| Domestic pipes: pipe mounting | Domestic pipes: pipe installation | Roof, gutters | Reservoirs | Industrial pipelines up to 300 m | |||

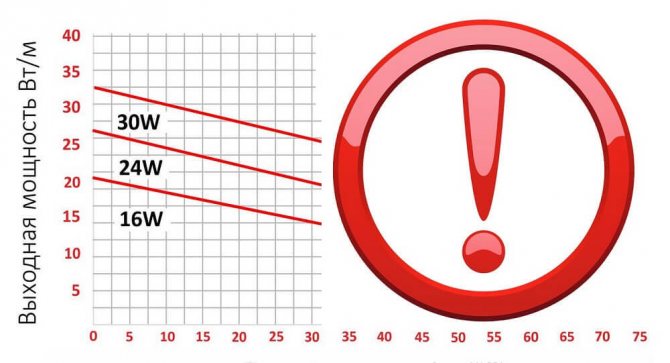

| Without braid | Low temperature | Polyolefin | 16-30 W / m | ||||

| Braided | Low temperature | Polyolefin | 16-90 W / m | ||||

| Fluoropolymer | 16-30 W / m | ||||||

| UV protection | 24-40 W / m | ||||||

| Medium temperature | 24-60 W / m | ||||||

| High temperature | |||||||

| Explosion-proof | |||||||

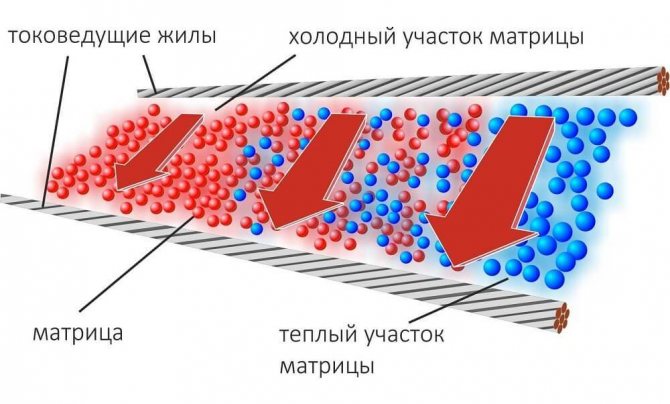

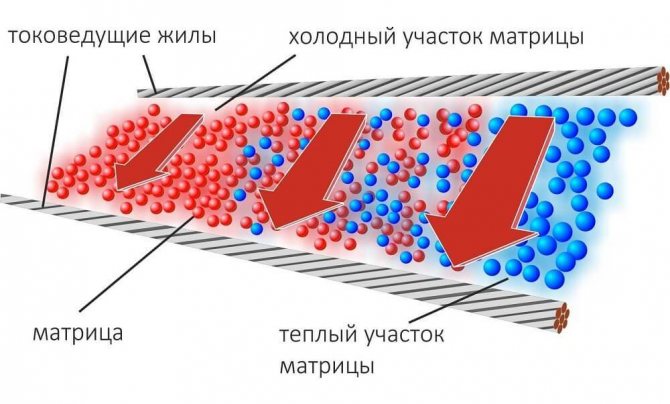

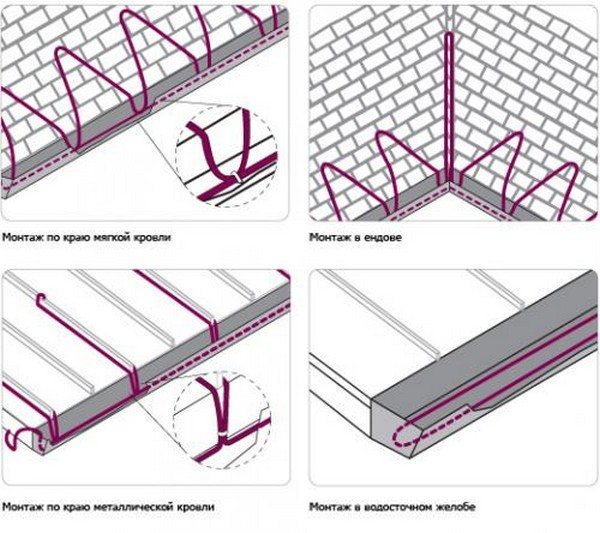

The heating element of a self-regulating cable is a matrix of semiconductor material, the resistance of which depends on the ambient temperature and the temperature of the object on which the cable is installed.

The appearance of a heating cable capable of self-regulation of linear power and heating temperature without additional control equipment made it possible to significantly expand the scope of application of cable heating in industrial and domestic spheres.

The main advantages of Samreg

- Not afraid of overheating in any separate area, locking, even when crossing the cable;

- the self-regulation effect ensures a safe temperature regime of the object, which makes the system more reliable and durable;

- saving electricity by changing the linear power at each separate heating section;

- ease of installation, the cable can be cut into sections of any length right at the installation site;

- the ability to operate without thermostats and automation systems.

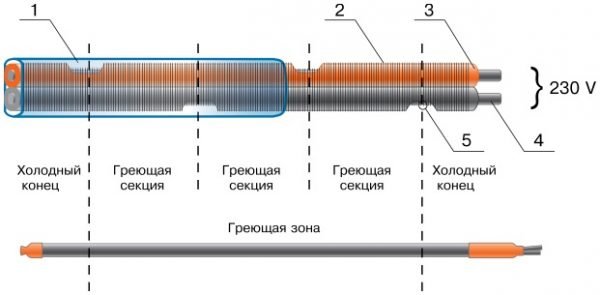

Heating cable structure

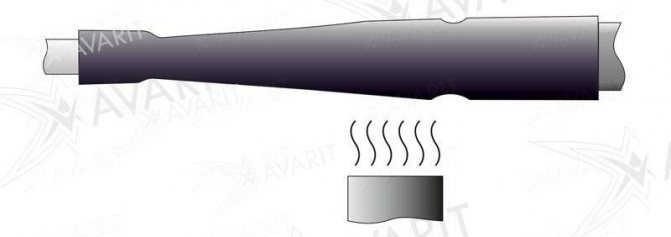

Self-regulation effect

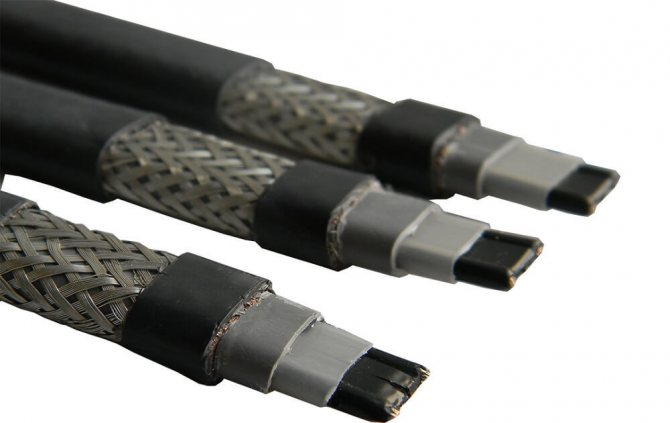

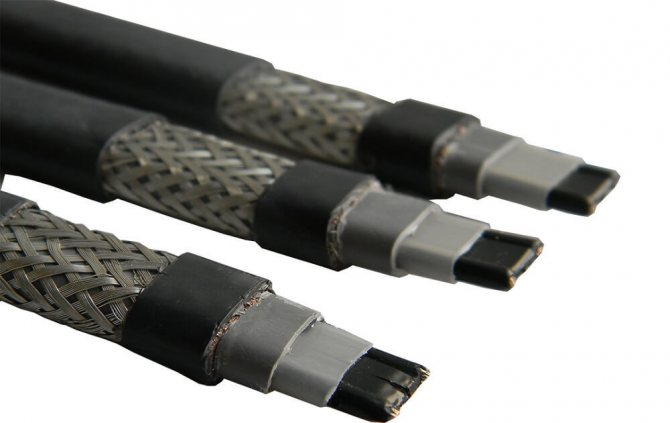

Finished section view

Heating cable connection

2015-11-26 Articles

In recent years, the range of applications for heating cables has expanded significantly. Initially, they were used in underfloor heating systems, but now their area of application has expanded significantly - these are anti-icing systems for ramps, roofs, open stairs, heating pipes, gutters, etc. Installing and connecting a heating cable is not difficult, however, as in any business, there are nuances that must be taken into account during installation.

Heating cables are of two types:

- resistive

- self-regulating

Resistive cables are divided, in turn, into single-core and double-core cables. The heating element of a resistive cable is a metal core, when an electric current passes through it, it heats up. The heating core itself is insulated, on which the braided shield and the outer sheath are located.

Single-core resistive cable device Double-core resistive cable device

When connecting a resistive cable, it must be remembered that it emits a constant amount of heat along its entire length, therefore it is intended for those places where there is no large temperature difference. In addition, it is forbidden to cut a resistive cable into parts, since when the cable length decreases, its specific heat generation increases, which can lead to overheating of the cable, it is not allowed to overlap two cables, which can also lead to destruction of insulation and overheating.

The resistive cable is connected to the thermostat by connecting the ends of the cable with a conventional electrical cable (the so-called cold end) using couplings.

A self-regulating cable has a number of advantages over a resistive cable. Firstly, it can be cut into pieces of the required length, secondly, it can be overlapped without fear of overheating of the cable, and thirdly, it can be laid in places with significant temperature changes, since each section of this cable regulates its temperature independently, as a result of which overheating is impossible ... Its only drawback compared to resistive cable is its higher price.

The self-regulating cable does not require the use of a thermostat, although its use is desirable, for example, to turn off the system in warm weather.

Self-regulating cables consist of two parallel conductors and a semiconductor self-regulating matrix. During operation, the temperature of the matrix rises, as a result, it expands, the gap increases, therefore the resistance increases, and the heating power decreases accordingly. On the contrary, when the temperature drops, the resistance falls and the heating power increases. Moreover, self-regulation works independently on each section of the cable, therefore, if the cable is laid in zones with temperature differences, then the heating of the cable in these zones will be different.

A thermostat and a temperature sensor must be used to connect the heating cable.

The thermostat is used to maintain the set temperature, as well as to turn on and off the system. It reads the readings from the temperature sensor and automatically cuts off the power if the system heats up to the set value. If the temperature regime deviates from the set one, the thermostat turns on the power supply and the system starts heating.

There are electromechanical, electronic, programmable thermostats on sale, which, although they differ from each other in their functionality, but the principle of connection is similar for everyone, there may be only minor differences. When buying a thermostat, you must pay attention to the fact that the load current does not exceed the maximum current for which the thermostat is designed, otherwise you will have to additionally use a contactor.

On the case of any thermostat there must be a connection diagram.

The supply wire is connected to terminals 1 and 2 (to terminal 1 - phase to terminal 2 - zero). Terminals 3 and 4 are used to connect the load. The temperature sensor is connected to terminals 6 and 7. There is no need to observe polarity for the sensor (Wiring diagram for other thermostat models may differ from the one shown).

Single-core cables are connected at both ends, so when laying, both ends must be brought together at one point. We connect the wire itself to terminals 3 and 4

A two-core cable is more convenient to connect, as it only connects at one end.

electric-blogger.ru

Samreg heating cable application

- Freezing protection of household and industrial pipelines, starting heating and maintaining the technological temperature of production processes, including water, oil and gas pipelines, sewer, technological and other surface and underground pipes;

- heating tanks, containers for various purposes, separators, receivers, bunkers and technological lines;

- frost protection of the system of external and internal roof gutters, as well as in the systems of snow melting of the roof of low-rise and multi-storey buildings, commercial real estate, industrial and warehouse premises.

Roof heating

Heating of pipes and pipelines

Tank heating

Depending on the maximum operating temperature, Samreg can be

- Low temperature (temperature class T6) - maximum exposure temperature 85 ° С, operating temperature 65 ° С;

- Medium temperature (temperature class T5) - maximum exposure temperature 135 ° С, operating temperature 110 ° С;

- Medium temperature (temperature class T4) - maximum exposure temperature 190-200 ° С, operating temperature 120 ° С;

- High-temperature (temperature class T3) - maximum exposure temperature 232-250 ° С, operating temperature 190 ° С;

In household cable heating systems, as well as in roof heating systems, a low temperature heating cable is used. Medium temperature heating cable is used in heating pipelines and tanks to maintain technological processes.The high temperature heating cable is used in the oil and gas industry, usually for pipelines and tanks subject to high temperature steaming.

How to connect the product to the network

Heating cable for water supply

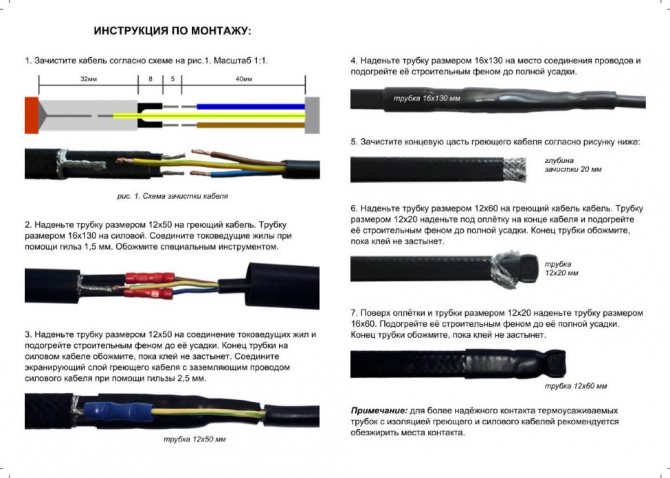

In view of the fact that now you are only studying the use of a heating cable, we have to get acquainted with another important point of work - the insulation of the end of the product. For this purpose, a special heat-shrinkable tube is used that can reliably protect the conductors from the harmful effects of moisture. In addition, for the device to work, its heating part must be connected to the "cold" part, as it is called. You will learn about all stages of this procedure from the videos below.

To make the heating of the pipeline as safe and economical as possible, it is recommended to additionally install a thermostat and an RCD. Thanks to the first device, you will be able to regulate the heating temperature by means of a temperature sensor, and thanks to the second, you can protect the heating line from electric current leaks. At the same time, it should be remembered, when connecting the sensor to the thermostat, that the proper functioning of most of the models is possible only with a total length of the pipeline no more than fifty meters (at the moment it is recommended to clarify it during the purchase).

According to the degree of explosion protection, Samreg is divided into

Learn more

- The explosion-proof self-regulating cable has a certificate of explosion protection of the international customs union and the Ex mark (Explosion-proof), which contains information about the degree and type of explosion protection of the cable. Explosion-proof cable is used at facilities with increased fire and explosion hazard. More details

- Without explosion protection, it is used in heating systems for industrial and domestic heating that do not require increased explosion protection or fire safety.

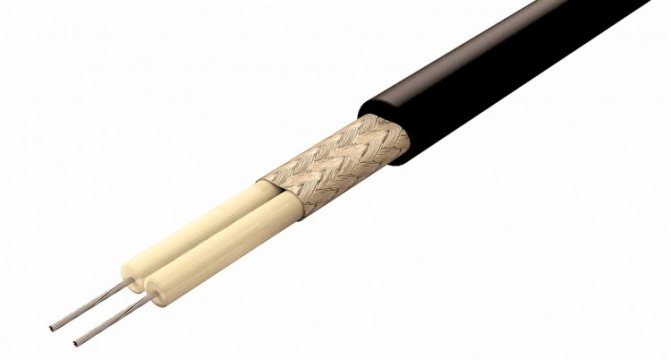

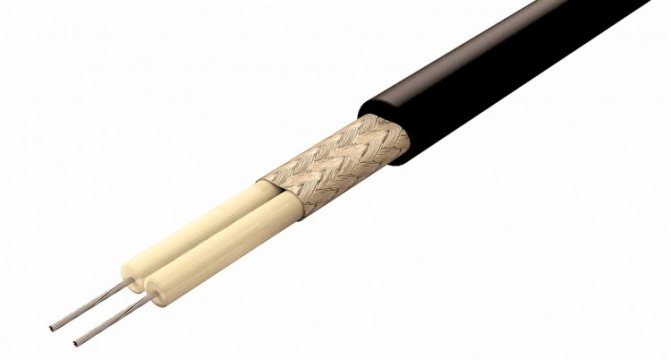

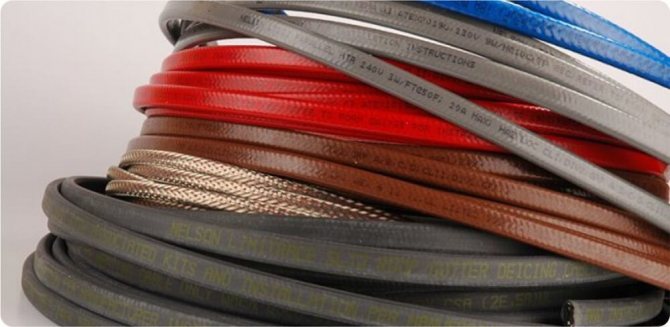

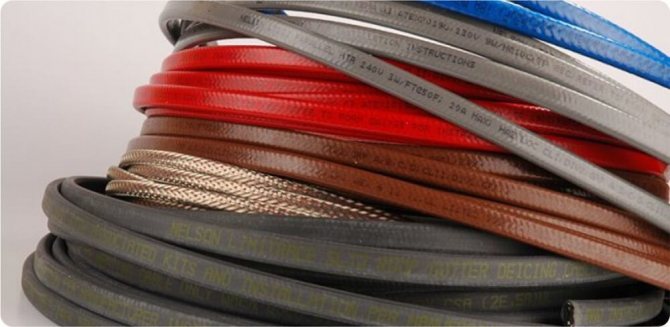

By design, the cable can be

- Shielded - under the outer sheath of the cable there is a braid made of tinned copper wires, which performs the function of protection against mechanical damage, as well as the function of grounding the cable. This type of cable is used for heating systems located outdoors (roofs, gutters), or at facilities requiring additional safety for the operation of electrical equipment (for example, tanks, pipelines, production lines).

- Unshielded - without protective braid. This type of cable is used for domestic heating of the pipeline and is mounted only under the heat-insulating material.

Why use cable heaters?

Many extended structures located outside are susceptible to ice formation with the subsequent occurrence of an emergency:

- eaves... Frost and icicles spoil the roofing, and if they fall, they are dangerous for the people below;

- gutter system... Icing causes deformation or breakage of the gutters, and moisture removal is also impaired;

- porch, walking paths... They become slippery, which leads to injury to people;

- water supply, sewerage, other pipelines, reservoirs. The ice plug clogs the pipeline, and in case of severe icing, the structure collapses (water expands during freezing).

There are several types of heaters.

Unregulated

It is often also called resistive, but this is wrong: all heating cables have resistivity. Unregulated is the simplest type. The conductors are made of a high resistance alloy such as nichrome. Accordingly, the power of heat dissipation is always constant. The advantage is low cost.

- in case of a violation of the heat sink (the overlap of the cores or the section of the heater is covered with something) or during warming, the cable burns out;

- it cannot be shortened: this will lead to a decrease in resistance and, accordingly, an increase in current strength above the calculated one;

- a thermostat or human intervention is required to switch on and off.

Non-regulated are divided into two types:

- 1-core... They have serious disadvantages. Firstly, they are a source of an electromagnetic field and therefore are not suitable for "warm floors", paths, porches and other objects with which people come into contact. Secondly, they are connected from both ends, because the after-heater circuit is connected from one end, and the magnetic fields generated by the veins are mutually destroyed due to the multidirectional currents.

Unregulated zonal

Consists of 2 conductors with many heating wires between them. Unlike the previous one, it can be cut: since the wires are parallel-connected conductors, as their number decreases, the resistance increases.

Self-adjusting

It also includes two conductive cores, but a semiconductor matrix acts as a resistive element between them. Its feature is a much more pronounced dependence of resistance on temperature than that of metals. The higher the die temperature, the greater the resistance.

Advantages:

- overheating is impossible. The heated areas stop passing current, that is, they actually turn off;

- profitability. When heated, the cable reduces heat generation or turns off altogether, even if there was no command for this from the thermostat. Moreover, each section works with the heat transfer required in a given place;

- the ability to cut the heater.

The disadvantage is the high cost.

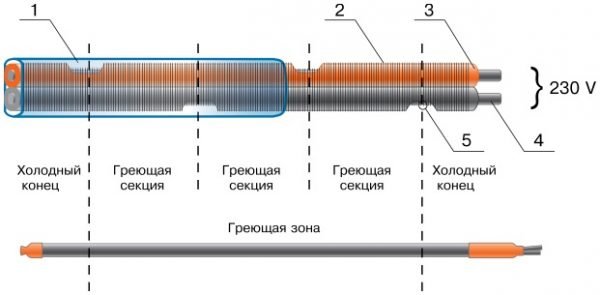

On the cornice, the cable is laid in a zigzag and fixed with special clips glued to the roofing. To heat the gutter, the heater is placed inside and secured with special plastic clips held at one end by the edge of the tray.

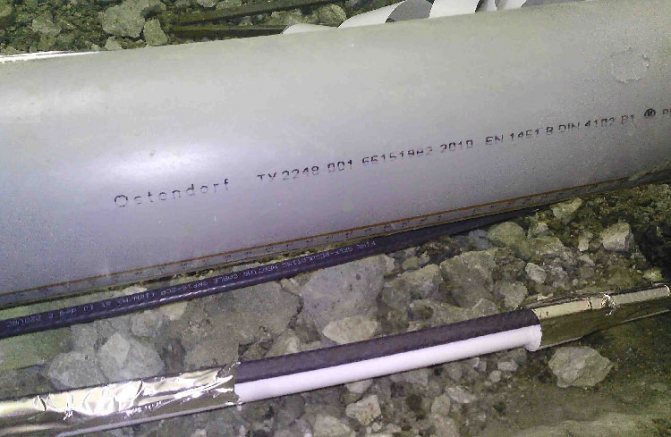

The section passed into the drainpipe is fixed in its upper part. If the building has several floors, the heater is attached to a steel wire, otherwise it will break off under its own weight. On the path, porch or floor in the house, the cable is laid out in a zigzag, fixed with clips with dowels and poured with a screed. On pipelines, the cable heater is placed outside or inside.

With external heating, the line is laid over the pipe in one of the following ways:

- in the form of one or more straight sections under the pipe;

- zigzag under the pipe;

- spirally wound around the pipe with equal pitch.

The cable is fixed with plastic clamps or fiberglass self-adhesive, then the pipe is insulated with a heat insulator in the form of flexible mats or shells. Some manufacturers indicate the specific material of the heat insulator and if this point is not observed, the instructions will refuse warranty service.

When using rigid insulation, for example, expanded polystyrene, the place where the cable passes through the insulation is sealed with special bushings. Aluminum tape is wound over the insulation - protection against mechanical damage. If the surface of the pipe to be insulated is rough, it is recommended to wrap aluminum tape on it before installing the heater.

Internal heating is used on short pipe sections with a diameter of more than 40 mm - in the absence of access from the outside. A special type of cable is used - in food-grade plastic insulation.

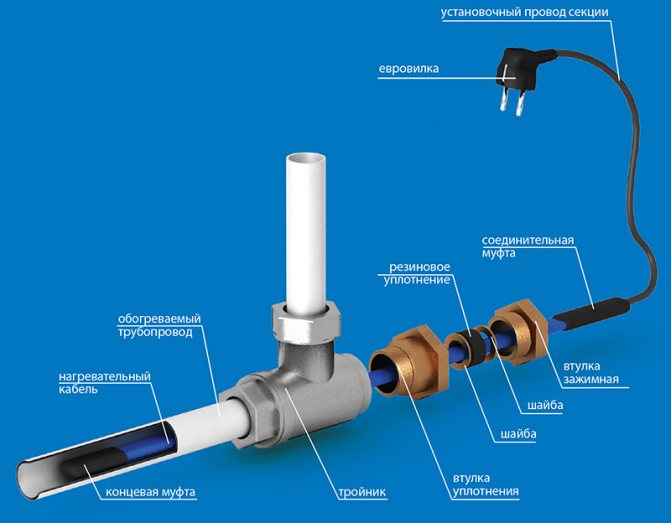

To enter the heater, a tee is cut into the pipeline. The cable is passed through the hole in the plug provided with O-rings. After installation, the pipe is also insulated.

The type of outer sheath of the heating cable depends on the application.

- The polyolefin sheath is used in self-regulating heating cables for household use for laying under thermal insulation.

- The fluoropolymer sheath is used in cables that are approved for use in chemically aggressive environments, as well as inside pipelines and drinking water tanks.

- The casing with protection from UV radiation contains UV absorbers, usually these are finely dispersed soot particles (at least 2%), which protect the polyolefin from decomposition under the influence of solar radiation. More details

Polyolefin sheathed cable

Fluoropolymer sheathed cable

UV protected cable

Self-regulating cable delivery form

Heating cable in coils 180-300 m

Cut - the cable is supplied in pieces of the required length, or in coils of 180-300m

Ready set

Ready-made kits are pre-assembled sections of the heating cable with an end seal and a power cable for connecting to the power system. The collapsed sections are ready for use, you just need to install them according to the instructions.

Tips and useful videos on the topic

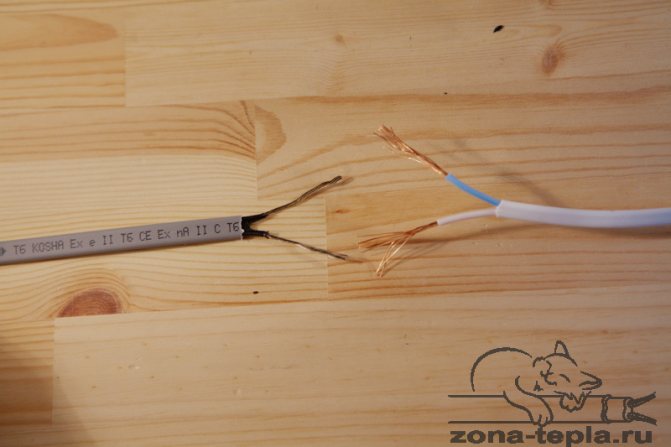

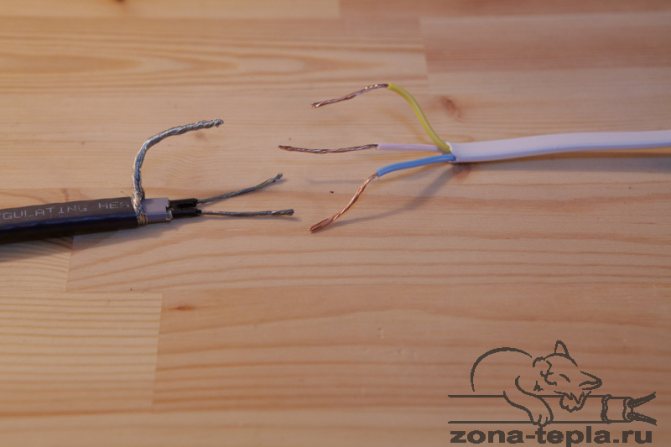

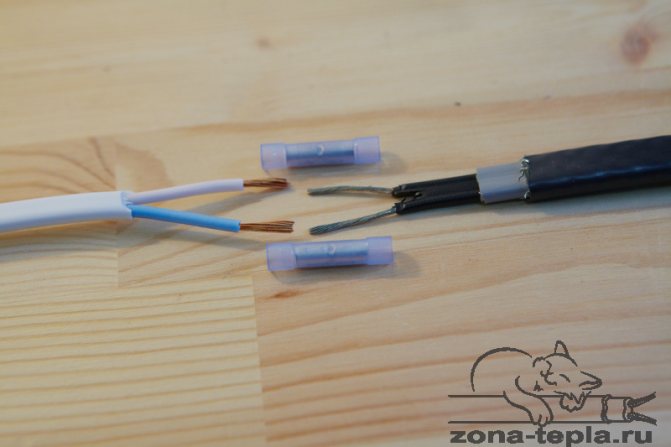

Watch the video for step-by-step instructions on how to strip the cable and connect with the free end:

Stickers on the pipe on which the heater was installed to indicate the presence of heating. If a separate section of the heater is damaged, it is necessary to turn off the system and replace it. When planning the formation of heating, it is better to purchase only a high-quality element.

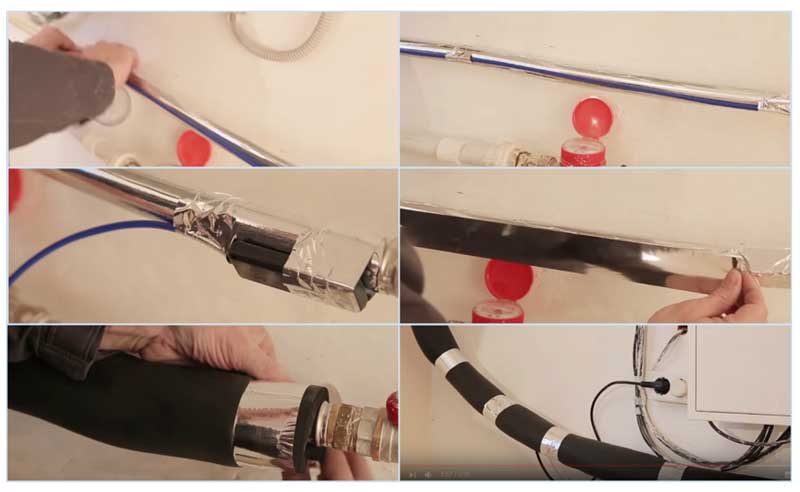

Video material on connecting the heating system to the power wire:

A poor quality heating product can quickly break. Replacing it in winter can cause an ice plug to form and additional costs for heating the system.

To save pipes from freezing, they must be heated. A very simple and relatively cheap method is used for this. A heating cable is laid along them. This method can be used to heat:

- Sewer pipes.

- Plumbing with technical and drinking water.

There are many types on the market. However, the most optimal properties are self-regulating. For its operation, the installation of an additional thermostat is not required. It heats up even very cold pipe sections well. Since it is not difficult to connect the heating cable, you do not need to call a specialist, but do all the work yourself.

Heating cable service life

Learn more

The service life of the heating cable depends on the quality of the material of the semiconductor matrix, the rate of its degradation, the so-called “aging of the matrix”. In fact, the cable works for 10-15 years, but gradually the power of the cable decreases as a result of the loss of its conductive properties by the matrix.

To compensate for this process, 30-40% of the power reserve is laid during cable production. The wear rate of the matrix depends on several factors, which are determined by the number of system starts, “cold starts”. The ideal operating mode of the heating system is maintaining the temperature, namely, switching on at the beginning of the season and constant operation in the normal mode of autonomous control. More details

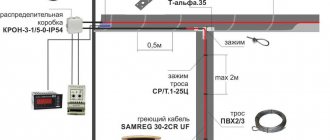

System control based on self-regulating cable

In household electric heating systems for pipeline heating (water supply, sewerage), additional control devices are not required, in the case of connecting one heating line up to 20 m long. Systems consisting of several lines require additional safety measures in the form of automatic differential protection. Control cabinets are used to control the heating of industrial pipelines and tanks. More details

In roof heating systems, various types of control cabinets are used, from simple household ones that combine controllers and a thermostat, to complex systems with multi-level protection, soft starters, and so on. More details

Control cabinets for electric heating of the roof and open areas (ShUEOk, ShUk)

Control cabinets for electrical heating of pipelines and tanks (ShUEOT, ShUT, ShUEOR, ShUR)

Heated heating control cabinet with insulation

Resistive: pros and cons

Resistive cable has a simpler design and lower price. There are three types:

- single core;

- two-core;

- zonal.

During installation, it requires care and accuracy, since the failure of one of the sections requires the replacement of the entire chain. A distinctive feature of a resistive cable is that it provides stable, uniform heating along the entire length of the route.

It is produced in the form of coils and sections with a given wire length and power. If the factory product is shortened, it is possible to increase the resistance of the conductor, and thereby increase its heating temperature. This is fraught with melting of the insulation and failure of the heating system.

Many manufacturers of resistive cables accompany their products with detailed installation instructions and complete the following materials:

- disc with video materials;

- corrugated pipe for installing a temperature sensor;

- mounting tape.

Single-core

This conductor is simple in design.

The simplest conductor in construction. Consists of several elements:

- metal wire (heating core);

- insulation made of polymer alloys or magnesium oxide;

- copper braid serving as a shield;

- external insulation.

The maximum heating temperature for conductors of this type is 60–65 ° С.

Two-core

Two-core cable consists of several elements

A two-core one differs from a single-core one in the number of conductive wires and the method of connection. It is a more powerful conductor, consisting of several elements:

- two heating conductors, each of which is in fluoroplastic insulation;

- one drainage core without insulation (laid on top of the first two);

- a shielding foil covering all three cores;

- external heat-resistant insulation.

Single-core and two-core resistive cables are called "series", since the conductive elements in them are evenly located throughout the wire. The most reliable products are offered by the following companies:

- Norwegian NEXANS;

- Finnish ENSTO;

- DEVI (Denmark);

- Spanish CEILHIT;

- Ukrainian "EXSON";

- Russian "SST".

Zonal

Zones make up a system of heating elements

A zoned resistive cable is also called a "parallel" cable. It differs from the two previous types of resistive-type conductors in design.

- Consists of two conductors. After a certain distance (100–150 cm), “contact windows” are provided in the core insulation.

- A spiral made of an alloy with high resistivity is laid on top of the cores.

- The spiral at its bending points (contact windows) alternately closes with each of the two cores. In this case, parallel heating zones are formed, the maximum length of which can be 200 cm.

The zones form a system of heating elements - resistors and are independent, independent from others, sections of the heating system.

Zone cable advantages:

- guarantees stability of power, regardless of the ambient temperature;

- allows you to design systems of any length without loss of heating power.

Features of heating cable installation

Installation of a self-regulating heating cable in domestic piping systems can be carried out independently, using the instructions for installing heating sections.

In the case of cutting the heating cable, the sections are made by means of coupling (sealing of the end and connecting parts). To connect a piece of cable to the network, use a power wire of the required length.

Ready-made cable sets are equipped with a termination and a connecting sleeve, have a power cable (2-2.5 m) and a Euro plug for connection to the network.

Installation of heating cables on roofs and gutters requires specialized knowledge and experience with electrical products. The features of the roof heating device, as well as the rules for the selection of components and installation, are given in a separate section.More details

Heating the water supply with a heating cable

Installation of heating cables on roofs and gutters

Heating cable into the pipe. Heating inside the pipeline

Installation methods

The heating cable for the water supply is laid outside or inside the pipe. For each method, there are special types of wires - some for outdoor installation only, others for indoor installation. The installation method is necessarily prescribed in the technical specifications.

Inside the pipe

To install a heating element inside a water pipe, it must meet several requirements:

- the shell should not emit harmful substances;

- the degree of electrical protection must be at least IP68;

- hermetically sealed end coupling.

In order to be able to tuck the wire inside, a tee is placed at the end of the pipeline, into one of the branches of which a wire is inserted through the gland (included in the kit).

Please note that the joint - the transition point between the heating cable and the electrical cable - must be outside the pipe and gland. It is not intended for wet environments.

The tee for mounting the heating cable inside the pipe can have different angles of outlet - 180 °, 90 °, 120 °. With this installation method, the wire is not fixed in any way. It is simply tucked inside.

Outdoor installation

It is necessary to fix the heating cable for the water supply on the outer surface of the pipe so that it fits tightly over the entire area. Before installation on metal pipes, they are cleaned of dust, dirt, rust, traces of welding, etc. There should be no elements left on the surface that could damage the conductor. A reason is laid on pure metal, fixed every 30 cm (more often it is possible, less often it is not) with the help of metallized adhesive tape or plastic clamps.

If one or two threads stretch along, then they are mounted from below - in the coldest zone, stacked parallel, at some distance from each other

When laying three or more wires, they are located so that most of them are at the bottom, but the distance between the heating cables is maintained (this is especially important for resistive modifications).

There is a second installation method - a spiral. It is necessary to lay the wire carefully - they do not like sharp or repeated bends. There are two ways. The first is to unwind the sleeve by gradually winding the released cable onto the pipe. The second is to fix it with sagging (bottom picture in the photo), which then wind up and secure with metallized adhesive tape.

If a plastic water pipe will be heated, then metallized tape is first glued under the wire. It improves thermal conductivity, increasing heating efficiency. Another nuance of installing a heating cable on a water supply system: tees, valves and other similar devices require more heat. Make a few loops on each fitting when laying. Just keep an eye on the minimum bend radius.

How to insulate

It is unambiguously undesirable to use mineral wool of any origin to insulate a heated pipeline. She is afraid of getting wet - in a wet state, it loses its thermal insulation properties. Having frozen wet, after the temperature rises, it simply crumbles into dust. It is very difficult to ensure the absence of moisture around the pipeline, so it is better not to take this insulation.

Insulation materials that shrink under the influence of gravity are not very good. Shrinking, they also lose their thermal insulation properties. If your pipeline is laid in a specially built sewage system, nothing can put pressure on it, you can also use foam rubber. But if you just bury the pipe, you need rigid insulation. There is another option - on top of a crumpled insulation (for example, expanded polyethylene with closed cells), put on a rigid pipe, for example, a plastic sewer pipe.

Another material is expanded polystyrene, molded in the form of fragments of pipes of different diameters. This type of insulation is often called a shell. It has good thermal insulation characteristics, it is not afraid of water, it can endure some loads (it depends on the density).

What power is required for a heating cable for a water supply

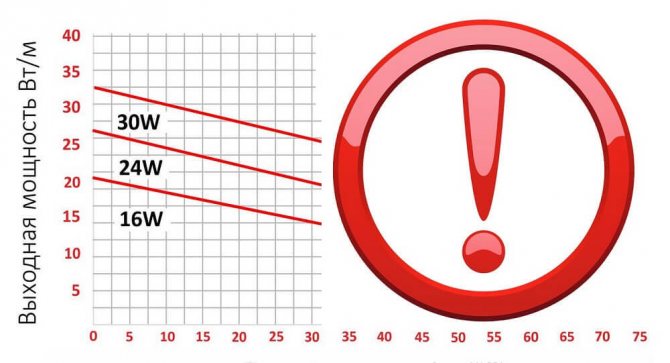

The required power depends on the region in which you live, on how the pipeline is laid, on the diameter of the pipes, whether it is insulated or not, and even on how you lay the heating - inside the pipe or on top of it. In principle, each manufacturer has tables that determine the cable consumption per meter of pipe. These tables are compiled for each power, so it makes no sense to lay out some of them here.

From experience, we can say that with average insulation of the pipeline (expanded polystyrene shell 30 mm thick) in Central Russia, a power of 10 W / m is sufficient to heat one meter of pipe from the inside, and at least 17 W / m must be taken outside. The farther north you live, the more power (or thicker insulation stand) you need.

Calculation of the cable length for the heating system

Methods for calculating the amount of samreg for various heating systems is determined by the type of object (roof, pipeline, drain, reservoir), system requirements, initial data (minimum temperature), and so on.

The amount of cable for heating the edge of the roof is calculated based on the requirement of 250-300 W / m2, depending on the complexity of the site and the material from which the roof is made. In this case, the linear power of the cable can vary from 24 to 40 W / m. The total power is regulated by the pitch of the cable.

Downpipes, trays and storm drains are heated with a 30W / m cable (for plastic pipes), 40 W / m for metal ones. Gutters less than 150mm are heated in 1 thread, more than 150mm - in 2 threads. Storms and gutters less than 150mm - in 2 lines, wider - in 3 lines. More about calculating the roof heating system

The power of the cable for a pipe heating system is calculated based on the diameter of the pipe, the thickness of the insulation material, and the minimum ambient temperature. There is a table for calculating the power of the cable for heating the pipeline, given in the corresponding section.

The length of the heating cable for domestic pipes depends on the capacity of the selected cable in order to ensure the appropriate system capacity. If, for example, according to the table, the calculated power of the cable is 36 W / m, then 2 heating cable strings with a linear power of 16 W / m can be used in the system. On separate sections of the pipeline that need additional heating (most often these are shut-off valves), the cable is laid according to the rules specified in the corresponding section. More details

For tanks, a shielded cable 15-90 W / m is used, it is laid with a snake on the surface of the tank, forming turns. Part of the tank surface is heated depending on the heat loss. More details

Heating the water supply with a heating cable

Heating cable for roofs and gutters

Calculation of the heating system of tanks with a heating cable

Working principle and design

Self-regulating tapes and cables alter the power and heat generation, taking into account the temperature of the atmosphere, i.e. they constantly sense temperature changes without any additional sensors. As a result, different places where the cable is connected to the heated object may have different temperatures, and the devices and mechanisms adjacent to the connection will increase their temperature to different degrees.

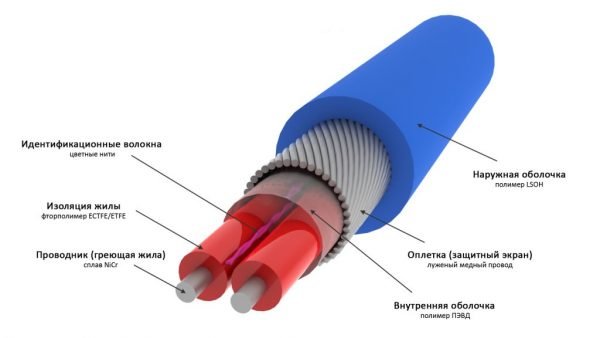

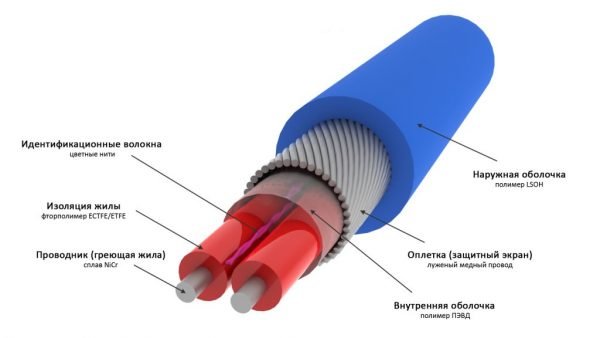

To supply voltage along the entire length of the self-regulating tapes, without crossing, a pair of copper stranded conductors is built in. They are supplied with constant electrical voltage. Between the conductors of electricity is a key element of the cable - a specially made semiconductor carbon polymer matrix with the designation PTC (Positive Temperature Coefficient). The meaning of the PTC effect is that the carbon nanomaterial that makes up the matrix, upon reaching a threshold value, changes its resistance and releases less power.Each manufacturer of self-regulating cable has its own unique secret technology or recipe for making a matrix (like a recipe for making bread for each baker). Moreover, the recipe for soot, from which the matrix is made, differs for different types of samreg, different in power and purpose. During the production process, the soot undergoes a "crosslinking" process by irradiation with an electron particle accelerator. This is to help the matrix maintain PTC performance and polymer stability over repeated heating and cooling.

It is also known that in the matrix structure, in addition to graphite particles, small metallic nano-particles are added to conduct current inside the entire structure. The heated matrix expands, the conductive metal-graphite bridges break. As a result, the resistance of the section increases, the current decreases, and the heat release decreases. During cooling, the opposite process occurs: the matrix contracts, the number of communication channels between conductive metal nanoparticles becomes larger, the resistance of the power section decreases, the power and heat release increase.

Protective inner insulation made of Polyolefin or Fluoropolymer protects the matrix from wear and moisture, and an additional metal braid performs the function of mechanical protection and grounding at the same time. The outer sheath of the cable is also coated with Polyolefin or Fluoropolymer. If necessary, UV-resistant elements are added to the sheath if the cable is intended to be exposed to the sun.

When a self-regulating electric cable is connected to the network, the matrix begins to glow along its entire length. Then, depending on the amount of heating, equilibration occurs, i.e. different junction points will emit a different amount of thermal energy.

Maximum length of heating cable section

Learn more

For the design of electrical cable heating, it is necessary to know the number of segments (lines) united by the control system. The maximum length of a section is determined by the linear power of the cable, exceeding this length leads to premature failure of the system, disruption of the automation and, ultimately, can cause an emergency. A table of starting currents for cables of various powers in the next article.

Heating zones for drainage systems

In winter, due to the effects of low temperatures, a number of zones on the roof find themselves in extreme conditions:

- The joint between the wall and the roof. In this zone, the highest temperature is observed due to the rising heat from the windows of the house and its leakage through the walls and ceiling. The snow is actively melting here, and the resulting moisture can flow under the roof and accelerate the decay of the rafter system and the upper part of the walls.

- Roof overhang or roof canopy. Heat does not spread to the hanging part of the roof, and the cold does its job. The flowing water turns into ice. As a result, ice forms on the edge of the roof and icicles grow. Walking under such a roof is simply dangerous for humans.

- The drain. Moisture remains in the downpipe. When freezing, water expands sharply, which leads to deformation of the metal and even to its rupture.

- Stagnant areas of a non-standard roof. The presence of valleys, towers and other complex elements create areas where snow accumulates, and it gradually melts into the attic.

- Roof window. They are often subject to icing, and the problem can be eliminated by heating the nearby downpipes and the edge of the roof.

Thus, on the roofing part of the house there are characteristic zones where in winter there is an increased danger to the structure and people.

A de-icing system is needed at the edge of the roof, roof gutters and in dead zones of complex roofs.

Self-regulating cable starting current

Learn more

Inrush current is the maximum current that occurs when the cable is plugged into the system. It depends on the line power of the cable and the ambient temperature at the moment the system is switched on, the so-called "cold start". A feature of self-regulating heating tapes is significant ST, sometimes 4-5 times higher than the nominal value. The value of the starting current determines the rating of the automation, as well as the power consumption of the system. The longer the heating cable section, the higher the starting current at the moment of switching on. More details