What is it and what is it for

This device is designed to remove smoke and gases from heating devices into the external environment. It is a smoke channel of various shapes and cross-sectional areas.

Another important function of the channel is to provide adequate thrust in the fuel system.

Smoke removal structures are required for stoves, fireplaces, gas boilers.

Previously, with the predominance of stove heating, they were built mainly of bricks. With the advent of gas units, steel chimneys became widespread.

General characteristics

The main part of an industrial chimney is a vertical pipe structure made of brick, concrete or metal. Horizontal and inclined branches are connected to it, drawing carbon monoxide, ash and soot directly from heating devices (burners, stoves, stoves, boilers) operating on liquid and solid fuels, liquefied hydrocarbons, and natural gas. Several pipes are often brought to one chimney, placing their entry points at different levels.

Industrial pipes in cross-section are round, polygonal and oval, in height they can reach several hundred meters. To determine the size, in each case, a calculation is made, for which:

- identify the features of operation;

- take into account the climatic conditions of the region;

- specify aerodynamic loads;

- determine the heat engineering conditions;

- pay attention to the features of fuel units;

- adhere to compliance with environmental standards.

Each of the designs of industrial chimneys has its own characteristics and varieties, a certain service life and disadvantages. But they are all equally used in modern construction.

How the chimney works

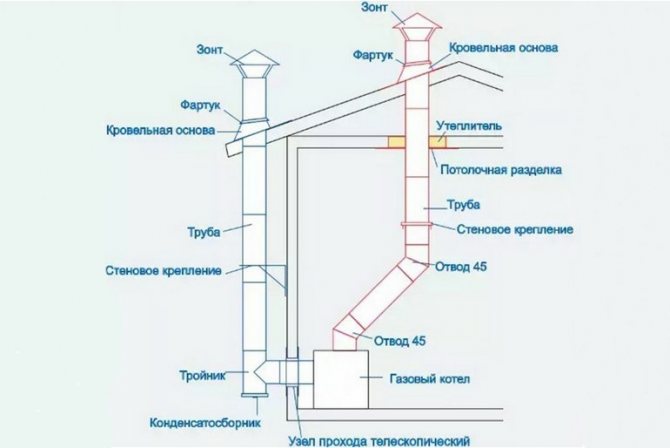

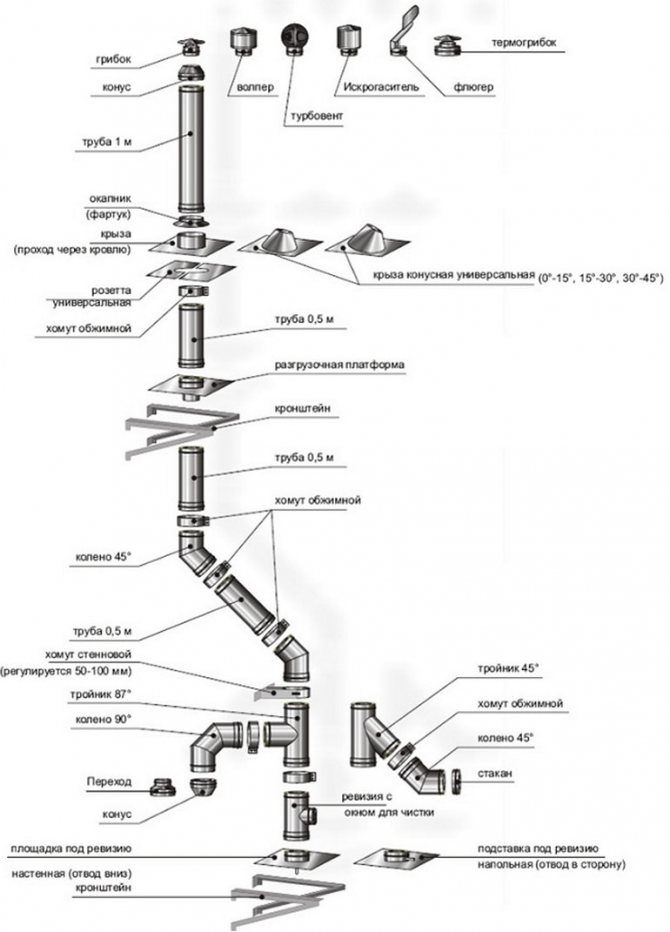

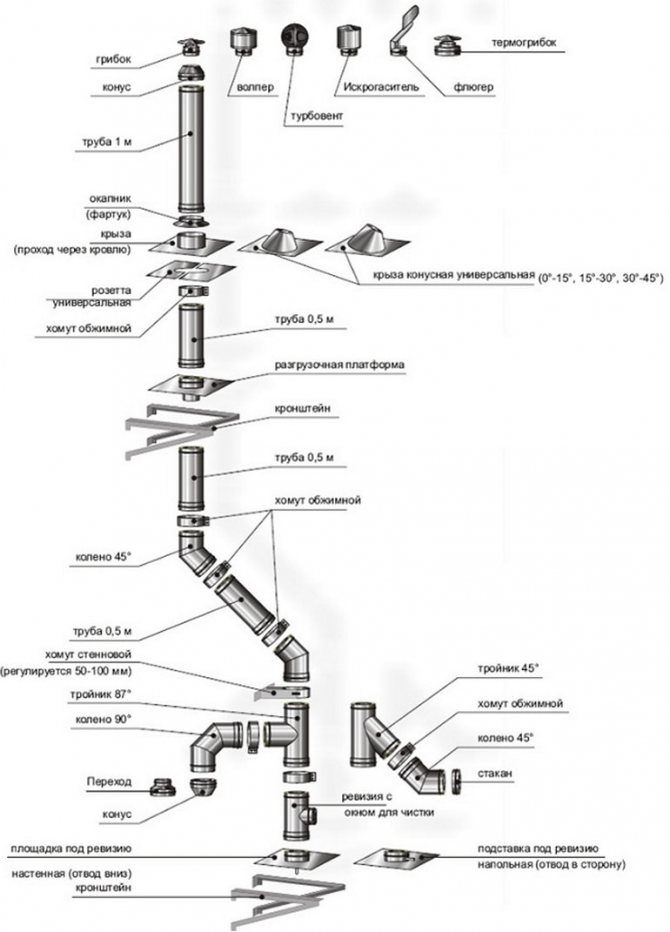

The basis of a metal chimney is made of metal pipes of different lengths. The design makes it easy to connect them by the socket method. Elbows and tees are designed for pipeline bends. Fasteners are crimping clamps, brackets.

A head is installed on top. It protects the drainage from snow and rain, serves to increase traction, decorate the roof.

Supports, nozzles, deflectors, spark arresters and other parts required for the installation of a smoke exhaust device also provide effective operation.

How to calculate the required section and height of the pipe

To calculate the required parameters of the chimney, you need to adhere to the following requirements:

- Section of a round pipe. If a stove or boiler runs on solid fuel, then the volume of the flow chamber affects the cross section of the chimney. In a ratio of 1:10, here 1 - refers to the cross-section of the chimney, and 10 is the size of the combustion chamber.

- The pipe height is over 5 meters. The distance is measured from the outlet of the heating system to the top of the pipe - the head. It has the form of a "umbrella-cone", "deflector-cone", an insulated head that protects the chimney and decorates the roof.

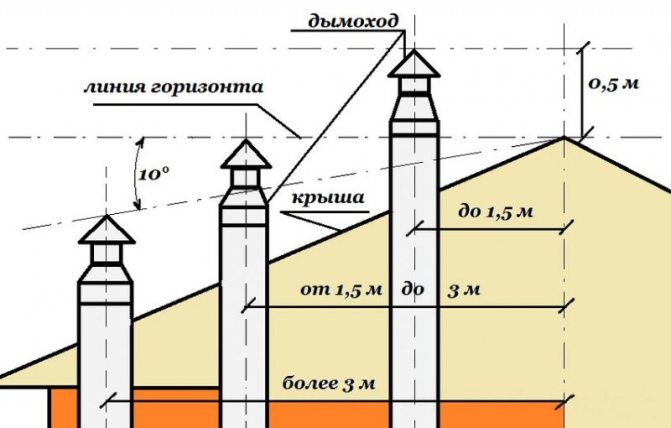

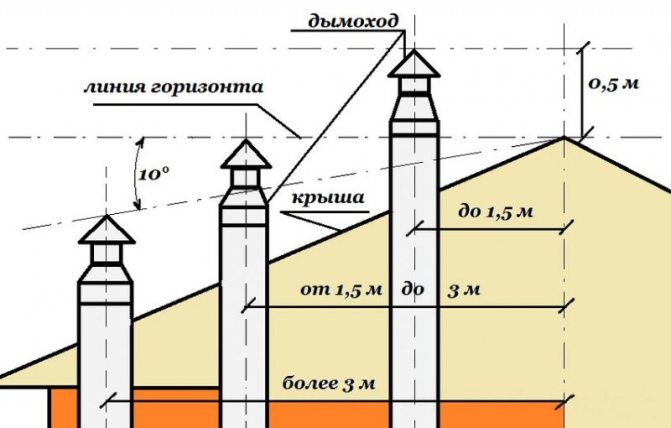

- The height of the outer part of the chimney depends on where the pipe outlet will be, relative to the ridge. If the pipe from the ridge is located at a distance of 1.5 m, then the height of the pipe must be at least 0.5 m.If the chimney is at a distance of 1.5-3.0 m from the ridge, then its height is the same as the height of the ridge or more by 0.1- 0.3 m.

For your information! The temperature difference inside the heating system and outside, as well as the height of the chimney, affects the draft of combustion products.

Types and designs

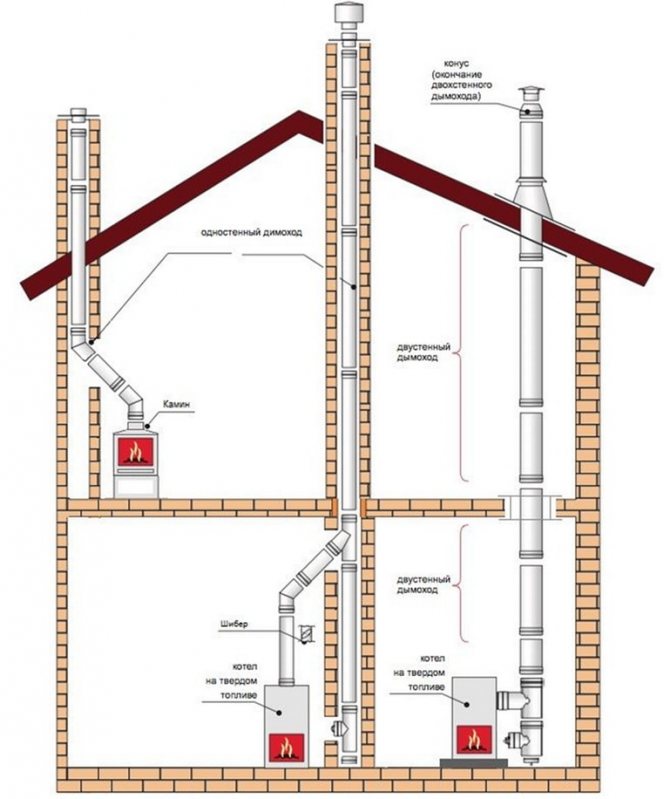

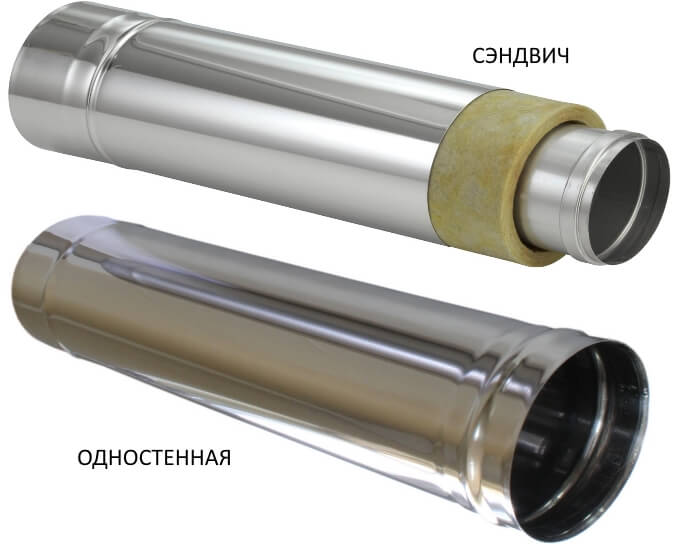

By the type of structures, metal chimneys are divided into:

- single-walled. They are used as temporary branches, for example, for ovens in baths;

- two-layer, called "sandwich". They consist of inner and outer pipes, between which insulation is laid;

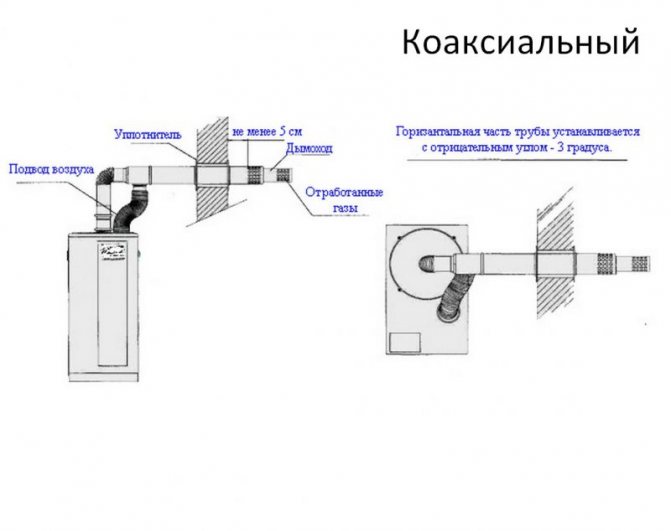

- coaxial chimneys. The design of two channels, simultaneously carrying out the smoke outlet and oxygen supply to the furnace. It is used only for heaters with a closed combustion chamber.

Distinguish also:

- straight chimneys. They are installed vertically and led out through the roof;

- lateral attachments. They are brought out with the help of a knee and mounted on the wall of the house;

- the lateral inner ones go out into the smoke shaft built into the wall, or they themselves are built into the load-bearing wall of the house.

Steel chimneys are made from various metals.

Black steel

Chimneys made of this material are of low cost. They do not have the best strength characteristics, but they can stably withstand temperatures up to 500C.

To increase the service life, enameled products, pipes with thickened walls are used. Chimneys of this type are installed more often in summer cottages, in baths, where heating devices are not used so intensively.

Low alloy steel

Small additions of alloying components give such bends increased corrosion resistance and strength. Able to withstand an operating temperature of 1200 oC. They can be connected to solid fuel foci.

Galvanized iron

Pipes made of this material practically do not rust, the price for them is lower than for stainless steel. However, there are concerns about their negative impact on human health. At a heating temperature above 419C, zinc begins to emit toxic fumes.

In this regard, it is recommended to use galvanized products in systems with low operating temperatures up to 350C. There are no contraindications for their use in sandwich smoke removal devices. Here, the inner channel is filled with stainless steel, the outer one is galvanized.

It should also be noted that a galvanized channel installed without insulation will last only 1-2 heating seasons.

Stainless steel

This type of steel has high heat resistance and resistance to acids and moisture. Chimneys made of stainless steel are made of both single and double-layer types. Withstands temperatures at peak load up to 850 C.

Single structures are used as the inner part of the bends and for casing brick chimneys. The product is inserted inside the old brick channel and connected to the boiler pipe.

Two-layer insulated chimneys have become the most common. They retain heat well, due to which they consistently provide proper traction.

| Sandwich pipe | ||||||

| Name | Diameter | Price | ||||

| External | Interior | Galvanized. | Stainless steel | Zerk. St. | Polyester. | |

| Sandwich pipe L-1 m | 200 mm | 100-120 mm | 1000 RUB | 1620 RUB | RUB 1,750 | 1490 RUB |

| 250 mm | 130-150 mm | 1360 RUB | RUB 2050 | RUB 2160 | 1730 RUB | |

| 250 mm | 160-170 mm | 1470 RUB | RUB 2160 | 2270 RUB | RUB 1820 | |

| 300 mm | 180-200 mm | 1840 RUB | RUB 2,600 | 2810 RUB | RUB 2050 | |

| 350 mm | 250 mm | 2270 RUB | RUB 2920 | RUB 3130 | 2500 RUB | |

| Sandwich pipe L-0.5 m | 200 mm | 100-120 mm | RUB 500 | RUB 780 | RUB 525 | 750 RUB |

| 230 mm | 130-150 mm | RUB 680 | 1015 RUB | 1080 RUB | 870 RUB | |

| 250 mm | 160-170 mm | RUB 740 | 1080 RUB | 1150 RUB | RUB 910 | |

| 300 mm | 180-200 mm | RUB 930 | 1170 RUB | 1360 RUB | 1040 RUB | |

| 350 mm | 250 mm | 1150 RUB | 1360 RUB | RUB 1580 | 1250 RUB | |

The chimney is one of the most important elements of heating systems for residential and industrial premises. Correctly designed, manufactured and installed chimney ensures stable and efficient operation of heating boilers. It is advisable at the design stage to determine the location of the boiler installation, the type of fuel, the model and power of the boiler, the diameter or cross-section of the chimney, its height and the possibility of removing the combustion products, i.e. determine the design of the chimney. Very often, when designing, chimneys are laid in intra-house partitions 40 cm thick (1 1/2 bricks).In partitions of such a thickness, a normal chimney for modern heating boilers with a gas outlet pipe diameter of 180-250 mm is practically impossible, given that the chimney duct must be larger than the boiler flue diameter and, moreover, be insulated. Its cross-section must be at least 250 × 250 mm.

Modern boilers are more than 90% efficient and therefore have a low flue gas temperature. Gas passing through the chimney cools down to the “dew point” temperature and condenses in the form of a water droplet on the walls of the chimney. To such a temperature, the exhaust gases cool down at a height of 4-5 m from the boiler outlet, therefore, with a chimney height of more than 4 m, it is inappropriate to make it in brickwork (without additional measures to increase condensate resistance) The reasons for the formation of condensate are discussed in more detail below. A heating boiler is not a stove or a fireplace, so you need to think not about refractory bricks, but about a sealed flue. Any fuel contains impurities, including sulfur, which, when burned, forms an anhydride, which, in turn, mixing with water, forms an acid. Since the fuel contains half of the periodic table as impurities, the acid mixture in the chimney is so aggressive that it can destroy brickwork.

Hence the conclusion - a chimney in brickwork should not be done. If the chimney is nevertheless laid in the wall, an inset stainless steel chimney must be placed in the resulting channel. Chimneys made of non-corrosive material allow the removal of combustion products and withstand temperatures up to 250 ° C. This pipe can be led out through the roof or through the side wall of the house. Pipes made of stainless steel of the "sandwich" type (a pipe in a pipe, and between them thermal insulation) are light and take up little space, they can also be used as liners in brick chimneys.

CAUSES OF CONDENSATE FORMATION

In the process of combustion of any hydrocarbon fuel, carbon dioxide (CO2) and water (H2O) are formed in the form of water vapor. The maximum temperature of the exhaust gases, depending on the thermal power of the heating boiler, is 150-180 ° C, at the exit from the pipe mouth - 100-110 ° C. In a heated chimney, water vapor is carried away along with the flue gases to the outside. When the temperature on the inner surface of the chimney is below the temperature of the "dew point" of gases, water vapor is cooled and deposited on the walls in the form of tiny drops. If this is repeated frequently, the brickwork of the walls of the chimneys and chimneys is saturated with moisture and collapses, and black resinous deposits appear on the surfaces of the chimney.

In the presence of condensation, the draft weakens sharply, and the smell of burning is felt in the rooms. Leaving flue gases decrease in volume as they cool down in chimneys, and water vapor, without changing in mass, gradually saturates the flue gases with moisture. The temperature at which water vapor will completely saturate the volume of flue gases, that is, when their relative humidity is 100%, is the dew point temperature: the water vapor contained in the combustion products begins to turn into a liquid state. The dew point temperature of the combustion products of various gases is 44-61 ° С. For example, the dew point temperature for natural gas is about 55 ° C.

The amount of condensate depends on the flue gas temperature. The temperature of gases from burning solid fuels is usually much higher than from burning gas. The relatively high temperature of the exhaust gases from the combustion of solid fuel ensures good heating of the smoke channels, as a result of which there are less frequent cases of condensation and precipitation of water vapor on the inner surface of the walls. In addition, the amount of water vapor in gas combustion products is much higher than in solid fuel combustion products, since they contain a large amount of hydrogen. The temperature of the flue gases can be determined in a simple way:

- a dry splinter is placed across the opening of the view during the heating;

- after 30-40 minutes, take out the torch and scrape off the smoked surface;

- if the color of the splinter does not change, then the temperature is within 150 ° С;

- if the torch turns yellow (to the color of the crust of white bread), then the temperature reaches 200 ° C;

- turned brown (to the color of a rye bread crust) - the temperature rose to 250 ° С;

- a blackened torch indicates a temperature of 300 ° C;

- and when it turns into coal, the temperature reaches 400 ° C;

- when firing the furnace, the temperature of the gases must be regulated so that the view is within 250 ° C.

In modern heating boilers, the boiler temperature is controlled automatically or manually. Cracks and holes in the pipe, through which cold air penetrates, also contribute to the cooling of gases and the formation of condensation. When the cross-section of the channel of the pipe or chimney is higher than the required one, the flue gases rise along it slowly and the cold outside air cools them in the pipe. The surface of the chimney walls also pays great attention to the draft force - the smoother they are, the stronger the draft. Roughness in the pipe reduces draft and retains soot. The combustion process itself plays an important role. For example, wood ignites at temperatures not lower than 300 ° C, coal - at 600 ° C. The normal combustion process takes place at a higher temperature: wood at 800-900 ° C, coal at 900-1200 ° C. This temperature ensures continuous combustion, provided that air (oxygen) is supplied without interruption in the amount required for combustion. When it is supplied in excess, the firebox cools down and combustion deteriorates, since a high temperature is needed for combustion. With complete combustion of the fuel, the color of the flame is straw-yellow, the smoke is white, almost transparent. Soot on the walls of the pipe channels is almost not deposited.

Condensation also depends on the thickness of the chimney walls. Thick walls slowly warm up, but also cool down more slowly, retaining heat well. Thinner walls heat up faster, but retain heat poorly, which leads to their cooling. The thickness of the brick walls of the chimneys passing through the inner walls of the building must be at least 120 mm (half a brick), and the thickness of the walls of the smoke and ventilation ducts located in the outer walls of the building must be 380 mm (one and a half bricks). Chimneys made of asbestos-cement or pottery pipes have an insignificant wall thickness, therefore, their thermal insulation is necessary throughout, if they are not built into the brickwork.

Outside air temperature has a great influence on the condensation of water vapor contained in gases. In the summer season, when the temperature is relatively high, condensation on the inner surfaces of the chimneys is too low, since their walls cool for a long time, therefore, moisture instantly evaporates from the well-heated surfaces of the chimney and condensation does not form. In the winter season, when the outside temperature is negative, the walls of the chimney are very cooled and the condensation of water vapor increases. If the chimney is not insulated and is strongly cooled, increased condensation of water vapor occurs on the inner surfaces of the chimney walls. Moisture is absorbed into the pipe walls, which causes the masonry to become damp. Ice plugs in the upper sections (at the mouth), which are formed under the influence of frost, are especially dangerous. It is also not recommended to connect boilers and other heat generators to chimneys of large cross-sections and heights, since the draft weakens and increased condensation forms on the inner surfaces. Condensation is also observed when boilers are connected to very high chimneys, since a significant part of the flue gas temperature is spent on heating a large heat absorption surface.

DISCUSS

Advantages and disadvantages

The advantages of metal chimneys compared to brick ones include:

- ease of construction, variability of the assembly configuration;

- optimal ratio of price, quality, ease of installation;

- simple and quick process of assembly and installation of the structure;

- smooth surface of internal walls, on which combustion products do not linger.

Metal chimneys have limitations that should be attributed to their disadvantages:

- the high cost of individual stainless steel structures;

- inability to use at constant operating temperatures above 500C;

- with the exception of certain types of stainless steel, chimneys from other metals are highly susceptible to rust.

Excerpt from Smoke Pipes

- After the day after tomorrow. Too late ... Rostov turned and wanted to leave, but the man in the help stopped him. - From whom? Who are you? “From Major Denisov,” answered Rostov. - Who are you? an officer? - Lieutenant, Count Rostov. - What courage! Serve on command. And you yourself, go, go ... - And he began to put on the uniform given by the valet. Rostov went out into the vestibule again and noticed that there were already many officers and generals in full dress uniform on the porch, past whom he had to pass. Cursing his courage, dying at the thought that at any moment he could meet the sovereign and be disgraced in his presence and sent under arrest, fully realizing the indecency of his act and repenting of it, Rostov, lowering his eyes, made his way out of the house, surrounded by a crowd of brilliant retinue when a familiar voice called out to him and someone's hand stopped him. - You, father, what are you doing here in a tailcoat? His deep voice asked. He was a cavalry general, who during this campaign deserved the special favor of the sovereign, the former head of the division in which Rostov served. Rostov, frightened, began to make excuses, but seeing the general's good-naturedly playful face, stepping aside, in an agitated voice conveyed the whole matter to him, asking him to intercede for the well-known general Denisov. The general, after listening to Rostov, shook his head gravely. - Sorry, sorry for the fellow; give me a letter. As soon as Rostov had time to hand over the letter and tell the whole case of Denisov, rapid steps with spurs rattled down the stairs and the general, moving away from him, moved to the porch. The gentlemen of the sovereign's retinue ran down the stairs and went to the horses. The rider Ene, the one who was in Austerlitz, let the emperor's horse down, and on the stairs there was a slight creak of steps, which Rostov now recognized. Forgetting the danger of being recognized, Rostov moved with several curious inhabitants to the very porch and again, after two years, he saw the same features he adored, the same face, the same look, the same gait, the same combination of greatness and meekness ... And the feeling of delight and love for the sovereign with the same strength revived in Rostov's soul. The sovereign in the Preobrazhensky uniform, in white leggings and high boots, with a star that Rostov did not know (it was legion d'honneur) [star of the Legion of Honor] went out onto the porch, holding his hat close at hand and putting on a glove. He stopped, looking around and illuminating everything around him with his gaze. To some of the generals, he said a few words. He also recognized the former chief of the Rostov division, smiled at him and called him over to him.

Building regulations

The construction of a smoke removal device requires compliance with the building rules set out in SNiP.

Let's list the main ones:

- the height of the straight chimney to ensure normal draft must be at least 5 meters;

- above the ridge of the roof, it should rise by 50 cm, and be at a distance of 150 cm from it;

- connections of pipes in outlet or passage openings of the wall and ceilings are prohibited;

- the diameter of the flue duct should not be narrower than the Ø of the outlet of the heating unit;

- pull-down chimneys should not have more than three bends along the entire length of the duct.

Used steel grades, wall thickness

For stoves, fireplaces and other types of heating systems, different types of fuel are used - solid, liquid and gas. The exhaust gases are discharged through steel chimneys, which are of different brands and have different wall thicknesses.

| Stainless steel grade | AISI 321 | AISI 304L | AISI 316L | AISI 304 | AISI 309/ 310 | AISI 316Ti | AISI 430 | AISI 439 |

| Wall thickness (inner tube), mm | 0.6, 0.8, 1.0 | 0.8 | 30 | 0.8 | 0.8-1.0 | 100 | 1.0 | 0.8 |

| Exhaust gas temperature, ℃ | 600-800 | 120-200 | 150-250 | up to 300 | up to 1000 | 450-600 | up to 900 | up to 850 |

| Thermal insulation thickness, mm | 50-100 | 30-50 | 30-50 | 30-50 | 100 | 100 | 30-50 | 40-50 |

Characteristics of steel grades for chimneys:

| AISI 304 L | The material can withstand temperature extremes and other climatic influences. Possesses high anti-corrosion properties. |

| AISI 316 L | Alloying additives increase acid resistance. They are connected to the diesel system. |

| AISI 304 | Used for the manufacture of chimneys in a private house, which are connected to gas equipment. |

| AISI 309/310 | Used for stoves, fireplaces that run on solid fuels |

| AISI 316 Ti, 321 | Steel grades that are often used for the manufacture of chimney systems. They have high thermal and acid resistance properties. They are the best choice for diesel and gas systems. |

| AISI 430 | The metal has a low carbon content. Used for the manufacture of sandwich pipes. Possesses high strength and anti-corrosion properties. |

| AISI 439 | This is a type of AISI 430 steel to which titanium has been added. The metal is corrosion resistant and durable. Sandwich pipes are made from it, which are used in conjunction with heating systems with low power (less than 3.5 kW) |

In the modular metal construction of the chimney, the chemical composition of the material is of great importance. Alloy additions increase strength, anti-corrosion, hardness, ductility and ability to withstand shock loads.

Traction force

The draft of a straight flue duct depends on its diameter and height. For the correct selection of these parameters, a special table is used. A height of 5 m is considered optimal.

For horizontal clamping ducts, the pulling length is 3 meters.

When combining both sections, it is recommended to increase the height of the pipe by one meter for each meter of the horizontal section.

To increase traction, you can apply one of the following options:

- increase the height of the bend above the roof;

- attach a special weather vane to the head;

- use an electric smoke exhauster.

Metal chimneys

The construction of metal chimneys consists of individual sections, which are delivered from the factory directly to the installation site. The number of elements is determined based on the results of individual calculations made by specialized companies.

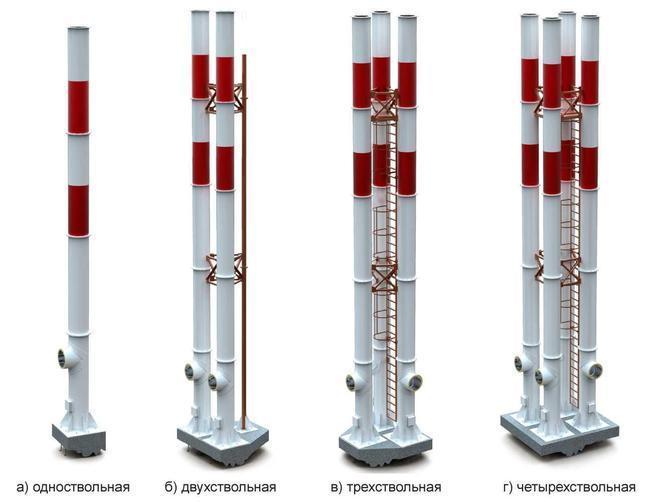

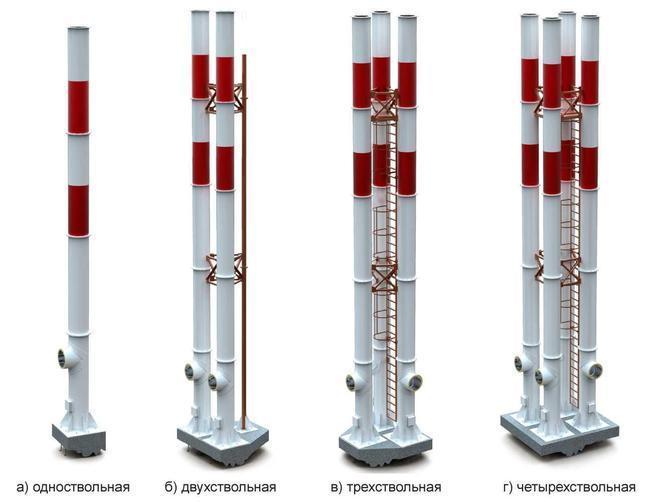

Industrial metal chimneys are divided into several groups:

- self-supporting frameless;

- with pull-off elements (guy lines);

- column (with internal gas outlet shafts);

- front;

- wireframe.

The main structural components of metal flue pipes are modular segments or individual elements with a shell (shell). In addition, industrial chimneys are equipped with:

- inspection hatches;

- service platforms with ladder brackets and fences;

- lightning protection;

- light-protective structures.

Acid-resistant stainless and carbon steels, as well as aluminum, are used as materials for the manufacture of shells and gas ducts. Chimneys are insulated with mineral wool or basalt wired mats.

The height of metal chimneys for industrial facilities can reach from 8 to 60 meters with an outer diameter of a single-barrel structure from 300 to 1400 mm. The multilateral system includes in one group from 2 to 5 pipes with diameters from 200 to 800 mm.

Self-supporting chimneys

The frameless self-supporting chimney is a single-barreled, freestanding structure with a height of no more than 30 meters. It is allowed to start horizontally or obliquely located gas outlets from one or several heating installations into it. But it should be borne in mind that the throughput of a single-barrel chimney metal pipe may not cope with the volume of combustion products during the period of maximum loads, if carbon monoxide gases from three or four "connected" objects are fed into it at a time. Therefore, preliminary calculations are required.

It is not allowed to "by eye" determine the number of chimney shafts and gas outlet pipes from equipment to them.

Multi-barreled self-supporting chimneys are installed in a separate group, and the barrels are attached to a common frame.Such a composition is quite massive and requires a more powerful foundation.

As a base for a self-supporting chimney, sheet steel of increased thickness and area is used, fixed to the foundation with anchor bolts. Additional stability is provided by stiffening ribs, firmly fixed to the base and the pipe. In this case, the entire load from the structure is taken over by the base plate together with the foundation.

If necessary, the industrial chimney is insulated with mineral wool (up to 10 cm thick) and covered with a shell.

The relatively low production cost of a self-supporting chimney and its simple installation are covered by significant disadvantages, which include:

- large weight of a thick-walled pipe, requiring the construction of a massive foundation;

- metal consumption, which affects the final cost;

- the need for complete dismantling of the barrel in case of destruction of one of its parts;

- expensive transportation due to the massiveness of the pipe;

- difficulties in maintaining the chimney if several outlets from fuel installations are inserted into it.

Industrial chimneys with braces

The main advantages of chimneys with exhaust elements are their low cost and weight, as well as simple installation technology. Such designs are widespread and in demand.

On single-barreled free-standing pipes, belts are installed, which serve to fasten the guy wires. They are located at a certain design height from ground level. The lower part of the pipe is mounted on a base plate and rigidly fixed. The stability of the structure is ensured by the lower stiffening ribs, and its verticality is ensured by braces made of round steel with a diameter of about 20 mm. Metal braces are securely attached to the belts on one side and to the foundation on the other, at an angle of 30 degrees relative to the gas outlet.

The most significant drawback of this design is the short service life of the chimney, no more than 15 years. In addition, for reliable fixation of the braces, a foundation is required for each of them, which entails the allotment of additional territory and an increase in the volume of work.

Column pipes

The column chimney consists of a bearing shell-shell and two to five gas exhaust shafts installed inside it. They are self-supporting structures reaching 60 meters in height and 3.5 meters in diameter.

A heat-insulating layer is placed between the shafts and the shell to prevent the formation of condensation. Its thickness depends on the climatic conditions of the region and the technological features of the industrial facility.

The shell is painted from the outside with modern zinc-containing compounds. In the upper part of the pipe, vibration dampers are installed to help avoid wind resonance.

Facade chimneys

A feature of this version of the chimney is considered to be an economical way of its construction, which does not require a foundation and the presence of frame structures. The gas outlet is attached directly to the facade of the capital structure or to the load-bearing wall of the extension.

The chimneys are fixed using light frames, or clamps with anchors.

Due to the fact that thin-walled lightweight pipes are used for facade chimneys, they must be thermally insulated in order to minimize the formation of condensation on the inner walls. A shell or sheet steel is used as protection against atmospheric precipitation.

Frame industrial smoke exhaust pipes

As a supporting structure for frame chimneys, special trusses are used, made of tubular shaped rolled products. Modular elements with a three-layer structure are attached to them.

- The inner layer is made of stainless steel, which is resistant to aggressive media and high temperature conditions.

- The intermediate layer is made of heat-insulating materials (mineral or basalt wool).

- The outer layer is made using a sheet metal that is resistant to corrosion and mechanical damage (stainless steel or polymer-coated steel).

Making and installing a chimney with your own hands

The correct choice and competent installation of a ready-made chimney kit is essential for its further functioning. It would be wise to entrust this work to professionals. If you have the appropriate skills and are confident in your abilities, you can assemble and install the smoke extraction device yourself.

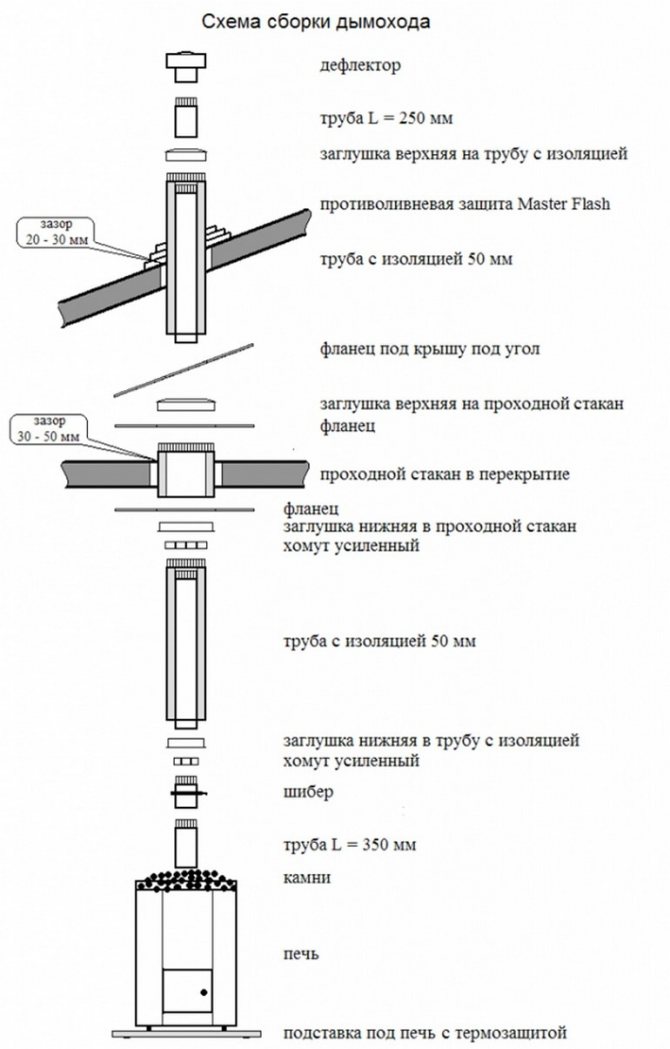

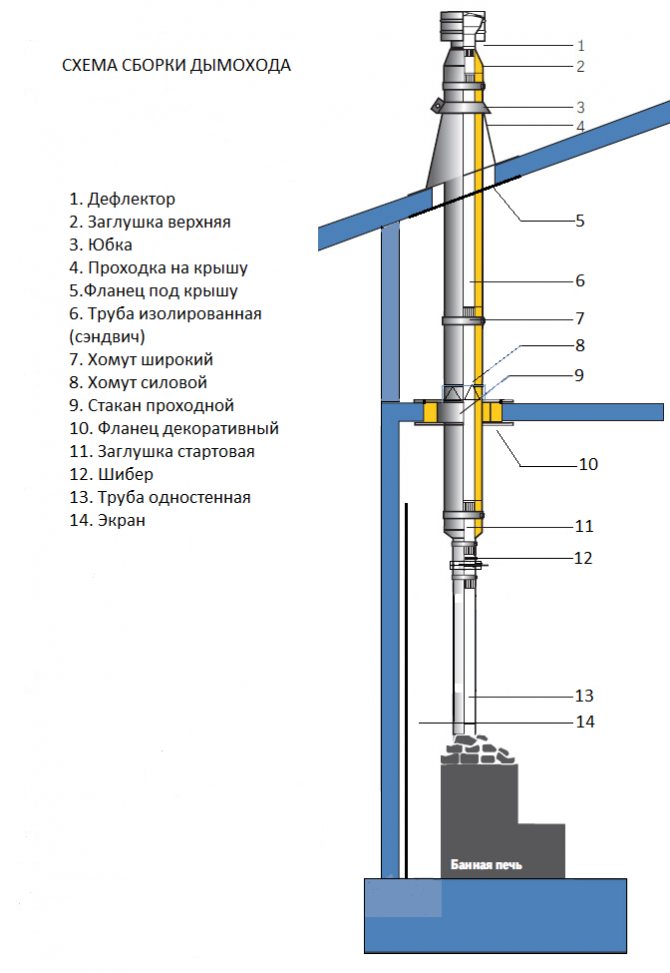

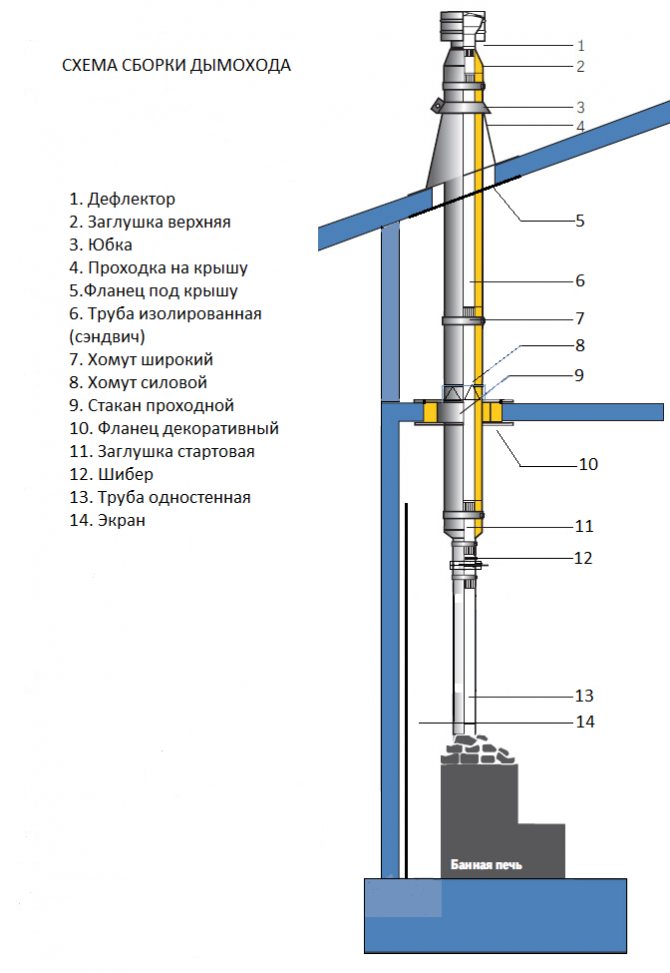

The installation process includes the following steps:

- determination of the chimney configuration;

- calculation of the required pipe size depending on the power and size of the outlet pipe of the heater;

- marking of openings on the wall and ceilings;

- drilling these holes;

- laying thermal insulation in them;

- connecting the initial section of the pipe to the heating device;

- assembly and fastening of chimney units, output of the end part to the outside;

- securing the sleeve in the outlet openings;

- installation at the end of the chimney of a windscreen and elements that prevent the formation of condensate and its freezing at the outlet of the pipe;

- finishing the chimney, both on the roof and inside.

Drawing and diagrams

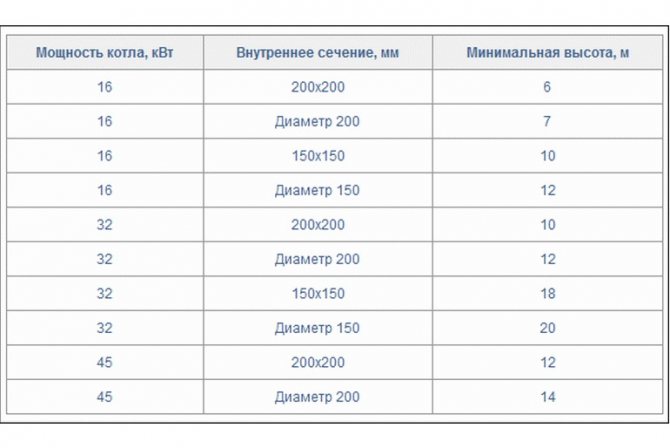

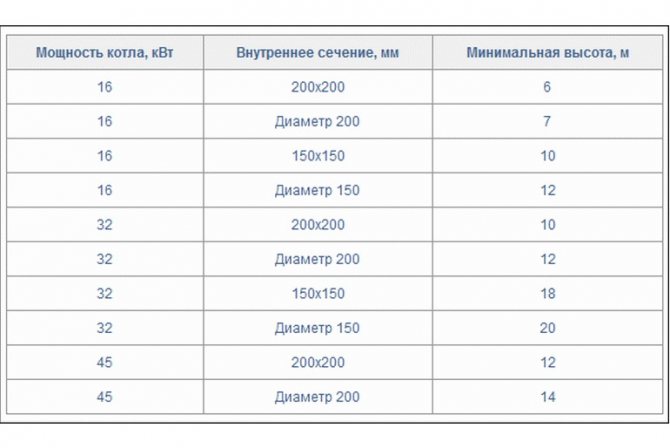

Sizing calculation

We determine the power of the heating device.

We measure the cross-section of the outlet of the boiler or furnace.

Using the table, we calculate the dimensions of the chimney:

Varieties of steel structures

Metal chimneys are of 2 types:

- single-walled;

- three-layer sandwiches.

The first type is made from galvanized or stainless steel. The designs are cheap and easy to install. A significant disadvantage of such chimneys is a high degree of heat exchange, which reduces the efficiency of the entire heating system.

The scope of application of single-walled products includes installation in outbuildings, where heat loss is not of great importance, inside houses as an additional source of heat and as an additional channel for a combined chimney. Structures require insulation and installation of fire protection elements.

More advanced sandwich chimneys already include insulation that is placed between the outer and inner chimneys. Such products completely eliminate heat loss and have high fire-fighting characteristics. Their installation involves the installation of exclusively pipes and fittings. The only drawback is the high cost, which pays off in the future.

Installation features

The installation is designed so that most of the chimney is indoors. Thus, heat loss is reduced.

The correct assembly of the chimney begins from the heater. Pipe connections are carried out using the bell-shaped method: the upper part is inserted into the lower one up to the latch, if it is not there, by half the channel diameter.

Wall mounts are spaced at least 1.5 meters apart. Elbows and tees are mounted on separate brackets.

Contact of structural elements with the communications of the house is not allowed.

Chimney fixing

The workpiece must be taken to the roof through the attic. All gaps, especially the voids between the roof and the branch pipe, are filled with waterproofing. When withdrawing the workpiece, you must remember the safety precautions.

28a68763ca5396a3ddd85de429ee95d8.jpe

A knee is used to secure the chimney pipe. It is designed to adjust the vertical position of the structure. To give everything reliability, the pipe is additionally attached to the wall, using suitable brackets. Usually they come in a ready-made set. They can also be made by hand, it is best to use metal corners as a basis for them.

Frequent errors and problems during installation

Low height of the chimney device. As a result, traction is lost.

The chimney outlet must be higher than the ventilation ducts if they are designed in one block. Otherwise, reverse thrust occurs.

The choice of a chimney, guided only by a low price. Single-wall pipes made of ferrous metal, thin galvanized are suitable only as temporary devices. Even from stainless steel, not all brands are sufficiently heat-resistant. Preference should be given to alloys that can withstand 700 oС and above: AISI 304, 309, 316, 321.

Expert comments

Anatoly Trokhin, chimney systems engineer:

“A high-quality chimney is made of materials that can withstand high temperatures and the effects of corrosive condensate - these are steel AISI 304, AISI 321 (operating temperature 550 ° C) and heat-resistant basalt wool. To check the quality of steel, simply attach a magnet to it. The magnet is attracted to cheap steel, but not to high-alloy stainless steel.

The most tight and reliable seam is obtained when the pipe is butt-welded in an inert gas environment. High dimensional accuracy contributes to obtaining neat and tight connections of elements.

Chimney certification is not required in Russia, but the responsible companies have certificates confirming the quality of the products. And, of course, each manufacturer must give a guarantee for their products.

Chimneys made of stainless steel can be used for heat generators operating on different types of fuel - wood, pellets, briquettes, brown coal, natural gas, diesel fuel, except for coal, in which the temperature of the exhaust gases can be higher than 550 ° C. Only one heat generator is connected to one chimney. If there are more, then they must be used in turn, otherwise smoke may become possible. "

Nikolay Vostrikov, Head of Steel Chimney Systems, Schiedel:

“For the production of elements of steel chimney systems, Schiedel plants use stainless steel and the highest quality thermal insulation materials from leading European manufacturers. One of these plants of the Schiedel company, located in the Czech city of Teplice, produces more than 1900 running meters of steel chimney systems of a wide range every day. This number is sufficient to equip approximately 270 cottages. During the heating season, this figure rises by 40%.

The inner pipe of the Permeter metal chimney system is made of ferritic heat-resistant stainless steel AISI 444. The outer shell is made of galvanized steel, which, after welding and other technological operations, is powder-coated in one of three colors: black, gray or white. The Permeter chimney system matches well in color with stoves and fireplaces. A unique thermal insulation material SUPERWOOL 607 is used as insulation between the external and internal circuits of the system. It has the best thermal resistance to date, does not lose its properties when heated to a temperature of 1100 ° C and is absolutely environmentally safe due to the absence of binding adhesive components.

Schiedel experts recommend the ICS chimney system for use with modern gas and diesel boilers. Its inner tube is made of corrosion-resistant steel AISI 316L, and the thermal insulation is SUPERWOOL 607 with a thickness of 25 or 50 mm. "

Sergey Nasonov, director:

“The design and height of the chimney is chosen based primarily on the technical characteristics of the heat generator. Then, taking into account the characteristics of the room, the location of the boiler, stove or fireplace, the structural nuances of the roof, surrounding buildings, the chimney system is completed and installed in accordance with the Code of Rules of SP 7.13130.2009 and SNiP 41-01-2003.

Not only the efficiency of the heat generator depends on the correct installation of the chimney, but also the safety of the inhabitants of the house, therefore, the installation of chimney systems must be carried out by qualified licensed personnel, taking into account all fire safety requirements and the named regulatory documents. Specialists in various ways increase the ability of metal chimneys to withstand the effects of condensation, precipitation, wind, temperature changes and other factors.In the design of LOKKI chimneys that have recently appeared on the market, these tasks are solved in the most efficient way.

The peculiarity of LOKKI modular systems is the application of an enamel coating to the entire surface of the pipe. It not only provides high protective properties, long service life (15 and more years) and hygienic safety of chimneys, but also gives them aesthetic appeal.

SibUniversal is the first and currently the only manufacturer of enameled chimneys on the Russian market. "

Text: Vladimir Breus

Expert advice

The highest system temperature is observed at the point where the flue duct is connected to the heat generator. Therefore, the initial part of the insulated chimney must be non-insulated, made of heat-resistant material in order to prevent overheating.

It is better to place the condensate trap indoors. On the street in severe frost, it can turn into ice and break the container.

The traditional umbrella fungus does not cope well with extinguishing sparks, wind protection. Instead, it is recommended to install a deflector on the top of a straight pipe, which is fixed with self-tapping screws.

Bath chimney

When performing the insulation of the chimney in the bath, the safety of people should be paramount. The main threat in the room comes from open flames. Therefore, it must be protected, having previously made the overlap resistant to high temperatures.

Basically, baths are built from wood, a flammable material. A very common misconception is the opinion that sheathing the ceiling with metal sheets will be a sufficient measure. But in reality, such protection is not enough. After all, the upholstery will still heat up, which can lead to ignition. A popular solution to the problem is to insulate the chimney with red bricks. But this is not suitable for every bath design.

There are now two good options for chimney insulation:

- Folgoizol. A bath with such insulation will not lose heat, everything works like a thermos. At the same time, it warms up quite quickly, maintaining the temperature for a long time.

- Thermal insulation. The material is used for winding the chimney.

A popular solution is the use of sandwich pipes, which show a high degree of safety. The insulation structure consists of several sections that can be easily combined with each other. This option is also suitable for saunas with a metal stove.

How to insulate

Chimney insulation is an urgent task in the Russian climate.

For this, a sandwich system has already been invented, when a pipe made of insulation is put on the outlet channel, and an outer pipe acting as a protective box is put on it.

The so-called two-layer system with insulation is now widespread.

You can make a similar design yourself. Basalt wool is used as a heater, which is applied to the inner part, wrapped with a reinforced mesh and an outer pipe is put on top.

Friendly exploitation

Over time, soot accumulates on the inner walls of the pipe, which can ignite and, if it hits the roof or destroys the chimney, cause a fire. And although the formation of a "critical mass" of soot in metal products is less likely than in a rough channel of a brick chimney, preventive measures should be taken regularly.

Chimneys should be cleaned from soot and carbon deposits at intervals not exceeding: - three months for heating stoves; - two months for continuous furnaces and hearths; - months for stoves and stoves of continuous (long-term) firebox.

When cleaning chimneys, do not use devices and detergents that are not intended for this.

According to Russian regulations, one boiler on each floor can be docked to a "multi-user" smoke system.To determine the permissible number of connections, depending on the total height of the pipe, its cross-section and the power of the boilers, manufacturers have compiled tables and diagrams, which are guided by specialists when fulfilling specific orders.

Rules for the care and cleaning of a metal chimney

If the chimney is operated all year round, then you cannot do without cleaning the inner surface. The ventilation will work smoothly and there will be no release of combustion products through the flow chamber.

Soot removal

It is performed twice a year. If coniferous wood is used for the firebox, it is recommended to clean it once a quarter. Chimney systems are cleaned with chemicals and a special tool, which consists of a steel line with a load. A ruff with a hard nap is fixed at its end. The diameter of the brush is equal to the inner section of the chimney. It is lowered on top of the pipe. He removes all the soot from the pipe walls.

With the help of chemicals, tar deposits are removed naturally. For this, the product is laid out on coals. When it burns out, salt is released, which softens the soot, and it sinks into the furnace or flies out.

To prevent soot from settling on the inner walls of the pipe, you need to periodically use aspen firewood or potato peelings for the firebox. The wood burns well, and a large fire will help burn off the carbon deposits. This method is used for structures if they are designed for temperatures above 1000 ℃.

Ruff with a load for cleaning the chimney

Chimney repair

Chimney repair can be done in three stages:

- Clean the flue duct.

- Carry out diagnostics with special equipment.

- Replace the problematic item.

Dismantling of a metal chimney in a private house is carried out in the damaged area. The burnt or damaged part of the pipe is replaced with a new one. The demolition of the chimney of the boiler room is carried out in the following ways:

- With the help of industrial mountaineering.

- Directional explosion.

- Using special equipment.

- With the help of robotic manipulators.

For your information! The burning of potato peelings helps to soften the carbon deposits. But it is considered ineffective. It is used before mechanical cleaning.

The chimney system has a simple appearance, but it has a very important function. Without it, it is impossible to imagine the environment around us. Common modular systems provide a smooth interior surface and extend service life.

Recommendations and typical mistakes

If mistakes were made during the construction of the chimney, this can lead to costly alterations, burnout or fire.

The main five mistakes that can occur when performing installation work.

- Don't fancy with the pipe configuration. The shape of the chimney must be cylindrical.

- The lengths of the horizontal sections are not respected. Their length must be ≤ 1 m.

- Don't skimp on materials. The pipe must be 0.5 m higher than the ridge. If the roof is flat, the pipe height is ≥ 1 m.

- Do not use materials that are not intended for pipes - asbestos, aluminum.

- When installing an additional stove or fireplace, you should not combine them into one chimney system.

In order not to make mistakes, it will be useful to get acquainted with SNiP 41-01-2003 "Stove heating".

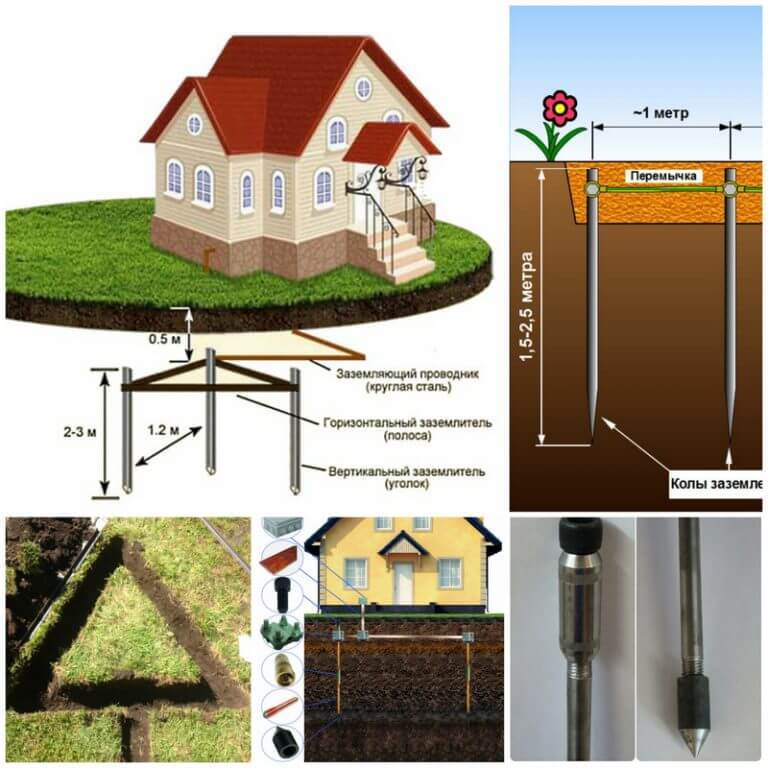

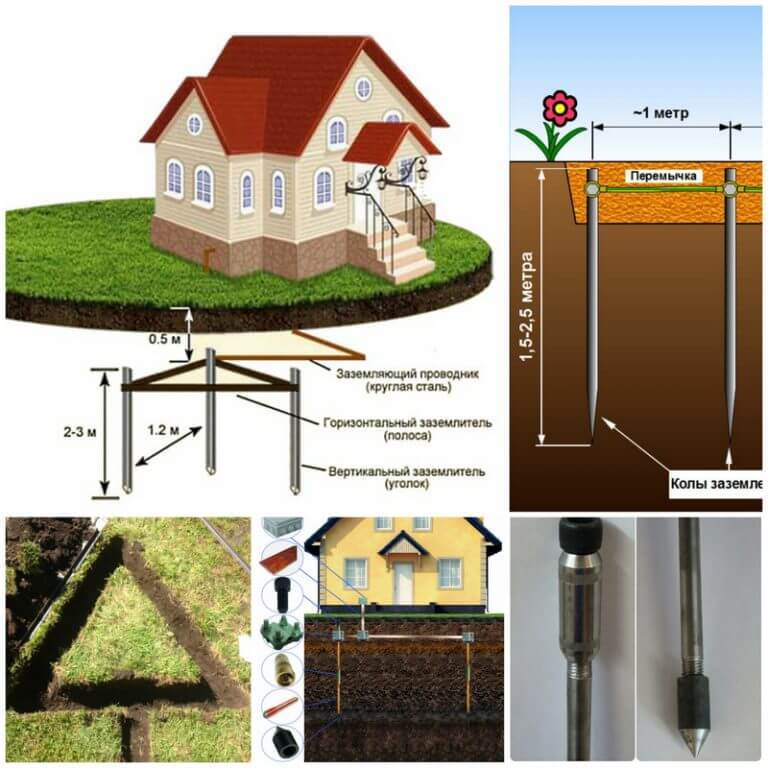

Chimney grounding circuit

The role of the chimney is not only in the harmless removal of combustion products into the atmosphere, but also in protecting a person from electric shock if lightning strikes him. To avoid this, you need to use RD 34.21.122-87 "Instructions for the device for lightning protection of buildings and structures" and install grounding:

- It does not need to be erected if reinforcement is laid in the foundation of the chimney, and any metal parts attached to the reinforcing rods are present in the base submarine. In this case, the chimney already has a lightning rod.

- To protect the structure from lightning strikes, use a ground loop. The norm of the ground loop is stipulated in the PUE (electrical installation rules) p.1.7.101, p. 1.7.103. It needs to be calculated and built from steel rods, fittings or pipes that have a circular cross-section. The grounding contour has the form of an equilateral triangle with a side ≥ 2 m.At the top of each corner, a vertical support must be driven in to a depth of 2 m.The distance between them must be at least 1.5 m.When the elements are in the ground at the base of the pipe, they must be reinforced with nuts, bolted or welded. When making grounding, you need to choose longer supports, the thickness of which is indicated in the rules for electrical installations - table 1.7.4.

Lightning protection of a chimney

Today, ready-made kits (ZU) are sold for grounding a house - screens made of armored cables, reinforcement or pipe structures.

Installation procedure for metal chimneys

During installation work, you need to take care of fire safety: think about how to insulate the chimney pipe through the wall? For insulation, a ceramic mixture, refractory paper LYTX-2368, CIP-2368, SUPERWOOL 607 paper, refractory mastic SUPERWOOL 607 HT MASTIC, KAOWOOL MASTIK, ceramic MKR tubes and other thermal insulation materials are used.

Installation technology:

- You need to install the chimney system from the stove, going up to the head. The beginning of the upper tube is inserted into the upper part of the lower tube.

- At the junction of the chimney elements, an inspection window must be provided.

- Joints, bends, joints, other components are connected with clamps, coated with a heat-resistant sealant designed for 1000 ℃.

- On a vertical pipe section, the fastening distance should be ≥ 150 m, and on horizontal sections ≥ 100 cm.

- Chimney systems run through the walls, ceiling and out onto the roof. The diameter of the hole should be significantly larger than the diameter of the flue. The pipe with the hole must not touch. To do this, cut out a square metal plate. You will also need a stainless steel pass-through glass, on which an insulating material is reinforced.

- The installation of the head finishes the work, It protects the structure from external precipitation and debris.

Chimney assembly diagram

Chimney height organization rules

If you install the pipe yourself, you can make a mistake in calculating the length of the chimney. In this case, you need to familiarize yourself with the instructions attached to the equipment or consult with experienced stove-makers.