red brick;

- metal channel;

- building mixture;

- cement.

You also need to prepare tools, without which it will be impossible to perform certain actions. These include:

- ax;

- welding machine;

- roulette;

- hammer;

- set of electrodes;

- plumb lines for installation;

- building level;

- Bulgarian.

It will be easier to build a homemade stove if you follow the step-by-step instructions:

- You need to take a prepared cylinder (it is recommended to use an empty gas cylinder).

- Unscrew the valve.

- Fill the bottle with water.

- Cut off the top of it and set it aside (it will be used later).

- They take cuts of reinforcement and weld them to the bottom of the barrel, constructing legs.

- A circle with a diameter slightly less than the diameter of the main body is cut out of a metal sheet.

- Another circle is cut in the cut out circle in the middle.

- A pipe is applied to the cut-out inner round hole, and then a pipe is welded, which will serve as a chimney.

- On the reverse side of this metal circle, four sections of the channel are welded, which are located perpendicular to each other.

- Take the previously cut off top of the barrel, cut a hole for the pipe in its center.

- A hole is cut in the body, which will be used for loading fuel.

- A metal door is welded to the cut hole.

- A handle is welded to the door.

- Below this door, another smaller hole is cut out, and the door is also welded to it.

- Next, a place is prepared in which a homemade stove will be installed (they make a depression in the wall).

- At the bottom of the constructed niche, a layer of brick is laid out and poured with cement.

- Check that the constructed site is perfectly level.

- The following steps are directed to the installation of a chimney pipe. A straight piece of pipe is welded to the hole in the barrel.

- The main part of the chimney is constructed from a curved pipe.

- Lay an asbestos fabric that will provide reliable insulation.

- Attach the clamp.

- A special cap is installed on the upper part of the pipe, which will provide reliable protection against pollution and natural precipitation.

- A reflector is installed, which is also called a protective screen for the furnace (it is made of metal or brick).

This completes the process of constructing a long-burning furnace. During the operation of such a unit, high temperature air is supplied, due to which it is possible to heat up the interior space of the room well.

You can build a long-burning stove that will operate on wood with your own hands. Before starting work, it is necessary to take into account all the recommendations of specialists, prepare quality materials and tools. You will also need skills in working with special tools or a specialist of the appropriate level.

Similar publications

- To read

Choosing a long-burning boiler for a house with a water circuit

- To read

Long-burning double-circuit wood-burning boilers for the home: everything you need to know

- To read

DIY pizza oven

- To read

How to fold a simple brick oven with your own hands

- To read

Do-it-yourself oven for burning garbage in the country

- To read

Furnace models and manufacturers

Before you buy an inexpensive wood-fired home stove, you should get acquainted with the features of products from well-known manufacturers. In this case, it will be easier to navigate in the assortment offered in the store, in the advantages and disadvantages of individual models.

Buleryan

A furnace of this design was first developed in Canada. It is characterized by simplicity of design and high performance characteristics.

The cylindrical firebox is made of steel with a thickness of 5 - 6 mm. The furnace door is located on the front side. Hollow pipes with a circular or rectangular cross-section are welded to the body. After the furnace has warmed up, the air in the pipes heats up, providing an active convection process.

The grate is located inside the chamber at the bottom of the cylinder. There is a partition in the upper part, dividing the firebox into two parts. The first is intended for laying firewood, the second is for afterburning pyrolysis gas. The chimney is located on the side opposite to the door and goes inside the combustion chamber. This contributes to the fact that the combustion products formed in the depth of the main chamber return to the front wall, and then rise to the top and enter the chimney.

Buleryan - time-tested quality

Stoves Butakov

The patented model has shown good results in harsh climatic conditions. Several models are produced under this trademark, with different technical characteristics:

| Model | power, kWt | Weight, kg | Internal volume, cubes |

| Student | 9 | 70 | 150 |

| Engineer | 15 | 113 | 250 |

| Assistant professor | 25 | 164 | 500 |

| Professor | 40 | 235 | 1000 |

| Academician | 55 | 300 | 1200 |

Butakova - reliability and durability

Breneran

Russian analogue of the Canadian model, manufactured using European technology. Presented by several models:

| Model | power, kWt | Heated area, squares | Weight, kg |

| AOT-6 | 6 | 40 | 56 |

| AOT-11 | 11 | 80 | 105 |

| AOT-14 | 14 | 160 | 145 |

| AOT-16 | 27 | 240 | 205 |

| AOT-19 | 35 | 400 | 260 |

Continuous ovens can be equipped with glass doors. Connection to the water circuit is permissible. However, unlike its foreign counterpart, such equipment has insufficient tightness of the smoke nozzle, which can cause condensate to enter the room.

Breneran is the Russian analogue of Buleryan

Teplodar

Products of a well-known Russian manufacturer. Differs in high efficiency due to a carefully thought-out design. Compact size and light weight. You can choose a long burning stove for your garage or home with suitable characteristics.

Teplodar Matrix-200 is relevant for rooms with an area of up to 200 squares. Siberia provides fast room heating. Models of the T series will be the best choice for the garage. For the kitchen, it is better to purchase a vertical heating and cooking stove

Teplodar Matrix-200 - a good choice

Vesuvius

Russian development. Such a long burning wood-burning stove for a bathhouse, a summer residence or a country house can be the best solution. They are often used for heating outbuildings. The choice of a model is influenced by the purpose of the room for which it is purchased. They provide uniform heating due to a special design: pipes are welded into the furnace through which heated air passes.

Vesuvius for uniform heating of the house

Thermophore

Domestic development for any home. Several models are produced under this trademark:

- Herma;

- Cinderella;

- Indigirka;

- Normal;

- Fire battery.

The stoves can be used to heat various rooms with an internal volume of 50-250 m³. Their power ranges from 4 to 13 kW.

Thermophore brown

Ermak

Heating equipment with small dimensions and classic design. The robust casing protects against harmful infrared rays. This is the best solution for a small country house.

The principle of operation of the Ermak furnace

For giving efficiency - not the most important indicator!

Will you really be constantly thinking about saving firewood at the weekend at the dacha? Unless, of course, you live in the country every day all summer. On the other hand, in the summer, the question of saving firewood may not arise - if it is not cold, you will not spend an excessive amount of it anyway. Another thing is at the beginning and at the end of the season ...

Before talking about choosing a wood-burning stove for a summer residence, let's say that the point of view changes a lot if you live in the country all the time (winter-summer, or at least only spring-autumn) or you come on short visits.

Let's talk about the last option first. Here are three things, in our opinion, that are really important when operating a stove in the country:

- Do not freeze;

- Quietly leave children (grandchildren) near the heating device;

- Do not run often (or at night, early in the morning), throw up firewood or early in the morning;

- Of course, the price of the heater itself.

If you come to the dacha on the weekend or after a weekend + vacation, then you already do not have a lot of firewood for heating and this indicator is unlikely to fall into the first lines of your expenses. The comfort of these rare days spent with the family is another matter.

It would be foolish to describe dozens of models of iron stoves if you have not yet decided what is more suitable for you and what indicators are important to consider when choosing a stove for a summer residence. Let's talk about this too.

Operating rules for long burning stoves

To ensure a long life of a metal wood-fired home stove during the operation of the stove, the following rules should be adhered to:

- Do not overheat. Due to the high inertia of the equipment, it will take some time for the temperature to drop. Especially in the presence of pipes made of plastic or metal-plastic.

- It is worth taking care of the availability of supply ventilation.

- Flammable objects must not be placed on the boiler.

Overheating is not allowed

Do-it-yourself installation of a long-burning furnace

Installation of a long-burning stove in a house or bath can be performed in the following sequence:

| Illustration | Description of work |

| We carry out the assembly of the furnace, installing all the necessary elements. |

| We check the correct dimensions of the place prepared for placing the oven. |

| We mount the portal using a special sealant designed for the installation of stoves and fireplaces. The stove is located in one room (steam room), and the outlet for laying firewood is in another. | |

| We assemble the chimney, ensuring a tight connection of all elements. |

| We carefully control the spatial position of all elements. |

| We carefully insulate the part of the pipe located in the attic area. |

| For safe operation, we attach a protective sheet to the ceiling. |

| We mount the rest of the chimney on the roof, installing a silicone corrugation. We are testing the system. |

If you decide to give preference to the classic version, you can make a do-it-yourself oven for a brick house. Having certain skills, it will be possible to cope with the entire volume of work on your own. Drawings with the orders of a brick oven for the house will help not to make mistakes when performing work.

How to calculate the power correctly

It is not difficult to calculate the power of a long-burning furnace. Most manufacturers indicate how much area each oven can heat. For example, the model "Fire-battery 5" is capable of heating a room up to 100 m2.

When calculating the power yourself, keep in mind that 1 kW equals approximately 12 m2... If the calculation is carried out for several rooms, then the capacity must be selected for the total area of all rooms that are supposed to be heated.

Where to buy a wood-fired home stove inexpensively: prices and models

Before buying, we suggest that you get acquainted with the average prices for the most popular models of home stoves with water heating. Prices are shown in the table:

| Photo | Model | Average price, rub. |

| Cast iron stove Persee (Supra) | 130000 |

| Furnace Persee Sur Bucher (Supra) | 134000 |

| Fireplace stove (potbelly stove) Koza / K6 thermostat | 66000 |

| Heating boiler Teplodar Kupper OK 20 | 26000 |

| Stove Fireplace Teplodar Rumba | 32000 |

| Heating stove Termofor Fire-battery 11 | 17800 |

| Heating stove Vesuvius AOGT 100 m3 (00) under glass | 9200 |

Thus, at present, it is not necessary to install a brick oven for a wood-burning house. Its modern counterparts of long burning will do the job much better. Installation work is easy to do on your own.