Characteristics of asbestos cement pipes

Anti-advertising to asbestos has done its job. Building materials made on the basis of asbestos components began to leave the market, but this did not affect asbestos-cement pipes.

Because these products have a fairly wide list of advantages, besides, they are also made of white asbestos - chrysotile, which, as scientists have proven, is not dangerous to human health.

The raw material for the production of asbestos-cement pipes is fiber cement mortar, which contains asbestos fibers in the amount of 15-20% of the volume of used Portland cement.

The production of pipes is not very difficult, which affects the cost of production. Therefore, the price for asbestos-cement pipes is several times less than for metal ones.

Advantages and disadvantages of asbestos-cement pipes

Rather strict standards are applied to any pipe material, which determine the quality of the product. Therefore, the advantages of asbestos-cement pipes include:

- Long-term operation, where manufacturers give a guaranteed service life of 25 years.

- They perfectly cope with low temperatures, so their laying in the ground at a shallow depth does not reduce their technical and operational characteristics.

- It can withstand temperatures above +115 C.

- Smooth inner surface that does not allow sludge to settle on it, similar to plastic pipes.

- The hydraulic resistance is very low.

- Corrosion resistant.

- Loyalty to almost all chemically active substances is absolute inertness.

- Simplicity of the installation process, where an asbestos-cement coupling is used to connect individual pipes and sections.

- The small specific weight of the products, therefore, when laying pipes of small diameter, there is no need to use special equipment, the installation can be done by hand.

- Wide range of sizes.

- Acceptable price.

Of the shortcomings, only one point can be distinguished. According to the established standards, it is impossible to use asbestos-cement pipes for laying water pipes in residential buildings, hospitals, and children's institutions.

They can only be used for water supply with industrial water. It should be noted that today in Europe, asbestos-cement pipes are used for laying gas pipelines. This type of pipe found its main application in the laying of cable products as a protective tunnel that ensures the safe operation of cables and wires.

Scope of asbestos-cement pipes

Some areas where you can use asbestos-cement works have already been said, but this is just a small part. They are used by:

- Drainage sewerage. Manufacturers currently offer asbestos-cement perforated products, with the help of which subsoil water and precipitation are collected and removed from suburban areas.

- Sewerage systems: pressure and non-pressure. This is especially true of the pressure sewage system, because asbestos-cement pipes can withstand pressures up to 15 atm. Therefore, there is no need to install cast iron or steel pipes, which are several times more expensive than asbestos-cement pipes.

- Casing construction when drilling wells and finishing wells.

- The regulations allow the construction of garbage chutes in apartment buildings. This reduces building construction costs.

- Low thermal conductivity and large thickness of asbestos pipes make it possible to use them in chimney structures. At the same time, fire safety requirements are met one hundred percent.

- They are used for the construction of fences and various protective structures as pillars.

- Permanent formwork is made of them for pouring columnar foundations and supporting pillars for floors.

- Designers also pay attention to asbestos-cement pipes. They make flowerpots, flower beds, decorative racks and so on. Fortunately, these products are easy to process, and this is another plus of them.

Nuances when installing an asbestos pipe for a chimney

It is possible to smooth out the shortcomings of asbestos-cement pipes if they are installed correctly.

It is necessary to pay attention to many parameters: properties of the coolant, distance from the heater to the pipe, diameter and length, properties of insulating materials

Wood or coal cannot be used as a heat carrier with such a chimney. Sometimes such a chimney is built in baths, but an adapter must be installed. The greater the distance from the heating structure to the pipe, the lower the temperature inside.

Therefore, the more heat the coolant gives off, the longer the adapter is needed. It is recommended to install a chimney made of several materials, with asbestos cement being the farthest from the boiler.

Another parameter is reliable insulation and insulation. They protect the chimney and the surrounding materials from condensation. The fact is that asbestos itself has a good waterproofing ability, but the condensate does not consist of pure water. Such a pipe really does not let water through. Condensate, on the other hand, has impurities of salts, acids and metals, which easily penetrate into the pores of the pipe and spread to other parts of the chimney.

In addition to internal condensation, it is necessary to protect the pipe from external moisture. For this, in addition to insulation and insulation, special umbrellas are used, which are attached to the head of the pipe.

Classification of asbestos-cement pipes

The production of asbestos products is regulated by GOST 539-80 (pressure) and GOST 1839-80 (non-pressure), in which it is determined that asbestos-cement pipes can be produced with a diameter of 100 mm to 500 mm, and their length has 2 standard sizes: 3.95 and 5 m.

Pressure

Asbestos-cement pressure pipes are classified according to the pressure acting on them passing through the medium. They are divided into 4 classes:

- VT6 - withstand pressure up to 6 kgf / cm², this is practically 6 atm. To connect such products, a CAM6 coupling is used.

- VT9 - they hold a pressure of 9 atm, a CAM9 coupling is used.

- VT12 - 12 atm, CAM12 coupling.

- VT15 - 15 atm, CAM15 coupling.

The indicated pressure is the maximum provided that there is no external pressure on the pipeline.

Asbestos-cement pressure pipes are divided into 3 more types, which are based on the inner diameter and length of the product. We will not analyze all the proposed options, we will consider only one with a nominal bore of 200 mm, which will show the difference.

First type:

| Asbestos-cement pipe brand | Inner diameter, mm | Wall thickness, mm | Length, m |

| VT6 | 196 | 14 | 3,95 |

| VT9 | 189 | 17,5 | 3,95 |

| VT12 | 181 | 21,5 | 3,95 |

| VT15 | – | – | – |

Second type:

| Asbestos-cement pipe brand | Inner diameter, mm | Wall thickness, mm | Length, m |

| VT6 | 200 | 12 | 5,0 |

| VT9 | 196 | 14 | 5,0 |

| VT12 | 188 | 18 | 5,0 |

| VT15 | 180 | 22 | 5,0 |

Third type:

| Asbestos-cement pipe brand | Inner diameter, mm | Wall thickness, mm | Length, m |

| VT6 | 196 | 14 | 5,95 |

| VT9 | 189 | 17,5 | 5,95 |

| VT12 | 181 | 21,5 | 5,95 |

| VT15 | 176 | 24 | 5,95 |

It should be noted that the pressure options have a turned chamfer to fit into the coupling. It is smaller in outer diameter. The length of the chamfer should not be less than 20 cm.

Free-flow

This type of pipe does not have a landing chamfer, i.e. they are purely straight. As in the previous case, asbestos products are divided by size. However, the range is not that large.

- Conditional passage: 100; 150; 200; 300 and 400 mm.

- Wall thickness, respectively: 9; 10; eleven; 14 and 17 mm.

- Length: the first two diameters have two indicators: 2.95 and 3.95 m, the last three have only 3.95 m.

Characteristics

All pipe products made of asbestos cement must pass a series of tests described in GOST 11310-90. To be admitted into operation, a product must meet several parameters:

- test for water tightness by filling the pipe cavity under a specified pressure.Non-pressure products must withstand feeding for 10 seconds, pressure ones - 30 seconds;

- flexural strength, rupture is also checked in a state filled with water. The pipe is placed under a press, the pressure of which is brought out to a predetermined value. Within 10 seconds, the walls should show no signs of destruction.

The pressure value for asbestos-cement pipes with different diameters and wall thicknesses is determined individually. According to the test result, the products are divided into 4 classes:

| Class designation | Working pressure | ||

| pipes | couplings | MPa | kgf / cm2 |

| VT6 | CAM6 | 0,6 | 6 |

| VT9 | CAM9 | 0,9 | 9 |

| VT12 | CAM12 | 1,2 | 12 |

| VT15 | CAM15 | 1,5 | 15 |

Installation of asbestos-cement pipes

The main criterion for the strength of an asbestos-cement pipe is the asbestos fibers that are distributed along the pipe structure. This peculiar reinforcing frame creates a strong and reliable material structure.

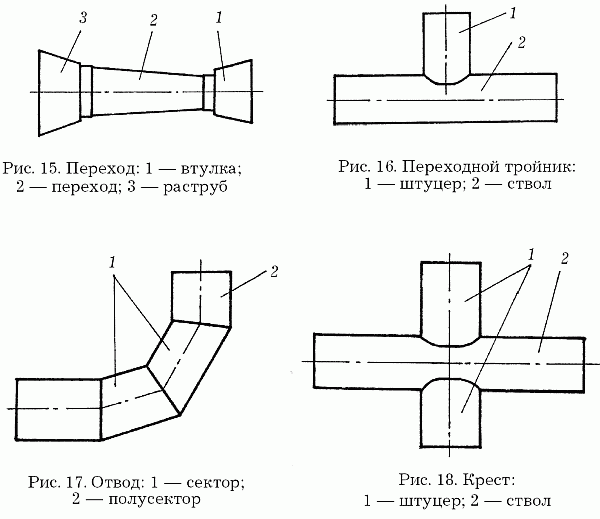

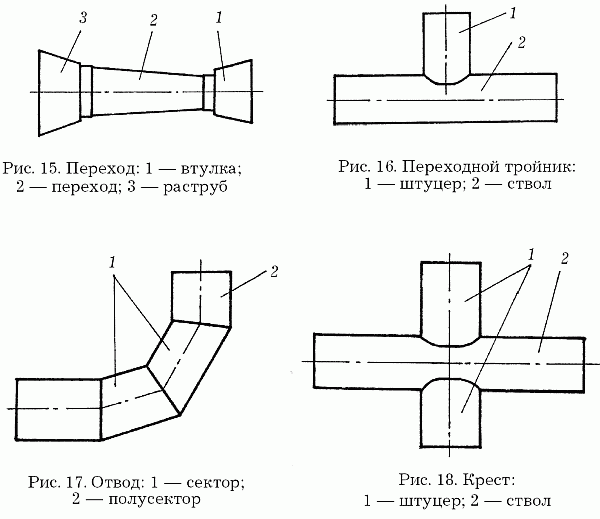

That is why shaped products (fittings) are not made of asbestos cement, except for the coupling, which repeats the shape of the pipe. In fact, this is a pipe segment. The thing is that asbestos fibers will be located chaotically in the fittings, and this is a decrease in strength several times.

Therefore, when assembling pipelines in a straight circuit, it is the connecting sleeve that is used. If it becomes necessary to branch the pipeline at different angles or to connect an additional line, then in this case, fittings made of metals are used.

So, a coupling made of asbestos cement is a pipe segment in which grooves are made from the inside on each side. A rubber seal is placed in them. The cross-section of the seal is not round, but complex, which makes it possible to carry out the maximum sealing of the butt joints. Therefore, seals are often referred to as cuffs.

Installation of the pipe into the coupling is not difficult. It is necessary to insert the coupling into the pipe with little effort or vice versa. In this case, it is recommended to leave a small radial gap of 3 °, which will ensure the bending of the connected pipe during elastic deformations.

For example, when the ground moves. By the way, this technology of the installation process with the installation of a gap makes it possible to do without the use of temperature compensators. If large-diameter pipes are connected to each other, then the coupling is installed using special devices.

How to do it right:

- A sleeve is placed in a trench near the first pipe.

- Rubber cuffs are inserted into it.

- The coupling is put on the pipe and, with the help of levers and jacks, is pulled onto the latter until it stops.

- The second pipe is laid next to it so that its end is pressed against the end of the coupling.

- Now the sleeve is moved back to the end of the second pipe using the same tools and devices. It is important not to overdo it here, therefore, accurately determine the possibility of movement, so as not to weaken the tightness of the structure.

It is very important that the connected elements are on the same axis, this is a guarantee of the quality of the final result. Be sure to keep an eye on the cuffs so that they do not twist or shift.

There is another option for connecting asbestos-cement pipes, where a polyethylene coupling is used. The latter is heated before installation, put on one of the pipes until it stops, which is located inside the connecting element.

Then a second pipe is inserted from the other side. If the coupling has cooled down before installing the second element of the pipeline, then part of it can be reheated. When it cools, the polyethylene shrinks, the coupling decreases in size, which leads to its tight fit on the outer surfaces of the connected parts of the pipeline.

Non-pressure asbestos-cement pipes, which are used as protection for cable networks laid in wet soils, are connected in a different way.

- For this, holes with a diameter of 2 cm are drilled in the coupling on both sides.In this case, there should be two holes on each side, located on opposite sides of the diameter.

- A tarred rag or tape is wound around the pipes.

- The coupling is pulled over one pipe.

- Then the second is installed next to it, onto which the connecting element is shifted in reverse order.

- The resinous materials are compacted.

- Now it is necessary to pour liquid hot bitumen into the drilled holes, while it is poured into the upper hole, and the lower one is controlled. As soon as bitumen flows out of it, it means that the cavity between the coupling and the pipe is completely filled.

The use of asbestos couplings to connect asbestos-cement pipes

To perform the process concerning the connection of asbestos-cement pipes, plastic couplings for asbestos pipes are used. This kind of connection acts as a common method of joining non-pressure asbestos-cement pipes together.

This is the case if the pipeline is being laid for communication cables. The method is used exclusively when working with pipe products, the diameter of which reaches 100mm - 300mm.

If their installation is carried out in dry ground. Before joining the joints between the pipes, the coupling must be heated up. To solve this problem, warming it up takes at least 10 minutes. For this purpose, they also use water, which heats up in the tank and reaches a temperature indicator of 100 ° C.

The dimensions of the inner diameters are for reference only.

Further, one end of the hot coupling must be slipped onto the asbestos-cement pipe. However, it is worth clarifying that the product is laid a little earlier on the place of its future location than its connection is made.

After the inner partition begins to interfere with the advancement of the product, it is necessary to insert the asbestos-cement product with its second end from the opposite side until it stops, which is created by the inner partition of the coupling.

Initially, asbestos-cement couplings for pipes with a diameter of 500 mm are pushed onto the end of the pipe product. It, in turn, should already be in the place of its location.

The end of the coupling, equipped with a shoulder that tends to protrude inward, should be at a sufficiently close distance to the end of the product that is intended to be joined.

The sleeve should initially be pushed on the pipe product more and more than its length itself suggests. Next, the second pipe is laid. In which working position the connecting element should be located is marked with a pencil using a template.

- on the outer diameter of the pipe

- by wall thickness

The coupling should be in a symmetrical position relative to the position in which the end of the products to be joined is located. The installation of rubber rings is carried out precisely in the plane that is located perpendicular to the placement of the longitudinal axis of the asbestos-cement pipe product.

Their position cannot be skewed or twisted. The pipes undergo a centering process after the rubber track and connection pieces have been slid onto them. How easy it will be to tighten the coupling depends on the correct implementation of the centering of the products.

In order to pull the double-breasted coupling over the joint, screw jacks are usually used. Centering of pipe placement and accuracy check is carried out with a lanyard and sight. They are fixed with the help of bedding, and compaction on both sides with soil.

When connecting asbestos-cement products with a double-breasted coupling, we monitor the degree of dryness of the connecting ends of the pipes. This indicator is important in order to avoid slipping on them, which is inherent in the sealing rubber rings when tightening the connecting part.

Repair of asbestos-cement pipes

In principle, their technology is exactly the same as that of their cast iron counterparts.The easiest option is to apply a rubber band, which is secured with wire or clamps. You can also use a bandage soaked in a cement mixture for this. True, you will have to wait until the pad dries out.

If the place of the defect is responsible or material moves under pressure inside the pipeline, then the best option is to dismantle part of the pipeline and install a new section. Fortunately, asbestos-cement pipes are easy to process. You can cut them, for example, with an ordinary hacksaw for metal.

As you can see, asbestos-cement pipes have not yet surrendered their positions. This is especially true in areas where it is necessary to take into account stringent fire safety requirements. We add that these products are by far the cheapest option with decent technical characteristics.

Areas of application of asbestos-cement pipes, new items with high performance. Video:

Installing an asbestos-cement pipe as a chimney

If, nevertheless, it was decided to use a pipe made of asbestos concrete for the installation of a chimney from it for heating gas appliances, it is necessary to carry out the entire process of installation, insulation and fastening correctly.

It should be noted that it is best to use such a pipe exclusively for the upper part of the chimney, then it will last a longer period.

For the stability of the asbestos part of the chimney, pieces of reinforcement are embedded in a brick pipe in front of the last or penultimate one next to it. After the solution hardens, a head is installed on the pieces of reinforcement sticking out inside, the distance between it and the brick pipe is insulated with cement mortar mixed with expanded clay. To prevent such insulation from leaking into the pipe, you can first lay pieces of any material around the pipe.

If the transition from a brick pipe to an asbestos one takes place in the area of the attic, then the passage of the asbestos chimney through the roof must be very well waterproofed.

Roof transition adapter

To do this, today in specialized stores you can purchase roofing passages that will tightly adjoin the pipe and roof with any volumetric pattern, thanks to the elasticity of the apron. It is fixed to the roofing material with a sealant.

Free-flow asbestos pipe

The product is manufactured using a special technology, taking into account standard sizes. The fields of application of free-flow asbestos pipes are different. They are widely used in carrying out a gravity sewage system without the possibility of building a pressure sewage system.

At the same time, the cost of the construction is much reduced. For manholes, cut asbestos rings are an excellent option.

They are also used as a waste chute. It is important to note that asbestos pipes do not pollute the environment, because the material is resistant to microorganisms. If the pipeline is turned off for a long time and the effluent stagnates, there is no possibility that the soil can be infected through the pipes.

Non-pressure asbestos pipes are widely used as a mine when carrying out various types of communications - telephone lines, electric cables, because they do not conduct electricity. For the same reason, they are not subject to electrochemical corrosion caused by stray currents.

Polyethylene couplings designed for connecting pipelines are easy to install, providing strength and reliability of fastening. Some varieties are used to create heating mains in various systems.

They are an economical way to transport heat, as they have a very low thermal conductivity, thereby minimizing heat losses.In such a system, inexpensive hydrophobized gravel is used as a heat insulator, with which the pipes are filled, and additionally covered with a polymeric material in the form of a film.

Non-pressure asbestos pipes are excellent for the installation of heating, plumbing, ventilation, chimneys, storm sewers, where large-diameter pipes are used as a water collector, and smaller pipes are used as drainage drains.

The use of free-flow asbestos pipes in the arrangement of the drainage system

Non-pressure asbestos pipes are used to create a closed drainage system. Installation is carried out taking into account the following aspects:

- Pipes intended for drainage must have openings for free penetration of water.

- As a rule, drainage pipelines are located at a slope towards the water flow.

- To install the system, you need to dig a trench manually or with the help of special equipment.

- In the drainage system, pipes with a diameter of 1-2 cm are usually installed, but in cases where high performance is needed, it is allowed to install products with a diameter of 3-4 cm.

- The products are also installed as wells serving the drainage system. The pipeline can be installed quite deep underground, as its walls withstand the effects of the environment and do not require regular maintenance.

The service life of asbestos-cement pipes is about 30 years.

How to connect asbestos-cement pipes. Couplings.

Asbestos-cement pipes are used in ventilation systems, chimneys, ventilation and drainage systems. Sometimes they are also used in sewer systems. These pipes do not rust, do not burn and are resistant to aggressive environments. To connect asbestos-cement pipes together, special double-breasted couplings with a rubber seal are used. At the same time, at the place of installation of the coupling, it is possible to change the direction of the pipeline up to three degrees

This is essential for ease of installation.

Structurally, a double-breasted coupling is a pipe segment with an inner diameter larger than the outer diameter of the pipes to be connected. Inside the sleeve, closer to the edges, there are rubber O-rings. It is due to them that reliable sealing of the connection is ensured. The connection itself is very simple. First, one end of the coupling is pulled over the end of the pipe so that the end of the pipe is in the middle of the coupling. In order not to be mistaken, it is worthwhile to first make marks on both pipes. Then a second pipe is inserted into the coupling. The surface of the pipes under the coupling must be dry and clean. Due to the fact that the rubber sealing rings during the installation of the coupling show significant resistance, a screw jack is used to move it along the pipe. There is a small gap between the pipes and the coupling around the outer perimeter, which must be cemented.

Sometimes it is necessary to connect asbestos-cement pipes of different diameters, which are laid in the ground. In this case, free-flow chrysotile cement couplings should be used. This work is much more difficult than the one discussed above.

Initially, two holes with a diameter of 12 - 20 millimeters must be drilled in the walls of the coupling. They should be aligned along the axis of the coupling. After that, a marking is made on the surface of the pipes to be connected so that the coupling is located symmetrically to the pipe joint. The sleeve slides over the edge of one of the pipes so that the holes are on top. The next step is to center the pipes to be connected. The gap between them should not exceed three millimeters. After that, the joint is wrapped with a bitumen tape 60 - 70 millimeters wide and the sleeve is pushed exactly symmetrically to the joint. The clutch must be fixed with wooden blocks. For this, such clamps are inserted between it and the inner wall of the pipes.When the coupling is installed tightly, you need to fill the gaps between it and the pipes with tow. Now you can start the final stage of work. Its essence lies in pouring molten bitumen into one of the holes in the coupling. It needs to be poured in a thin stream until it appears in the second hole. After complete solidification of bitumen inside the coupling, a reliable and durable connection is obtained.

Asbestos-cement pipes are also used as a protective sheath for electrical cables. Pipe connections in this case are made using polyethylene couplings. You should immediately make a reservation. Polyethylene couplings can only be used for pipes with a diameter of one hundred to three hundred millimeters. The connection technology is very simple. The clutch is simply heated in boiling water, and then put on one of the pipes. The second pipe is inserted into the sleeve without hesitation. Some skill is needed here so that the coupling does not have time to cool down. Otherwise, it will shrink and the pipe cannot be inserted.

Non-welded metal sleeves can also be used for similar purposes. They are put on a special sealing layer and tightened with screws. The gaps between the surface of the pipes and the coupling are sealed with cement mortar.

Asbestos pressure pipe

The pressurized version has a straight, clearly cylindrical or bell-shaped shape. The product is produced in standard formats. The production of such products is carried out strictly in accordance with established standards.

The process takes place in stages and with the obligatory holding of products in special steaming chambers in order to increase their strength by 70-75% in comparison with the original properties. Asbestos pressure pipes have a high degree of strength and durability. They also have low hydraulic resistance.

They are used in the construction of a gas pipeline, pressure water supply, sewage, pressure irrigation and other similar systems. In addition, they are used to create wells, wells, agricultural feeders, overlapping structures, and even as decor in household use.

Asbestos pressure pipes are fixed to each other with heat-resistant couplings and rubber seals. Due to the ability of self-sealing of the coupling under the influence of pressure in the pipeline, absolute tightness of the joints is ensured. The absence of weak welded joints is another plus of these products.

Application

Asbestos pipes have a wide range of applications:

- sewerage line device (free-flow);

- cold water mains (pressure products);

- cable ducts for optical and copper wire networks laid underground;

- pipes can be used as piles for small private houses;

- the device of drainage systems (for this, the pipes are perforated along the entire length);

- chimneys for stoves and fireplaces.

Pressure water pipelines and gravity sewerage are the direct and most common purpose of pipes made of combined material. They also work well as a backbone for wired networks - they maintain optimal moisture conditions, sufficient tightness, and resistance to soil pressure and deformation.

Pipe piles for a house - an economical option for building small cottages. Hollow pillars are buried in the ground, filled with a frame and concrete. Such supports are in no way inferior to columnar and pile systems.

The question arises: can an asbestos-cement pipe be used for a chimney?

If we compare a chimney made of different materials, asbestos cement is not the best solution:

- the material is able to withstand heating only up to + 300 ° С. Exceeding the temperature will cause the pipe to burst. For this reason, the installation of a chimney directly from the boiler is completely excluded;

- condensate is a real problem with asbestos cement. The material absorbs moisture, which is absorbed by the products of fuel combustion, and then released at a temperature difference.As a result, wet spots can "float" along the wall and roof. In addition, the caustic solution destroys the pipe walls over time;

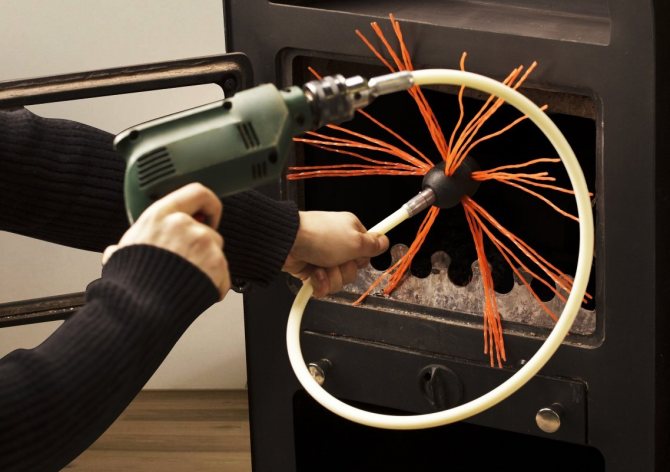

- It is impossible to remove soot from the pipe, but it accumulates at a decent rate. As a result, its inflammation often occurs;

- the device of inspection hatches for pipe maintenance is impossible.

Also remember that asbestos is harmful to human health. Of course, the chimney can be installed outside the dwelling, where the smoke temperature is already permissible. Nevertheless, the problem of condensation and soot removal remains relevant. The solution to the problem can be insulation and pipe sheathing.

Advantages and Disadvantages of Asbestos Pipes

Asbestos-cement pipes have several advantages. They are quite easy to install, reliable and sturdy, are not exposed to aggressive environmental influences and can be located deep underground without the need for replacement.

In addition to these properties, they have a relatively long service life than metal pipes. For example, metal products that do not have corrosion resistance have already been in need of repair measures for 5-10 years, because formations appear under the influence of corrosion and the inner diameter narrows, which causes a decrease in the pressure of the water circulating through the pipes, and also reduce the rate of heat.

Periodic cleaning does not solve the problem, because the rust accumulated on the walls inside the pipes is not removed and after a while again affects the throughput of the system, reducing the water pressure.

Asbestos modification does a very good job of dealing with this problem. Over time, it becomes stronger and stronger. This is due to the ability of asbestos not to corrode in the aquatic environment and to become stronger due to the hydration of Portland cement.

In addition, the inner surface of asbestos pipes is not subject to overgrowth under the influence of water flow, therefore the initial water pressure is maintained for many years.

So, asbestos pipes have the following advantages:

- absolute inertness to the adverse effects of corrosion, including corrosion as a result of stray currents, since asbestos is a dielectric;

- a wide range of all kinds of sizes and a relatively low cost;

- high temperature resistance - products can withstand temperatures up to 2000C;

- slight linear expansion when heated;

- incombustibility, asbestos pipes are fireproof;

- frost resistance, when the water passing through the pipes freezes, the products are not damaged;

- simple machining and easy assembly with couplings;

- insignificant hydraulic resistance due to the smoothness of the inner walls;

- lack of overgrowth, due to which asbestos pipes retain the throughput of the system throughout the entire operation.

However, in addition to all the advantages of asbestos pipes, there are also some disadvantages:

- their use in systems where there is a temperature above 3000C is not allowed; under the influence of such a high temperature, pipes may crack;

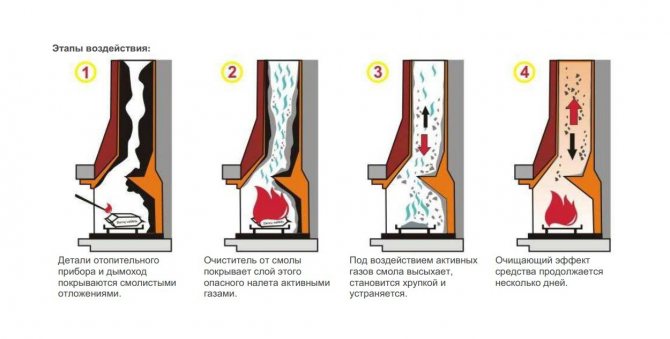

- when using asbestos pipes as a chimney that removes combustion products, they become covered with soot from the inside and absorb condensate;

- as a result of the low thermal conductivity of asbestos, a low chimney draft is formed;

- asbestos products are quite fragile, so you should be extremely careful when transporting them, as well as during installation. In addition, measures should be taken to provide additional protection against soil subsidence, which can lead to unwanted fractures;

- asbestos products have low sand resistance. In this case, plastic pipes are an excellent option in comparison with asbestos and ceramic products.

Therefore, if the presence of sand prevails in the ground, the use of asbestos pipes is not recommended.

Correctly executed chimney from an asbestos pipe

The misconception that installing an asbestos pipe as a chimney is not difficult can lead to many undesirable consequences. Boiler equipment is different, each has its own efficiency.

Therefore, before proceeding with the installation, you need to carefully study all the technical conditions. What a private developer should be ready for by doing a chimney with his own hands is a reliable fastening of the structure, arrangement of pipe insulation, compliance with fire regulations.

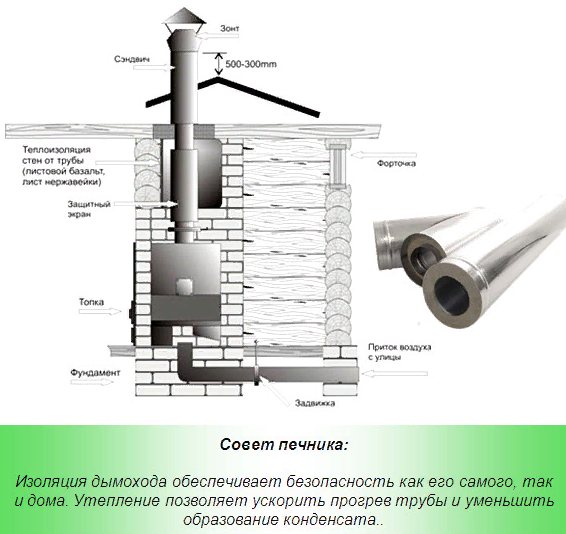

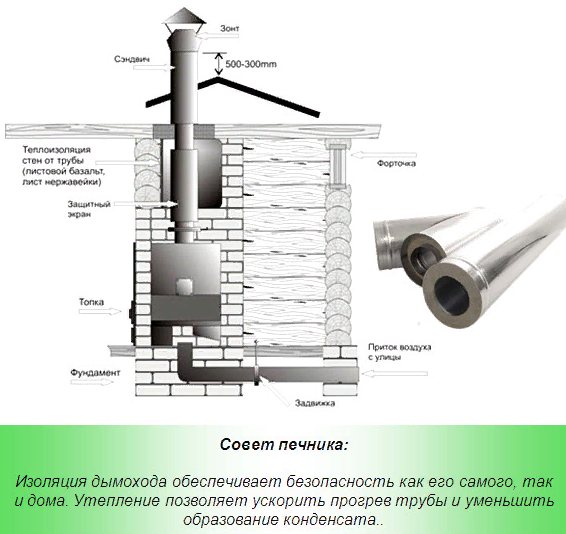

Chimney insulation

Fastening the chimney from an asbestos pipe

It is possible to install an asbestos pipe in the general chimney system from the area where the temperature of the combustion products does not exceed 300 degrees Celsius. It is permissible to output both a separate riser (external chimney) and a channel passing through the roof. When arranging, you must adhere to the following rules:

- When the pipe extends over the ridge over 2 meters, it is required to use additional clamps and stretch marks for fixing;

- A separately running chimney is attached to the bearing wall with pipe clamps at intervals of at least half a meter;

- When placing asbestos inside a channel made of brickwork, additional spacers from reinforcement are used;

- The chimney must be fastened at the place of its passage through the roof through an asbestos-cement bracket.

Extension of the chimney with an asbestos channel

Non-pressure pipes made of asbestos, which are used to organize a chimney, as a rule, are built up onto an already finished part of the chimney from another more heat-resistant material. The transition from metal to asbestos can be done through a special stainless steel sleeve.

Connection of an asbestos pipe with a coupling

If there is a build-up of one asbestos pipe with another the same, then the connection is carried out with a coupling of the CAM modification. The coupling has two internal grooves for a heat-resistant seal. When building up a brick chimney, the CAM coupling is fixed inside the masonry. It is propped up with reinforcement mortgages, and the space between the masonry and the coupling is poured with concrete.

Building up brickwork with an asbestos chimney pipe in the absence of a coupling can be done in another way. To do this, a slab of the same asbestos cement or steel with a hole not exceeding the diameter of the asbestos channel is installed on the last row of bricks. The latter is placed on top of the hole and fixed with a solution.

Thermal insulation cushion device

Asbestos cement has a porous structure. It has poor thermal insulation qualities, therefore it heats up a lot, to the temperature of the gases discharged outside. Asbestos-cement pipes for the chimney must be insulated with a material that is resistant to fire for the following reasons:

- To avoid heating and ignition of combustible materials that make up the structure of the house;

- In order to avoid the formation of condensation, which is one of the factors that have a destructive effect on the chimney.

Basalt wool

The classic version of insulation is based on the use of basalt wool, which is wound in several layers on the chimney and secured with special clamps or knitting wire. A layer of foil is arranged on top of the cotton wool. This must be done to waterproof the pipe and provide an additional fire barrier.

You can protect the insulation using a metal frame. For this, sheet thin galvanized metal or with a factory paint and varnish coating is suitable. It is advisable to use such a frame for pipes protruding above the roof, where the foil will look unaesthetic.

Tapping a tee into an asbestos-cement pipe

If the chimney is arranged in such a way that it is necessary to bring it through the side wall, add a condensate drain or install an inspection hatch to control and clean the chimney, use tees with a coupling system. After cutting the pipes, putting on the tee, the joint gap should be filled with a compound based on acid-resistant and heat-resistant components.

Chimney sections from an asbestos-cement pipe must not be performed in a strictly horizontal position. When the channel exits to the side, it must go at a slope of at least 3 degrees towards the boiler plant.

Installation process of asbestos pipes

Installation of systems from asbestos-cement pipes is not difficult, but at the same time provides maximum reliability. The connection is made using couplings with rubber rings, which ensure a tight fit and strong joints.

Couplings and rubber rings have a unique self-sealing ability due to the pressure of water passing through the pipes. During the installation of thermal systems, a channelless laying method is used, compensators are not used.

For the installation of tees, bends, valves on the heating system, metal pipes are used, which are connected to the asbestos pipe using a coupling, and the length and diameter of the flowing part of the coupling must strictly coincide with the same parameters for the asbestos pipe. Thanks to the laying of asbestos pipes, it is possible to ensure the complete tightness of the system.

Installation of asbestos pipes is carried out in the following stages:

- First, the parts to be joined are lubricated with a special substance based on glycerin and graphite - this facilitates the installation of the coupling.

- Ditching is carried out in advance according to the specified parameters manually or with the help of special equipment.

- The parameters of the ditch (length and depth) are determined in advance at the design stage of the system.

- Couplings are installed on the pipes, after which it is lowered into the ditch.

- After that, another product is lowered into the ditch without a coupling.

- Next, the coupling is installed on the third pipe and lowered into the ditch, and so on.

As you can see, asbestos pipes have both positive and negative qualities, however, according to scientific research, it is better not to use products for transporting drinking water, because it has not yet been precisely proven whether asbestos fibers penetrate into drinking water and their negative effects on the human body. ...

How to choose a chimney from an asbestos-cement pipe

Since this building material belongs to the budget, you should not try to save even more and look for the cheapest asbestos-cement pipes. It is better to buy them in a reliable store that provides guarantees for the quality of the products. Otherwise, there is a risk that cheap pipes will not even reach the installation site and will crack on the way.

Rusty deposits and dirt on the surface of asbestos-cement pipes are an indicator of improper storage and unsatisfactory quality

When buying a pipe, it is recommended:

- carefully inspect each product, make sure that there are no cracks and chips, lumps and uncharacteristic inclusions in the material;

- check (at least visually) the evenness of the pipe and the uniformity of the wall thickness;

- pick up an asbestos cord for sealing joints;

- make sure that the cross-section of the pipe exactly matches the diameter of the boiler pipe.

The range of asbestos-cement pipes will not limit your choice

Manufacturers offer asbestos-cement pipes with a diameter of 10 to 50 cm, so choosing the best option for your boiler is not difficult. To minimize the number of joints, it is worth purchasing a 5 m long pipe, but if it cannot be transported, you can take 3 m (this is the minimum permissible chimney length).It is recommended to purchase an adapter or a stainless steel gas outlet pipe directly for connection to the branch pipe, which can be tightly connected to both the metal branch pipe and the asbestos-cement flue duct.

Application of asbestos cement pipe

To solve the problems of modern construction, it is simply impossible to do without asbestos-cement products. With their help, the installation of water supply systems for drinking and technical purposes and sewage systems of a pressure and non-pressure type takes place.

However, the use of asbestos-cement products goes beyond pipeline setup. They are indispensable for the device of land reclamation, drainage, when laying cables, as well as for the construction of storm drains. Their characteristics make it possible to use the product for casing wells, wells, construction of garbage chutes.

The use of the material is regulated by SNiP 41-01-2003, which indicates that an asbestos-cement pipe can be used for the construction of chimneys. In Western countries, it has found its place in heat supply systems and gas pipelines. In such conditions, asbestos structures have been successfully working for several decades. The material is popularly used in the nuclear and rocket industry.

Features of the use of asbestos channels

Asbestos as a material has a fibrous structure and plays a reinforcing role in pipes. It ensures the strength of the product. The asbestos fiber is fluffed before use and then mixed with cement and water. The main technological processes for the production of pipes are:

- Formation.

- Hardening.

Formation takes place on the production line. After exposure to air and gaining strength by products, they are placed in warm water. The material is applied in layers on a forming drum.

It is interesting! Asbestos fiber is able to withstand longitudinal stress like some steel grades.

Asbestos pipes are pressure-resistant, withstanding a pressure of 6-9 atm. and free-flow. Their diameters vary from 10 to 50 cm, it is also possible to manufacture pipes with a cross section of 1 m.

Fire safety plays a decisive role in the installation of chimneys. In this regard, it should be borne in mind that an asbestos-cement pipe is capable of performing its functions at temperatures no higher than 280-300 ° C. This may be the upper part of the chimney, where the exhaust gases have almost cooled down. Such pipes are applicable only for gas heaters with low power.

Asbestos pipes come in different diameters and types

Chrysotile cement and ceramic products

Chrysotile cement pipelines are a type of asbestos products. Their production started quite recently. The difference between the two types of materials is that chrysotile is as safe as possible for health and the environment.

Amphibole asbestos, which until recently was used for sewage, can cause cancer.

It is classified as a carcinogen, since after entering the body, it remains in it for a long time, since it is excreted from it extremely slowly.

Installation of the pipeline between each other involves cutting the line. Sawing results in a saw, which makes the product harmful. It is strongly recommended to use a respirator when working with the material.

It is because of the pathogenicity of the effect of amphibole on the body that chrysotope is used today. The way the pipe is marked indicates that chrysotile cement products have greater strength. For example, BNT-100 is suitable for systems with low load, and BNT 150 is versatile and can be used in any systems.

Types of asbestos-cement pipes

Asbestos-cement products are divided, depending on their purpose, into:

- gas pipelines;

- plumbing;

- sewer.

Depending on the mode of operation, the design is:

- pressure head;

- free-flow.

Pressure and non-pressure BNT products are regulated in accordance with GOST 539-80, GOST 1839-80, GOST 11310-90.The pressure pipe has a diameter on the inner side from 50 mm to 600 mm.

It can withstand pressures ranging from 6 to 9 atmospheres. The pressure pipe is characterized by wear resistance and low hydraulic resistance, which makes it suitable for solving construction problems.

A pressure pipe is used when setting up a pressure water and gas pipeline, as well as for arranging irrigation and drainage systems. It is suitable for arranging wells, as well as overlapping buildings for household purposes.

Non-pressure asbestos-cement pipes or BNT are produced in sections from 2.95 m to 5 m. The inner diameter can be in the range from 50 to 500 mm.

BNT are suitable for setting up non-pressure engineering structures: sewerage, air duct, etc. They are characterized by exhibiting high electrical resistance.

The material of BNT products is not afraid of corrosion. BNT products are used as supports when laying fences, as well as other fences.

What are asbestos-cement pipes and what are they made of?

Asbestos-cement pipes are products made from asbestos-cement that are widely used in various spheres of human activity. Asbestos cement is a material that is obtained by pressing a water-cement mixture with the addition of asbestos fibers. The fibers are based on the mineral chrysolite and have an average length of about 5 mm. The share of asbestos fibers is about 10-15% of the total product, and it is thanks to its presence that a hard and high-strength material is formed. Strong asbestos fibers behave similarly to steel rods used in reinforcing concrete.

Initially, asbestos cement was used as insulating and fire-resistant protection - it is resistant to weathering and does not allow water to pass through. In modern industry, it is used to make corrugated roofs, drainpipes, water tanks, gutters, chimneys, street waste bins, oil pipelines, water tanks, etc. At enterprises for the production of asbestos-cement products, in addition to the main products, they produce fastening couplings, the main feature of which is an inner diameter slightly larger than the outer diameter of pipes, which provides a more reliable connection.

Product specifications and manufacturing

In practice, asbestos cement is fiber concrete. Its production includes the following stages:

- crushing of asbestos raw materials obtained from mining enterprises;

- fluffing up asbestos with further cutting of fibers;

- adding water to the ratio of cement to asbestos 85:15;

- removal of the resulting pulp on a drum with a mesh structure;

- winding the film on a rolling pin to give the product the required wall thickness.

The production of products takes place only under strict control in accordance with GOST. The weight of an asbestos-cement pipe per 1 m is from 6 to 11 kg. For example, the weight of 300 mm products is less than 500 mm.

The pressure pipe is available in lengths of 3.95 or 5 meters. Its flow area has the following dimensions: 100, 150, 200, 250, 300, 400 and 500 mm. The weight of the product varies from 45 kg for a 100 mm product to 67 kg for a 150 mm product or 19 kg for a 300 mm product.

Products with a small diameter of 100 and 150 are more suitable for arranging wells or garbage chutes. Low weight allows their installation in a private household. Pipes with a diameter of 300 and more have significant weight, and they are used for laying industrial pipelines.

As with other products, the standpipe 300 is watertight. The diameter of 300 mm allows quick and cheap installation of the system.

Non-pressure products are produced in lengths of 3.95 m, the diameter of which ranges from 100 to 200 mm. BNT 100 has a weight of 24 kg. Products 150 have a weight of 37 kg. The free-flow asbestos-cement pipe 200, the weight of which does not exceed 64 kg, provides a clean water supply through the pipeline, therefore its installation is popular in the economic sphere.

Briefly about asbestos: what kind of material is it?

Asbestos is one of the fine-fiber minerals belonging to the silicate class (in other words, a mineral). This material is distinguished by its relatively low weight, extremely high strength and resistance to chemical attack.

Asbestos cement pipes

Asbestos has long been used in construction, missile production, and the automotive industry. The main disadvantage of this material is its toxicity to the human body, and therefore it belongs to category I carcinogens according to IARC.

Can an asbestos chimney be used?

Given the health risks, pipes made of asbestos cement (if it is not chrysotile) are now used much less frequently than 30-40 years ago. But whether it is possible in this case to apply it even now is an open question, many experts do not recommend doing this and advise using more modern materials.

However, the use of asbestos chimneys is possible and, in principle, not prohibited, but it must be borne in mind that such pipes are not suitable for permanent use. They are comparatively effective only when they work periodically, but generally poorly suited for organizing a smoke exhaust system.

For which boiler is it suitable?

It should be noted right away that asbestos pipes are designed for temperatures not exceeding +300 degrees. This means that they are not suitable for solid fuel boilers. Therefore, asbestos chimneys are ideal for modern boilers with high efficiency and an output temperature of about 100-150 degrees.

The use of such pipelines is justified in the following cases:

- For the installation of an insulated chimney system - in this case, asbestos-cement pipes are mounted as a separate system. To connect to a heating device, for example, with a gas boiler, stainless steel docking sleeves are used. Tees or adapters are used to lay the chimney outside the building.

- To extend an existing chimney. With the help of asbestos, it is possible to lengthen the chimney with insufficient draft or with a constant accumulation of large amounts of condensate.

- Also, with the help of an asbestos-cement pipe liner, you can rehabilitate the existing smoke exhaust system.

Pros and cons of asbestos chimneys

This material has both a number of advantages and a number of disadvantages, which is typical of any building materials in general.

Among the advantages of asbestos are:

- simple production and, as a result, relatively low cost;

- simplicity of arranging a chimney (you can do it yourself, armed only with theoretical knowledge);

- It can be used as a chimney system in several types of buildings - for a stove, for a fireplace, it can be mounted for a bathhouse, a private house, but it is not suitable for any industrial purposes in this form.

Non-insulated asbestos chimney

Among the cons are:

- unstable to high temperatures - high temperature leads not only to deformation of the pipe, but even to its explosion;

- absorbs the resulting condensation;

- there is no way to make a large draft in the chimney from asbestos;

- due to the porosity of the material, it is not possible to clean it from soot accumulations (which is catastrophic during operation for a stove, for example);

- it is impossible to mount cameras to monitor the technical condition of the pipeline.

Installation of asbestos-cement pipelines

Asbestos-cement pipes are mounted according to some rules, including:

- Before installation, the outer diameter of the ends of each pipe should be turned to fit the dimensions and obtain a rough surface.

- The connection of the segments to each other is carried out using couplings. It is possible to qualitatively connect the products with the help of grooves applied to the coupling. Thanks to the rubber rings that are installed in the grooves, it is possible to make the most tight connection.

- The radial clearance applied to the connection of the coupling with the pipeline is responsible for compensating for elastic deformation during operation.

- Due to the presence of a gap between the ends, the connection can do without temperature compensators.

- When heated, the product lengthens only by 0.4 mm over a 5-meter length, which is 12 times lower than the elongation of a steel analogue.

- To ensure a tight connection, select a sleeve with an outside diameter that matches the size of the line.